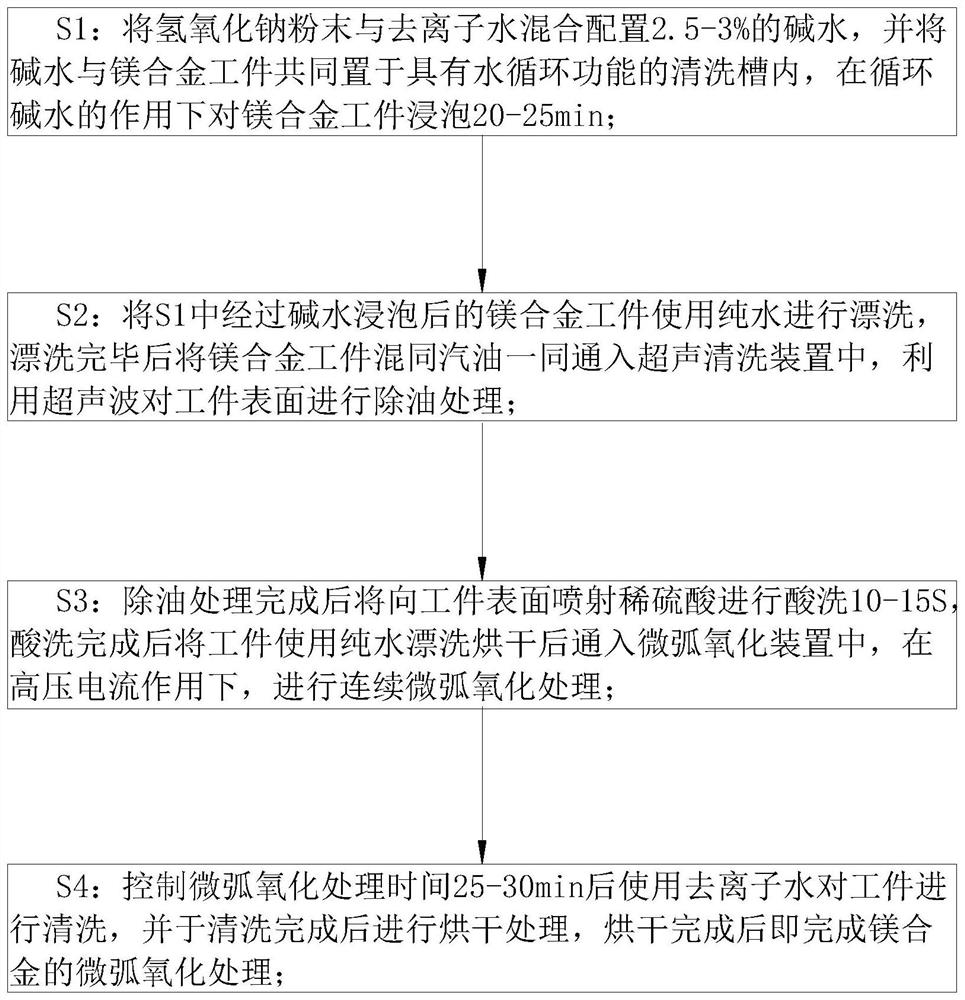

Magnesium alloy micro-arc oxidation treatment process

A micro-arc oxidation and treatment process technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of time-consuming and laborious, and high requirements for the heat dissipation capacity of the oxidation tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

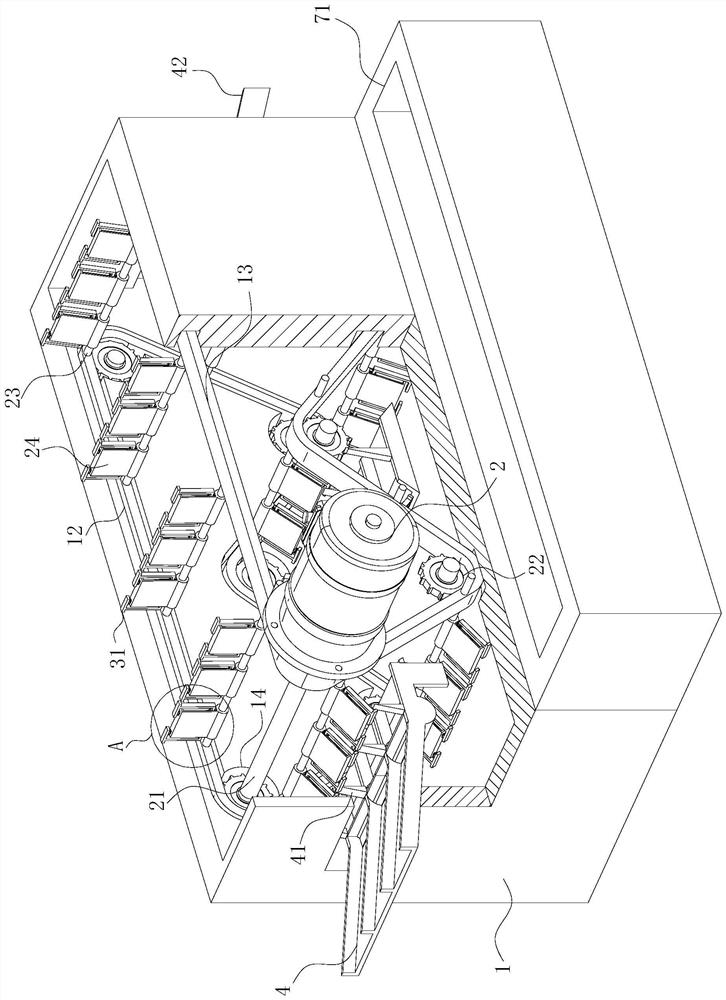

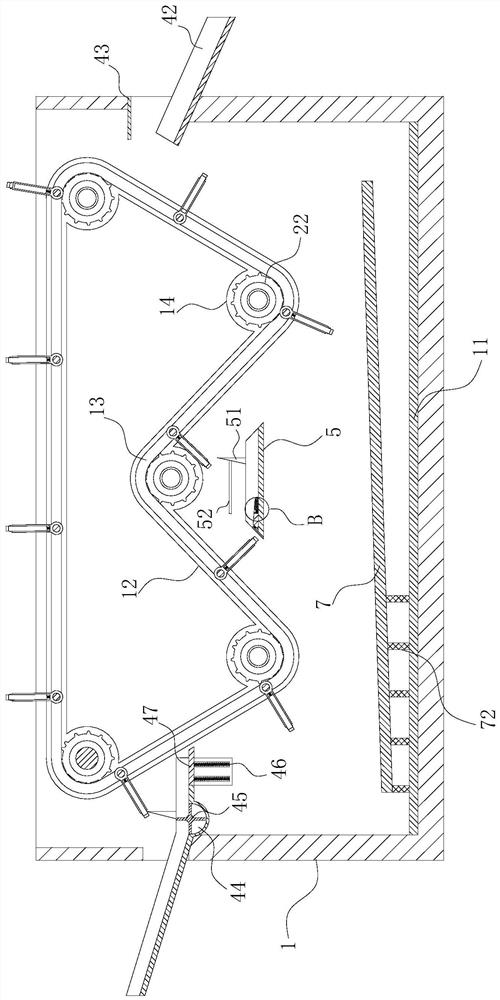

[0042] As an embodiment of the present invention, the air pipe of the vacuum suction nozzle 27 extends to the end of the second chute 3 away from the vacuum suction nozzle 27; in the initial state, the guide plate 31 blocks the air pipe under the spring tension; When the plate 31 loses the workpiece during the entire movement process, it will squeeze the air pipe under the effect of the spring force, causing the vacuum suction nozzle 27 to stop using, which can effectively reduce the impact of multiple vacuum suction nozzles 27 on the external vacuum pump during continuous rotation. The air pressure requirement, and then effectively make the vacuum suction nozzle 27 in contact with the workpiece have a stronger vacuum degree, and then effectively strengthen the fixing effect on the workpiece.

[0043] As an embodiment of the present invention, the feed plate 4 is provided with a toggle groove 44; a toggle wheel 45 is rotatably connected in the toggle groove 44; the blade length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com