Exhaust gas purifying system for internal combustion engine and soot filter regenerating method

An exhaust gas purification, internal combustion engine technology, applied in chemical instruments and methods, membrane filters, internal combustion piston engines, etc., can solve the problems of inoperable, uneconomical, and complicated structure of the shutter opening and closing mechanism, and reduce fuel consumption. , the effect of stable regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

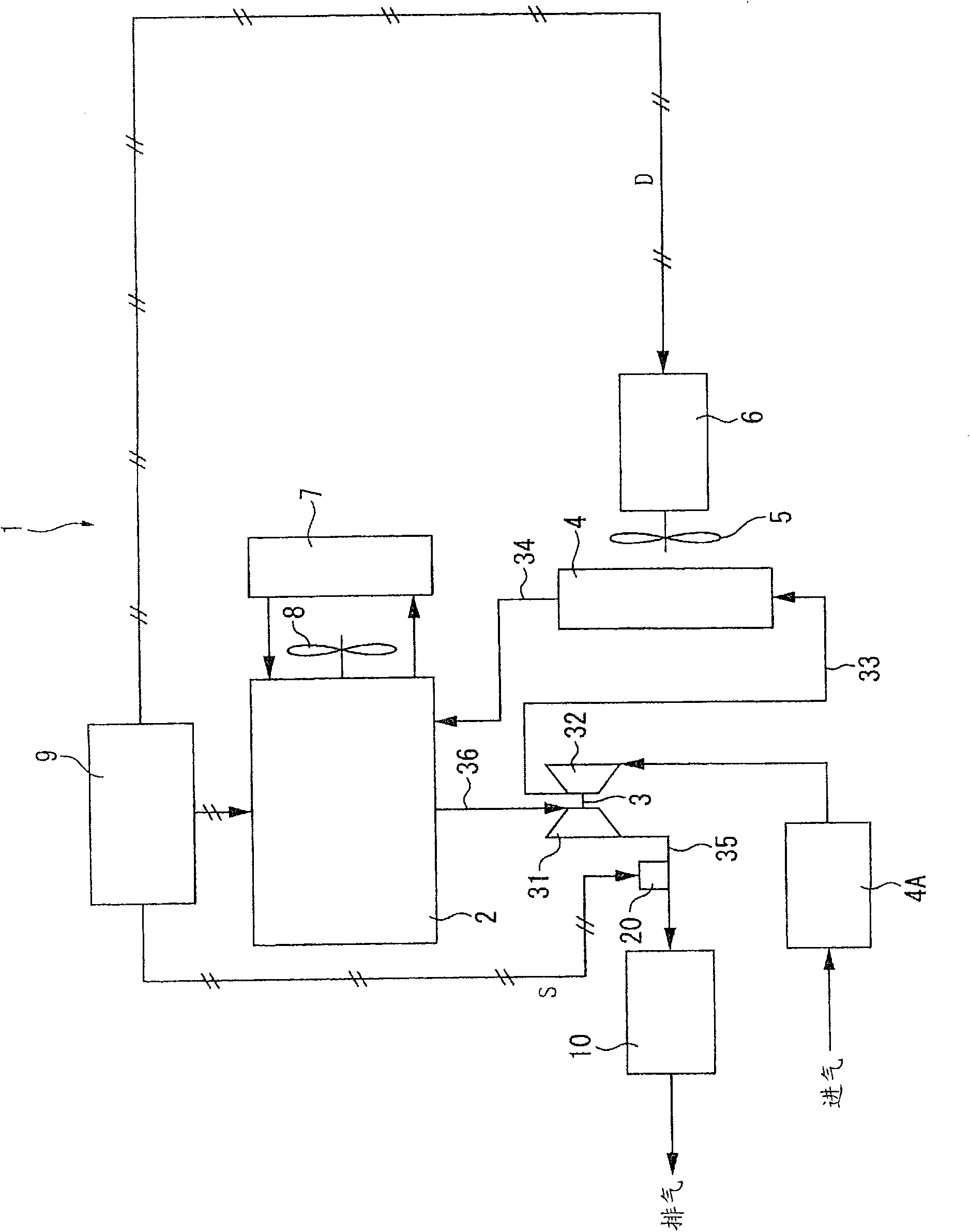

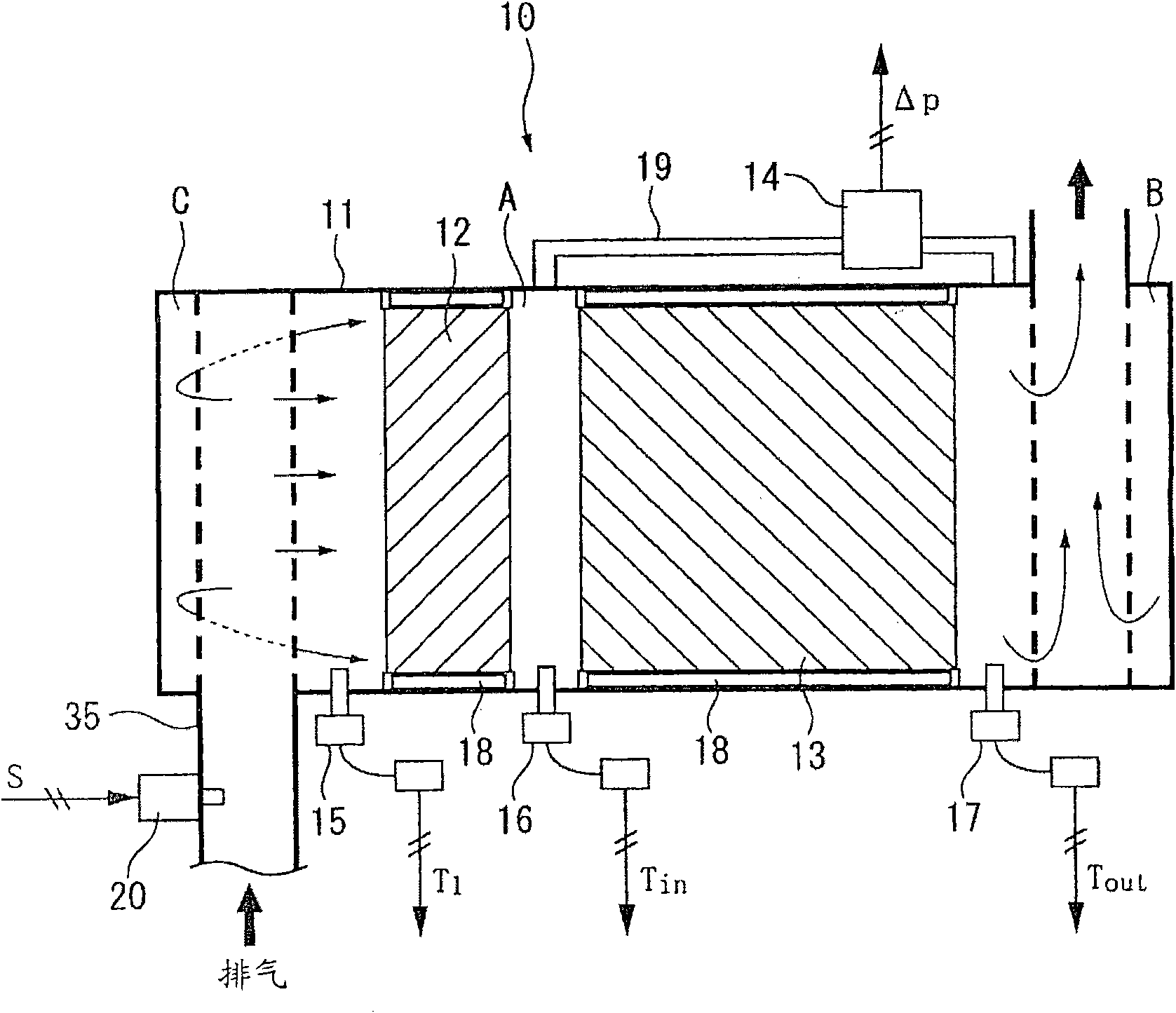

[0061] Hereinafter, a first embodiment of the present invention will be described based on the drawings.

[0062] figure 1 It is a block diagram showing the general configuration of the exhaust purification system 1 according to the first embodiment of the present invention. The exhaust purification system 1 is a system for capturing PM contained in exhaust gas from an engine 2 which is an internal combustion engine, and includes a PM filtering device 10 .

[0063] Here, the engine 2 in the present embodiment is assumed to be a diesel engine. An exhaust turbocharger 3 , which is a supercharger, is attached to the engine 2 via a not-shown exhaust branch pipe. The exhaust turbocharger 3 is composed of a turbine 31 driven by exhaust gas from the engine 2 and a compressor 32 rotating together with the turbine 31 , and the aftercooler 4 is connected to an intake outlet of the compressor 32 through an intake pipe 33 .

[0064] The aftercooler 4 is connected to the engine 2 via an...

no. 2 approach 〕

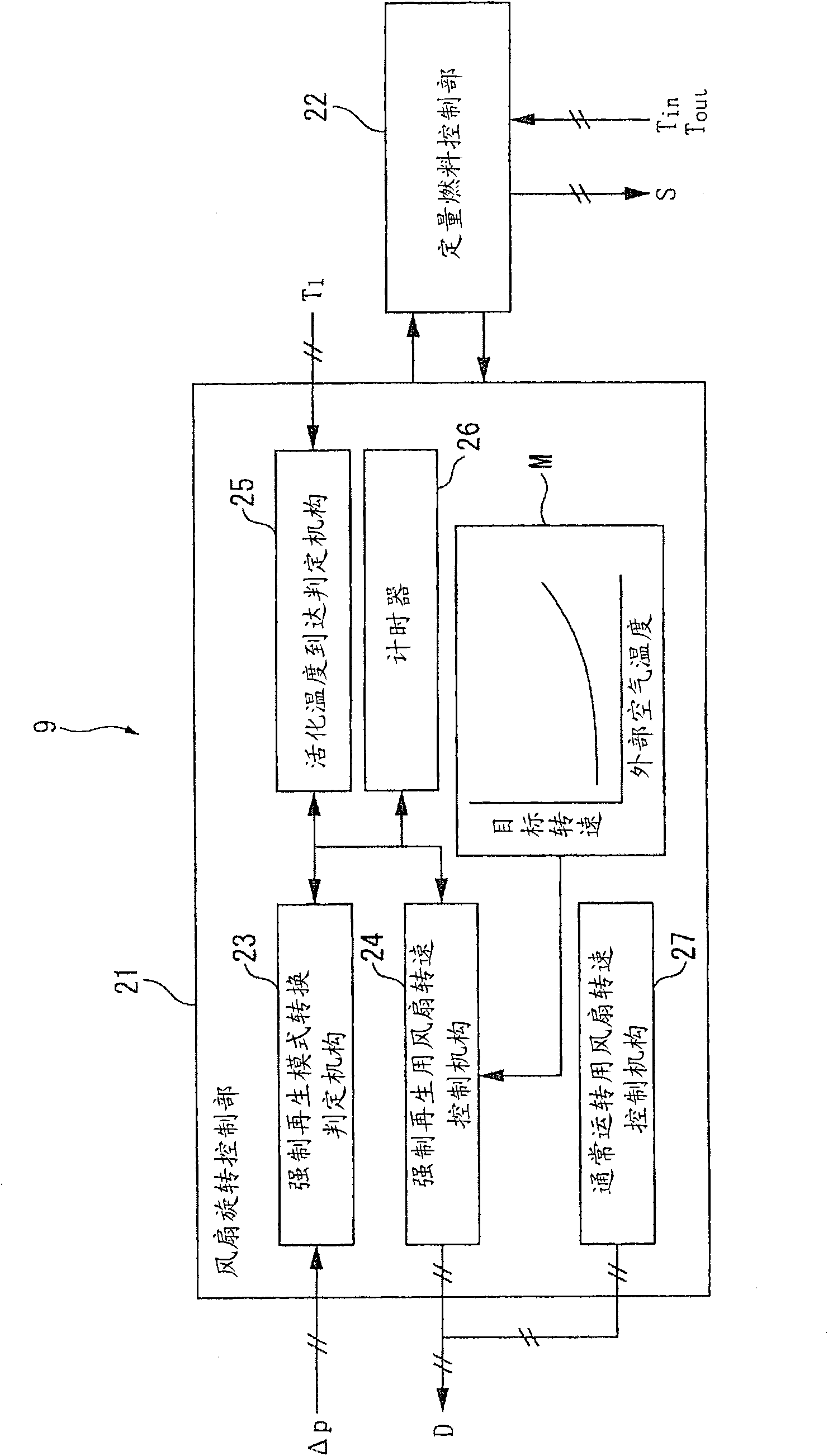

[0101] In the second embodiment of the present invention, as Image 6 As shown, there is a big difference from the first embodiment in that a rotation speed change determination mechanism 28 is provided in the fan rotation control unit 21 . The rotational speed change determining means 28 determines whether to lower the rotational speed of the cooling fan 5 in the forced regeneration mode.

[0102] Specifically, based on Figure 7 The flow chart of the figure shows that the rotation speed change determining means 28 is as follows: Based on the detection signal from the outside air temperature sensor not shown in the figure, the outside air temperature T is monitored. air , the outside air temperature T air It is compared with a preset temperature ( S12 ), which is a limit temperature at which the durability of the engine 2 may decrease due to forced regeneration fan control.

[0103] When the outside air temperature T air When the limit temperature is reached, the rotation...

no. 3 approach 〕

[0108] exist Figure 8 The third embodiment shown is largely different from the first and second embodiments in that the aftercooler 4 and the radiator 7 are cooled by the cooling air from the cooling fan 5 driven by the driving device 6 . And, in this third embodiment, although the cooling fan 8 driven by the engine 2 is not provided ( figure 1), but the cooling fan 8 can be provided in the same manner as the first method. Other structures, control methods, etc. are the same as those of the first and second embodiments.

[0109] In such a structure, by implementing the same control as in the first and second embodiments, that is, when the soot filter 13 is being regenerated, the rotation speed of the cooling fan 5 is reduced in the forced regeneration mode to raise the intake air temperature, and further The effect similar to that of the first embodiment can be obtained by raising the exhaust gas temperature.

[0110] Moreover, in this embodiment, since the layout is such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com