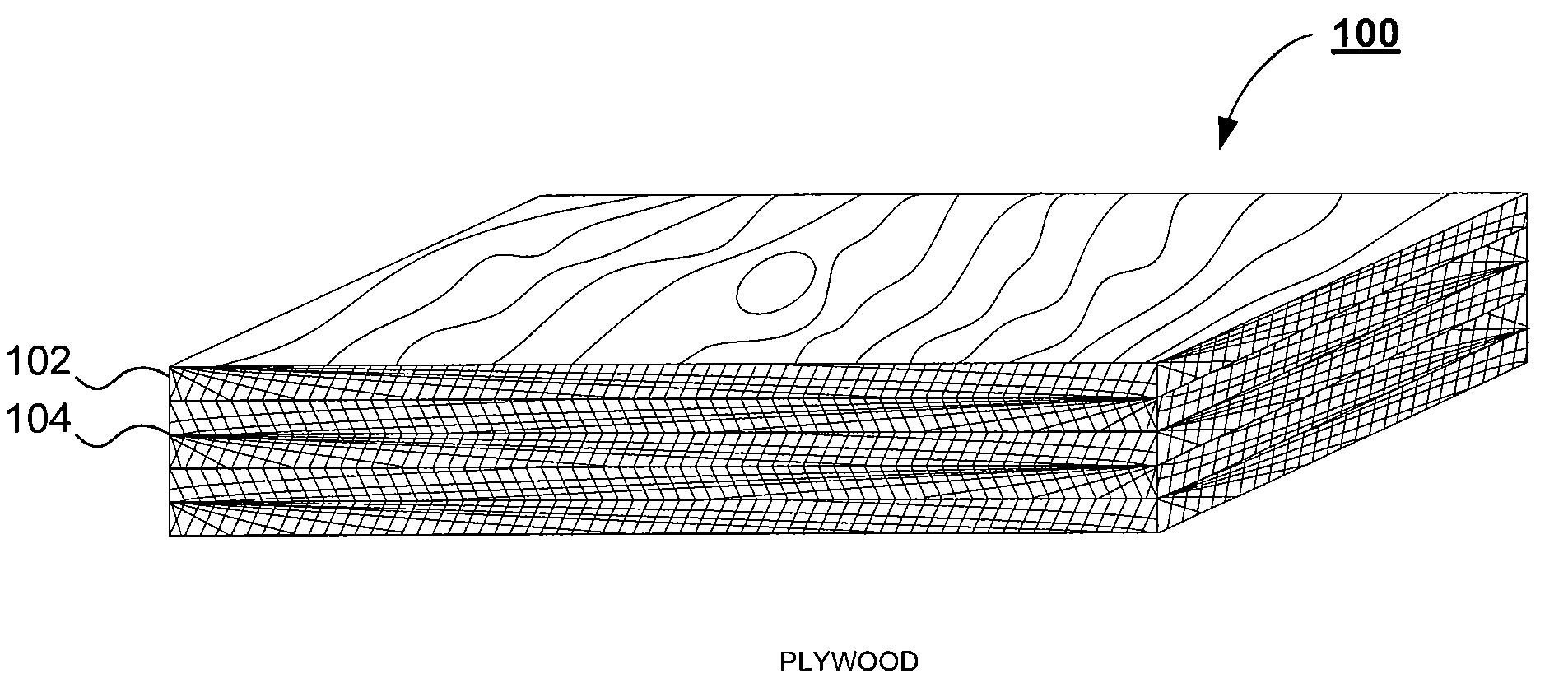

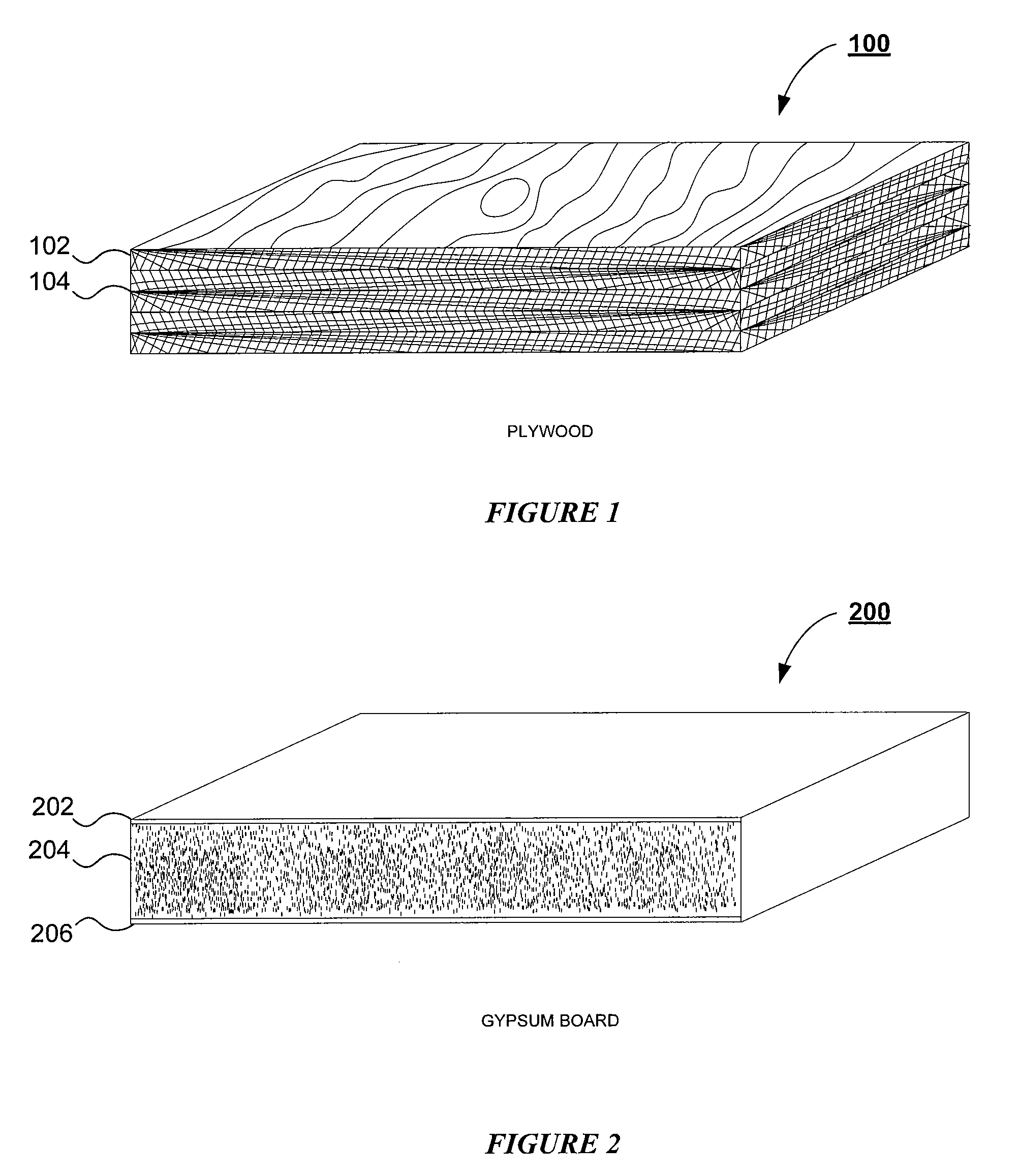

Processes and Manufacturing Methods to Produce an Aqueous Thermosetting Fire-Rated Fire-Retardant Polymeric Adhesive Composition for Manufacturing Interior or Exterior Fire-Rated Cellulosic Products

a polymeric and fire-retardant technology, applied in the direction of wood layered products, water-setting substance layered products, synthetic resin layered products, etc., can solve the problem of metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1.1

Preparing a Fire-Retardant Non-Corrosive Composition

[0062]The subject application features a stable, non-corrosive composition for imparting fire, insect and fungus resistant qualities and comprises an aqueous solution selected from a group of fire-rated, flame-resistant constituents and resin adhesive materials.

[0063]Relative proportions of the blended fire-retardant, non-corrosive constituents can be adjusted to optimize results based upon the stipulated design factors and the desired characteristics and qualities of the end-use physical and fire-rated cellulosic product. Those skilled in the art will be able to determine, through routine experimentation, the most effective relative percent by weight amounts of the constituents set forth above to create their preferred fire-rated non-corrosive composition.

example 1.2

Preparing a Liquid Mixture of a Fire-Rated Flame Resistant Aqueous Thermosetting High-Density Structural Adhesive

[0064]Using the methodology described below, the indicated percent amounts of the blended constituents (flame retardant agent, preservative composition, casein liquid modified melamine resin adhesive; and a monomeric-polymeric MDI catalyst, total weight by volume) together form a liquid mixture of the fire-rated, flame-resistant aqueous thermosetting high-density structural resin adhesive composition.[0065]A. To a mixing tank, add 48.98 percent (w / v) of the liquid flame-retardant component Melflam 136 / 12 / FR2®.[0066]B. Add about 30.5 percent (w / v) of the preservative composition Disodium Octaborate Tetrahydrate.[0067]C. Continue mixing with constant stirring until a smooth liquid mixture results.[0068]D. Add 20.33 percent (w / v) of the casein liquid modified melamine resin adhesive wood material bonding agent. MB 4650.[0069]E. Continue mixing with constant stirring until a ...

example 1.3

Application of a Fire-Retardant Adhesive to a Cellulosic Material

[0073]The following example is conducted in compliance with EN ISO 9001:2000; BS EN ISO:2000; ANSI / ASQ Q9011:2000; for the following scope of registration; 8734 (US): TESTING LABORATORIES (per test conducted by CRT LABORATORIES, INC., ORANGE, CA [an UNDERWRITERS LABORATORIES, INC. registered firm, A3135, LWR NO: 16756-R1] on Sep. 15, 2006).

[0074]The composition materials listed in Example 1.2, combined as set forth therein, together to form a liquid mixture of the fire-rated flame resistant aqueous thermosetting high-density structural adhesive composition.

[0075]SAMPLE DESCRIPTION: Blended proprietary Fire-Retardant Adhesive (polymer) Component and Oriented Strand (OSB) cellulosic material.

[0076]TEST PROCEDURES: Underwriters Laboratories, Inc. Test Method UL 94V0 Vertical Flammability Test; Flame Temperature: 843° C. (1,550° F.).

[0077]PREPARATION: UL 94 fire test specimens; ½″×5″ (1.60-1.64 mm thickness) were culled fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com