Application of multilayer foamed iron-nickel metal materials in isolation and suppression of gas explosion

A metal material, gas explosion technology, applied in the direction of testing metals, material inspection products, mining equipment, etc., can solve problems such as gas disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

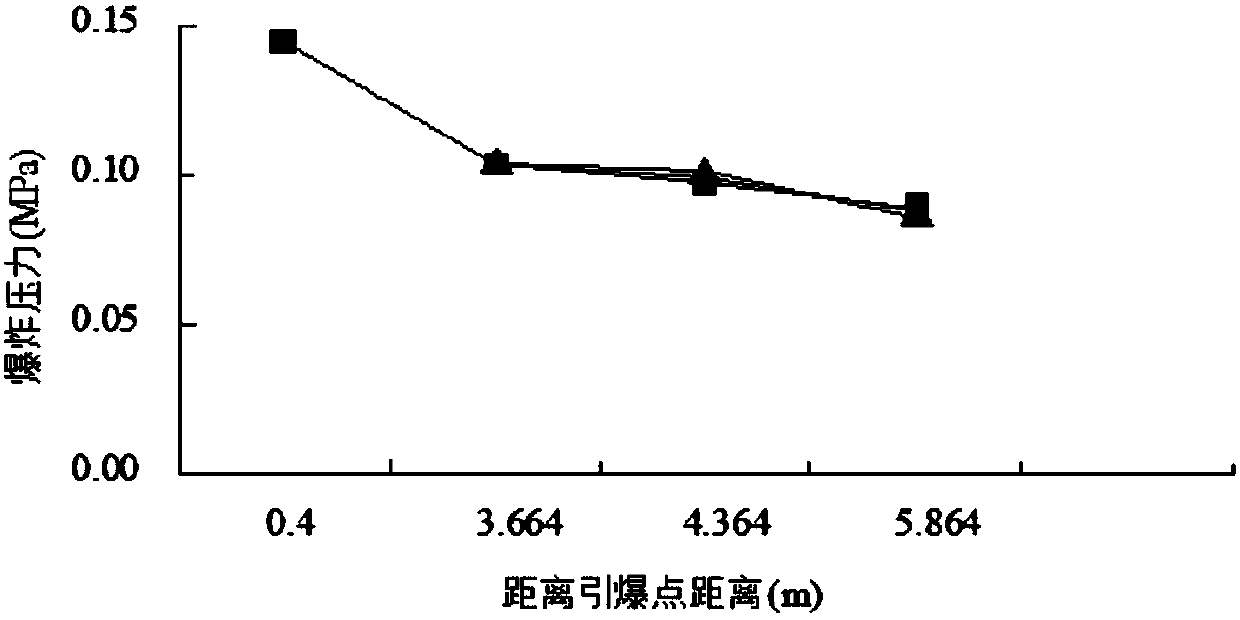

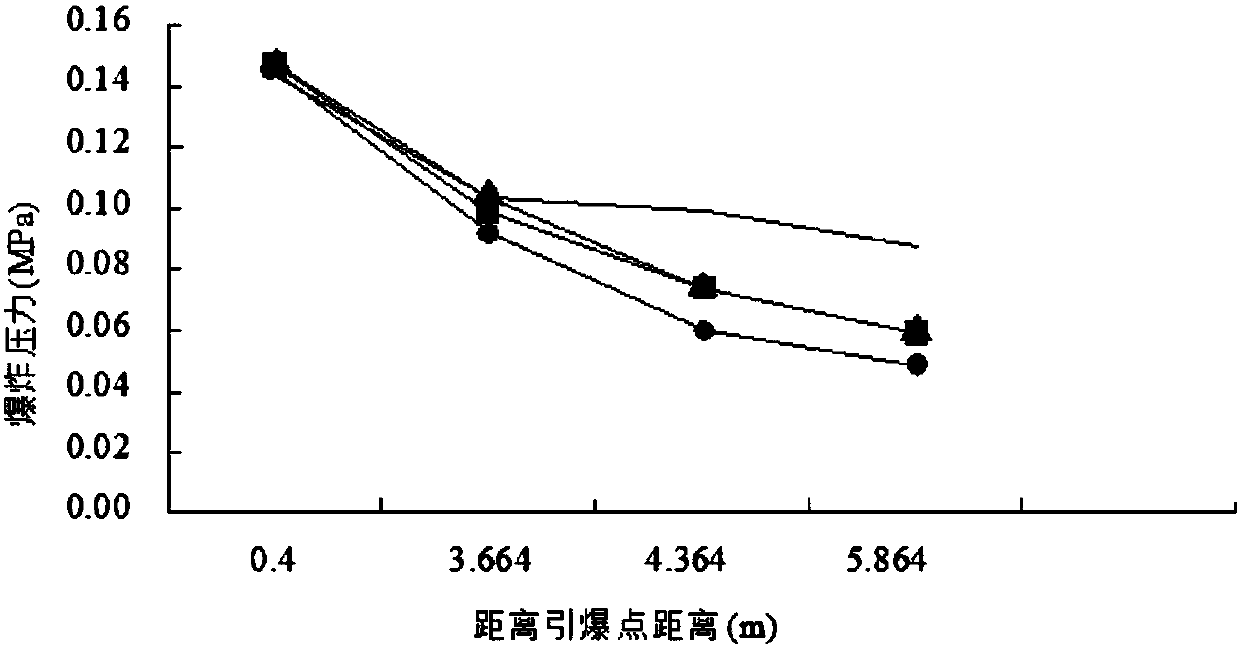

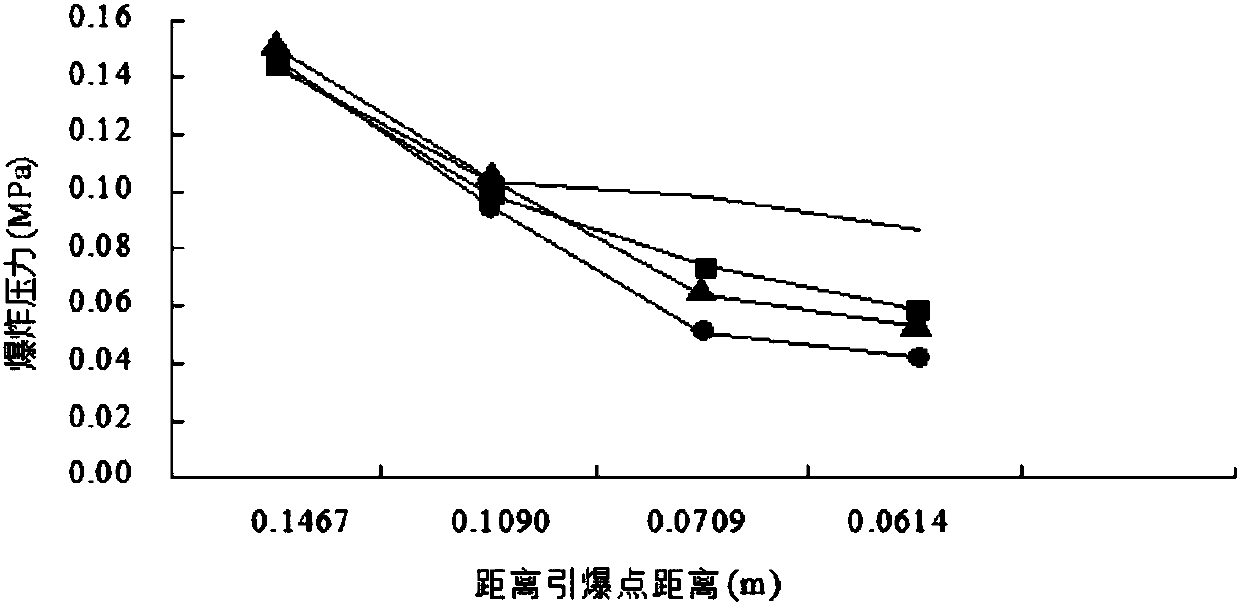

[0039] Specific implementation mode one: the application of multi-layer foamed iron-nickel metal material in the suppression of gas explosion in this embodiment, the specific method is as follows:

[0040] Place 2-3 layers of porous iron-nickel metal materials at intervals, the distance between two adjacent layers of foamed iron-nickel metal materials is 5-20cm, and the thickness of each layer of foamed iron-nickel metal materials is 2-3cm, close to the detonation point The pore size ratio of the foamed iron-nickel metal material on one side is 20-30PPI, and the pore size ratio of the rest of the foamed iron-nickel metal material is 10-30PPI, and the foamed iron-nickel metal material is composed of 10%-30% by weight It is composed of nickel and 70% to 90% iron, and the through porosity is 80% to 90%.

specific Embodiment approach 2

[0041] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that two layers of foamed iron-nickel metal materials are placed at intervals, and the arrangement distance between adjacent two layers of foamed iron-nickel metal materials is 5-10 cm, close to the detonation point The foamed iron-nickel metal material on one side has a porosity of 30PPI. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment one is: 2 layers of foamed iron-nickel metal materials are placed at intervals, the distance between the two layers of foamed iron-nickel metal materials is 5cm, and the iron foam on the side near the detonation point The nickel metal material has a porosity of 30PPI and a thickness of 2cm, and the foamed iron-nickel metal material on the other side has a porosity of 30PPI and a thickness of 3cm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com