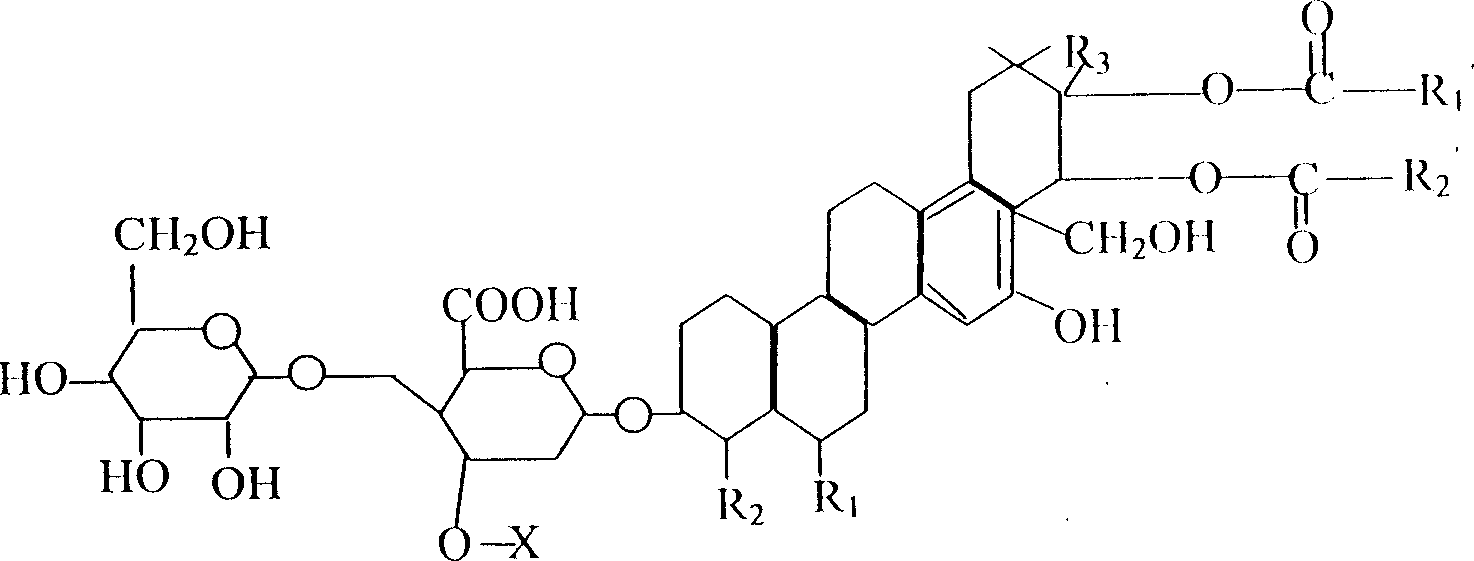

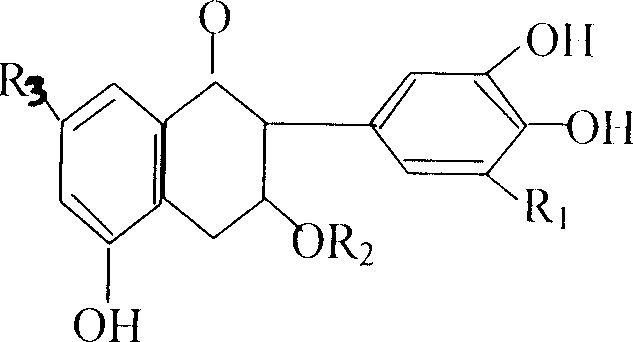

Heavy fuel oil additive containing benzopyran multi-hydroxy metal compound

A benzopyran polyhydroxyl and metal compound technology, applied in the field of heavy fuel oil additives, can solve the problems of aggravating fuel consumption, worsening combustion conditions, worsening fuel atomization, etc., so as to reduce ablation and wear and reduce harmful effects. Emission of gas, effect of controlling oxidation reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Example 1 Heavy fuel oil additives containing polyhydroxy benzopyran metal compounds, including a weight ratio of polyhydroxy benzopyran metal compounds, macromolecular surfactants, and a suitable amount of solvent, of which: (1) The benzopyran polyhydroxy metal compound is obtained by the following steps: the camellia plant raw material is removed, ground to obtain the original powder, and the chlorinated hydrocarbon is added 4 times the weight of the original powder for extraction, the chlorinated hydrocarbon is selected from tetrachloromethane, and the extracted liquid Phase recovery, the extracted solid phase is dissolved in a mixture of methanol and ethyl acetate with a weight ratio of 2 times its weight in a ratio of 1:2, the solid phase is discarded, and chlorination is added to 0.1 times the weight of the dissolved substance of methanol and ethyl acetate. Calcium, then adjust the pH value to 7.2 with alkali to obtain a precipitate, centrifuge to discard the supernata...

Embodiment 2

[0037] Embodiment 2 The heavy fuel oil additive containing benzopyran polyhydroxy metal compound includes a weight ratio of benzopyran polyhydroxy metal compound, a macromolecular surfactant, and an appropriate amount of solvent, of which: (1) The benzopyran polyhydroxy metal compound is obtained by the following steps: the camellia plant raw materials are removed, ground to obtain the original powder, and the chlorinated hydrocarbon is extracted with 3 times the weight of the original powder. The chlorinated hydrocarbon is selected from methylene chloride, and the extracted liquid Phase recovery, the extracted solid phase is dissolved in a mixture of methanol and ethyl acetate with a weight ratio of 2 times its weight in a ratio of 1:2, the solid phase is discarded, and chlorination is added to 0.1 times the weight of the dissolved substance of methanol and ethyl acetate. Calcium, then adjust the pH value to 7.0 with alkali to obtain a precipitate, centrifuge to discard the super...

Embodiment 3

[0040] Example 3 Heavy fuel oil additives containing benzopyran polyhydroxy metal compounds, including weight proportions of benzopyran polyhydroxy metal compounds, macromolecular surfactants, appropriate solvents, of which: (1) The benzopyran polyhydroxy metal compound is obtained by the following steps: the camellia plant raw materials are removed, ground to obtain the original powder, and the chlorinated hydrocarbon is added 5 times the weight of the original powder to extract, and the chlorinated hydrocarbon is selected as 1, 2, 3 Chloropropane, the extracted liquid phase is recovered, and the extracted solid phase is dissolved in a 1:2 mixed solution of methanol and ethyl acetate with a weight ratio of 2 times its weight. The solid phase is discarded and the liquid phase of methanol and ethyl acetate is dissolved. Add calcium chloride to 0.1 times the weight, and adjust the pH to 7.8 with alkali to obtain a precipitate. Centrifugal separation and discard the supernatant. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com