Water heat absorber system applied to concentrating solar energy belt superheating section

A heat absorber and solar energy technology, which is applied in the field of water quality heat absorber systems, can solve problems such as low heat transfer capacity of superheated steam, overheating of the overheated area of the heat absorber, and difficulty in accurately controlling light spots, so as to reduce the impact on operation and improve reliability Sexuality, easy switching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

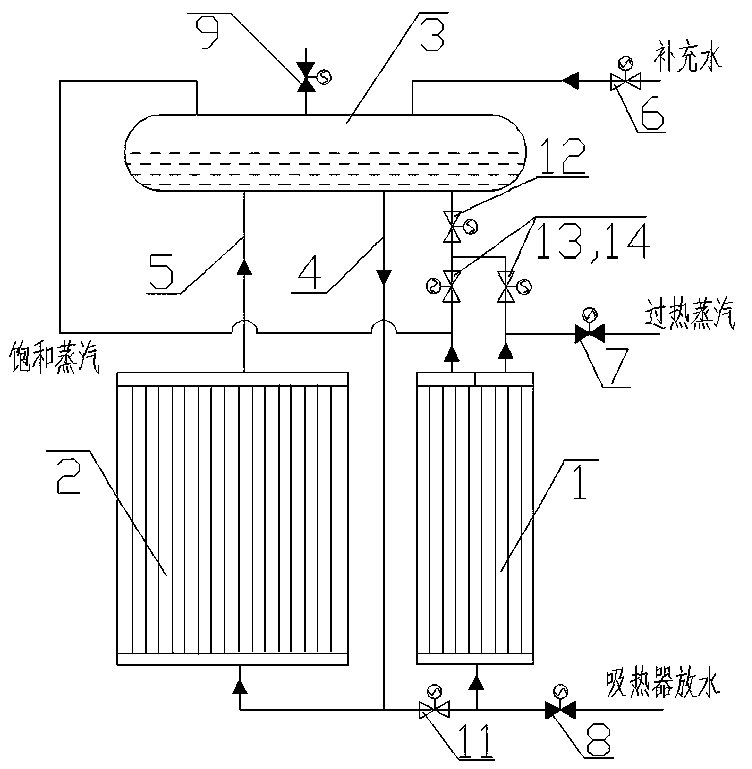

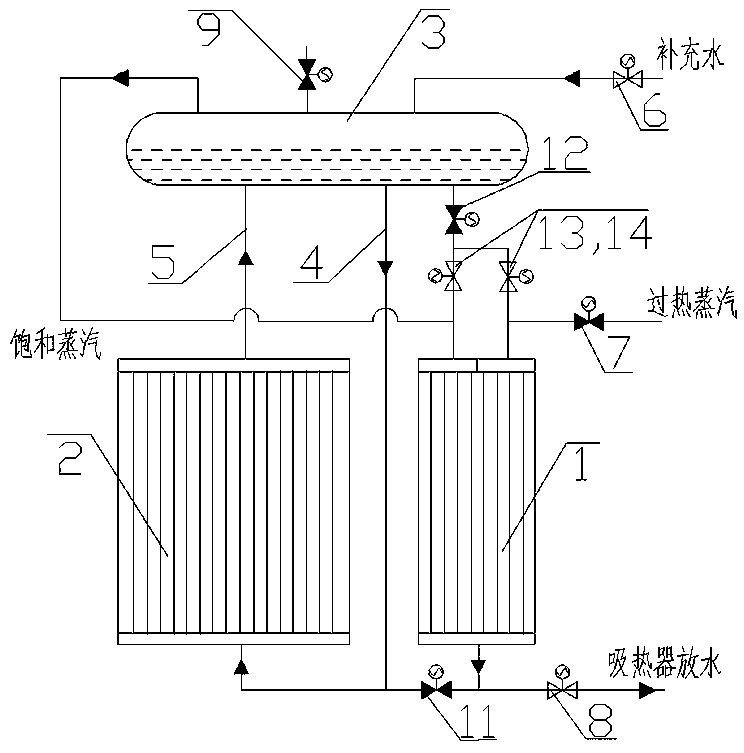

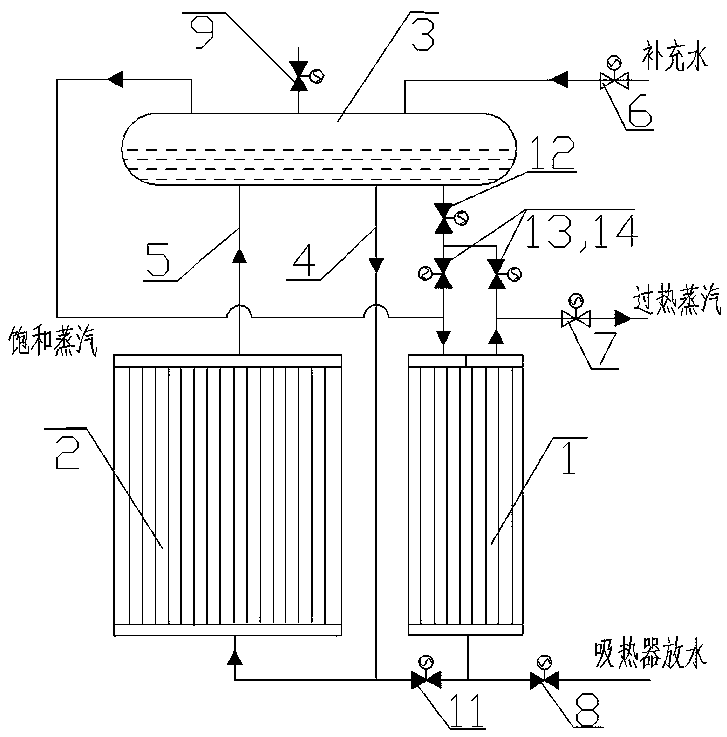

[0023] Example: as attached Figure 1-4 As shown, a water quality heat absorber system applied to the superheating section of the concentrating solar belt includes a superheater 1, an evaporator 2, a steam drum 3, a downcomer 4 and a riser 5, and the upper end of the evaporator 2 passes through the riser 5 Connected to the steam drum 3, the inlet end of the superheater 1 and the steam side of the steam drum 3 are connected with a steam pipe, and a steam connecting pipe is connected between the inlet end of the superheater 1 and the steam drum, and an isolation valve 12 and an isolation valve 13 are connected to the steam connecting pipe. The outlet of superheater 1 is connected to the superheated steam discharge pipe. The steam connection pipe is located on the pipeline between the isolation valve 12 and the isolation valve 13. It is connected to the outlet of superheater 1 through a connecting pipe. The superheated steam valve 7 is connected, the lower end of the evaporator 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com