Air suction warming method and warming system of gas turbine compressor

A technology for gas turbines and compressors, which is applied to gas turbine devices, air inlets of turbines/propulsion devices, combustion air/combustion-air treatment, etc., and can solve the problem of reducing the work of high-temperature turbines of gas turbines, reducing the efficiency of gas turbines, and consuming electric energy or natural gas and other issues to achieve the effect of reducing adverse effects, increasing temperature, and reducing relative humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

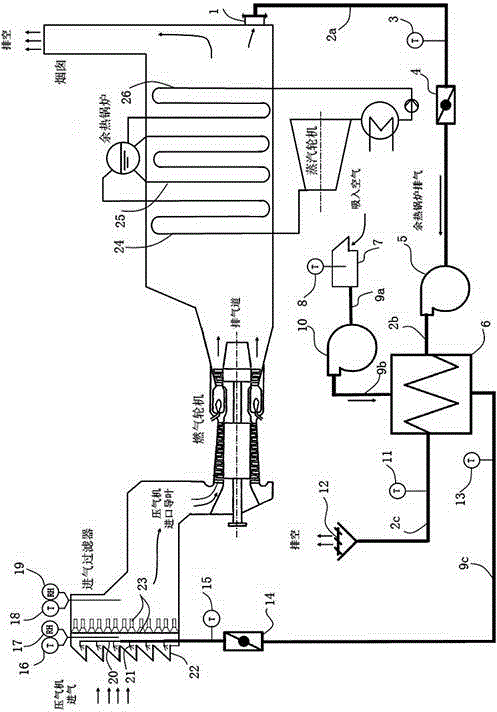

Embodiment 1

[0040] The gas turbine compressor inlet temperature raising system of the present invention comprises a gas turbine unit (compressor, combustor and turbine), the inlet passage of the gas turbine unit is provided with an intake filter, and the intake filter is arranged in sequence The coarse filter 22 and the fine filter 23 are composed of a thermocouple T between the coarse filter 22 and the fine filter 23 AIN2 16 and hygrometer T RH3 17. After careful consideration of 23, a thermocouple T is set AIN3 18 and hygrometer T RH2 19. The exhaust passage of the gas turbine unit is subsequently jointly equipped with a waste heat steam power generation system. The waste heat steam power generation system includes a waste heat boiler and a steam turbine. The high-temperature gas in the exhaust passage passes through the superheater 24, evaporator 25, and feed water of the waste heat boiler Heater 26 and chimney, its structure such as figure 1 shown.

[0041] The bottom of the chimn...

Embodiment 2

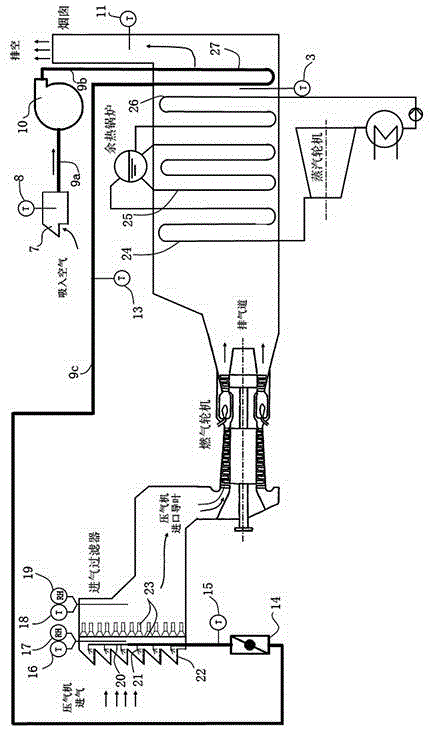

[0047] The gas turbine compressor inlet temperature raising system of the present invention comprises a gas turbine unit (compressor, combustor and turbine), the inlet passage of the gas turbine unit is provided with an intake filter, and the intake filter is arranged in sequence The coarse filter 22 and the fine filter 23 are composed of a thermocouple T between the coarse filter 22 and the fine filter 23 AIN2 16 and hygrometer T RH3 17. After careful consideration of 23, a thermocouple T is set AIN3 18 and hygrometer T RH2 19. The exhaust passage of the gas turbine unit is subsequently jointly equipped with a waste heat steam power generation system. The waste heat steam power generation system includes a waste heat boiler and a steam turbine. The high-temperature gas in the exhaust passage passes through the superheater 24, evaporator 25, and feed water of the waste heat boiler Heater 26 and chimney, its structure such as figure 2 shown.

[0048] A low-temperature air ...

Embodiment 3

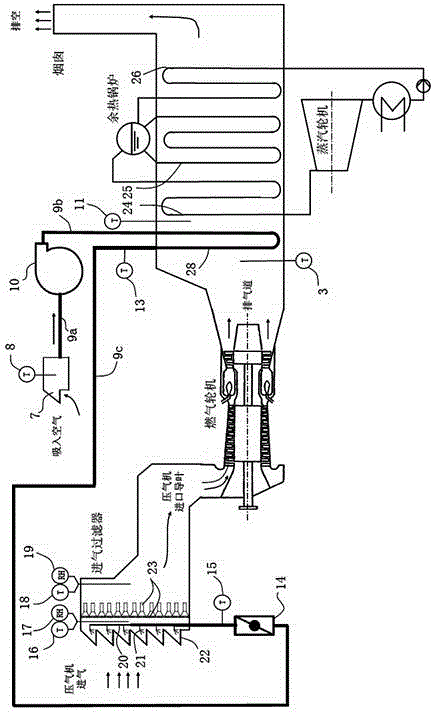

[0055] The gas turbine compressor inlet temperature raising system of the present invention comprises a gas turbine unit (compressor, combustor and turbine), the inlet passage of the gas turbine unit is provided with an intake filter, and the intake filter is arranged in sequence The coarse filter 22 and the fine filter 23 are composed of a thermocouple T between the coarse filter 22 and the fine filter 23 AIN2 16 and hygrometer T RH3 17. After careful consideration of 23, a thermocouple T is set AIN3 18 and hygrometer T RH2 19. At the same time, the exhaust passage of the gas turbine unit can also be selectively installed in conjunction with a waste heat steam power generation system. The waste heat steam power generation system includes a waste heat boiler and a steam turbine. The high-temperature gas in the exhaust passage passes through the superheater 24 of the waste heat boiler, evaporates Device 25, feed water heater 26 and chimney, its structure is as figure 2 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com