Radial magnetic field coreless permanent-magnet wind driven generator

A wind turbine, radial magnetic field technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, shapes/styles/structures of winding conductors, etc. , small output power and other problems, to achieve the effect of expanding the scope of application of wind speed, reducing starting torque, and improving torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

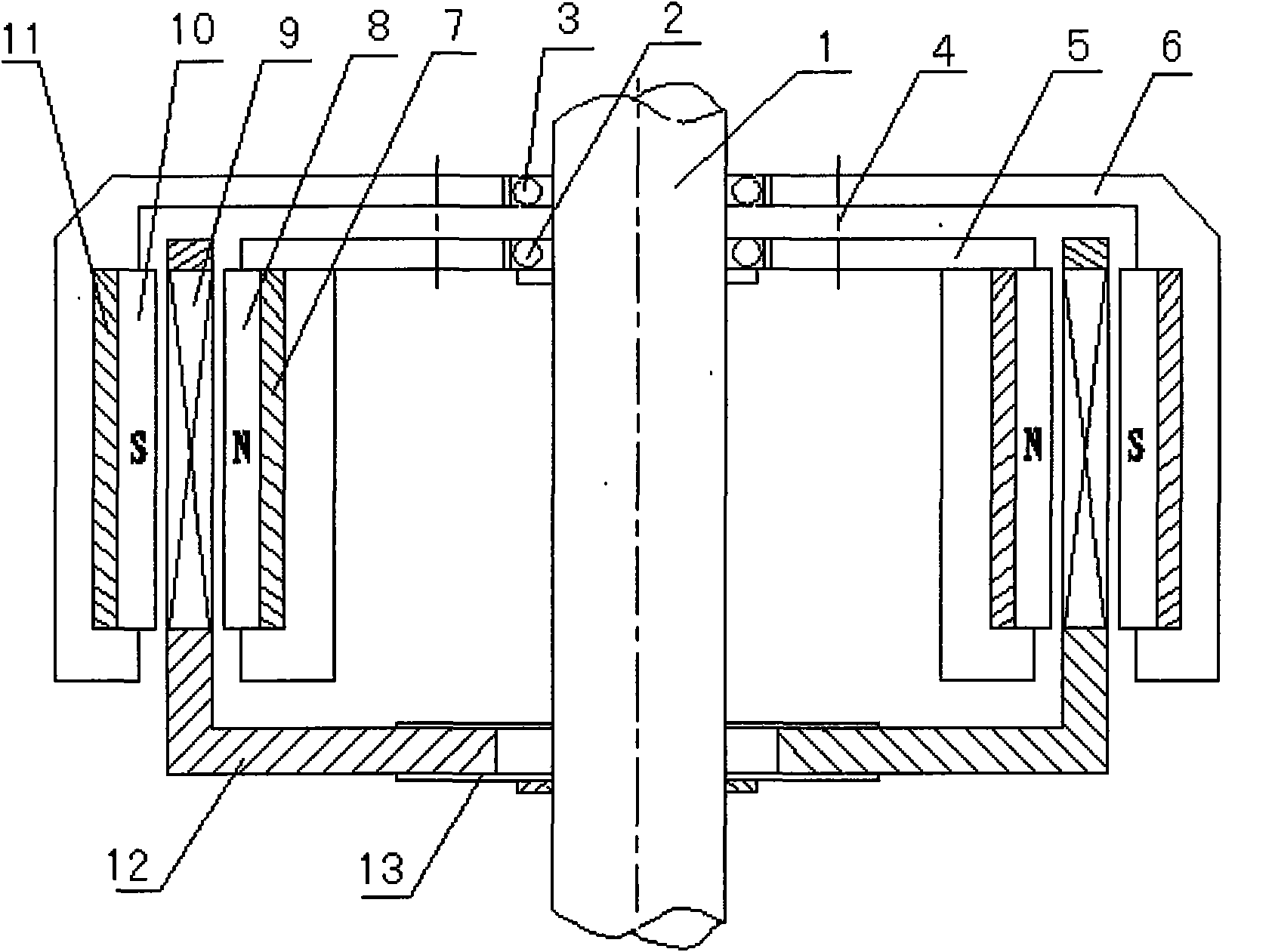

[0024] like figure 1 As shown, the present invention includes a rotor inner cylinder 5 , a rotor outer cylinder 6 and a stator cylinder 12 arranged coaxially. Among them, the rotor inner cylinder 5 and the rotor outer cylinder 6 form a double-cylinder rotor structure, and the cylinders made of aluminum alloy are the best embodiment. The rotor inner cylinder 5 is connected to the main shaft 1 through the rotor inner bearing 2, the rotor outer cylinder 6 is connected to the main shaft 1 through the rotor outer bearing 3, and the rotor inner bearing 2 and the rotor outer bearing 3 are tightly fitted and pressed on the main shaft 1 . In addition, the rotor inner cylinder 5 and the rotor outer cylinder 6 are integrally connected by bolts 4, so that the rotor inner cylinder 5 and the rotor outer cylinder 6 can rotate synchronously. Moreover, the nozzle directions of the rotor inner cylinder 5 and the rotor outer cylinder 6 are in the same direction, while the nozzle direction of t...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that in this embodiment, 24 pieces of three-phase inner magnetic steel 8 are evenly distributed along the circumference on the cylinder wall of the rotor inner cylinder 5, and on the cylinder wall of the rotor outer cylinder 6 24 pieces of three-phase outer magnetic steel 10 are evenly distributed along the circumference, and 18 wire coils 9 are evenly distributed along the circumference on the cylinder wall of the stator cylinder 12 . The polarity distribution of the inner magnetic steel 8 and the outer magnetic steel 10 is the same as that of the first embodiment.

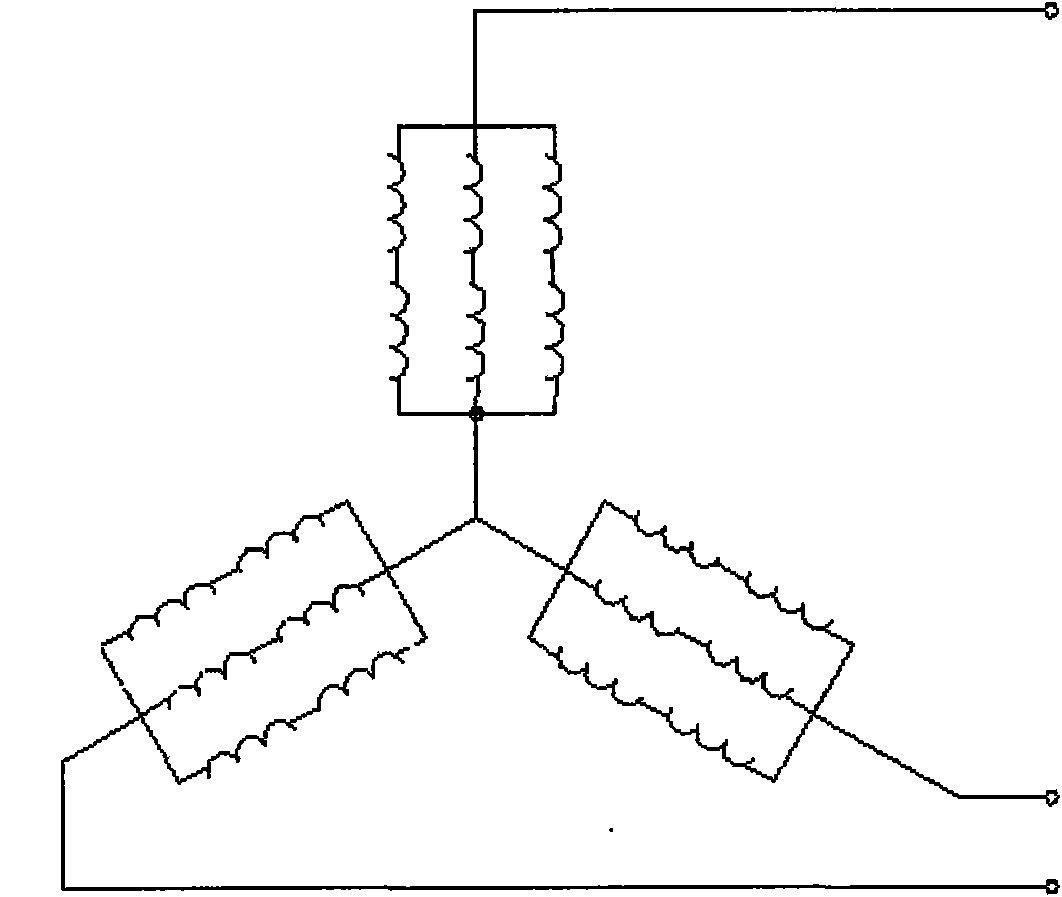

[0031] In addition, if image 3 As shown, the connection mode of the coil 9 is a three-phase Y junction, three series and two parallel 3S2P, that is, the coil 9 has a three-phase Y-shaped structure as a whole, and each phase is composed of two coil groups connected in parallel, each coil Groups are formed from three coils connected in series.

[...

Embodiment 3

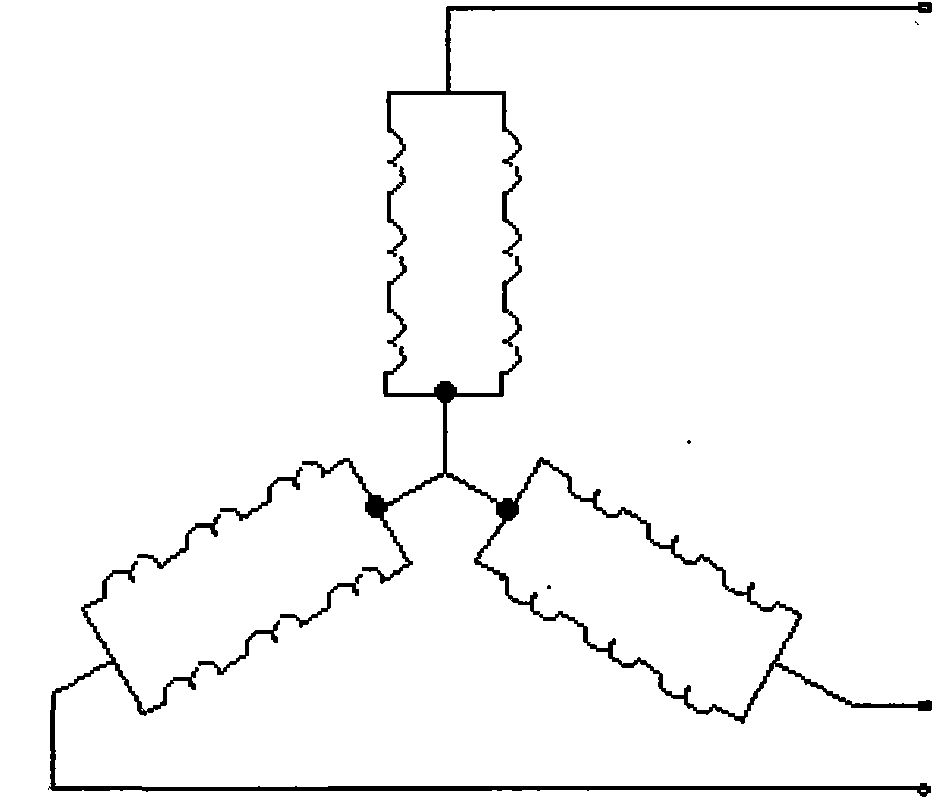

[0034] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this embodiment, the connection mode of the wire coil 9 is a three-phase Y junction, six strings and one parallel 6S1P, that is, the wire coil 9 as a whole is a three-phase Y Shaped structure, and each phase is formed by six coils connected in series.

[0035] Other technical characteristics are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com