Method for preparing electric Fenton cathode by recycling graphite from negative electrode of lithium ion battery

A lithium-ion battery and graphite technology, which is applied in the field of recycling graphite to prepare electro-Fenton cathodes, can solve problems such as environmental hazards of waste lithium-ion batteries, achieve good electro-Fenton degradation characteristics of pollutants, relieve environmental pressure, strong application prospects and Feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

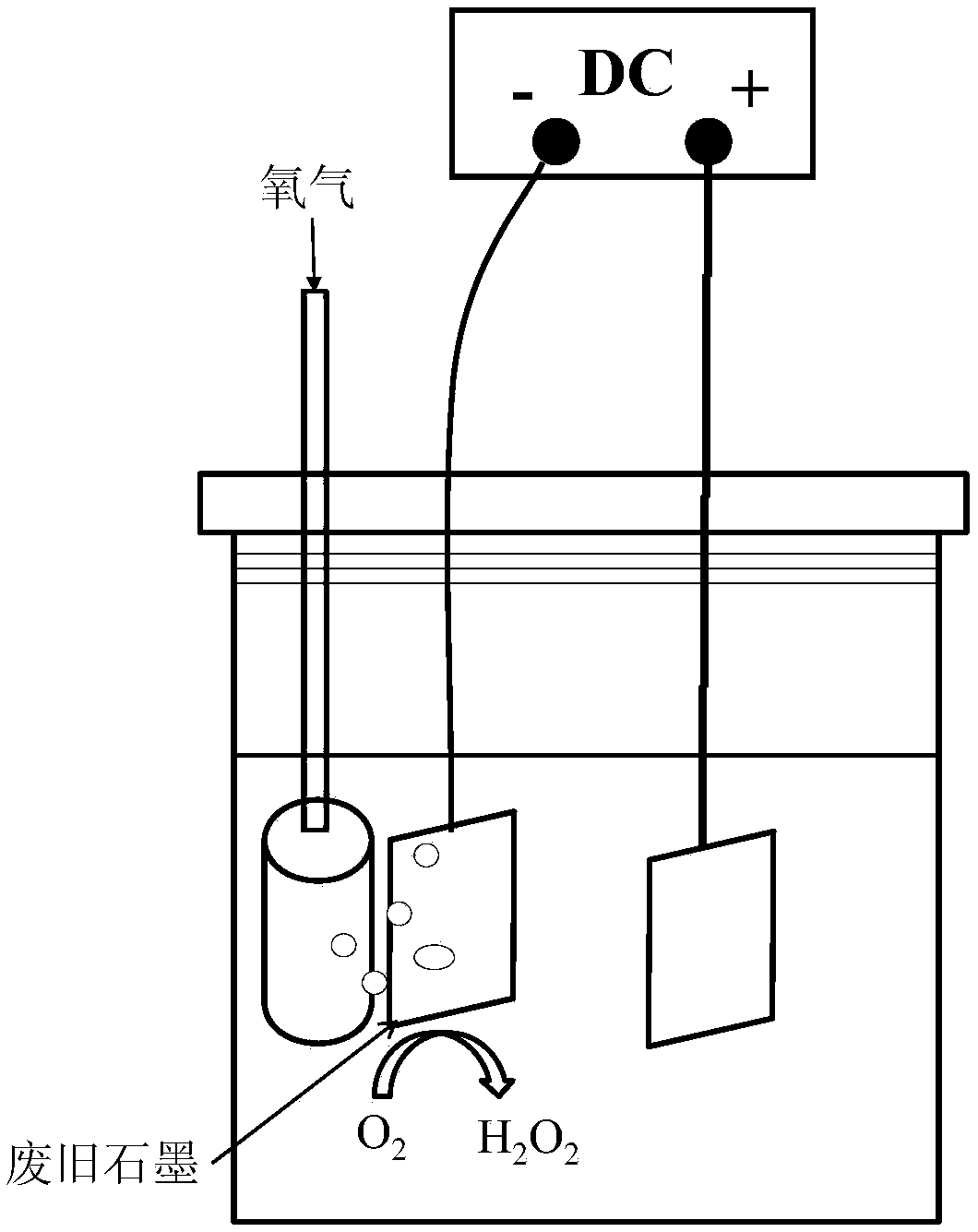

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a method for preparing an electric Fenton cathode by recovering graphite from the negative electrode of a lithium ion battery. The specific method is:

[0061] (1) Disassemble the recovered lithium ion battery to obtain a carbon-coated copper foil for the negative electrode.

[0062] (2) Trim the carbon-coated copper foil into 1×1cm 2 The small pieces, 100W ultrasonic vibration until all graphite powder comes off the copper foil.

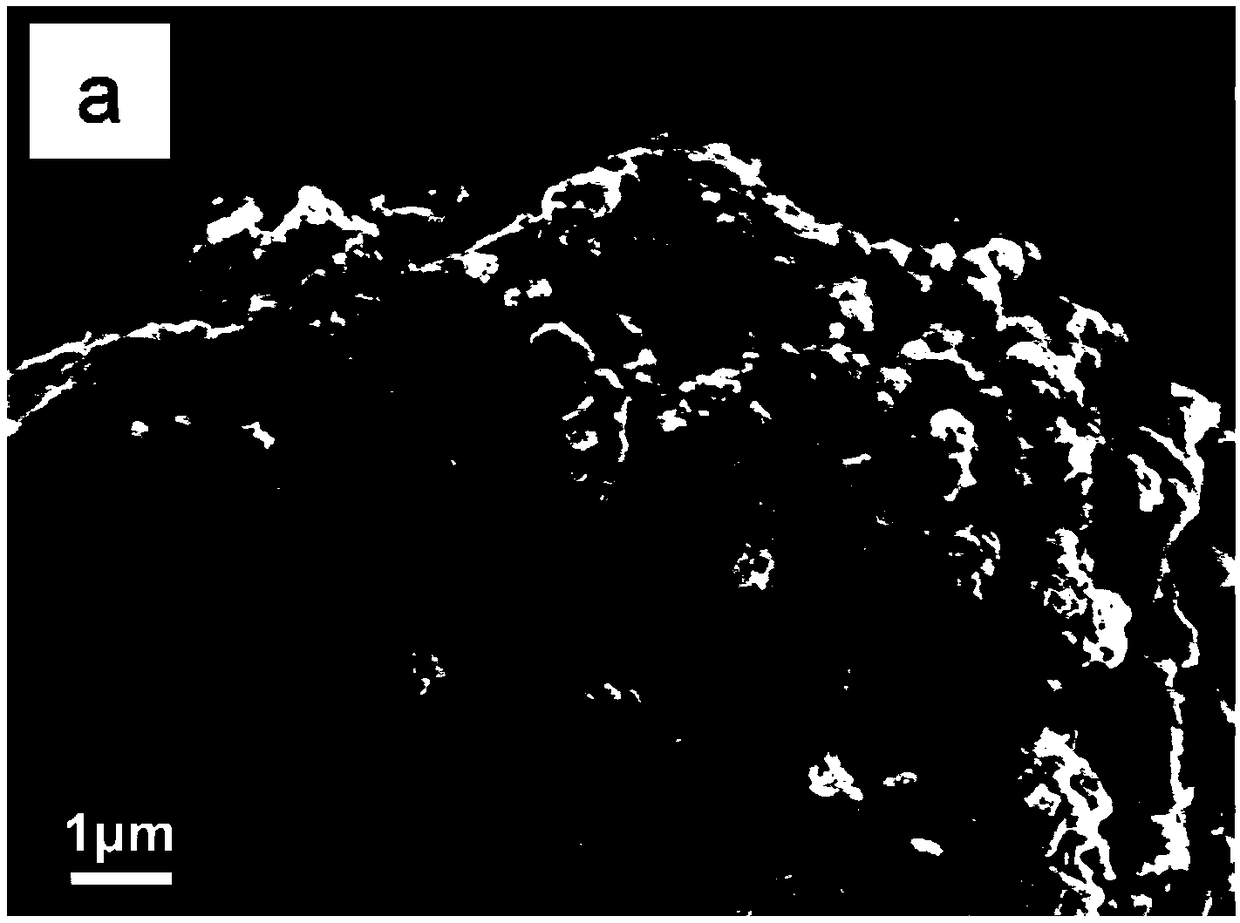

[0063] (3) Add the recovered waste graphite to the 2mol / L hydrochloric acid solution heated to 60℃ in advance according to the solid-to-liquid ratio of 50g / L, and then add H 2 O 2 Solution, hydrochloric acid and H 2 O 2 In the mixture formed by the solution, H 2 O 2 The volume fraction of 2V%, stirring for 2h, after the completion of the reaction, filtering, the filter residue needs to be washed with water at least three times to remove residual acid and metal ions. The filter residue is collected and dried overnight in an o...

Embodiment 2

[0078] This embodiment provides a method for preparing an electric Fenton cathode by recovering graphite from the negative electrode of a lithium ion battery. For specific steps, refer to Example 1. The difference is that in step (3), the sodium hydroxide leaching operation is eliminated, and only hydrochloric acid leaching is performed operating.

[0079] The graphite powder with higher purity obtained in step (3) of this embodiment is a typical layered graphite with a purity of 99.68%.

[0080] The test method of the electric Fenton cathode obtained in this example refers to Example 1, and the test results are shown in Table 1.

Embodiment 3

[0082] This embodiment provides a method for preparing an electric Fenton cathode by recovering graphite from the negative electrode of a lithium ion battery. The specific steps are as follows:

[0083] (1) Disassemble the recovered lithium ion battery to obtain a carbon-coated copper foil for the negative electrode.

[0084] (2) Trim the carbon-coated copper foil into 1×1cm 2 The small pieces, 60W ultrasonic vibration until all graphite powder comes off the copper foil.

[0085] (3) Add the recovered waste graphite to the 1mol / L nitric acid solution heated to 50℃ in advance according to the solid-to-liquid ratio of 60g / L, and then add H 2 O 2 Solution, nitric acid and H 2 O 2 In the mixture formed by the solution, H 2 O 2 The volume fraction is 6V%, stirring for 1h, after the reaction is over, filtering, the filter residue needs to be washed with water at least three times to remove residual acid and metal ions. The filter residue is collected and placed in an oven to dry overnight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com