Heat exchanger for food baking and heat exchange and heat dissipation integrated preheating baking equipment

A roasting equipment and heat exchanger technology, which is applied in special roasting containers, roasters/barbecue grills, heat exchange equipment, etc., can solve the problems of occupying external space, large heat loss of pipelines, insufficient combustion, etc. Achieve the effect of reducing working pressure, reducing heat, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

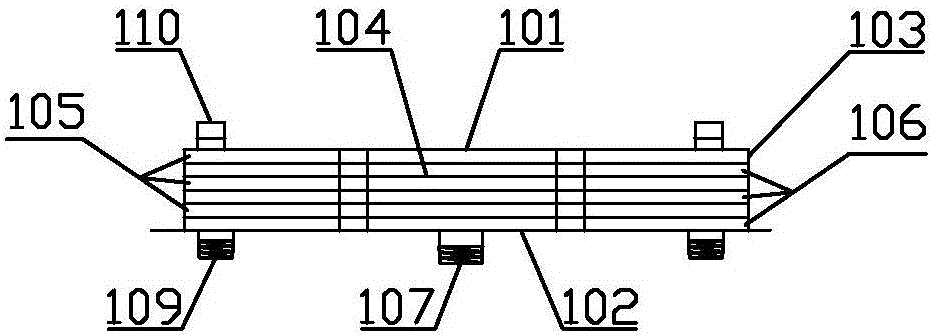

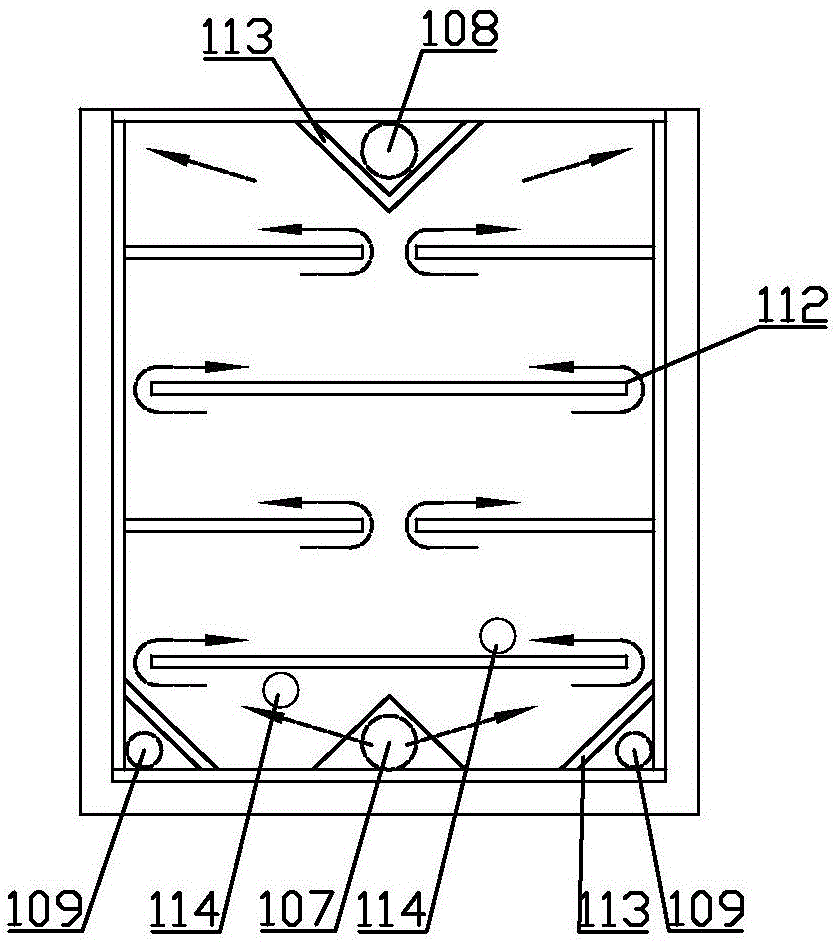

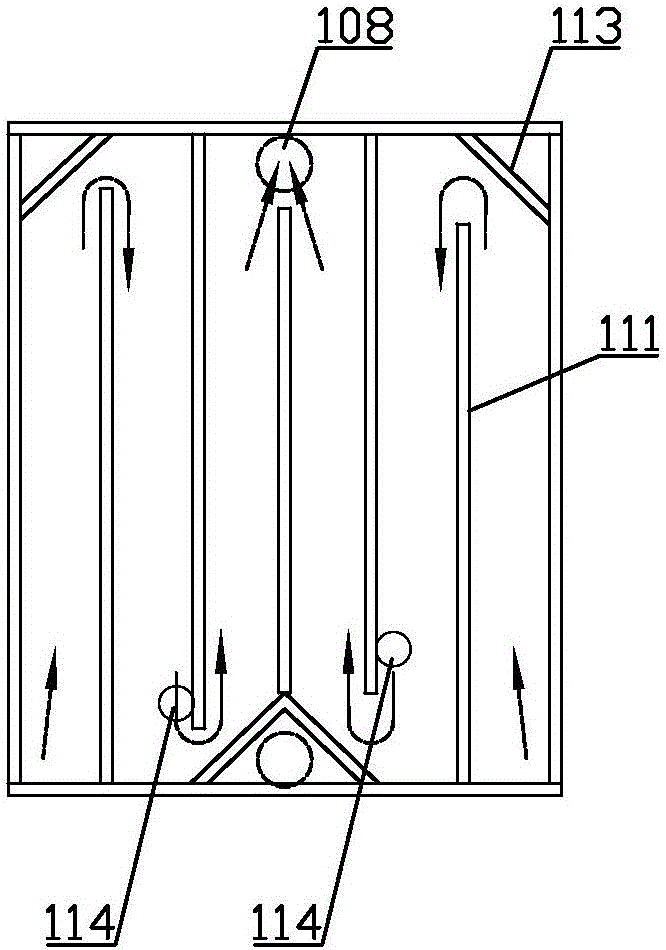

[0032] Such as Figure 1 to Figure 8 As shown, a food baking heat exchanger 100 includes a top plate 101, a bottom plate 102, a side plate 103 and a heat exchange partition 104 arranged between the top plate 101 and the bottom plate 102, and the heat exchange partition 104 is fixed on On the side plate 103, the heat exchange partition plate 104 divides the space between the top plate 101 and the bottom plate 102 into a plurality of medium layers, and the number of layers of the medium layer can be set according to needs. This embodiment takes six layers as an example for illustration . Wherein the heating medium layer 105 and the cooling medium layer 106 are arranged at intervals. In this embodiment, there are three layers of heating medium layers 105 and three layers of cooling medium layers 106. The tail ends of the uppermost heating medium layer 105 and the middle heating medium layer 105 are connected to each other. The head ends of the middle heat medium layer 105 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com