Tee joint material fluidistor of improved structure

A technology of fluidizer and tee, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of low feeding efficiency, poor fluidization degree, blockage of intake pipe, etc., and improve feeding efficiency , reduce the failure rate, improve the effect of intake air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

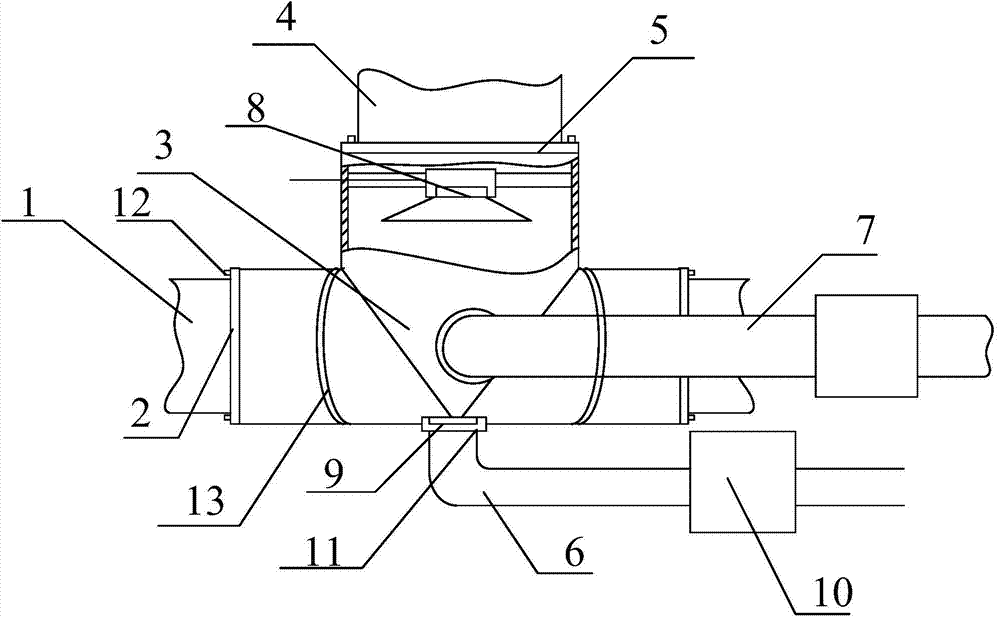

[0024] as attached figure 1 To attach Figure 4 shown

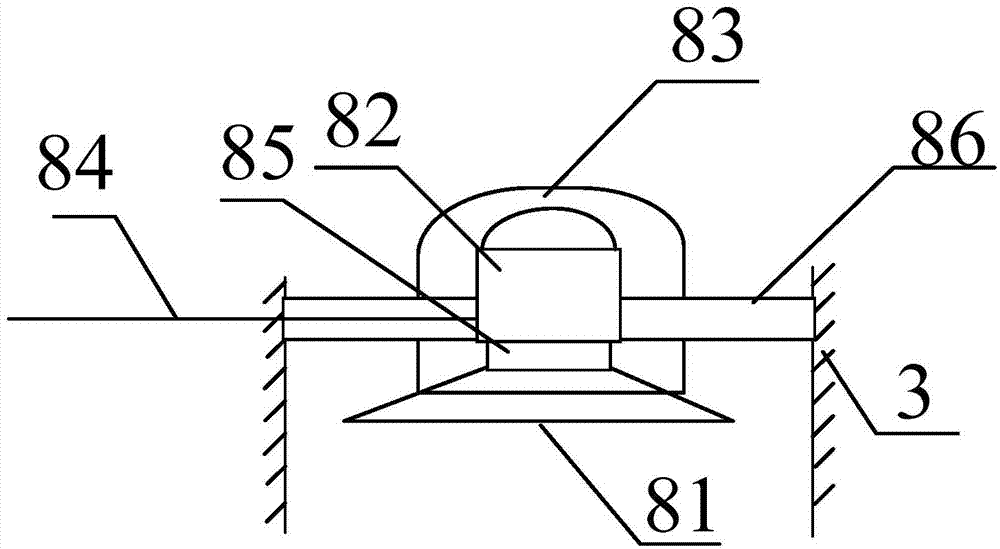

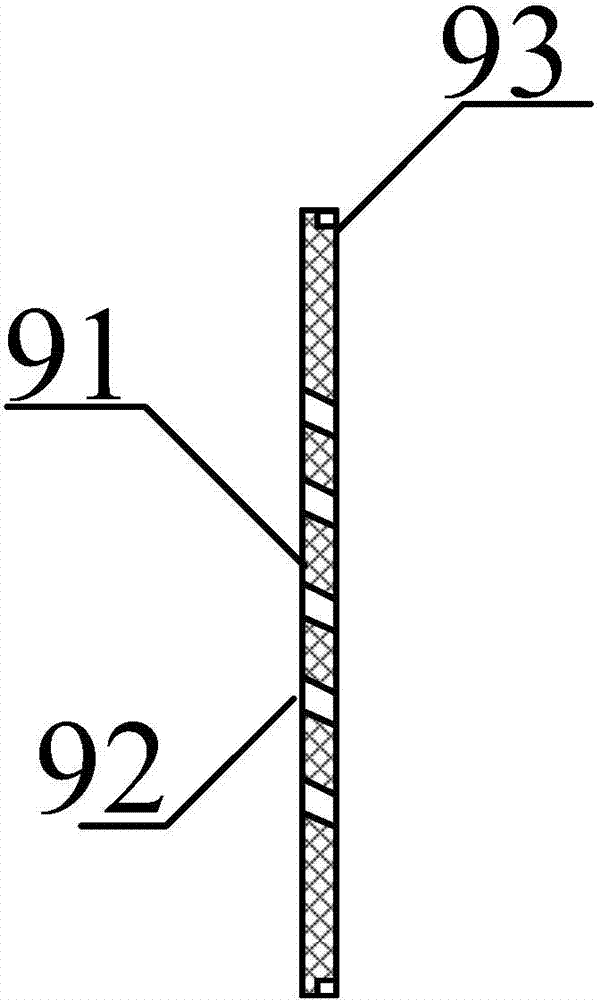

[0025] The invention provides a three-way material fluidizer with an improved structure, which includes a side discharge port 1, a discharge flange 2, a tee body 3, a top feed port 4, a feed flange 5, and a bottom inlet pipe 6. Side air intake pipe 7, vibrating device 8, cut-off plate 9, preheating device 10, air pipe joint 11, fixing bolt 12 and protective plate 13, the side discharge port 1 is installed on the three-way body through the discharge flange 2 The left and right sides of 3; the top feed inlet 4 is installed on the top of the tee body 3 through the feed flange 5; the bottom air intake pipe 6 is installed on the lower side of the tee body 3 through the air pipe joint 11; The side intake pipe 7 is installed on the front and rear sides of the tee body 3 through the air pipe joint 11; the vibration device 8 is installed at the bottom of the top feed port 4; the cut-off plate 9 is embedded in the inner side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com