High-pressure multi-stage pressure reducing valve

A pressure reducing valve, high pressure technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of unresolved valve sealing problems, inconsistent fluid speed, easy vibration, etc., to reduce equipment maintenance costs and avoid fluid speed Inconsistent, avoiding clogged or stuck effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

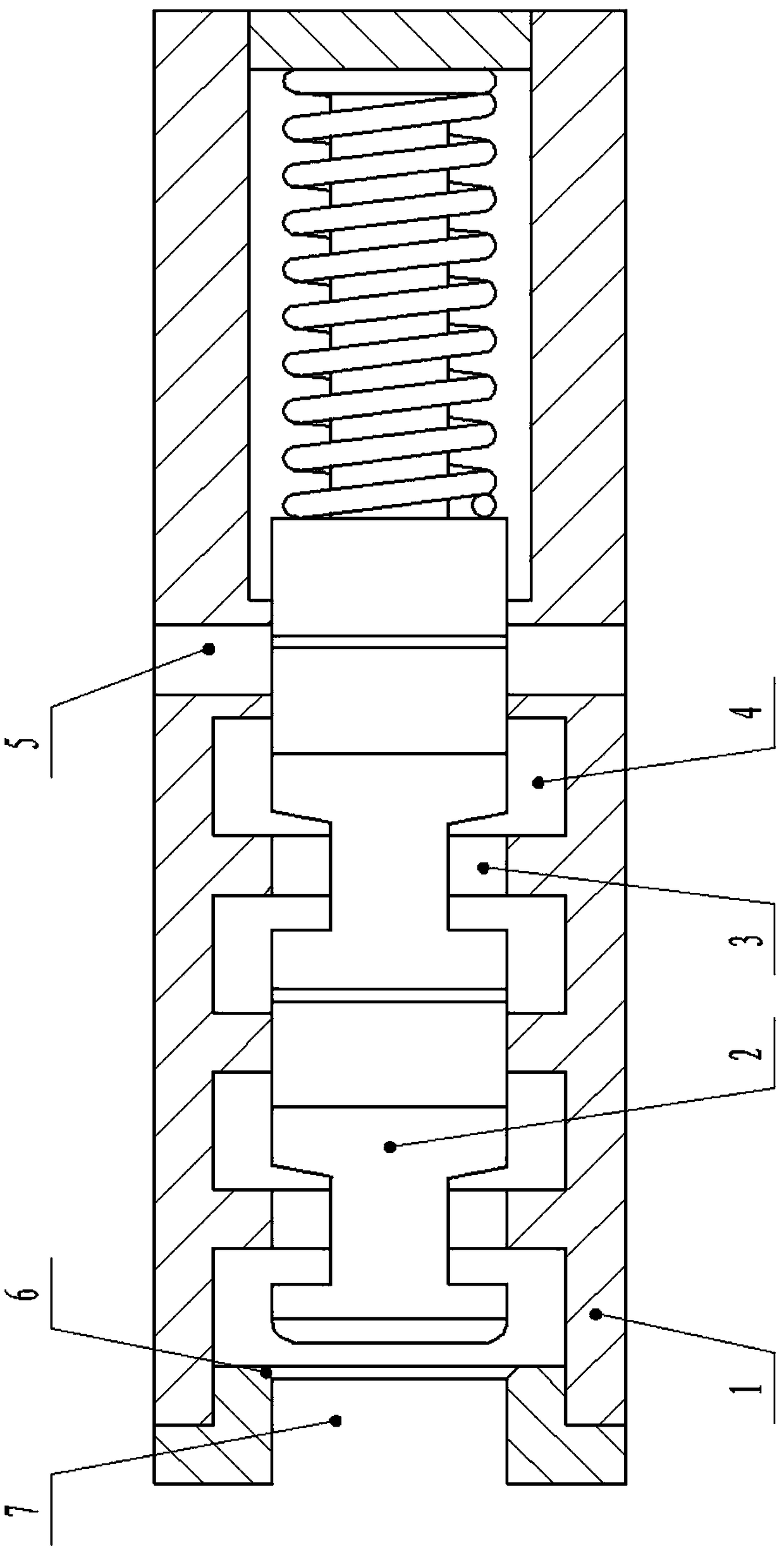

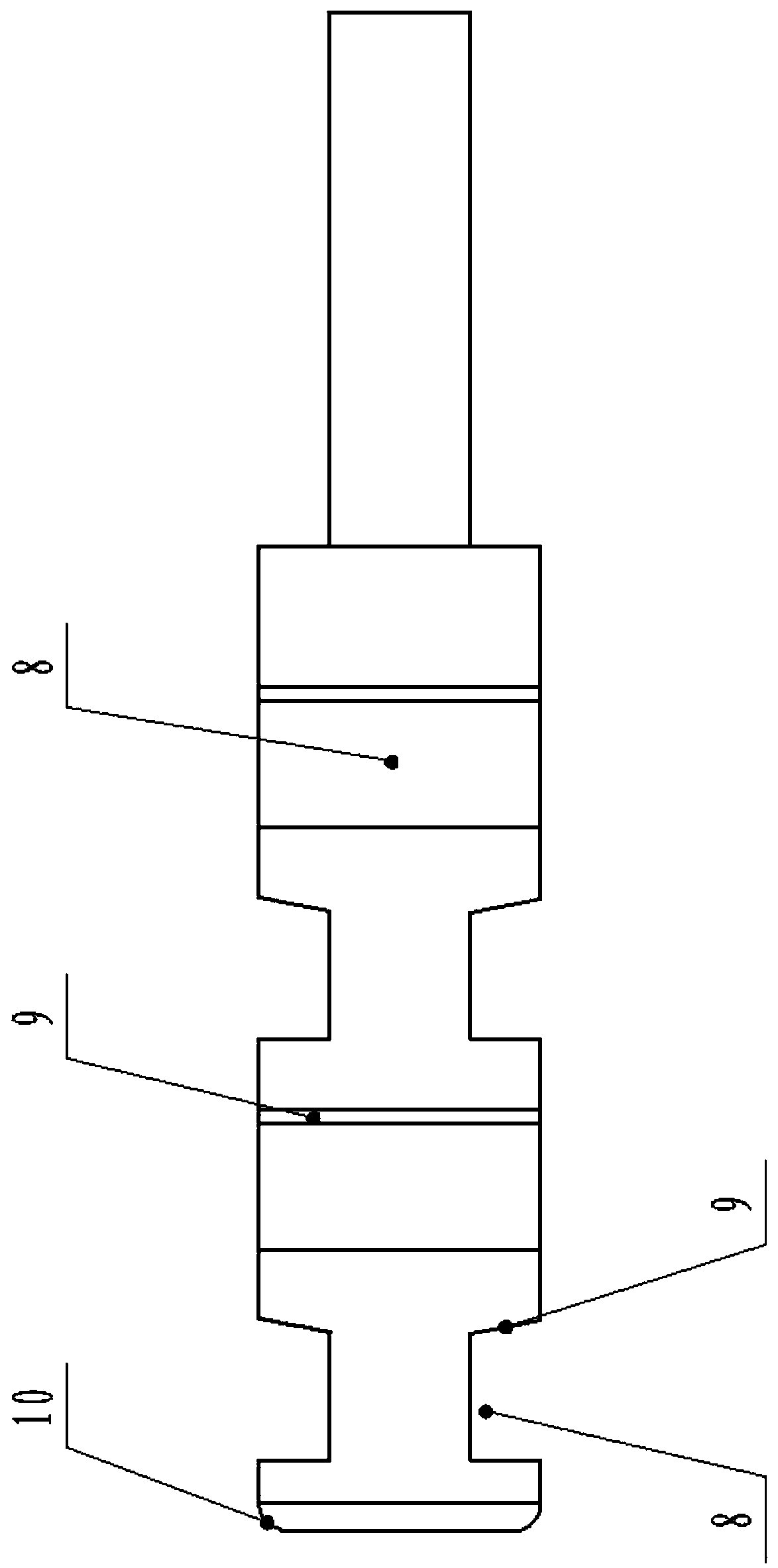

[0031] Such as figure 1 As shown, the present invention includes a housing 1, the housing 1 is provided with a fluid inlet 7 and a fluid outlet 5, and three sealing bosses 3 are arranged on the inside, and two grooves 4 are formed between the sealing bosses 3; The pressure reducing valve also includes a spool 2 connected to the sealing boss 3, the spool 2 is provided with two diversion grooves 8, and an angle α is set between the axially adjacent diversion grooves 8, and the value of α is 10 °.

[0032] In this embodiment, when the present invention is started, the high-pressure fluid enters the housing 1 from the fluid inlet 7, and enters the space formed by the groove 4 and the diversion groove 8 along the space formed by the valve core 2 and the edge of the sealing boss 3, and the depressurization The low-pressure fluid (relative to the pressure of the fluid inlet 7) finally flows out from the fluid outlet 5 to complete the function of decompression. Since this embodiment ...

Embodiment 2

[0034] The difference from Embodiment 1 is that four sealing bosses 3 are arranged on the inner side of the housing 1, three grooves 4 are formed between the sealing bosses 3, and three diversion grooves 8 are arranged on the valve core 2, Two diversion grooves 8 form a group, arranged radially symmetrically, and an angle α is set between axially adjacent diversion grooves 8, and the value of α is 30°.

[0035] Compared with Embodiment 1, this embodiment adds a sealing surface, which improves the sealing performance of this embodiment, and the angle between the axially adjacent diversion grooves 8 is increased, and the valve core 2 and the housing 1 are enlarged. The contact area effectively increases the guidance of the valve core 2, reduces the vibration between the valve core 2 and the housing 1, and reduces the noise of this embodiment.

Embodiment 3

[0037]The difference from Embodiment 2 is that: five sealing bosses 3 are arranged on the inner side of the housing 1, four grooves 4 are formed between the sealing bosses 3, and four diversion grooves 8 are arranged on the valve core 2, An angle α is set between axially adjacent diversion grooves 8 , and the value of α is 45°; the surface of the diversion grooves 8 away from the fluid inlet 7 is provided with a diversion slope 9 .

[0038] Compared with embodiment 2, this embodiment adds a sealing surface, which further improves the sealing performance of this embodiment, and the angle between the axially adjacent diversion grooves 8 increases, further increasing the distance between the valve core 2 and the shell. The contact area of the body 1 further increases the guidance of the valve core 2, further reduces the vibration between the valve core 2 and the housing 1, and further reduces the noise of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com