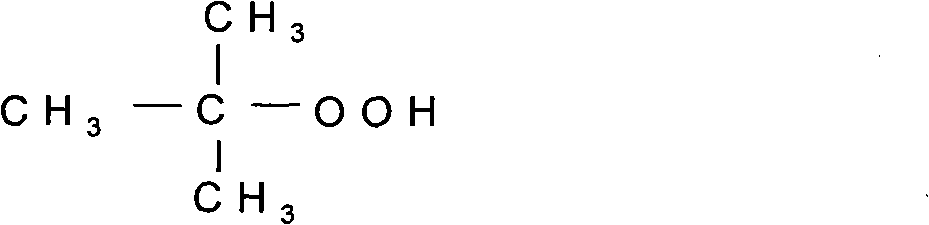

Preparation method for mixture containing tert-butyl hydroperoxide

A technology containing tert-butyl hydroperoxide and tert-butyl hydroperoxide, which is applied in the preparation of peroxy compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of not harsh reaction conditions, waste of raw materials, damage to environment and other issues, to achieve the effect of reducing preparation costs, protecting the environment, and saving energy and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

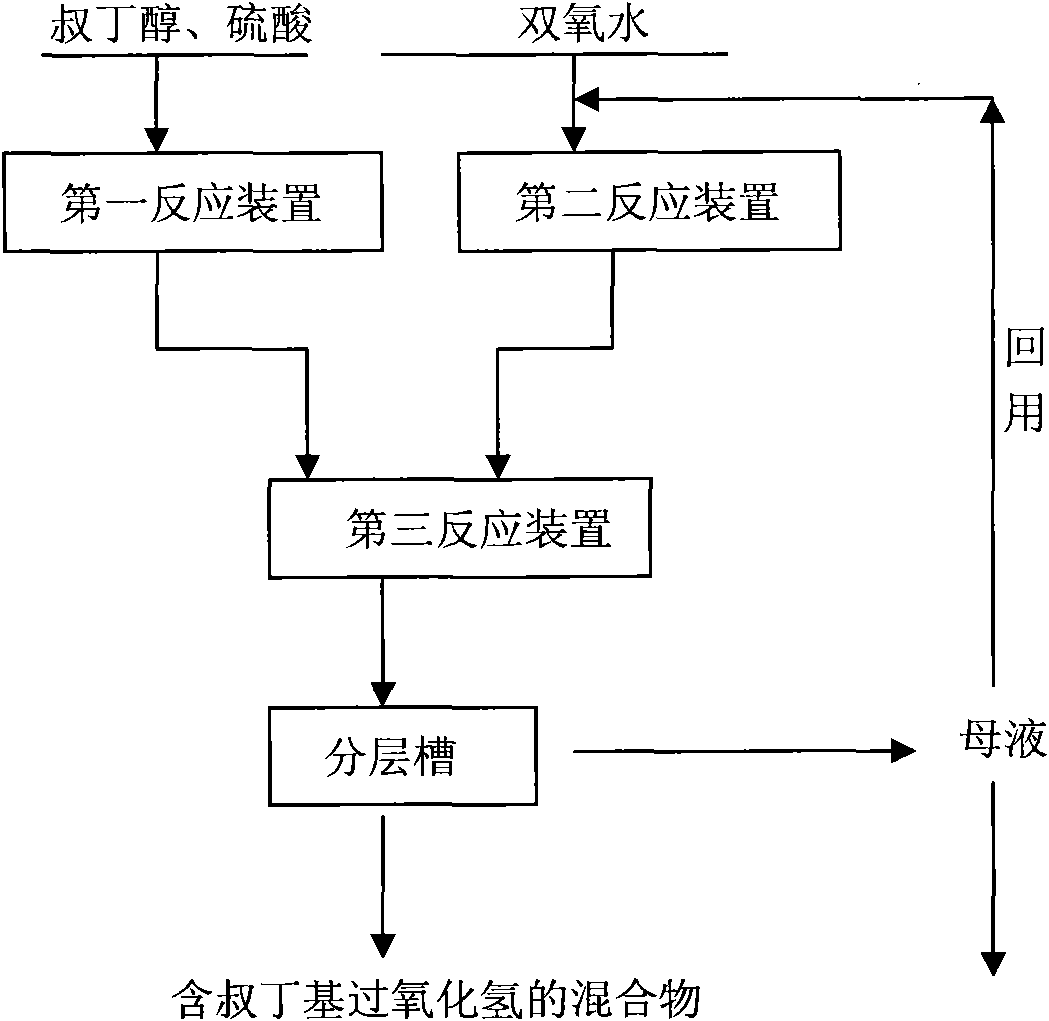

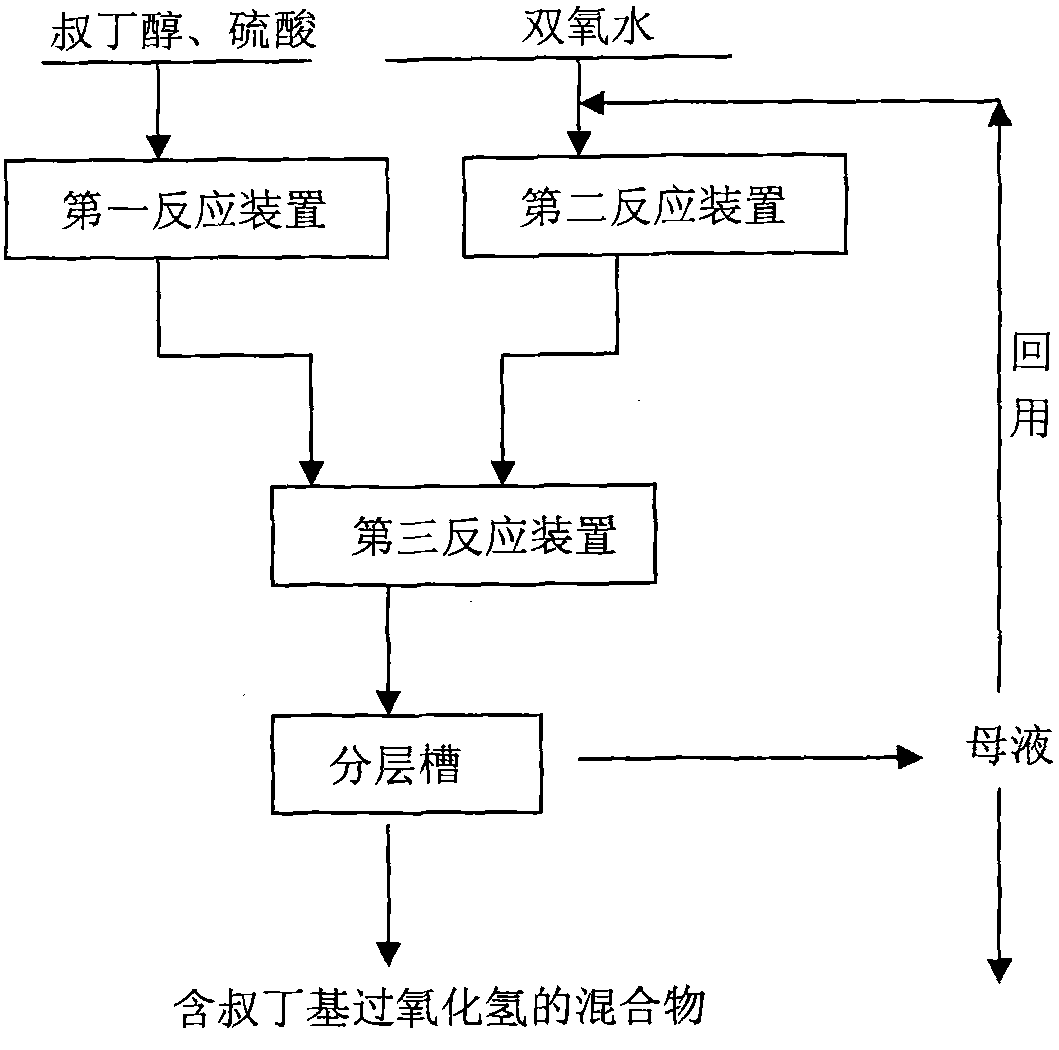

Method used

Image

Examples

Embodiment 1

[0027] A) 870Kg tert-butanol (mass fraction is 85%) is joined in the first reaction device earlier, promptly joins in the esterification reaction kettle, then under stirring state and control temperature is 0~40 ℃ with 370Kg sulfuric acid (mass fraction Fraction is 80%) is added dropwise in described tert-butanol, and dropwise time is 45min, continues to stir 30min after dropwise addition, obtains tert-butyl hydrogensulfate esterified liquid;

[0028] B) Under the condition that the stirring temperature is controlled between 0 and 50°C while stirring, slowly add 515Kg hydrogen peroxide (65% by mass fraction) dropwise to the 3080Kg reuse solution (34.6% by mass fraction containing sulfuric acid, In the second reaction device (the mass fraction containing hydrogen peroxide is 5.4%), that is, in the mixing tank, the dropwise addition time is 30min, and the stirring is continued for 25min after the dropwise addition to obtain a mixed solution;

[0029] C) Under the conditions of s...

Embodiment 2

[0032] A) 350Kg sulfuric acid (mass fraction is 98%) is joined in the first reaction device earlier, promptly joins in the esterification reaction kettle, and then under stirring state and control temperature is 0~40 ℃ with 870Kg tert-butanol (mass fraction Fraction is 85%) dropwise in the described sulfuric acid, dropwise time is 60min, continue to stir 20min after dropwise addition, obtain tert-butyl hydrogensulfate esterified liquid;

[0033] B) Under the condition of stirring while controlling the stirring temperature between 0 and 50°C, slowly add 2380Kg of recycled liquid (containing 35.3% sulfuric acid by mass fraction and 5.2% hydrogen peroxide by mass fraction) into the container In the second reaction device of 650Kg hydrogen peroxide (mass fraction is 50%), i.e. in the mixing tank, the dropwise addition time is 55min, and after the dropwise addition, continue to stir for 10min to obtain a mixed solution;

[0034]C) Under the conditions of stirring and controlling th...

Embodiment 3

[0037] A) Under the condition of stirring and controlling the reaction temperature between 0 and 40°C, slowly add 270Kg sulfuric acid (90% by mass fraction) and 820Kg tert-butanol (90% by mass fraction) to the first reaction simultaneously. In the device, it is added to the esterification reaction kettle, the dropwise addition time is 30min, and the stirring is continued for 50min after the dropwise addition is completed, to obtain the tert-butyl hydrogen sulfate esterification solution;

[0038] B) under the condition of stirring while controlling the stirring temperature between 0~50°C, mix 490Kg hydrogen peroxide (mass fraction is 70%) with 3780Kg reuse liquid (the mass fraction containing sulfuric acid is 35.5%, the mass fraction containing hydrogen peroxide is 8.8%) was slowly added dropwise into the second reaction device, that is, the mixing tank, and the dropwise addition time was 40 minutes, and the stirring was continued for 30 minutes after the dropwise addition to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com