Cooling system and method of engine

A cooling system and cooling method technology, applied in the direction of engine cooling, engine components, combustion engines, etc., can solve the problems of unguaranteed seawater cleanliness, poor cooling reliability and poor performance of intercoolers, and reduce the seawater pipes of the whole machine system, increase the intake air temperature, and reduce the difficulty of matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

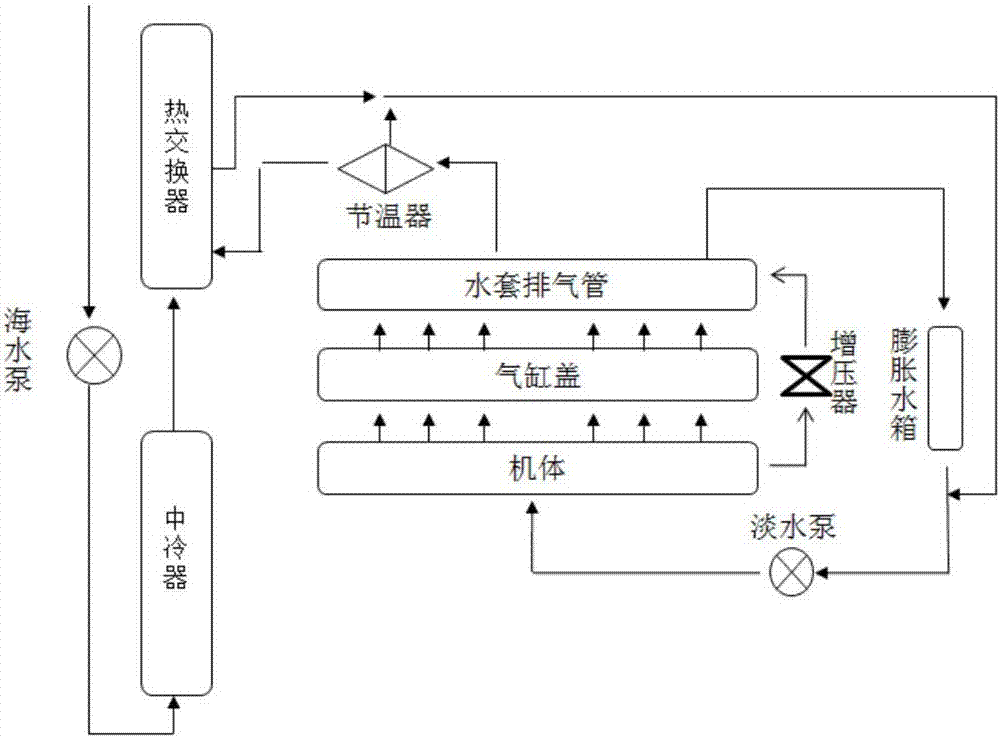

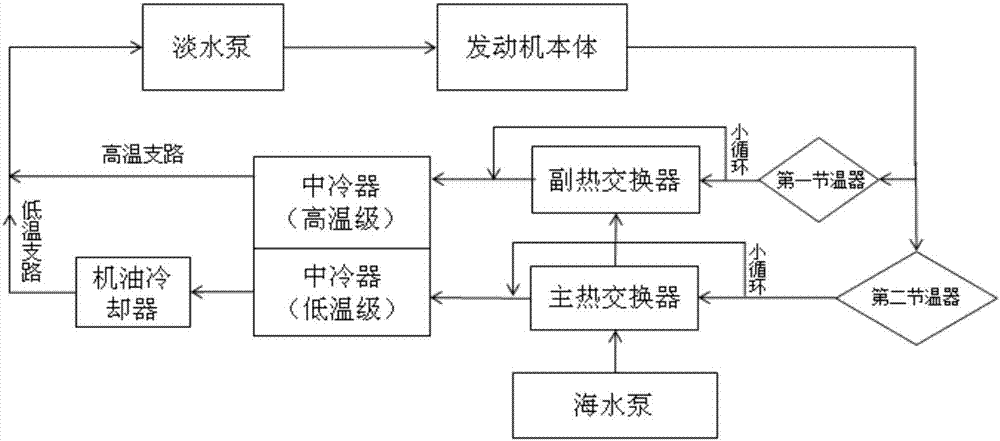

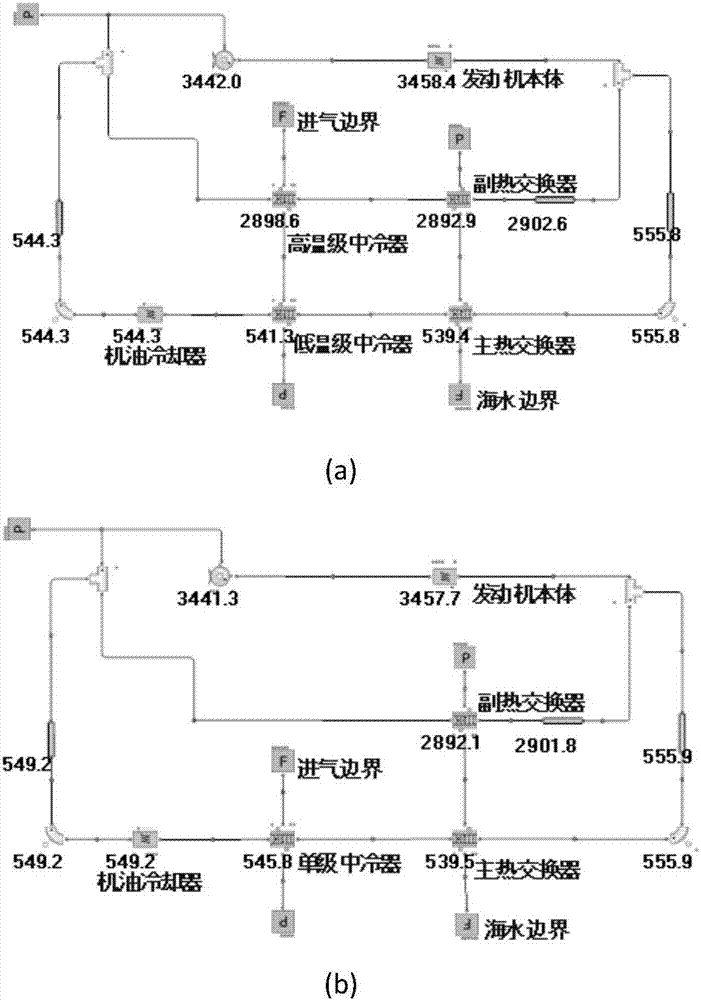

[0038] A cooling system for an engine, comprising, the engine has an engine body, and also includes a high-temperature stage intercooler, a low-temperature stage intercooler, a main heat exchanger, and an auxiliary heat exchanger, wherein the heat dissipation of the auxiliary heat exchanger is smaller than that of the main heat exchanger. The heat dissipation of the heat exchanger; the internal coolant is divided into the first internal coolant branch and the second internal coolant branch after being heated by the engine body: the first internal coolant branch includes the first thermostat, auxiliary heat exchanger, high temperature stage intercooler; the second internal coolant branch circuit includes a second thermostat, main heat exchanger, low temperature stage intercooler; through the first internal coolant branch circuit and the second internal coolant The internal coolant in the branch circuit merges and returns to the engine body to form a closed cooling circuit; the e...

Embodiment 2

[0049] A cooling system for an engine, comprising a closed cooling circuit in which an internal coolant flows, the closed cooling circuit comprising a first internal coolant branch and a second internal coolant branch, the first An internal coolant branch circuit includes a first thermostat, a secondary heat exchanger, and a high-temperature stage intercooler; the second internal coolant branch circuit includes a second thermostat, a main heat exchanger, and a low-temperature stage intercooler ; Wherein, the heat dissipation of the secondary heat exchanger is less than that of the main heat exchanger; the internal coolant is heated by the engine body and flows back through the first internal coolant branch and the second internal coolant branch the engine body;

[0050] It also includes an external cooling system, the external system first introduces the external cooling liquid into the main heat exchanger and then introduces it into the secondary heat exchanger to cool the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com