EGR (exhaust gas recirculation) gas temperature control device, EGR gas temperature control method, engine and engineering machinery

A gas temperature and control device technology, applied in the fields of engines, construction machinery, and EGR gas temperature control devices, can solve problems such as excessive emissions, uncontrollable EGR gas temperature, damage to the engine EGR valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0025] The basic idea of the present invention is to solve the problem of uncontrollable EGR gas temperature. The present invention proposes an EGR gas temperature control device. The flow rate of the liquid is used to adjust the flow rate of the coolant in the EGR cooler, so as to control the temperature of the EGR gas within the required range.

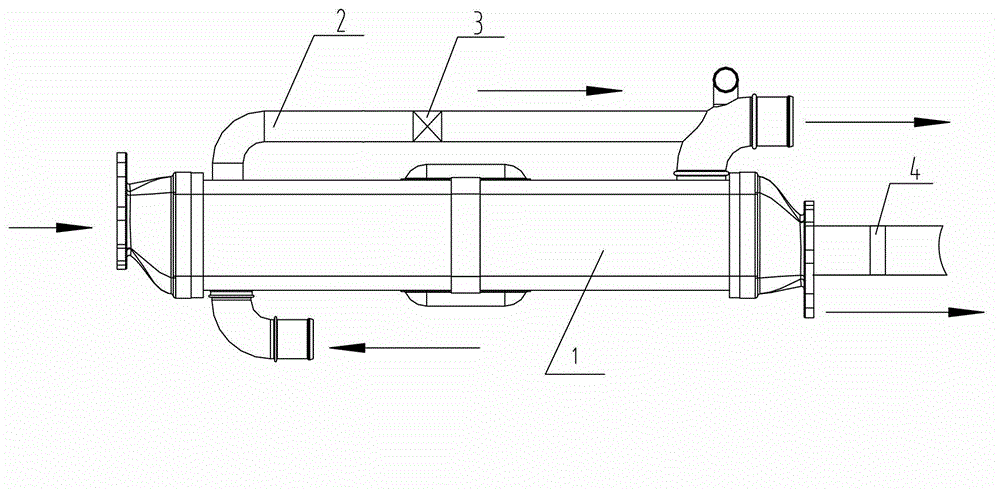

[0026] Combine below figure 1 , the preferred embodiment of the present invention is described in further detail: EGR gas temperature control device comprises: EGR cooler 1, is used for cooling the EGR gas that introduces from engine exhaust pipe; Bypass pipe 2, its inlet and EGR cooler 1 The coolant inlet is connected; the flow regulating valve 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com