Water-based ink resin for PVC furniture membranes and preparation method of water-based ink resin

A technology of ink and resin, which is applied in the field of water-based ink resin and its preparation, can solve the problems of flammability and explosion, printing workers and environmental damage, pollution, etc., to improve the resistance to plasticizer migration, stabilize the polymerization process and reduce slag, The effect of guaranteeing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

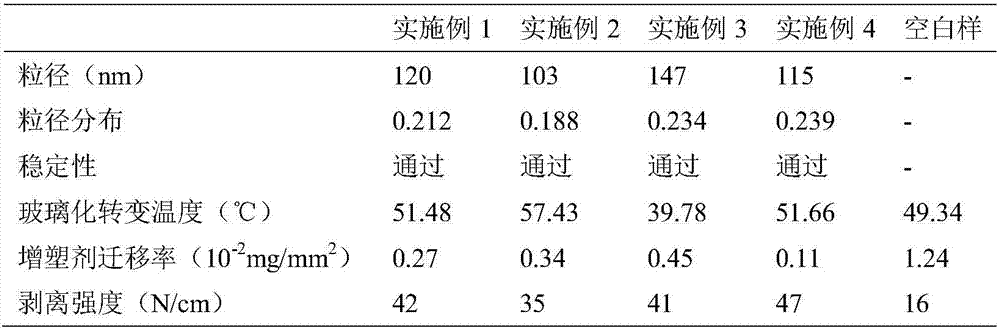

Examples

Embodiment 1

[0037] (1) Preparation of the monomer addition phase: 20.58 kg of methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), 21 kg of methyl acrylate monomer (Shanghai Merrill Chemical Technology Co., Ltd.) at room temperature , 0.42kg of glycidyl methacrylate monomer (Jiangxi Ruixiang Chemical Co., Ltd.), 0.0022 parts by weight of isooctyl 3-mercaptopropionate (Sinopharm Chemical Reagent Co., Ltd.) chain transfer reagent and 0.7kg of ER-40 (ADEKA company) nonionic emulsifier dissolves 20min with the speed stirring of 500rpm;

[0038] (2) Preparation of the primer phase: 1.5kg of DowFax TM 2A1 (DOW company) anionic emulsifier, 0.4kg of ER-40 (ADEKA company) nonionic emulsifier, 0.08kg of AMP-95 (Dow company) pH buffer, 0.08kg of sodium persulfate (Suzhou Huahang Chemical Technology Co., Ltd. Company) initiator joins the deionized water of 38kg, stirs and dissolves with the speed of 500rpm, and begins to heat up;

[0039] (3) Polymerization stage: when the temperatu...

Embodiment 2

[0042] (1) Preparation of the monomer addition phase: 24.48 kg of methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), 19.17 kg of methyl acrylate monomer (Shanghai Mairuier Chemical Technology Co., Ltd.) ), 1.35kg of glycidyl methacrylate monomer (Jiangxi Ruixiang Chemical Co., Ltd.), 0.00138 parts by weight of 3-mercaptopropionic acid-2-ethylhexyl ester (Bailingwei Technology Co., Ltd.) chain transfer reagent and 0.9kg of ER- 40 (ADEKA company) nonionic emulsifier is stirred and dissolved 30min with the speed of 400rpm;

[0043] (2) Preparation of the primer phase: 1.52kg of DowFax TM 2A1 (DOW company) anionic emulsifier, 0.5kg of ER-40 (ADEKA company) nonionic emulsifier, 0.08kg of AMP-95 (Dow company) pH buffer, 0.03kg of potassium persulfate (Wujiang Sanyuan fine Chemical Co., Ltd.) initiator joins the deionized water of 42kg, stirs and dissolves with the speed of 700rpm, and begins to heat up;

[0044] (3) Polymerization stage: when the temperature of t...

Embodiment 3

[0047] (1) Preparation of the monomer addition phase: 18.9 kg of methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), 22.68 kg of methyl acrylate monomer (Shanghai Mairuier Chemical Technology Co., Ltd.) ), 0.42kg of glycidyl methacrylate monomer (Jiangxi Ruixiang Chemical Co., Ltd.), 0.00264 parts by weight of 3-mercaptopropionic acid-2-ethylhexyl ester (Bailingwei Technology Co., Ltd.) chain transfer reagent and 2kg of ER-40 (ADEKA company) nonionic emulsifier dissolves 20min with the speed stirring of 600rpm;

[0048] (2) Preparation of the primer phase: 1.1kg of DowFax TM 8390 (DOW company) anionic emulsifier, the ER-40 (ADEKA company) nonionic emulsifier of 1kg, the AMP-95 (Dow company) pH buffering agent of 0.1kg, the potassium persulfate of 0.03kg (Wujiang Sanyuan Fine Chemical Industry Co., Ltd. Co., Ltd.) initiator joins the deionized water of 40kg, stirs and dissolves with the speed of 300rpm, and begins to heat up;

[0049] (3) Polymerization stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com