Low-Turbulence Impeller for a Fluid Pump

a centrifugal fluid pump and impeller technology, which is applied in the direction of liquid fuel engines, machines/engines, reaction engines, etc., can solve the problems of easy damage to blades, and more severe cavitation corrosion, so as to promote fluid-draining efficiency, reduce energy consumption, and eliminate cavitation corrosion of fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

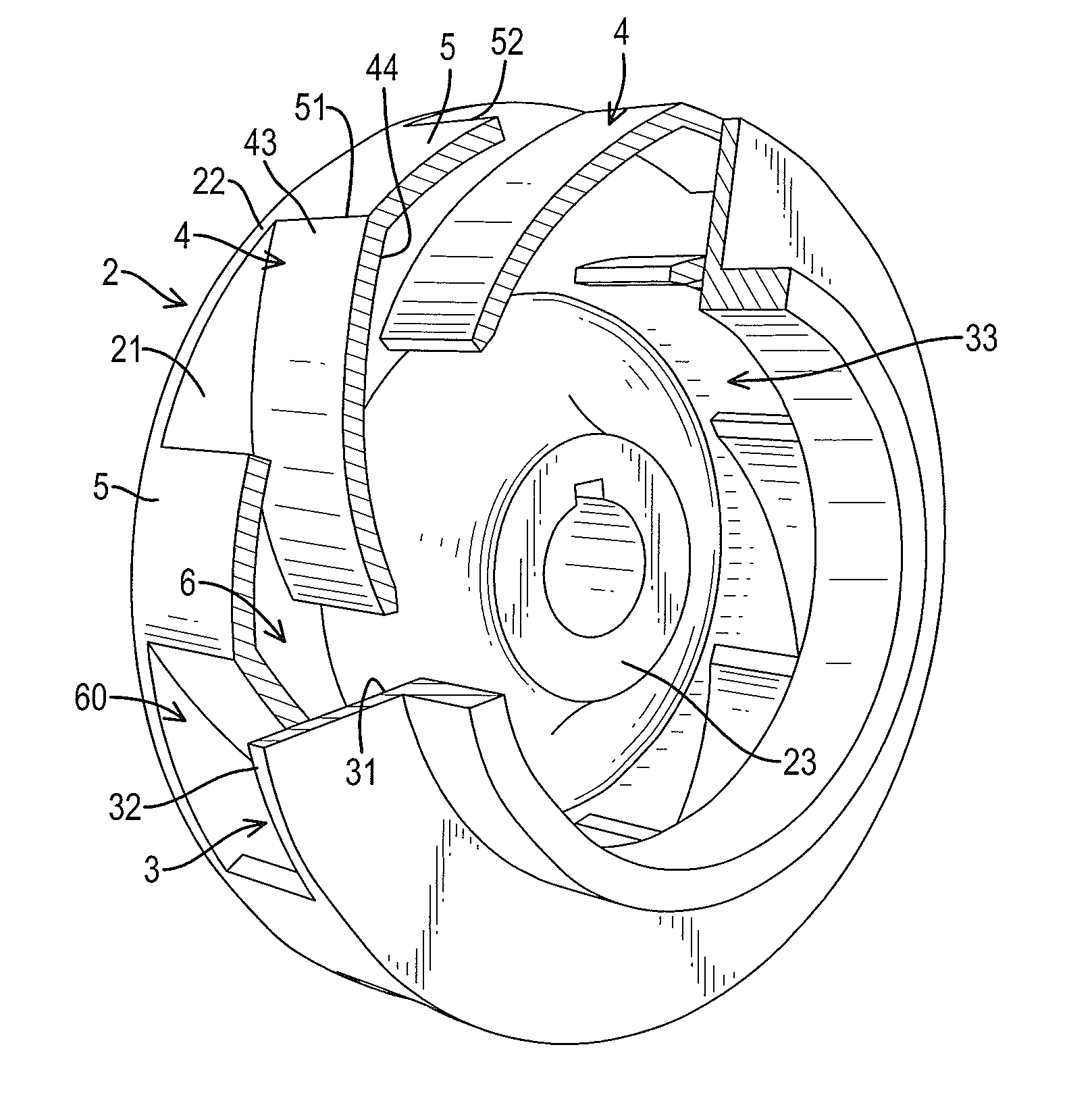

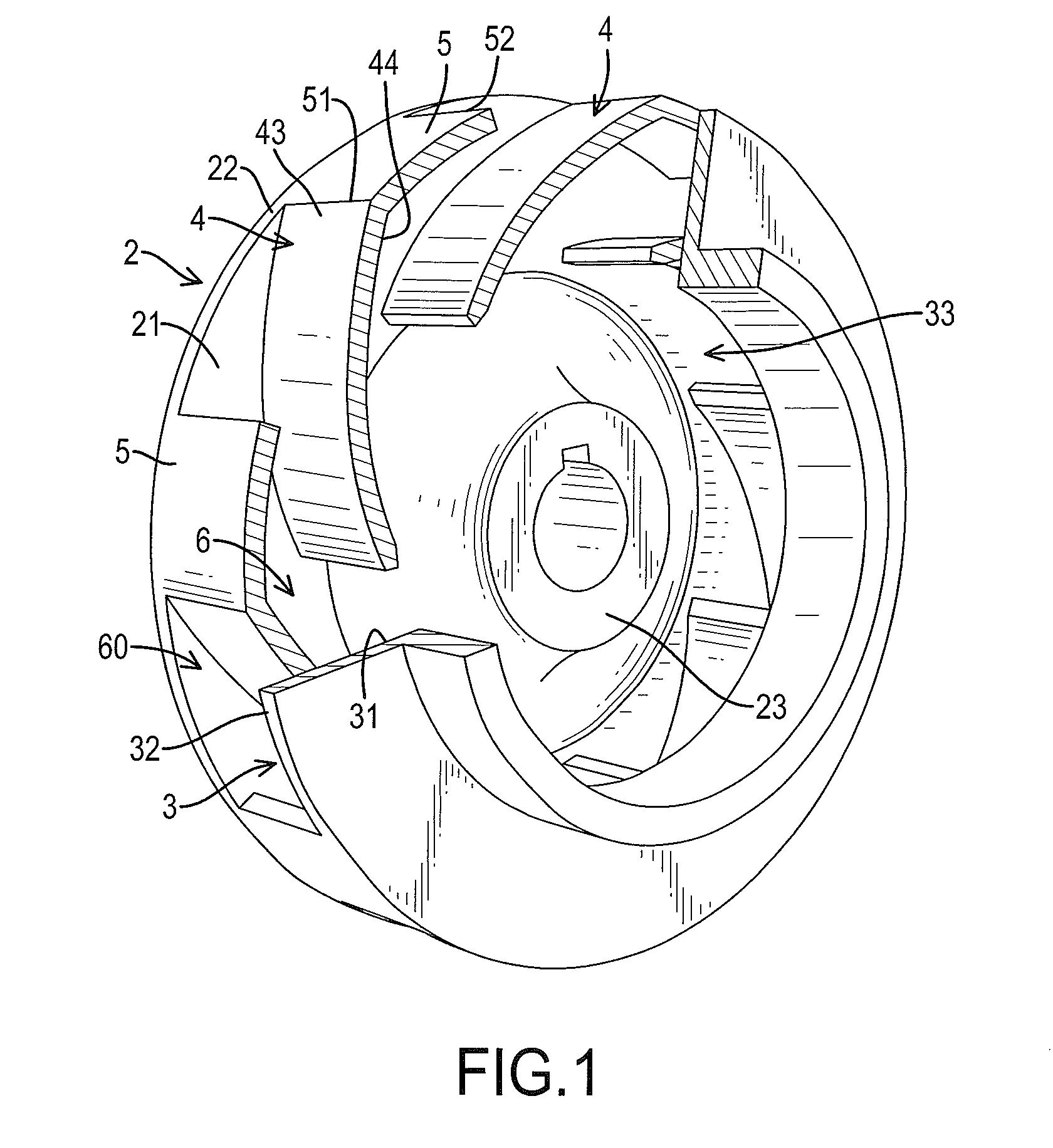

[0020]With reference to FIG. 1, a first preferred embodiment of a low-turbulence impeller for a fluid pump in accordance with the present invention is mounted in a casing of a centrifugal pump (not shown in figures). The centrifugal pump rotates the low-turbulence impeller.

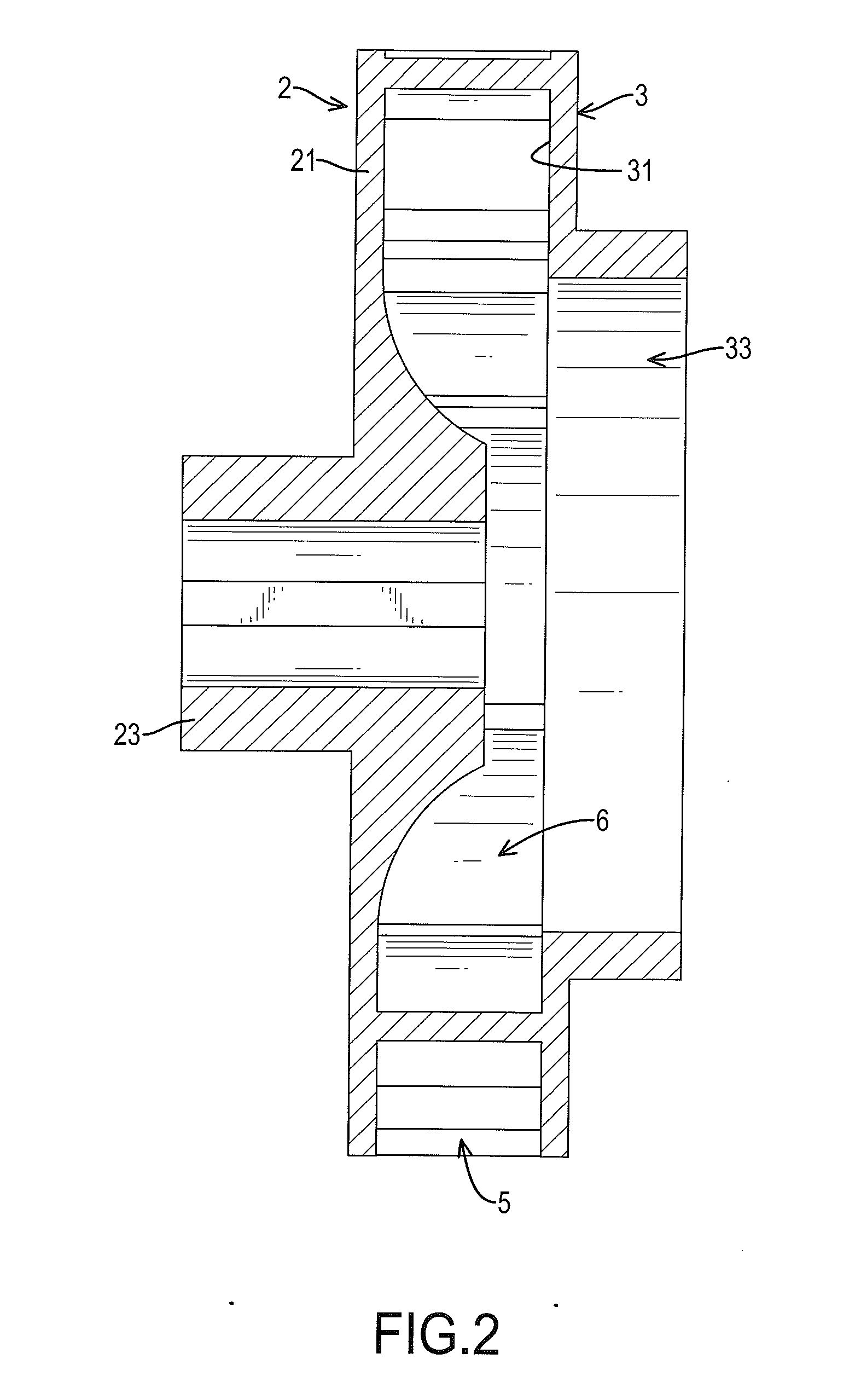

[0021]With reference to FIGS. 1 to 3, the low-turbulence impeller for a fluid pump comprises a first base wall 2, a second base wall 3, multiple guiding blades 4, multiple back-up plates 5, and multiple runners 6.

[0022]The first base wall 2 is circular and has a first inner surface 21, a first periphery 22, and a coupling portion 23. The coupling portion 23 is connected to a transmission shaft of a motor and is rotated by the motor. The second base wall 3 is spaced apart from and parallel to the first base wall 2. The second base wall 3 is circular and has a second inner surface 31 facing the first inner surface 21, a second periphery 32, and an inlet 33. The inlet 33 is formed through the second base wall 2 to al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com