Engine inlet air, crankcase and anti-freezing solution preheating combined system and preheating method thereof

A combined system and antifreeze technology, applied in engine components, engine starting, machine/engine, etc., can solve the problems of reduced engine starting speed, small air contact area, and increased lubricating oil viscosity, so as to increase the starting speed, reduce The effect of starting torque and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

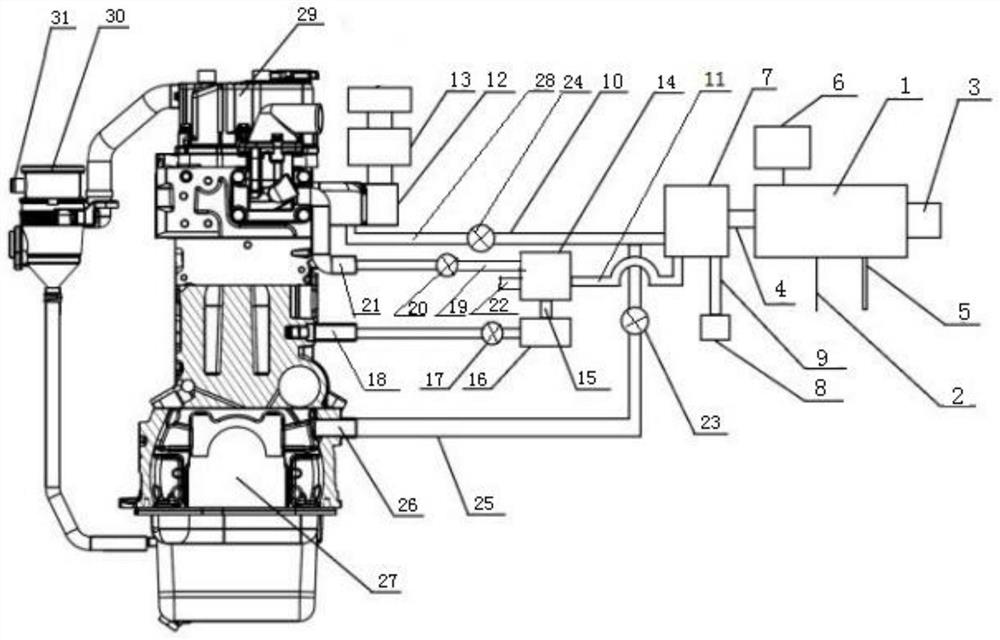

[0033] Such as figure 1 As shown, the air heating device is set as a split structure, including a burner 1, an air-air heat exchanger 7 and a controller 6, the burner 1 is electrically connected to the controller 6, and the burner 1 The gas outlet 4 is communicated with the gas-gas heat exchanger 7 through pipelines, and the gas-gas heat exchanger 7 is respectively connected with the engine intake pipe 12 and the crankcase 27 through two parallel pipelines on the heat exchanger outlet pipe 10. The crankcase intake channel 26 communicates, and the gas-air heat exchanger 7 communicates with the antifreeze preheating assembly through the exhaust connecting pipe 11; In the section, high-temperature gas enters the air filter 13 through the engine intake pipe 12 and is discharged through the air inlet of the air filter 13; the crankcase 27 is also provided with a respirator 30 and a dedicated exhaust port, so The respirator 30 communicates with the air outlet on the crankcase of th...

Embodiment 2

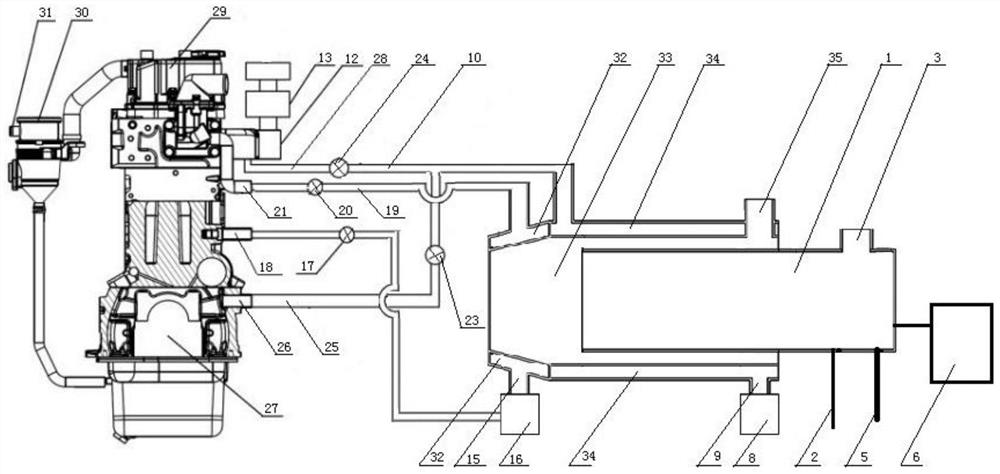

[0049] Such as figure 2 As shown, the air heating device is set as an integral structure, including a burner 1, a furnace 33, a gas chamber 34 and connecting pipelines, and one end of the burner 1 is provided with a power line 2, an air inlet 3 and an oil pipe 5 , the other end of the power line 2 is connected to the battery on the vehicle to realize power supply, the air inlet 3 is connected to the air filter on the vehicle through a pipeline, and the other end of the oil pipe 5 is connected to the fuel tank on the vehicle, The other end of the burner 1 extends into the furnace 33, and the gas cavity 34 is wrapped and arranged on the outside of the furnace 33; the furnace 33 is provided with an exhaust port 35, and the exhaust port 35 communicate with the outside air;

[0050] One end of the gas chamber 34 is provided with a heat exchanger inlet pipe 9, and the other end of the heat exchanger inlet pipe 9 communicates with the fan 8, and the air inlet of the fan 8 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com