A flame tube, an industrial low-nitrogen burner, and a step-by-step amplification method for a gas flame

A low-nitrogen burner and step-by-step amplification technology, which is applied in the flame cylinder, industrial low-nitrogen burner and gas flame step-by-step fields, can solve problems such as potential safety hazards, and achieve the effects of stable flame, full combustion and comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

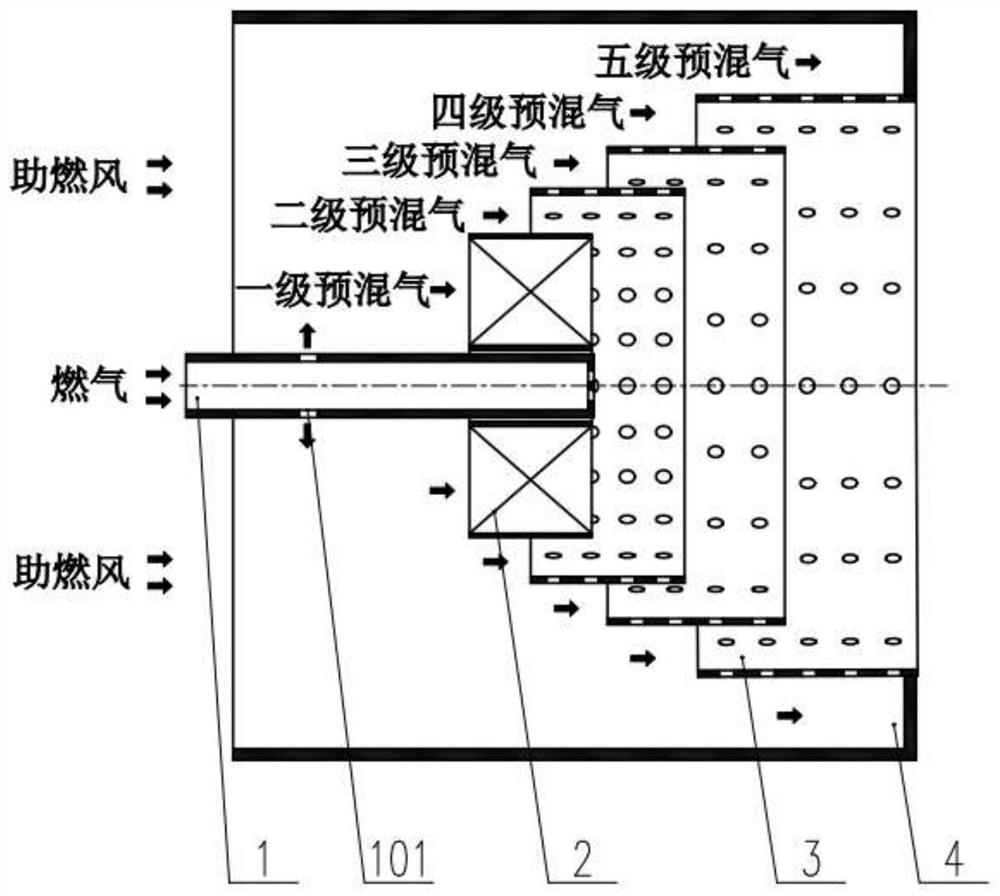

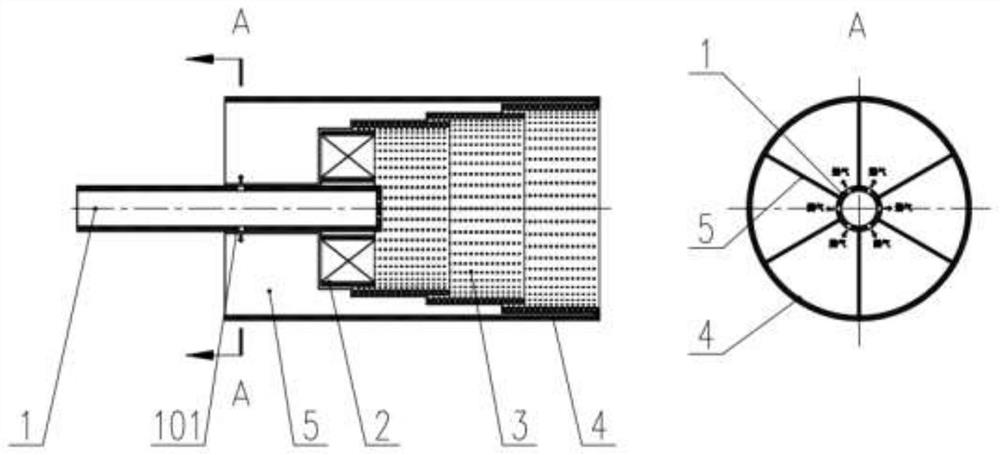

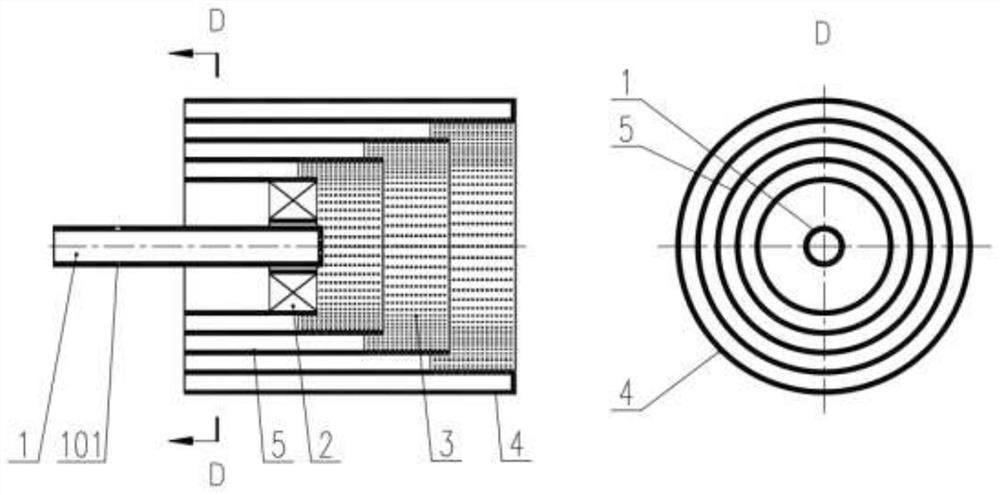

[0038] Such as figure 1 As shown, the parts involved in a step-by-step amplification method of a gas flame include an air gun 1, a stable combustion cover 2, an inner cylinder 3, an outer cylinder 4 and a premixing chamber partition 5, the inner cylinder 3 is divided into more than 3 levels, and the air gun 1 Several premix gas injection holes 101 are provided along the radial direction of the gun body.

[0039] Such as figure 1 As shown, 10-30% of the gas is directly sprayed into the interior of the inner barrel 3 at each level through the gun tip at the front end of the air gun 1. The flame formed by this part of the swirling gas is very stable, which can ensure that the main flame inside the inner cylinder will not be extinguished; 70-90% of the gas passes through several premixed gas radially arranged along the gun body of the air gun 1 The noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com