Engine layered rapid combustion method capable of achieving multi-time natural gas spraying

A rapid combustion and natural gas technology, which is applied to engine components, engine control, combustion engines, etc., can solve the problems of incomplete combustion of natural gas, inability to adjust in time, and influence on the stability of natural gas flame propagation, so as to increase the speed of flame propagation and ensure stability The effect of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

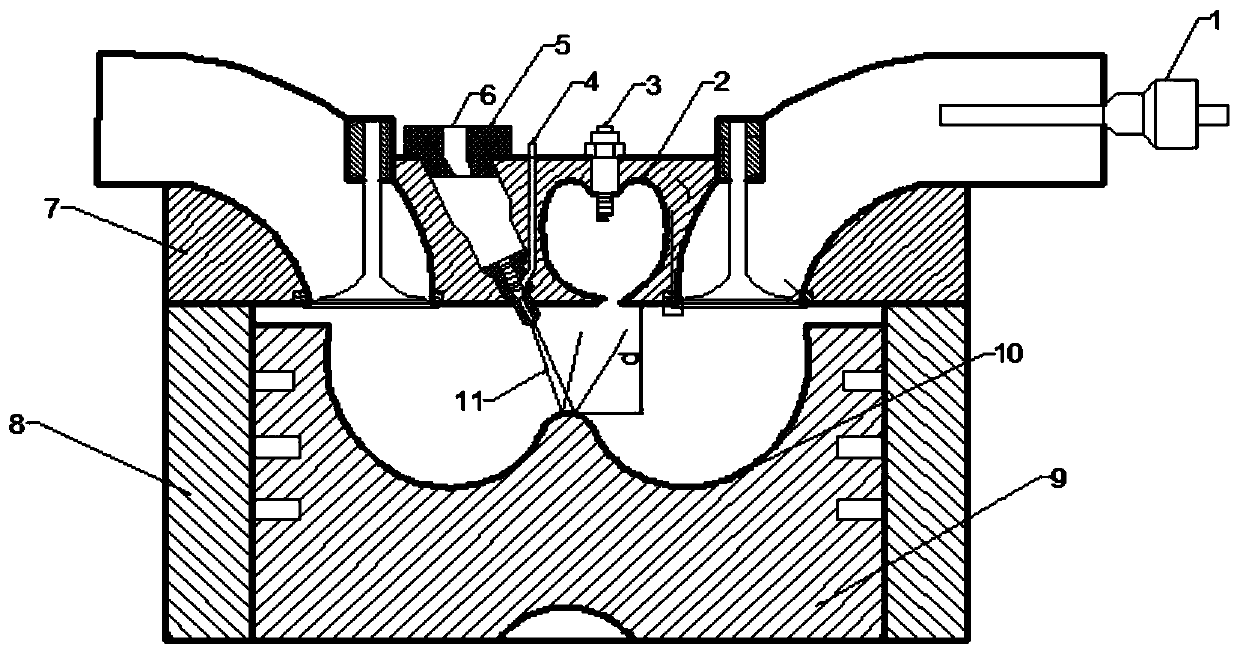

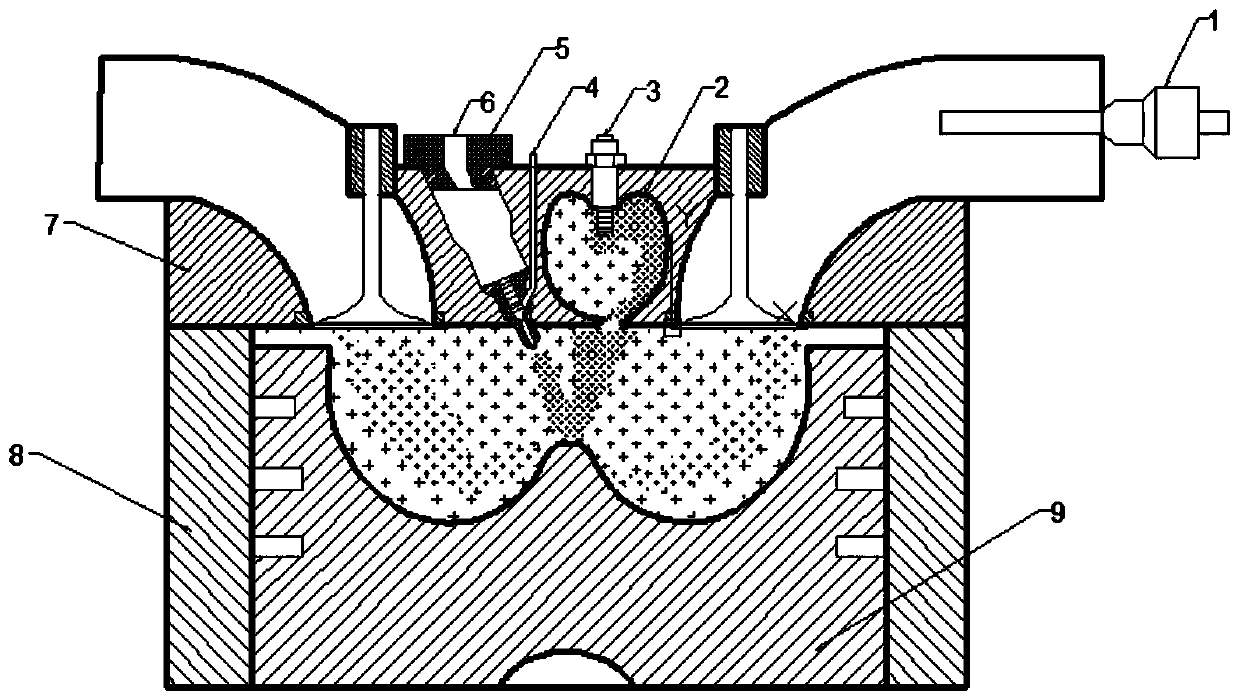

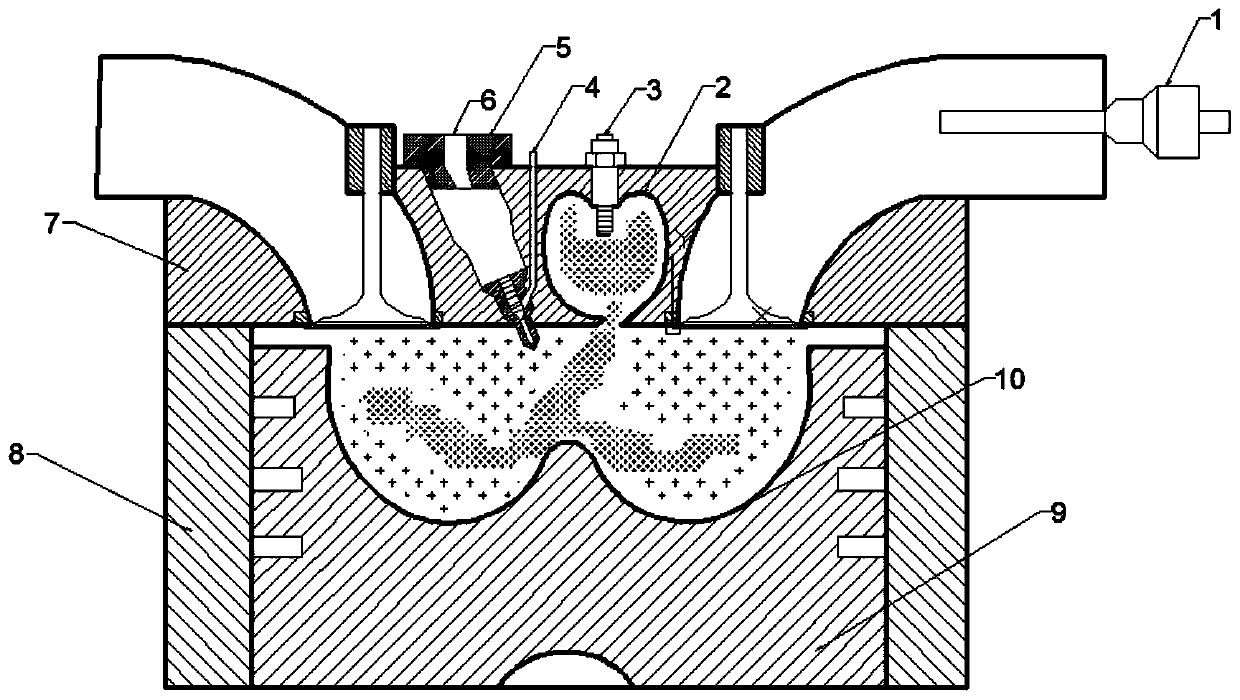

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] combine Figure 1-4f , the present invention a kind of pre-combustion chamber ignition cylinder high-pressure multiple injection of natural gas layered rapid combustion method, its system composition includes: low-pressure gas injection valve 1, cylinder head 7, heart-shaped pre-combustion chamber 2, spark plug 3, In-cylinder high-pressure direct injection valve 5, high-pressure natural gas supply pipeline 4, fixing device 6, piston 9, ω-shaped main combustion chamber 10, and cylinder 8. The natural gas engine used is a four-stroke natural gas engine, and each cycle includes an intake stroke, a compression stroke, a combustion stroke and an exhaust stroke; the natural gas engine uses two sets of fuel supply devices: a low-pressure gas supply device 1 installed on the intake In the channel, a set of in-cylinder high-pressure direct injection gas supply devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com