Anticlockwise-tumble-ratio combustion system for automotive engine

A vehicle engine and combustion system technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of flow dead zone, limiting the enhancement potential of direct injection engine in the cylinder, oil and gas enrichment knocking, etc. Reduce the tendency of knocking, increase the intensity of tumble flow in the cylinder, and reduce the effect of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

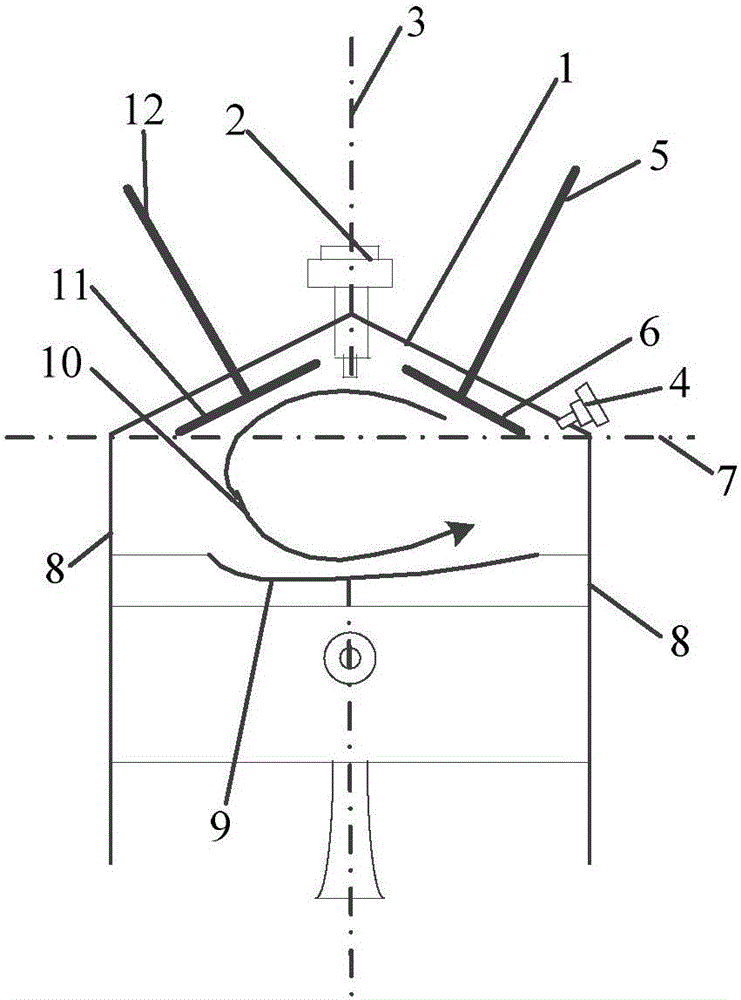

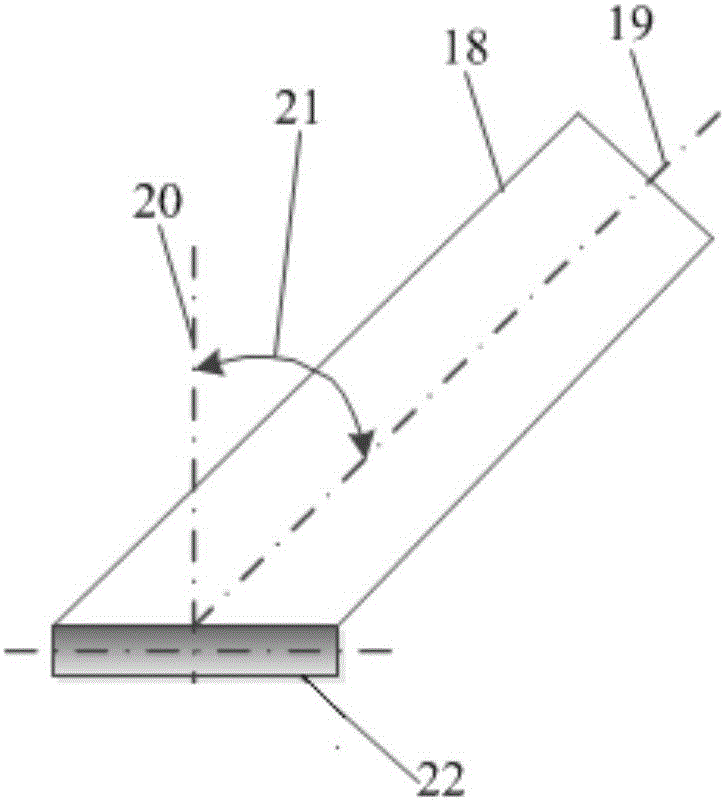

[0016] Such as Figure 4 , shown in 5 and 6, a vehicle engine reverse tumble ratio combustion system, including combustion chamber roof 1, cylinder wall 8, exhaust valve 11, exhaust valve stem 12, asymmetric intake valve stem 13, asymmetric Intake valve 14, exhaust side fuel injector 15, dimple piston 16, intake valve seat ring 22, vertical intake passage 26. Exhaust valve 11, exhaust side fuel injector 15, asymmetrical intake valve rod 13 and asymmetrical intake valve 14 are arranged on combustion chamber roof 1, and the center line of vertical air duct 26 is aligned with the center of intake valve seat ring. Line angle 24 is 15°~25°, combustion chamber top 1, spark plug 2, cylinder wall 8, pit piston 16, exhaust side injector 15, intake valve seat 22, exhaust valve 11, exhaust The door lever 12 forms a reverse tumble ratio combustion system that org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com