Patents

Literature

54results about How to "Oxidation resistance can be improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermally modified carbon blacks for various type applications and a process for producing same

InactiveUS20050063892A1Oxidation resistance can be improvedReduced metal and ash contentPigmenting treatmentMaterial nanotechnologyModified carbonOxidation resistant

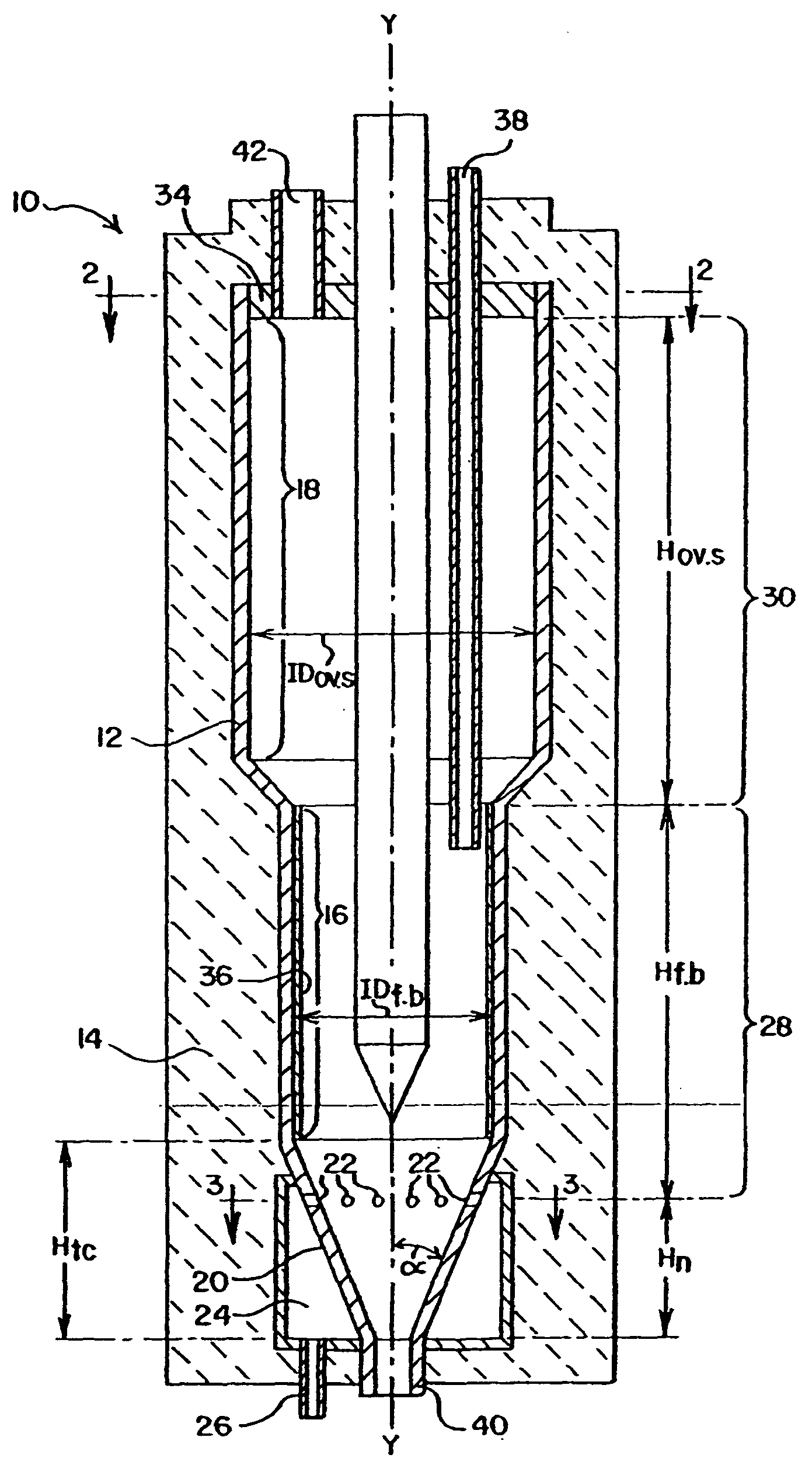

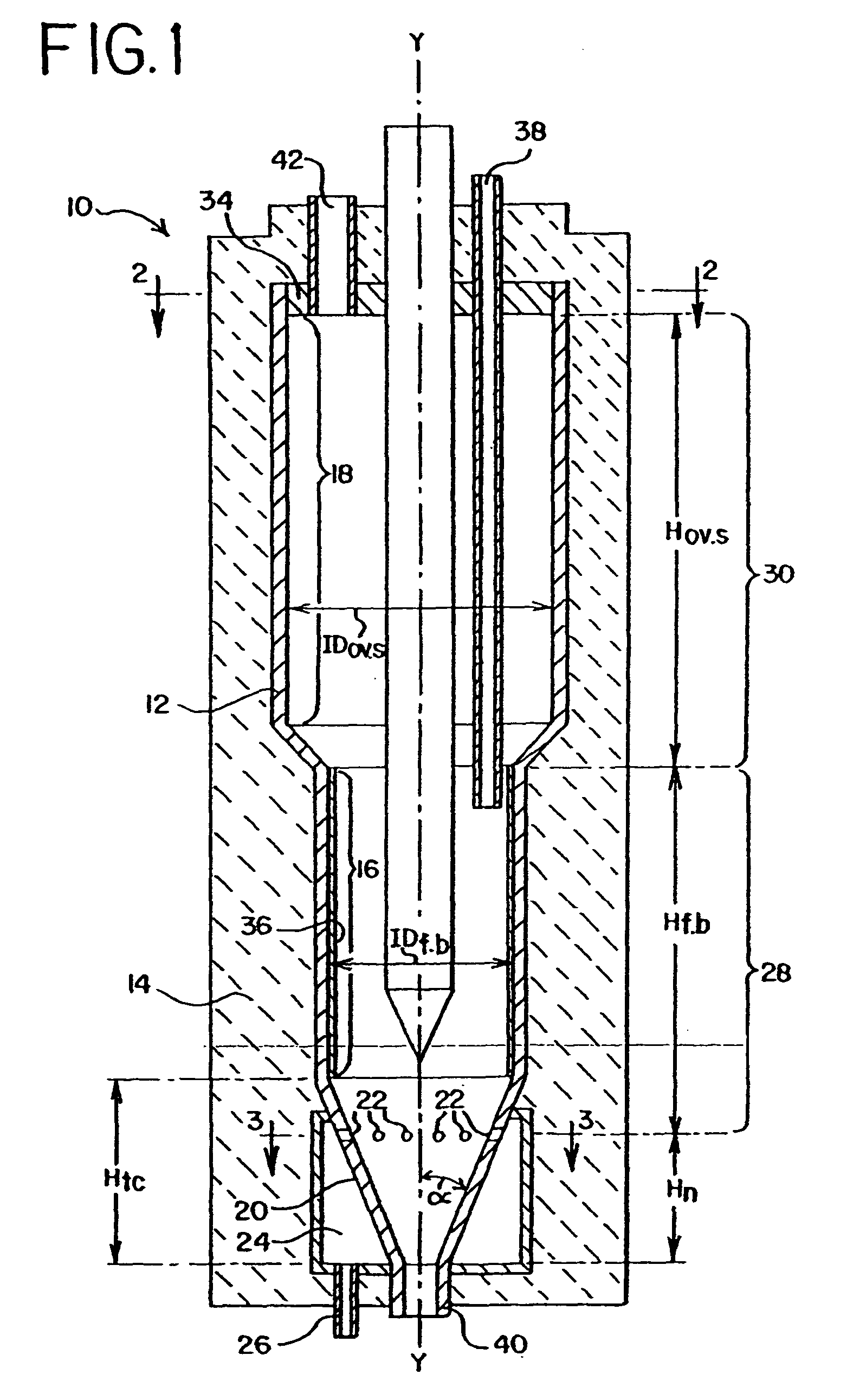

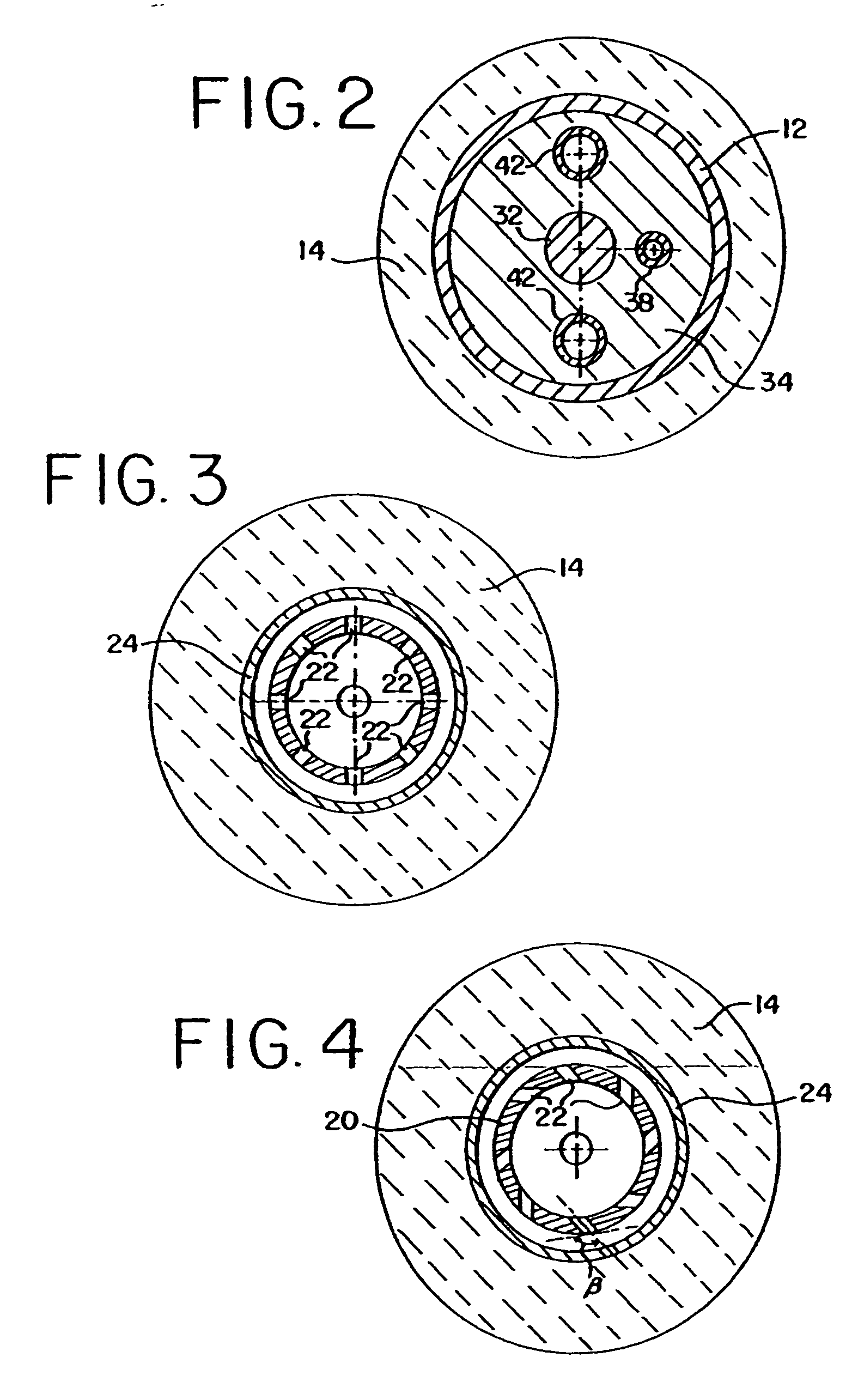

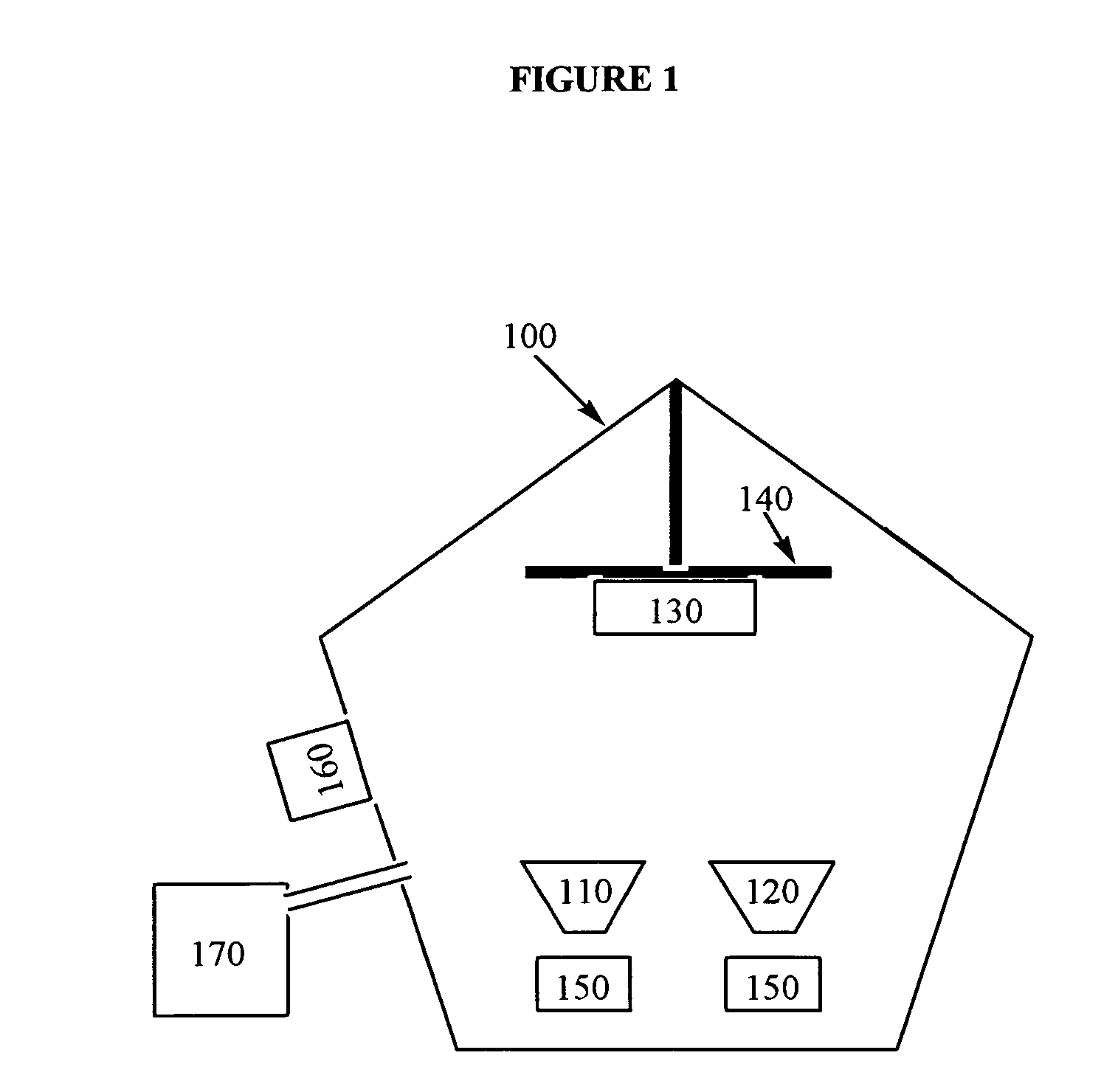

An electro thermal fluidized bed furnace is adapted to be used in a process for continuously heat treating of fine particulate matter, such as carbon black material, by continuously introducing a non-reactive fluidizing gas through the nozzles of the furnace at a pre-determined rate, continuously introducing untreated carbon black material through the feed pipe of the furnace at a predetermined rate so that it forms a fluidized bed, energizing the electrode so as to heat the fluidized bed, and continuously collecting the treated carbon black from the discharge pipe. The carbon black collected from the discharge pipe exhibits properties of having the PAHs and sulfur removed, the carbon black has been graphitized, the moisture pick-up by the carbon black has been eliminated and the carbon black is more oxidation resistant, Furthermore, the resultant furnace carbon backs have a particle size of 7-100 nm and an oil absorption number of 50-300 ml / 100 g., while the thermal blacks have a particle size of 200-500 nm and an oil absorption number of less than 50 ml / 100 g. All of these properties result in thermally modified carbon blacks having such properties and of such purity so as to provide improved performance properties in food contact type applications, moisture cured polymer systems, zinc-carbon dry cell battery applications, and semi-conductive wire and cable applications.

Owner:COLUMBIAN CHEM CO +1

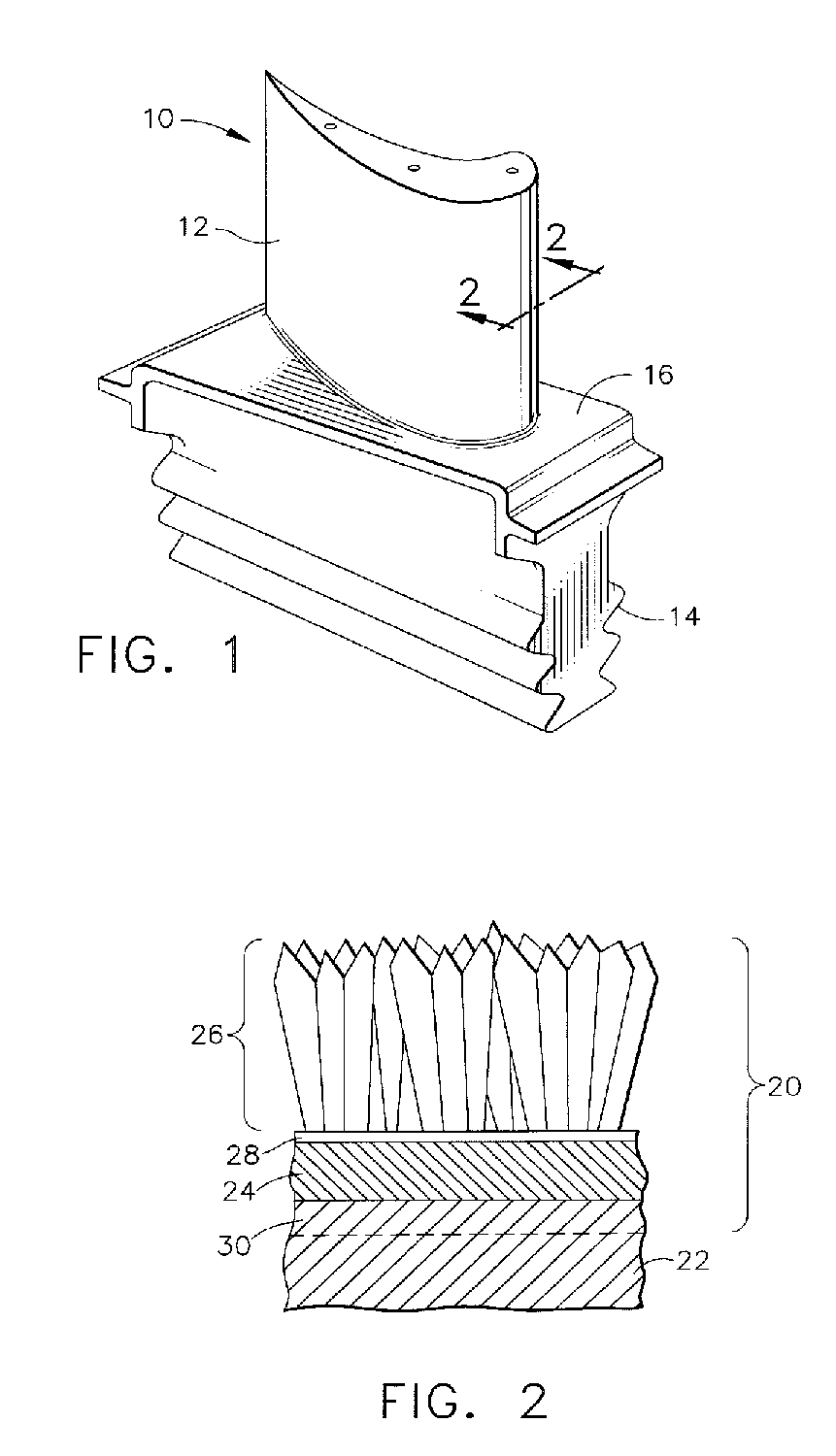

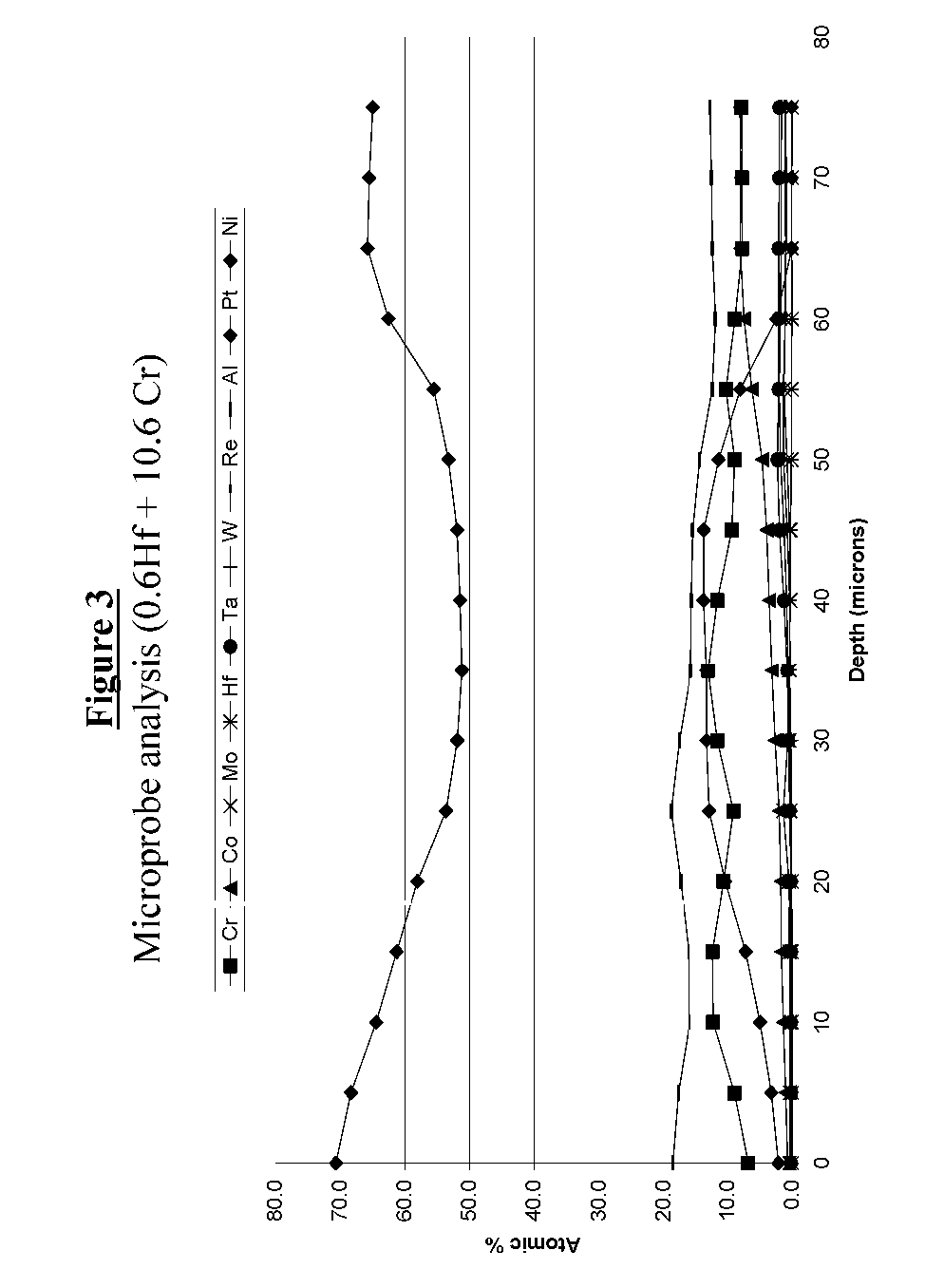

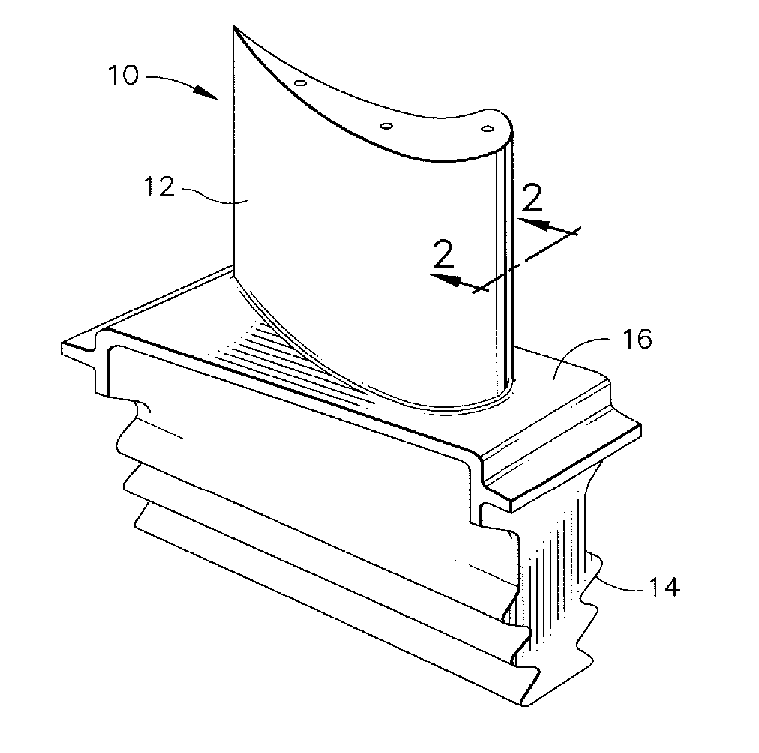

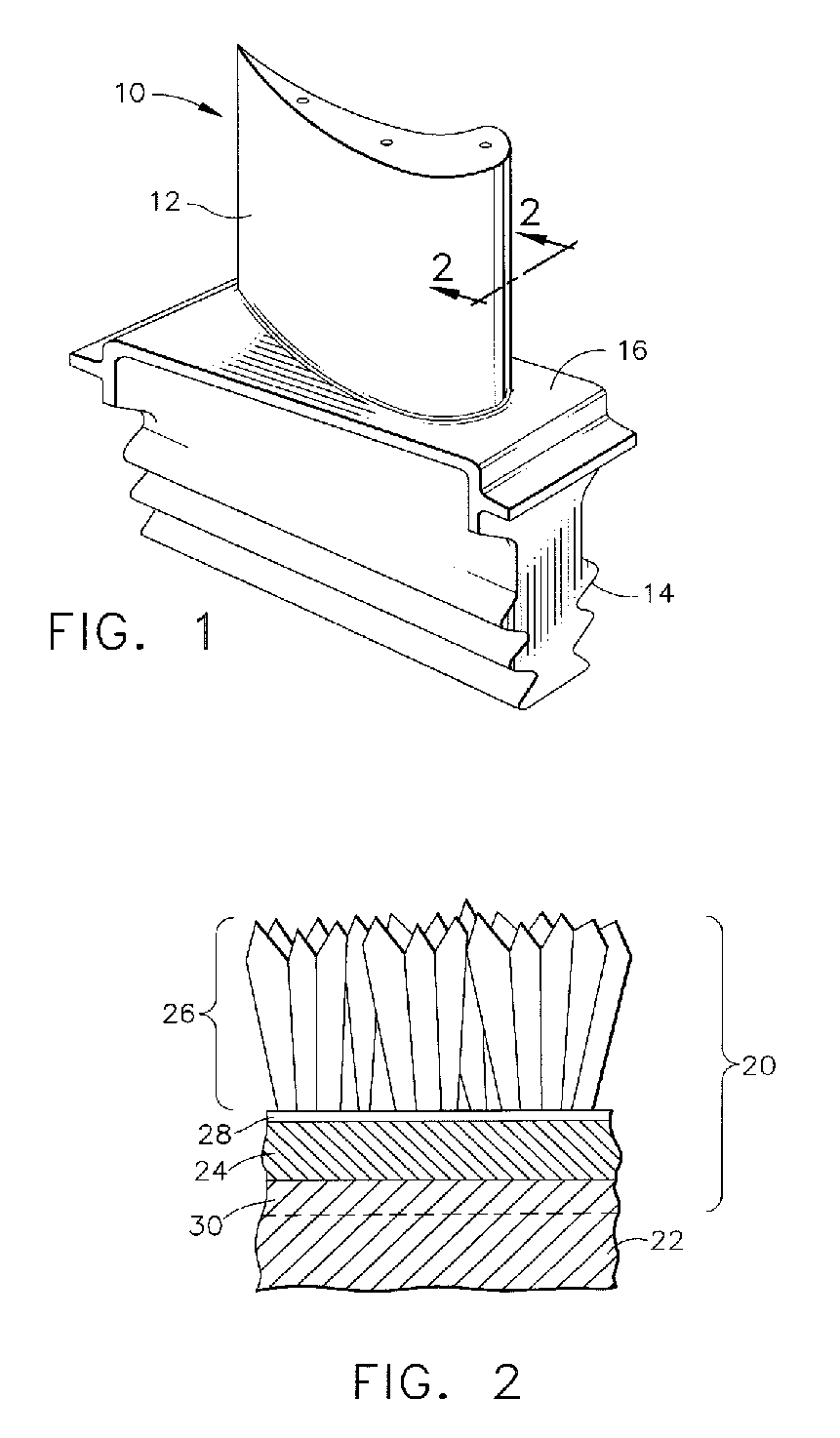

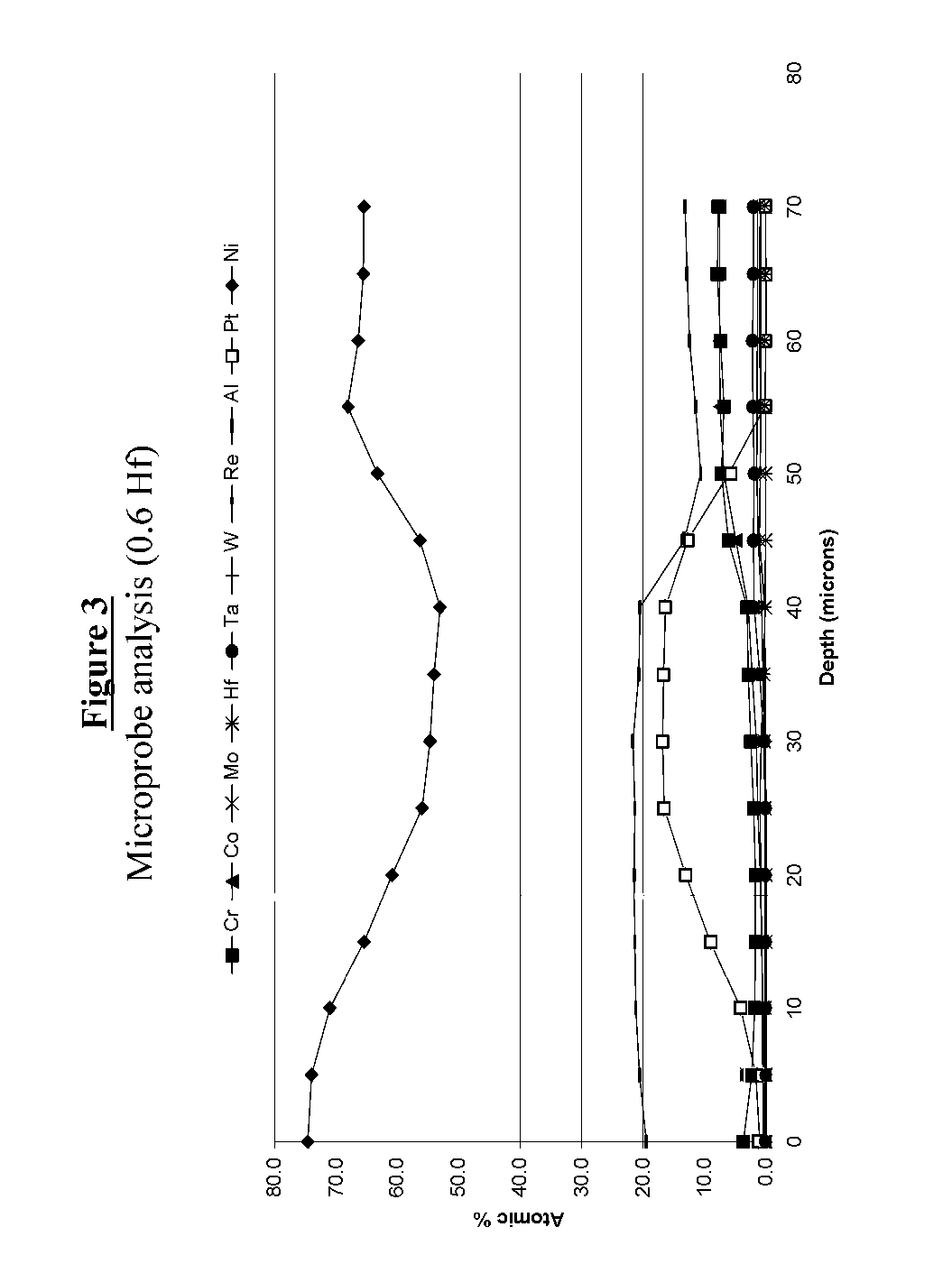

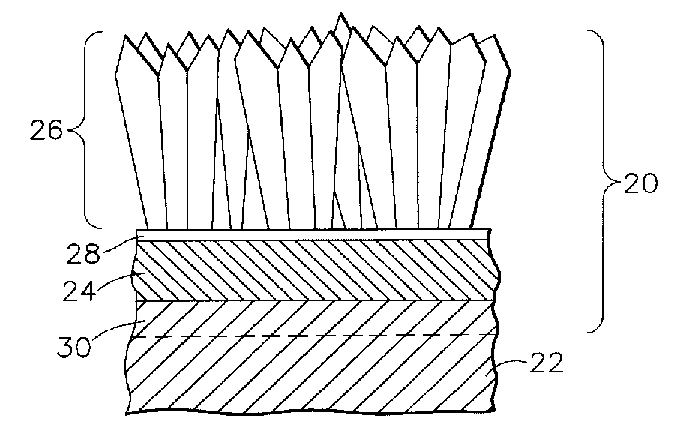

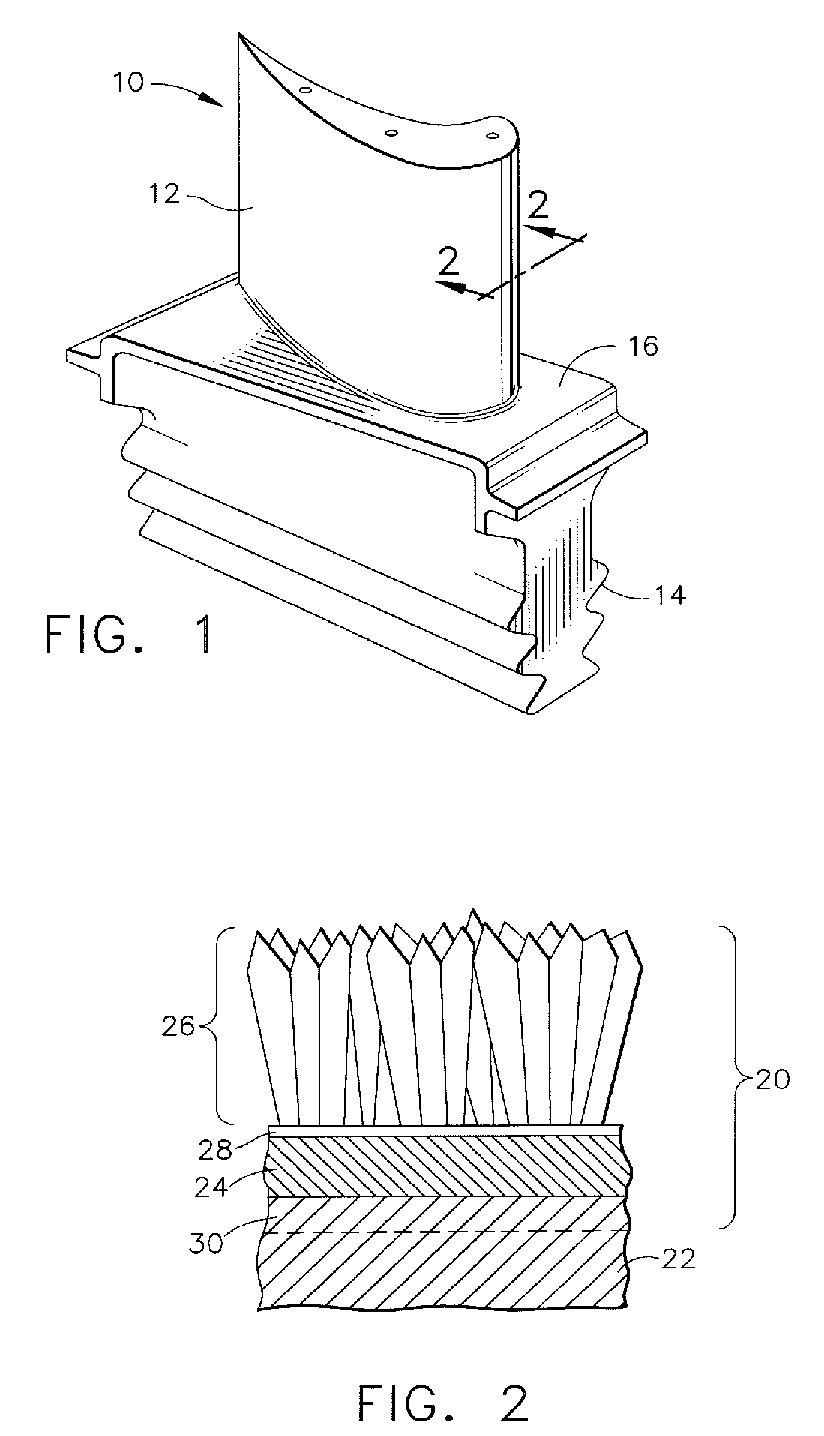

Gamma prime phase-containing nickel aluminide coating

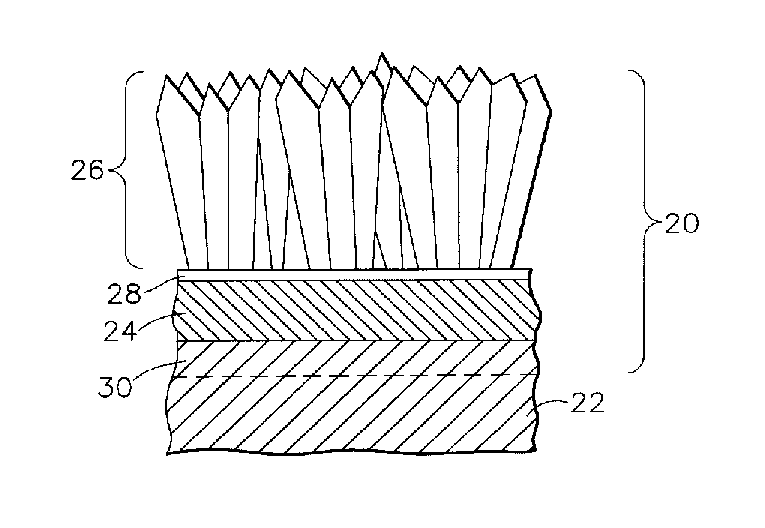

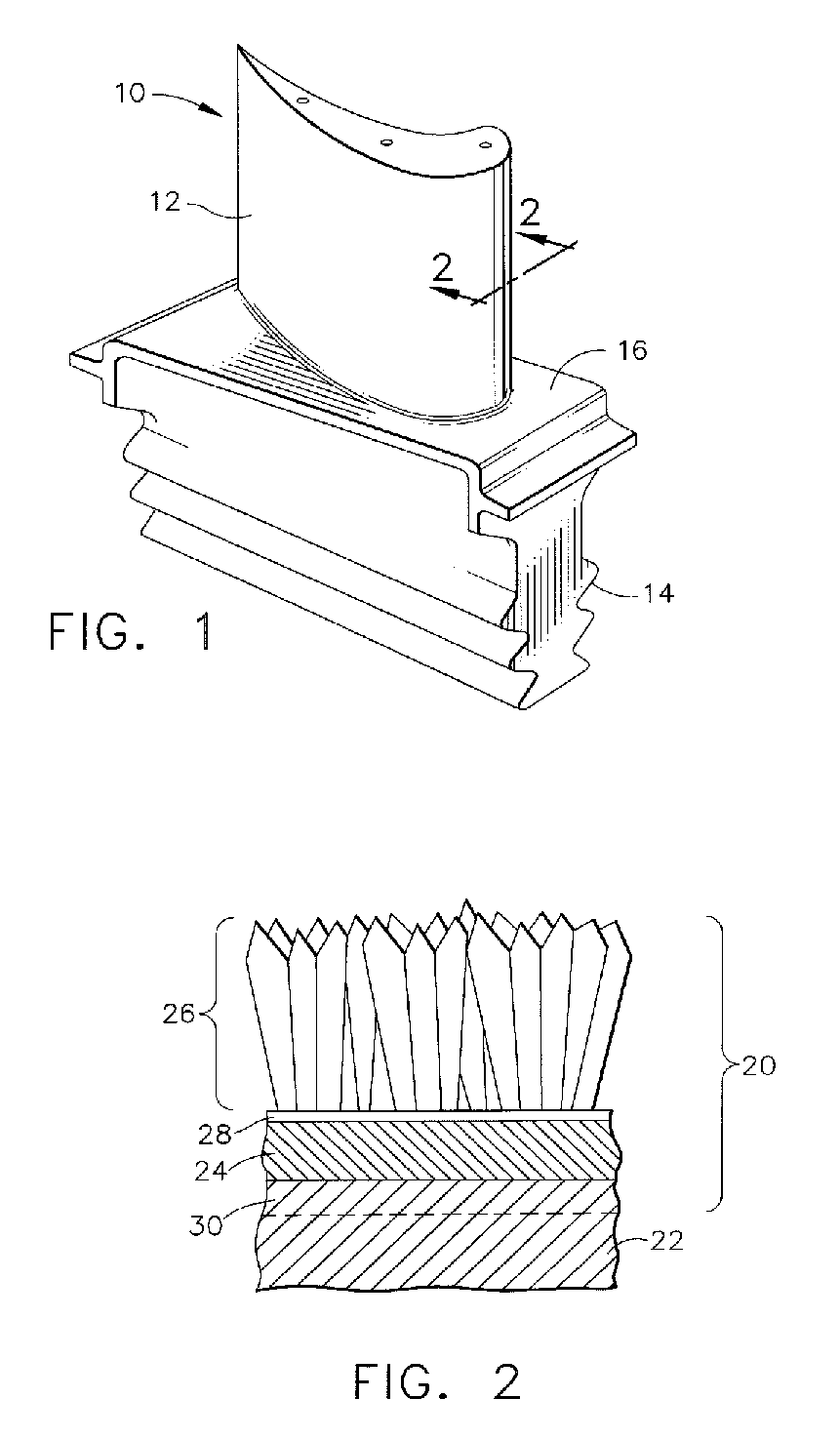

ActiveUS20070071996A1Desirable environmental and mechanical propertyOxidation resistance can be improvedPropellersReaction enginesCeriumHafnium

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, one or more of chromium, silicon, tantalum, and cobalt, optionally one or more of hafnium, yttrium, zirconium, lanthanum, and cerium, and incidental impurities.

Owner:GENERAL ELECTRIC CO

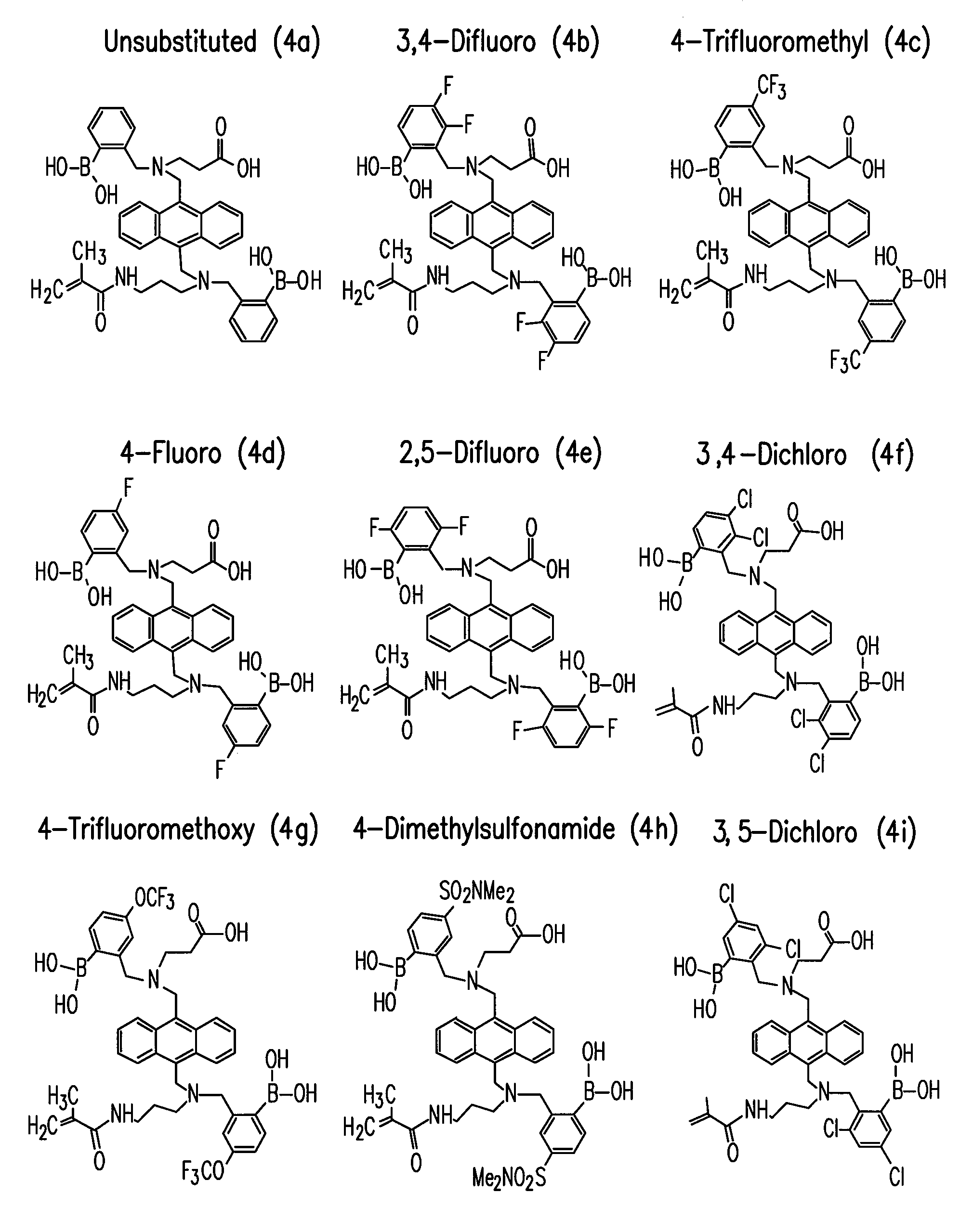

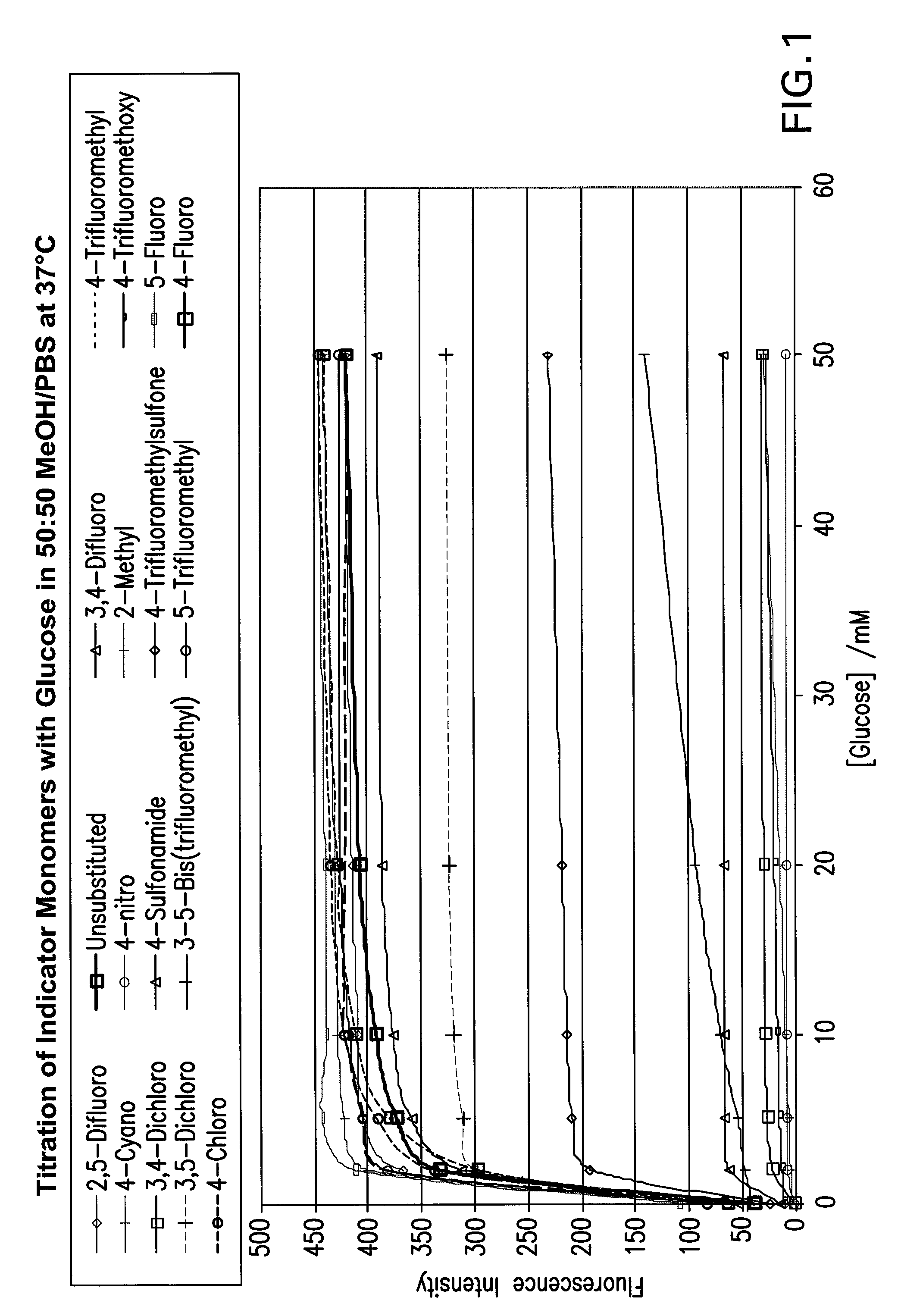

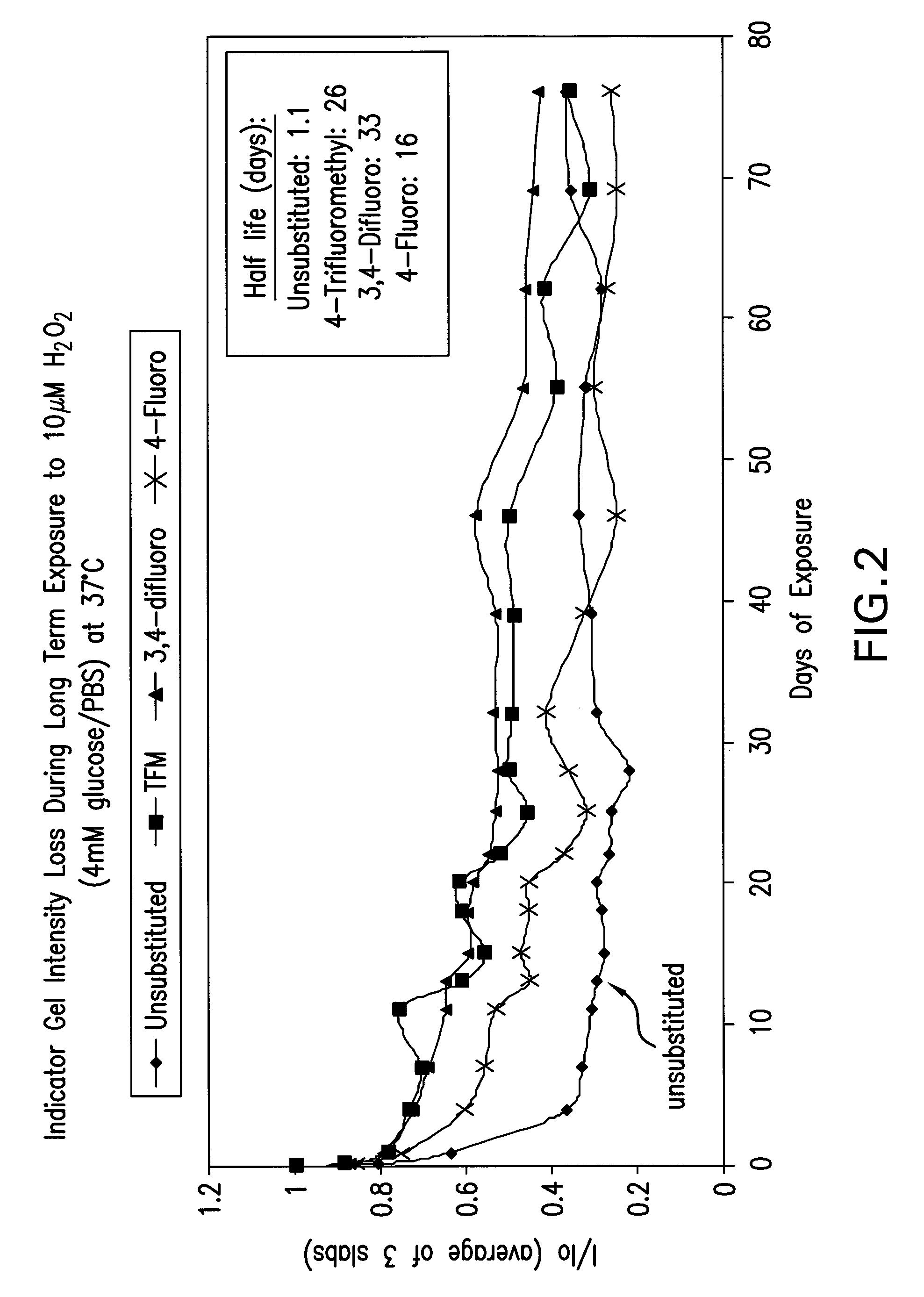

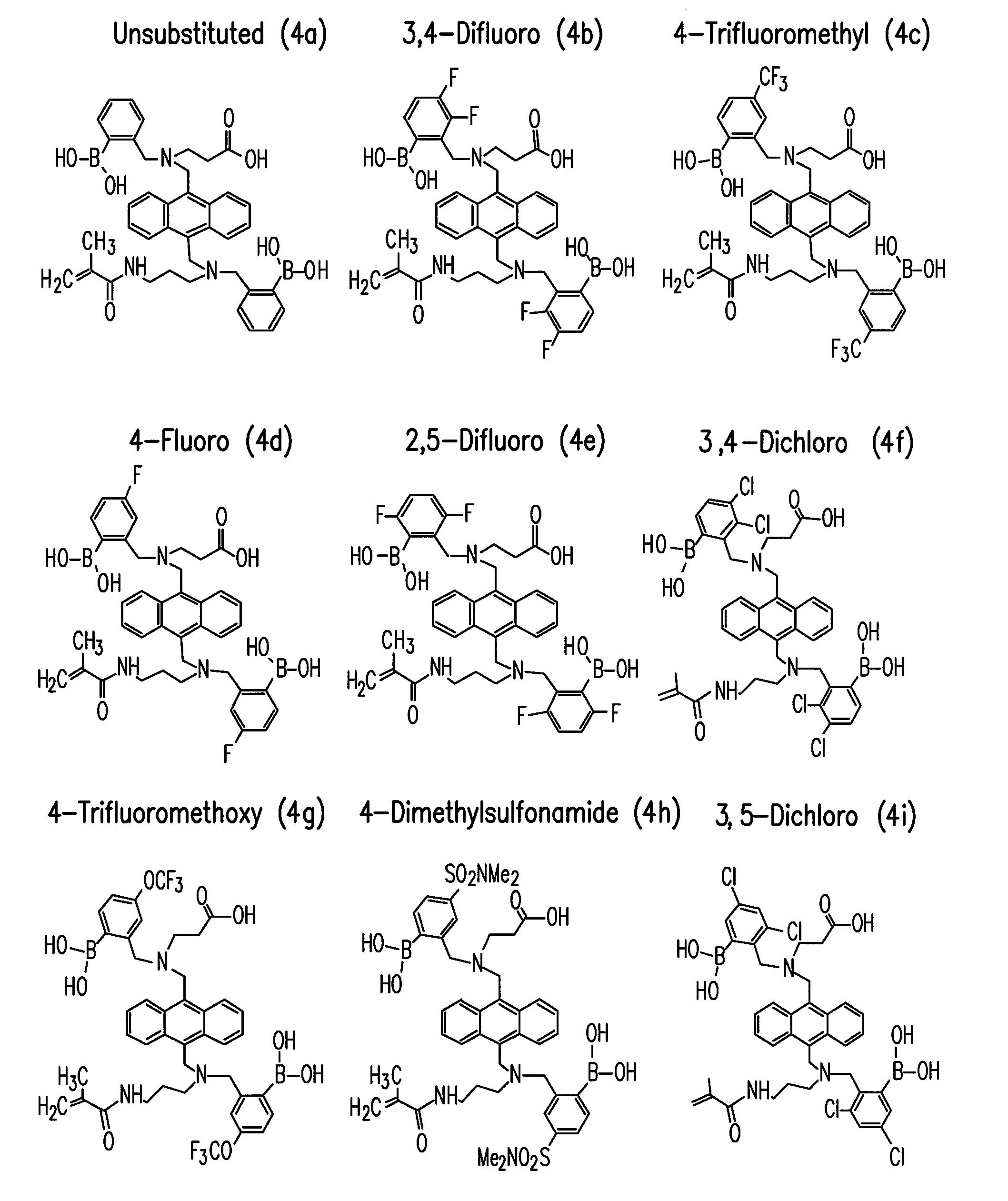

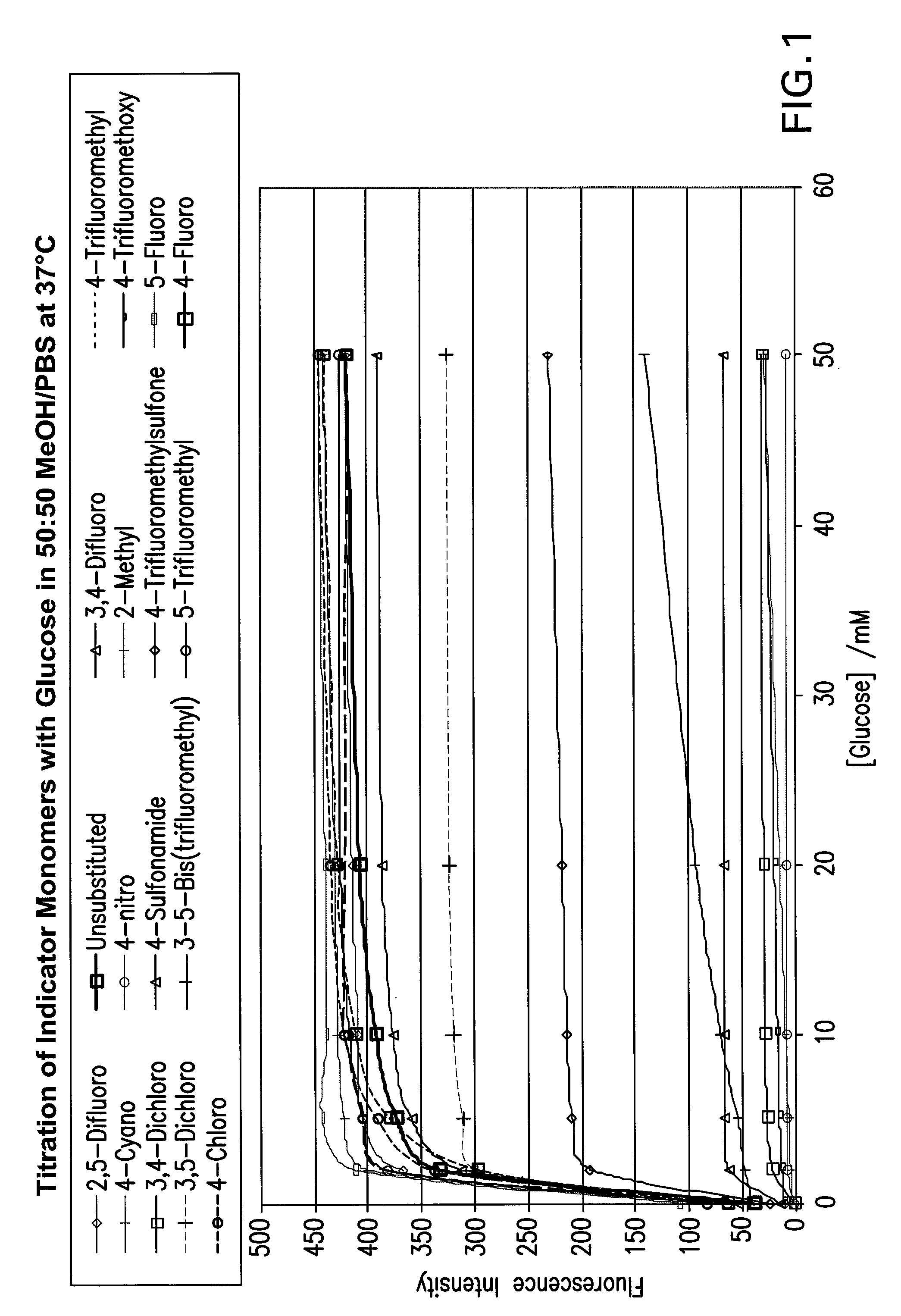

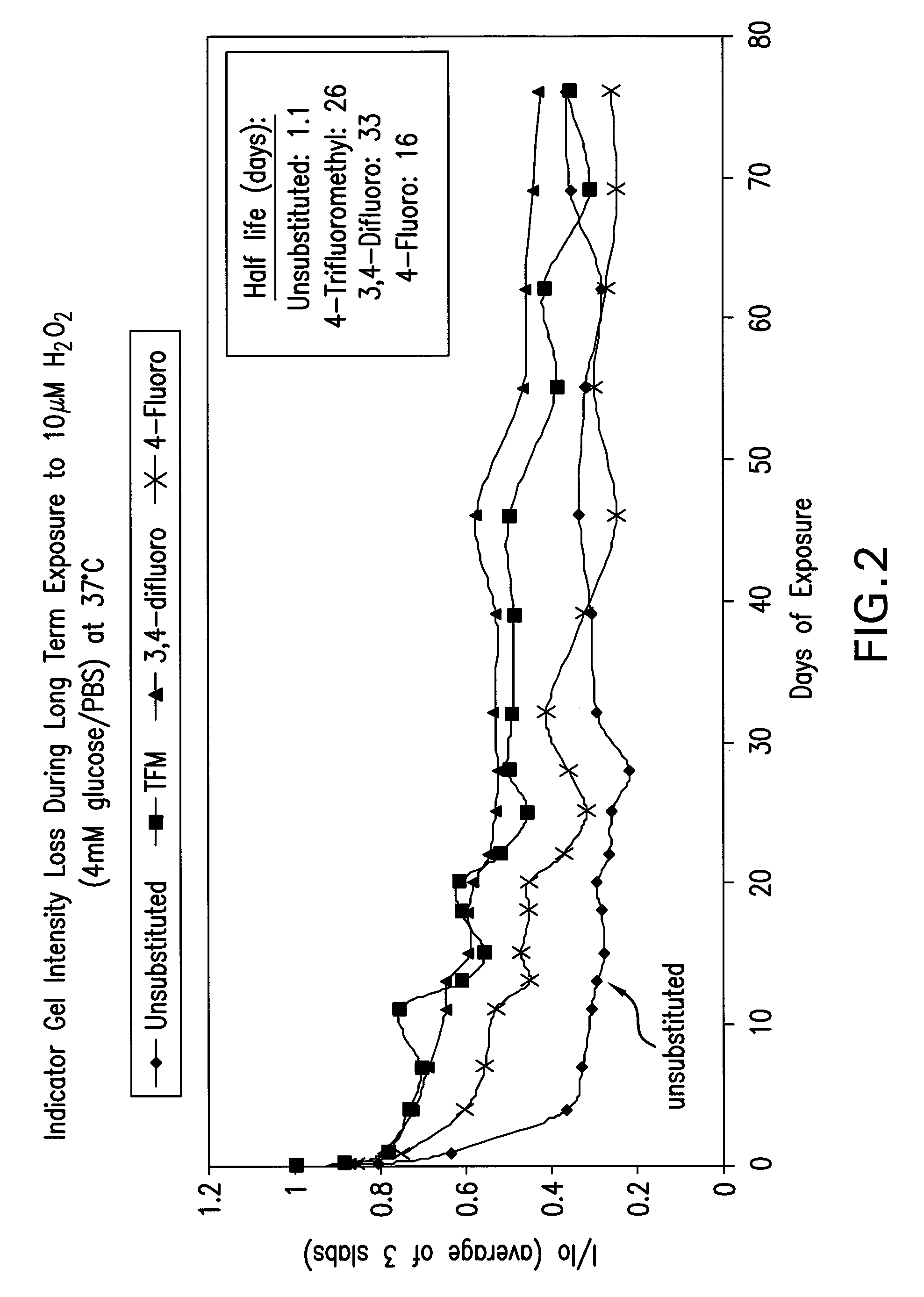

Oxidation resistant indicator molecules

ActiveUS7851225B2Oxidation resistance can be improvedMaterial analysis by observing effect on chemical indicatorGroup 3/13 element organic compoundsArylAromatic moiety

Compounds having enhanced oxidation stability are disclosed. The compounds have an aryl boronic acid residue having one or more electron withdrawing groups on the aromatic moiety which contains the boronic acid residue, such that the molecule has enhanced oxidation resistance as compared to a corresponding molecule without the one or more electron withdrawing groups.

Owner:SENSEONICS INC

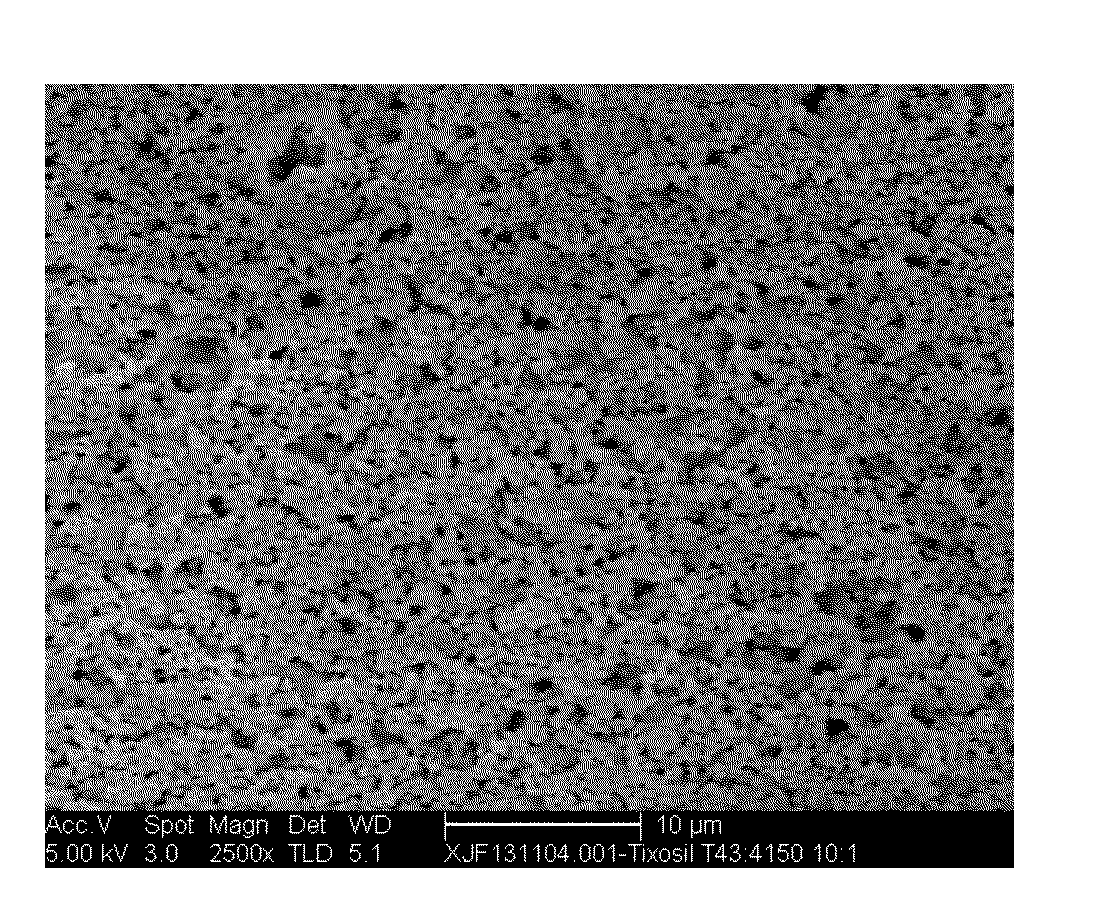

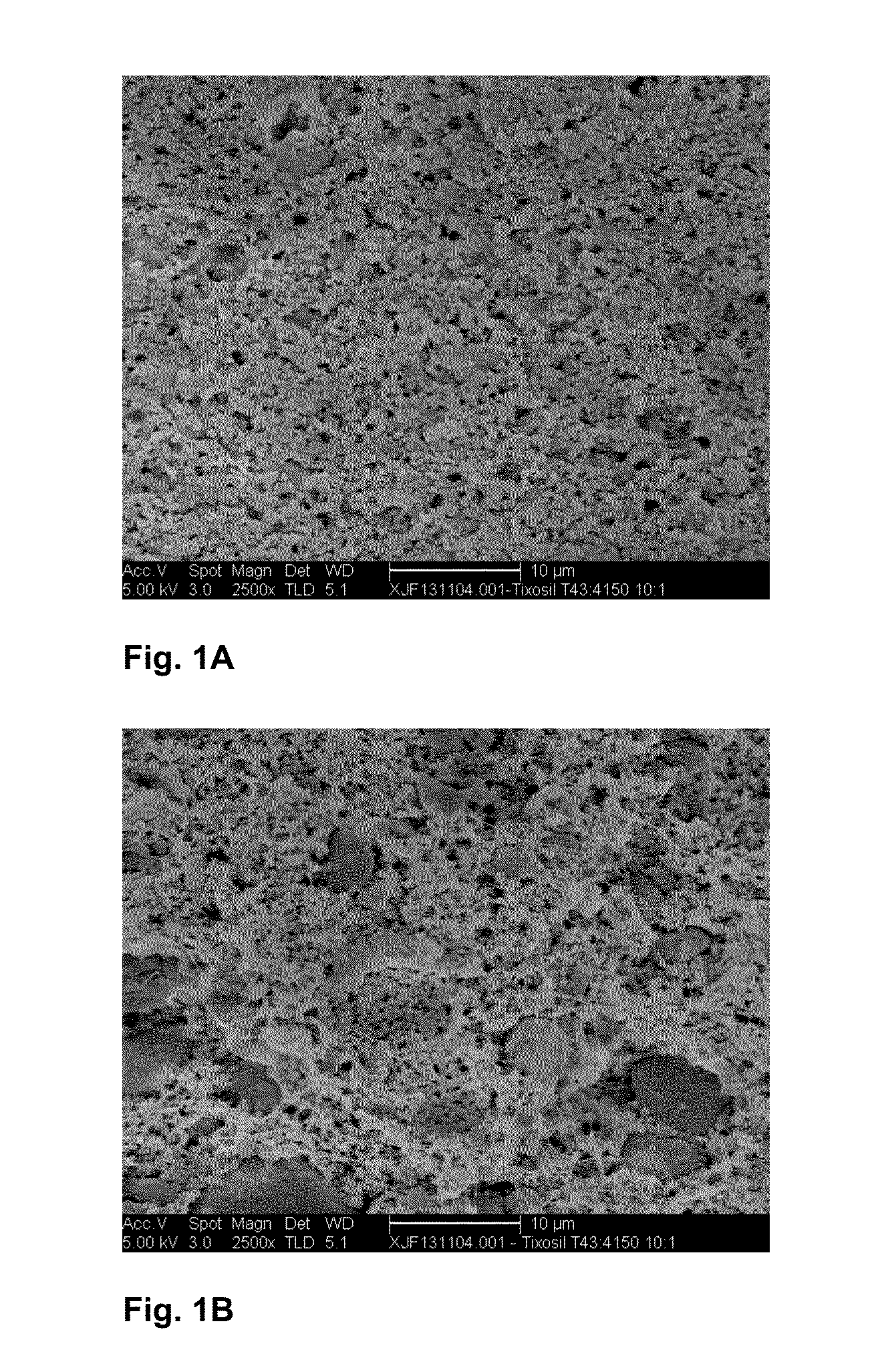

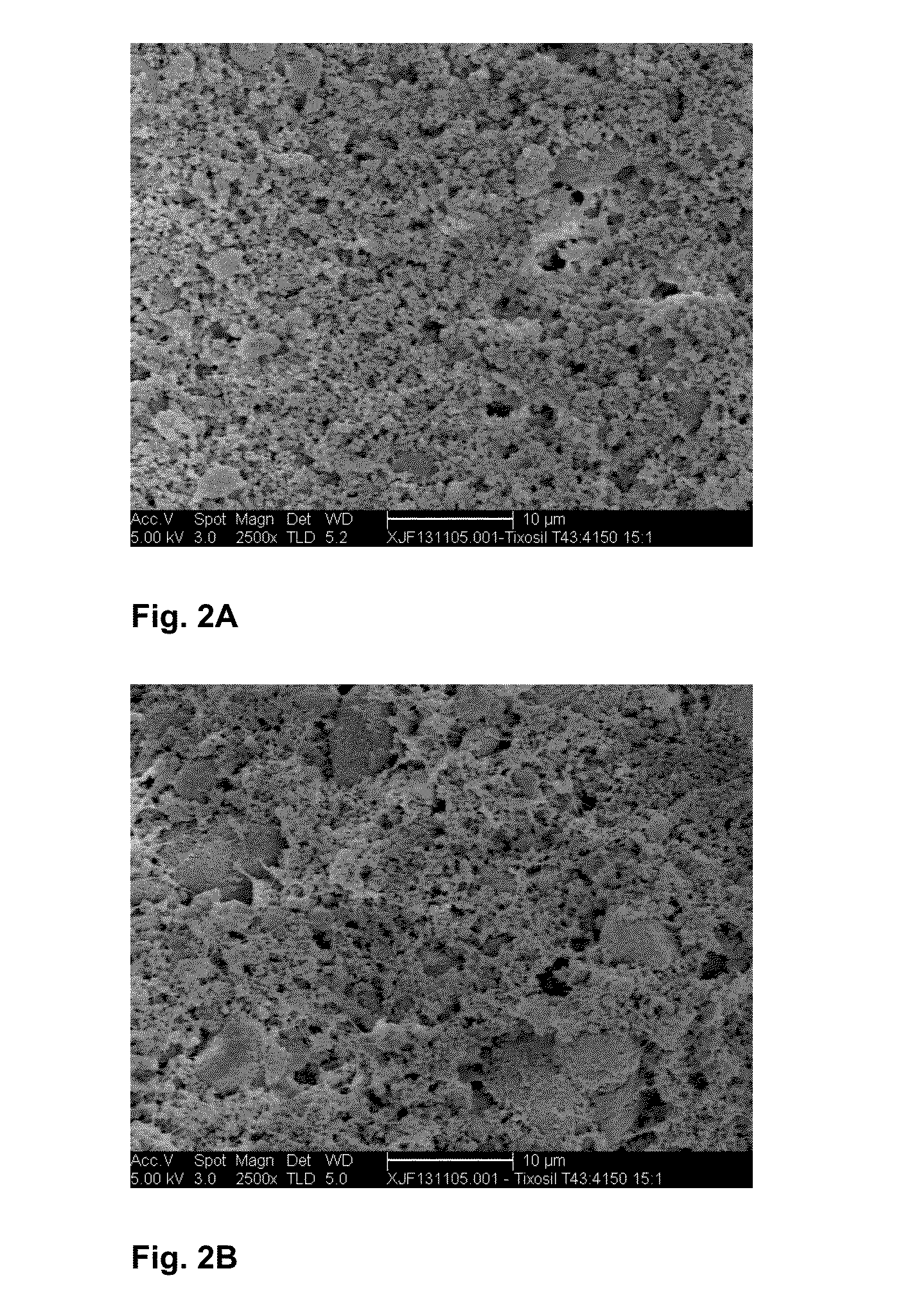

High porosity silica-containing microporous sheets

ActiveUS20150207121A1High porosityImprove mechanical propertiesLead-acid accumulatorsCell component detailsPorosityPolymer science

A flexible microporous polymer sheet having first and second opposite major surfaces comprises a polymer matrix binding a filler component that exhibits high oil absorption capacity in its initial state before the start of material processing. The polymer matrix includes a polyolefin component and has three-dimensional interconnecting and interpenetrating pore and polymer networks through which the bound filler component is distributed from the first major surface to the second major surface. The polyolefin and filler components are included in amounts that result in a microporous polymer sheet having between about 75% and about 90% porosity and containing less than about 10 wt. % polyolefin component. Preferred polyolefin and filler components include ultrahigh molecular weight polyethylene and high oil absorption precipitated silica, respectively.

Owner:AMTEK RES INT

Gamma prime phase-containing nickel aluminide coating

ActiveUS20070071995A1Improve oxidation resistanceImprove corrosion resistancePropellersRotary propellersGreek letter betaCombustor

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, incidental impurities, and optionally hafnium.

Owner:GENERAL ELECTRIC CO

Gamma prime phase-containing nickel aluminide coating

ActiveUS7247393B2Desirable environmental and mechanical propertyOxidation resistance can be improvedPropellersReaction enginesCeriumHafnium

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, one or more of chromium, silicon, tantalum, and cobalt, optionally one or more of hafnium, yttrium, zirconium, lanthanum, and cerium, and incidental impurities.

Owner:GENERAL ELECTRIC CO

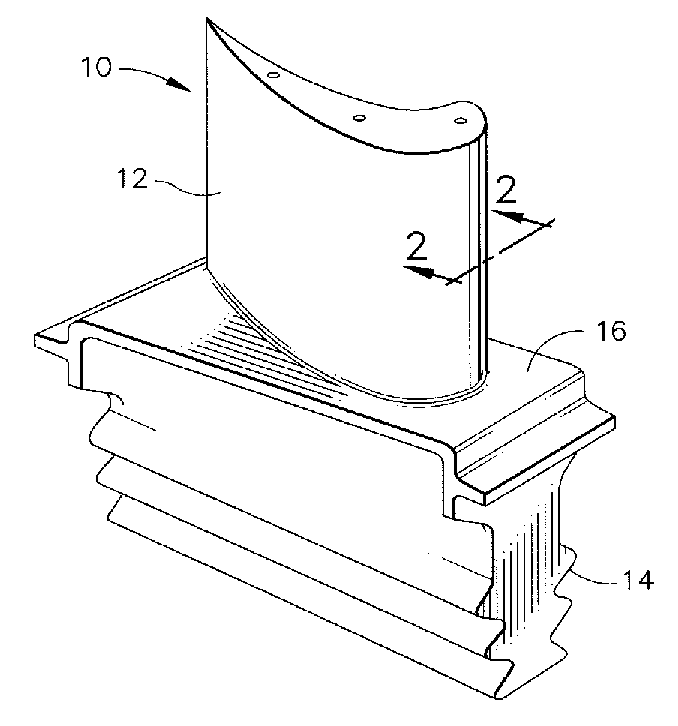

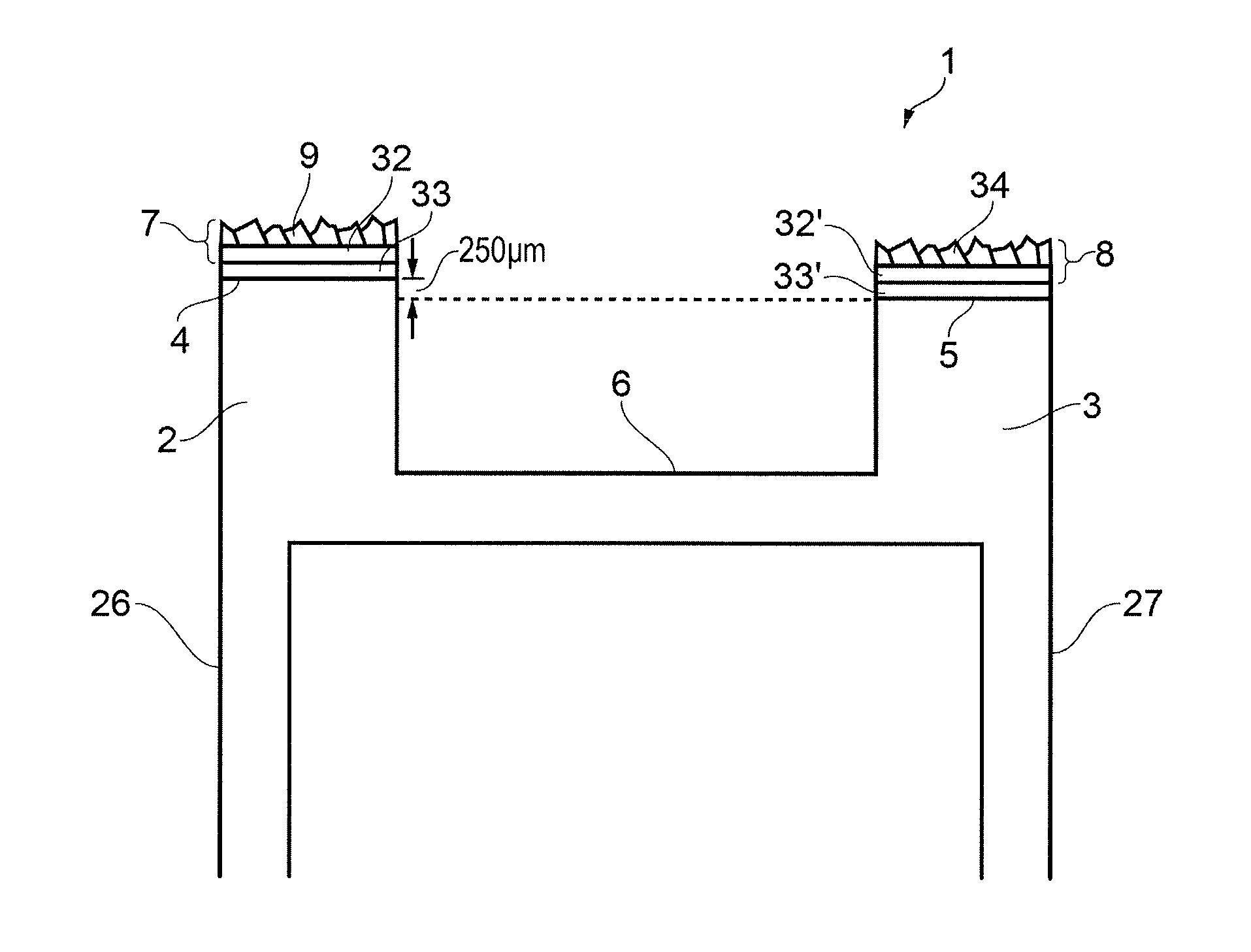

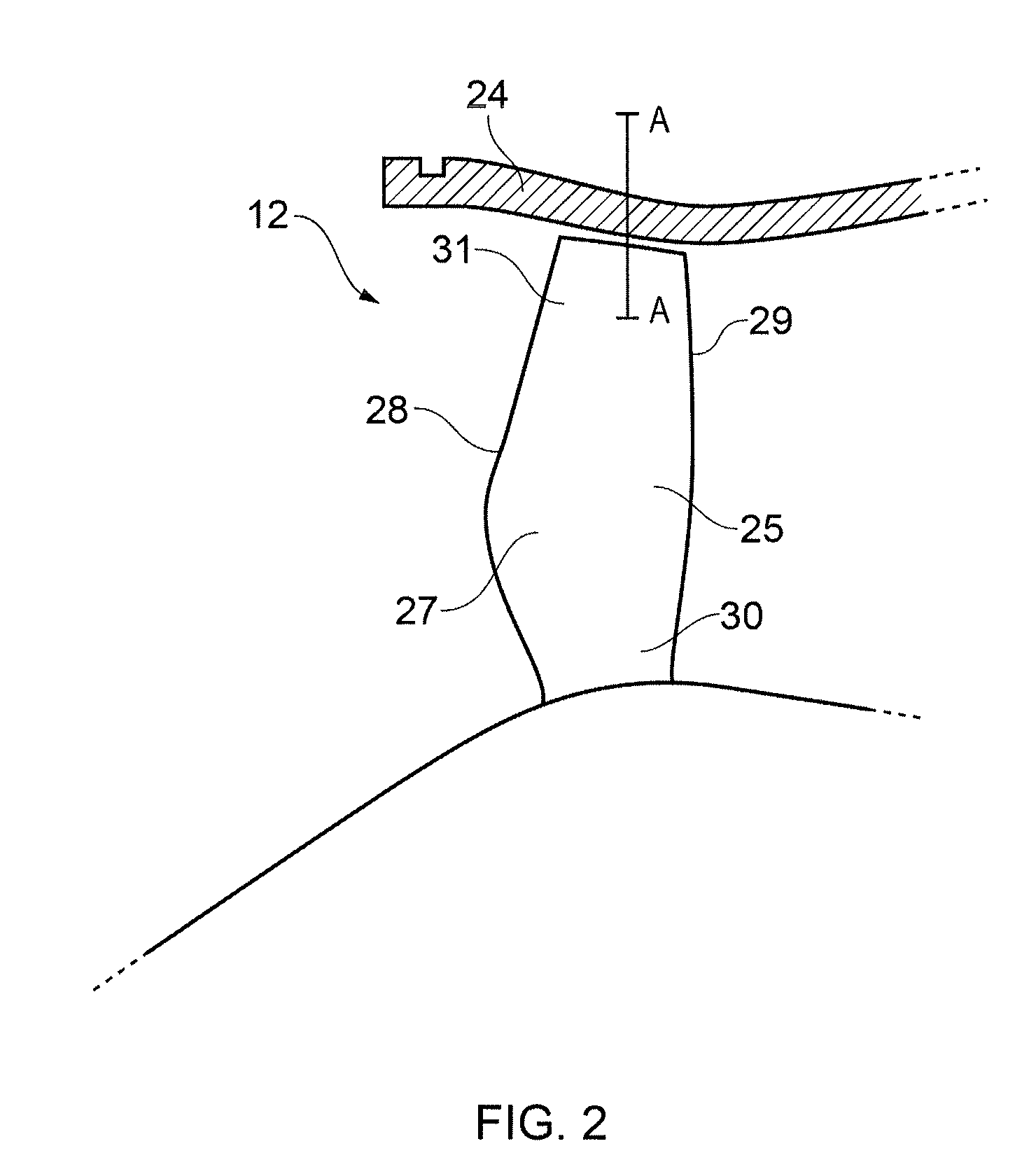

Rotary blade tip

InactiveUS20160069195A1Improve oxidation resistanceOxidation resistance can be improvedPropellersRotary propellersBoron nitrideNickel alloy

The present invention provides a blade tip for a rotary blade, the blade tip comprising a first portion and a radially-recessed second portion. A radially outermost surface of the first portion comprises a first abrasive coating e.g. a composite material comprising cubic boron nitride embedded in a matrix of nickel alloy. A radially outermost surface of the second portion comprises a second abrasive coating which has a greater resistance to oxidation than the first abrasive coating. The increased oxidation resistance of the second abrasive coating is achieved by providing a radially outer protective layer and / or using a material having a greater inherent oxidation resistance.

Owner:ROLLS ROYCE PLC

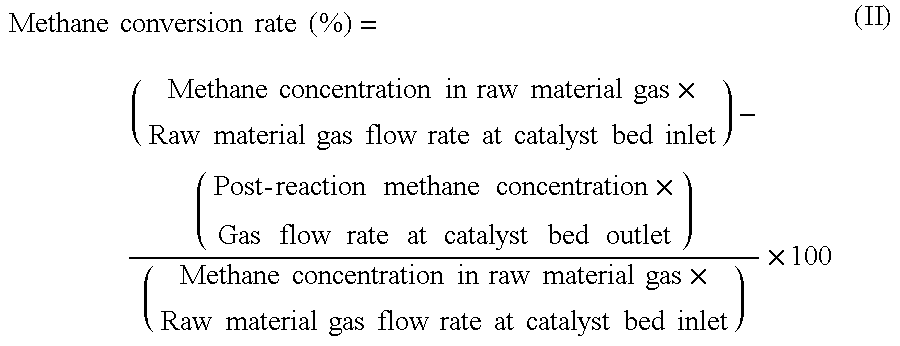

Composite oxide for hydrocarbon reforming catalyst, process for producing the same, and process for producing syngas using the same

InactiveUS20110121238A1High catalytic activityPrevent oxidationHydrogenProductsSyngasActive component

A composite oxide for a hydrocarbon reforming catalyst which maintains the catalytic activity at a high level over a long period of time, a process for producing the catalyst, and a process for producing syngas using the catalyst, are provided. The composite oxide for a hydrocarbon reforming catalyst is obtained by a process including preparing a mixed solution for impregnation which contains catalytic active components of Co, or Co and Ni, one or more oxidation resistance enhancing components selected from the elements of Group 3B and the elements of Group 6A of the Periodic Table, and one or more additive metal components selected from Ca and Mg; impregnating a carrier formed from a porous molded body selected from magnesia and a composite of magnesia and calcia, with the mixed solution for impregnation; drying the impregnated carrier; and calcining the dried carrier in an oxidizing atmosphere.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD

Gamma prime phase-containing nickel aluminide coating

ActiveUS7250225B2Desirable environmental and mechanical propertyOxidation resistance can be improvedPropellersRotary propellersCombustorHafnium

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, incidental impurities, and optionally hafnium.

Owner:GENERAL ELECTRIC CO

Polymer electrolyte membrane having improved oxidation resistance

InactiveUS20060105216A1Improve oxidation resistanceExcellent adhesion to electrodesSolid electrolytesIon-exchanger regenerationPolymer electrolytesPolymer science

The improved electrolyte membrane which is produced by grafting a styrenic monomer and bis(vinylphenyl)ethane as monomers to a polymer substrate and then introducing sulfonic acid groups into the graft side chains formed has improved oxidation resistance and good adhesion to electrodes. The polymer substrate is preferably made of a fluorocarbon polymer or an olefinic polymer. The styrenic monomer is preferably one or more species selected from the group consisting of styrene, α-methylstyrene, vinyltoluene, and trifluorostyrene.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP +1

Lead-free solder of sn-0.7wt%cu

InactiveUS20090065097A1Improve diffusivityImprove oxidation resistancePrinted circuit manufactureWelding/cutting media/materialsMetallic LeadSmooth surface

An improved lead-free solder of Sn-0.7 wt % Cu which contains 0.001-1.5 wt % Ti and an alkaline element of Li, Na, K, Rb, Cs, etc. The alkaline element accounts for 0.0001-0.8 wt %. Compared with the traditional lead-free solder of Sn-0.7 wt % Cu, the lead-free solder of the present invention is characterized by the resulting welding spots with glossier and smoother surface, alloy solder with improved diffusivity, and solder surface with enhanced oxidation resistance.

Owner:CHEN MINGHAN

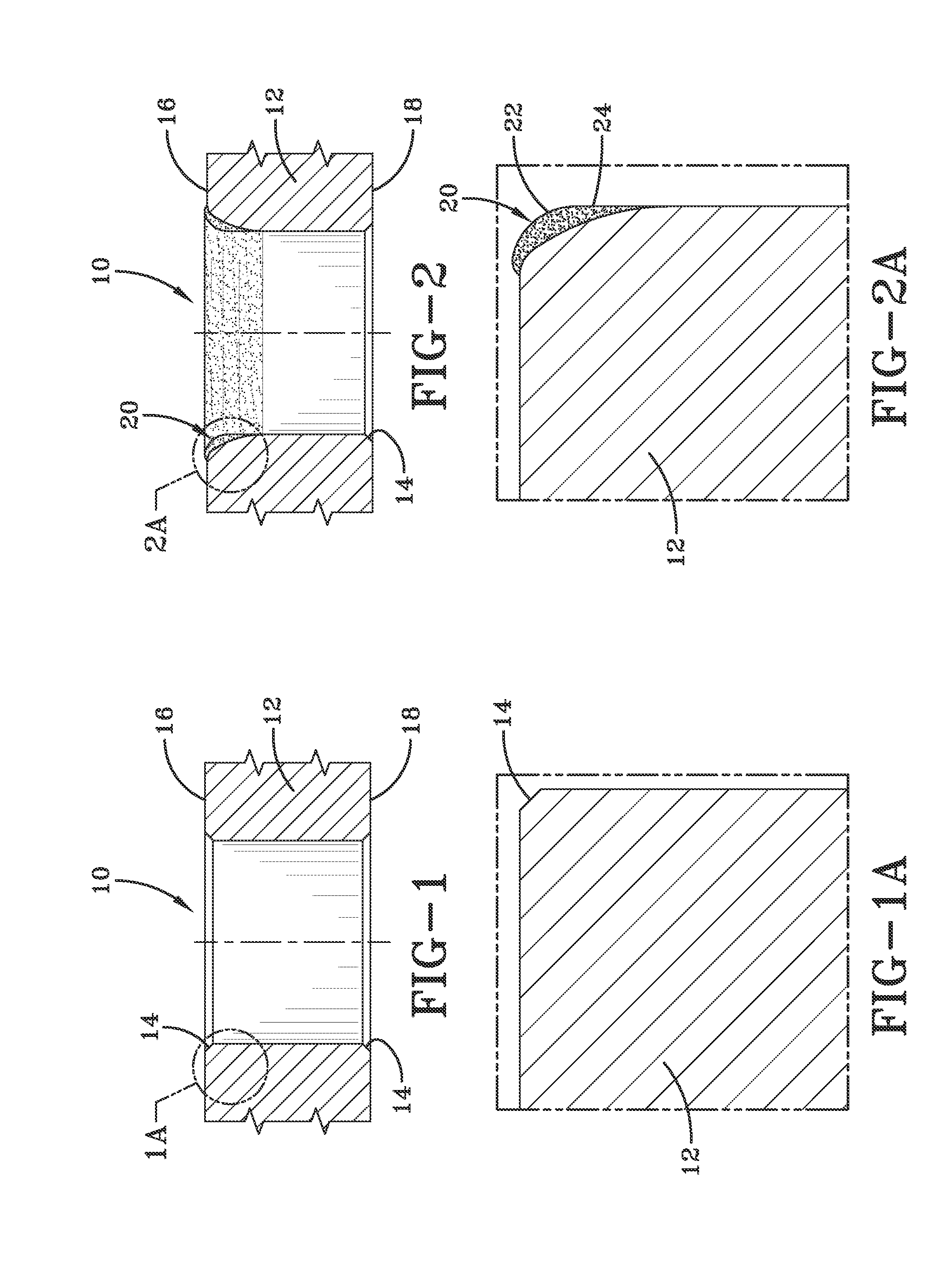

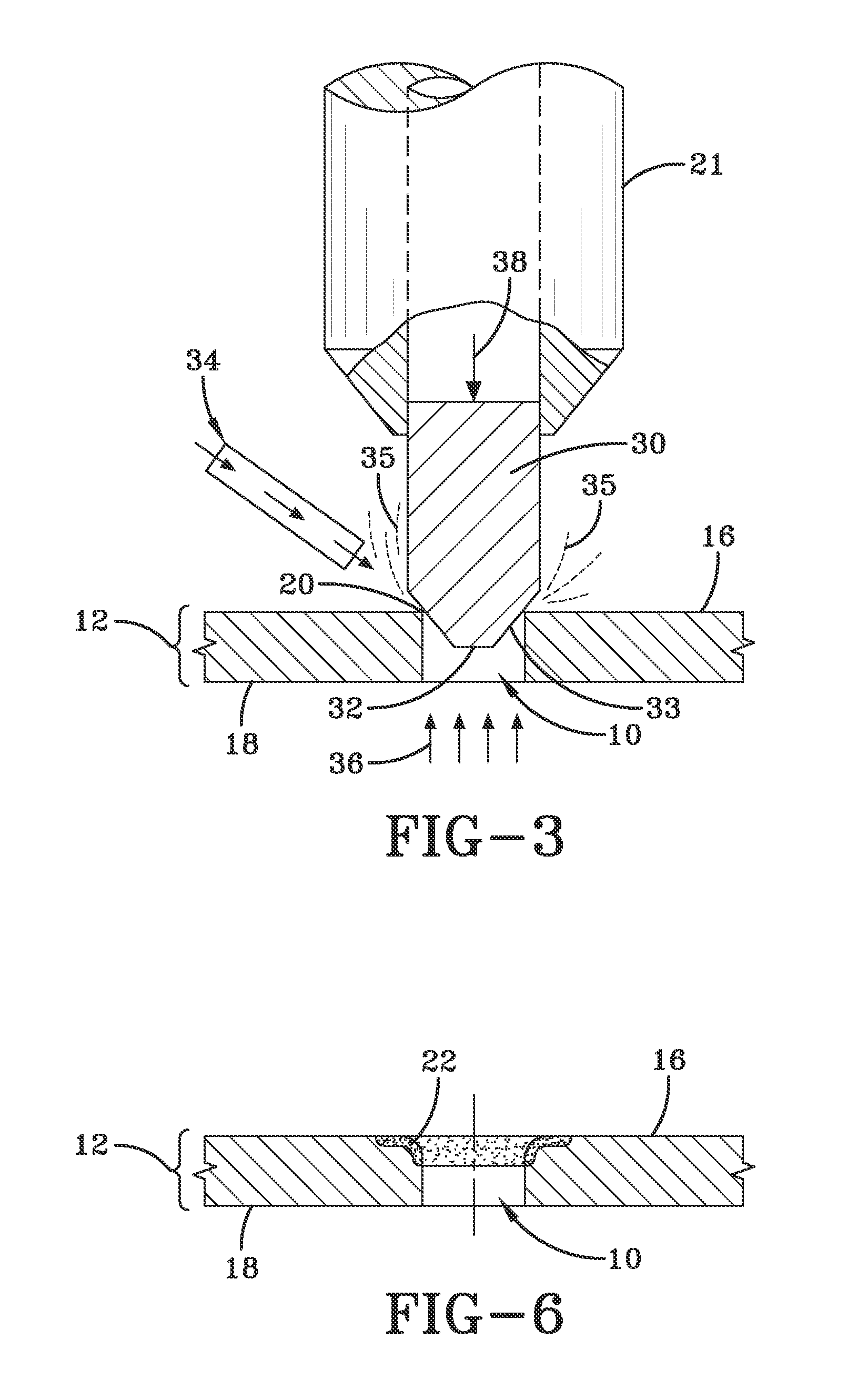

Electrospark deposition process for oxidation resistant coating of cooling hole

InactiveUS20140050938A1Enhance oxidation resistanceImprove resistanceLiquid surface applicatorsMolten spray coatingOxidation resistantElectrically conductive

A method of providing an oxidation resistant coating is disclosed. The method includes providing a substrate having a first surface and cooling holes. A portable coating device includes electro-spark deposition (ESD) equipment and an ESD torch connected with the ESD equipment. The ESD torch has an inert gas source and a rotary electrode conductive material. The rotary electrode is positioned within the ESD torch, and is shielded by an inert gas. The rotary electrode applies a compositionally controlled protective coating to the first surface of the substrate. Then the rotary electrode is inserted into the cooling hole and generates an electrospark between rotary ESD electrode and the substrate to form a rounded edge and deposit a coating of electrode material alloy at a cooling hole edge.

Owner:GENERAL ELECTRIC CO

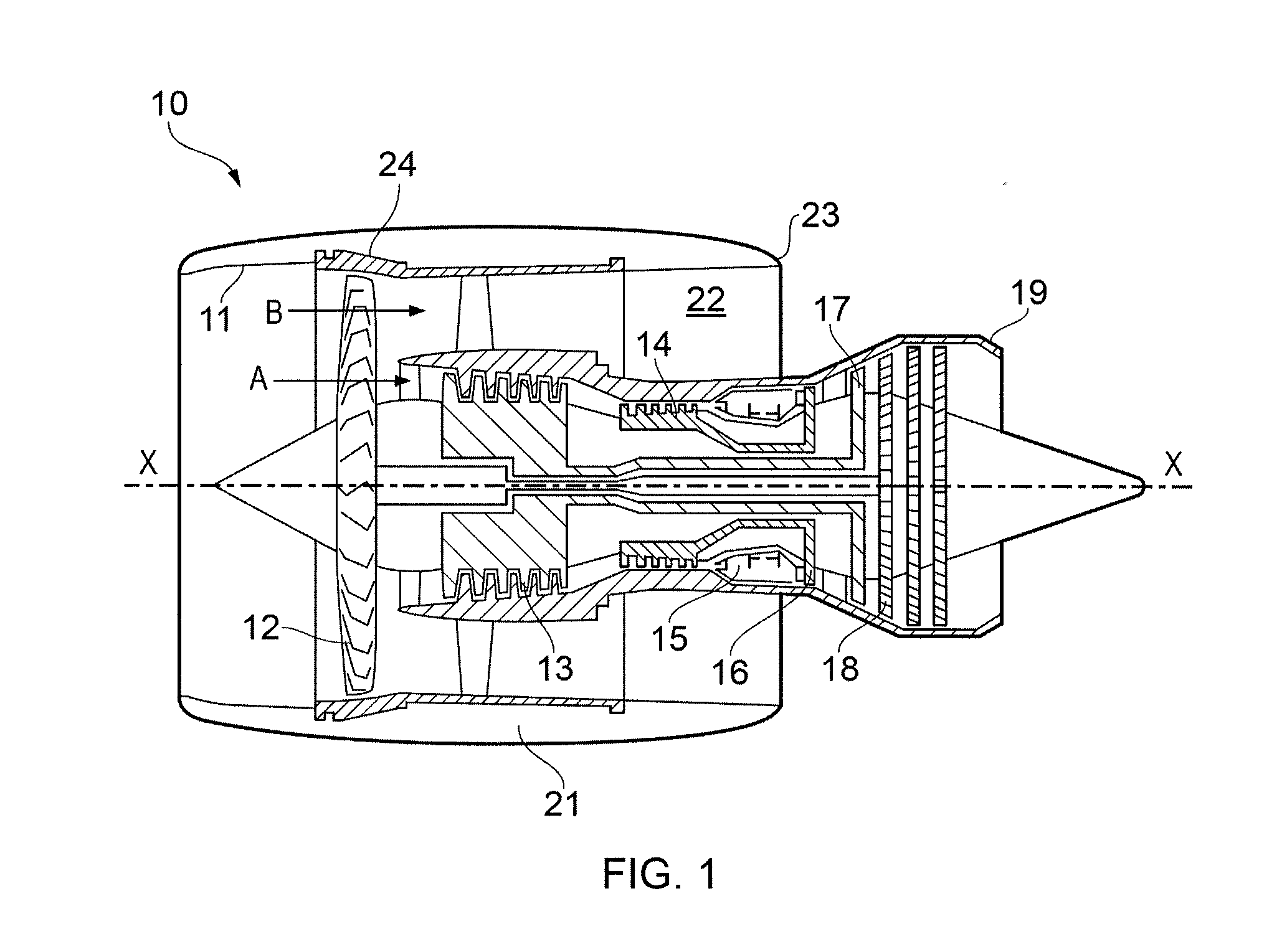

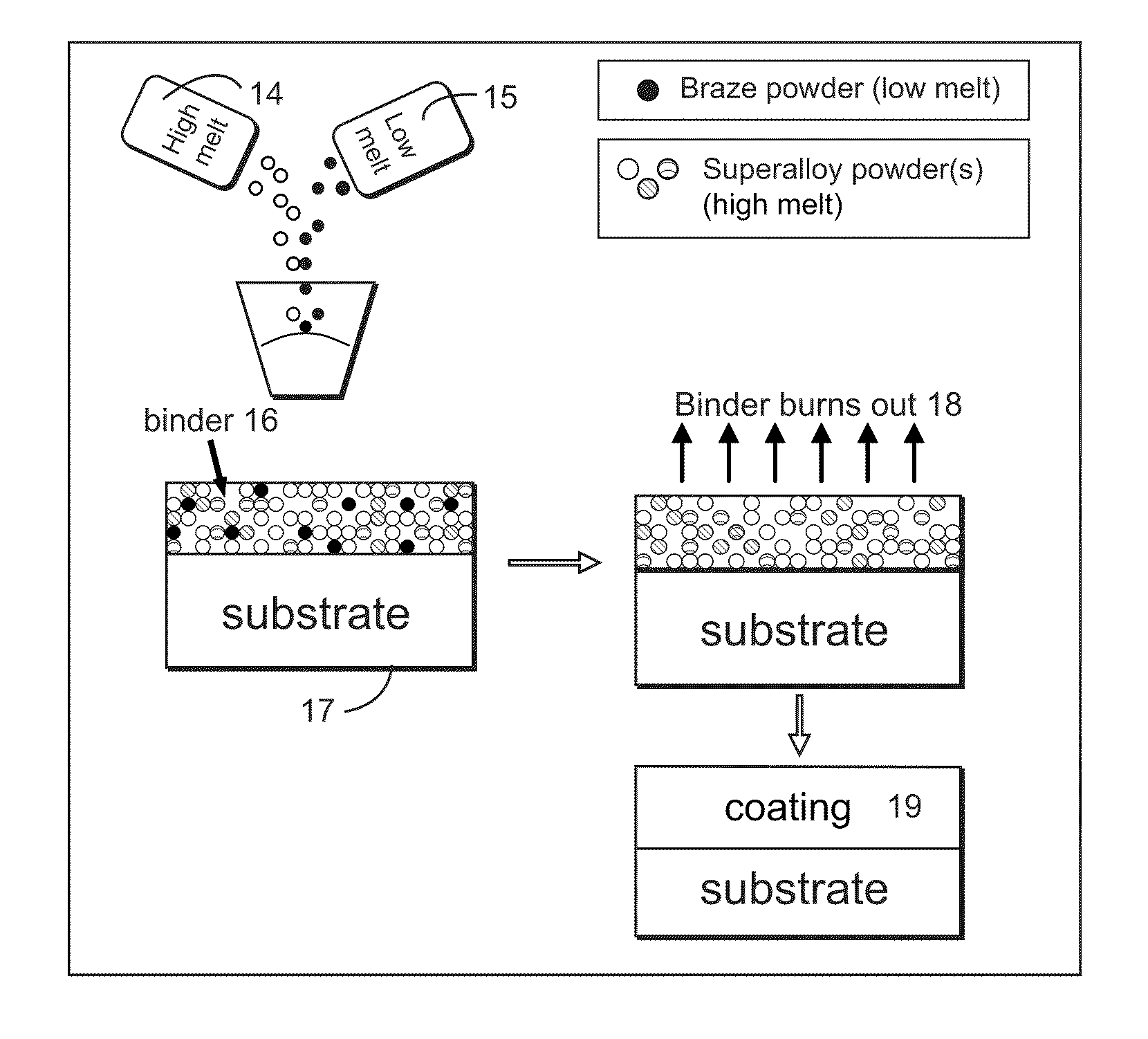

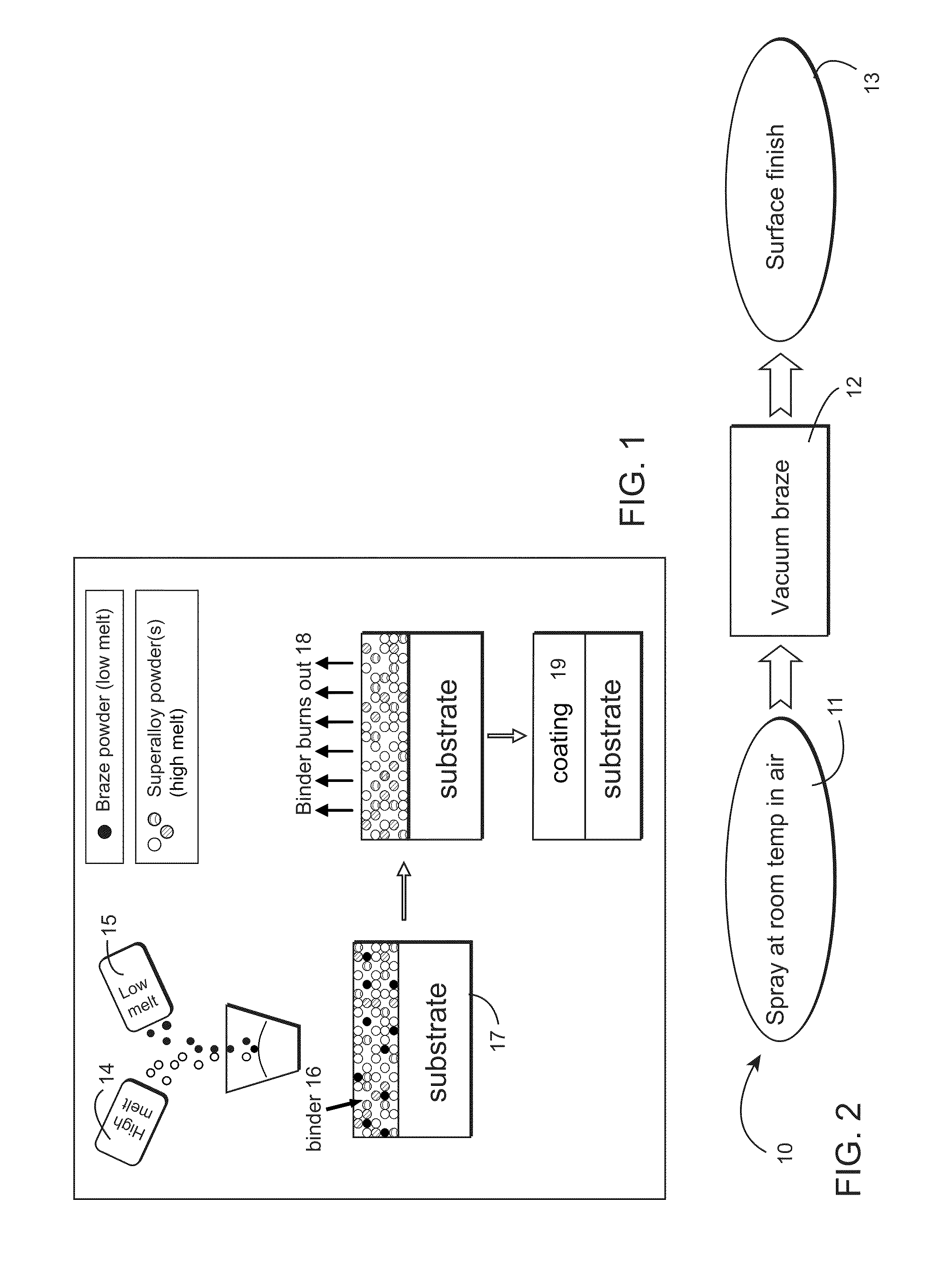

Method of deposition of metallic coatings using atomized spray

ActiveUS20110081480A1Oxidation resistance can be improvedImpart resistanceTurbinesSoldering apparatusOxidation resistantPowder mixture

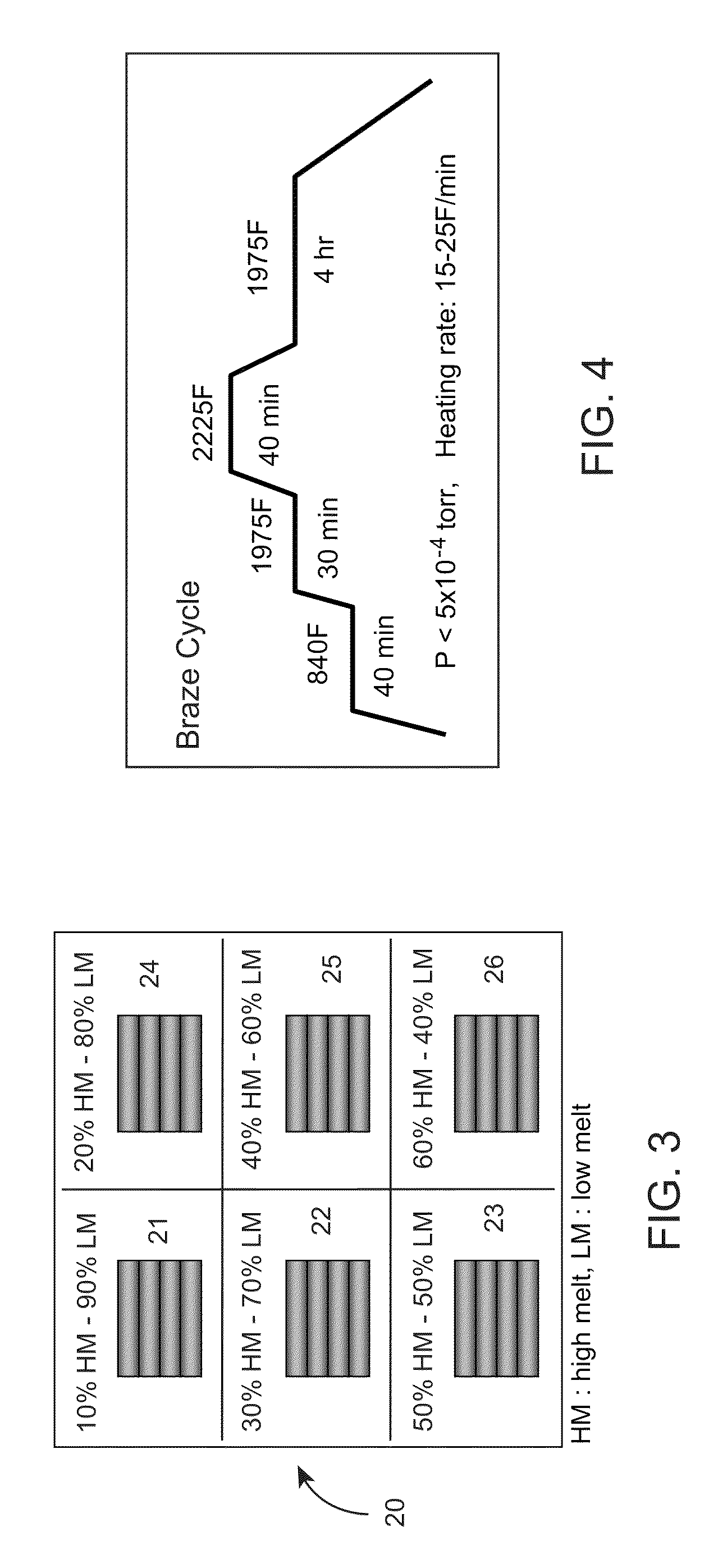

A method of coating a metal substrate such as the components in second and third stages of gas turbine engines in order to increase the oxidation and corrosion resistance of the metal substrate under high temperature operating conditions, the method including the steps of forming a powdered mixture of a high-melt superalloy or MCrAlY component, where M comprises Fe, Ni and / or Co, and a low-melt component containing about 2-5 wt. % silicon, boron or hafnium, applying the powdered mixture to the surface of the metal substrate at room temperature using an atomized spray to form a uniform surface coating, and then heating the coated substrate surface under vacuum conditions to a temperature in the range of about 1900° F. to 2275° F. to obtain a uniform coating composition providing oxidation resistance to the underlying substrate.

Owner:GENERAL ELECTRIC CO

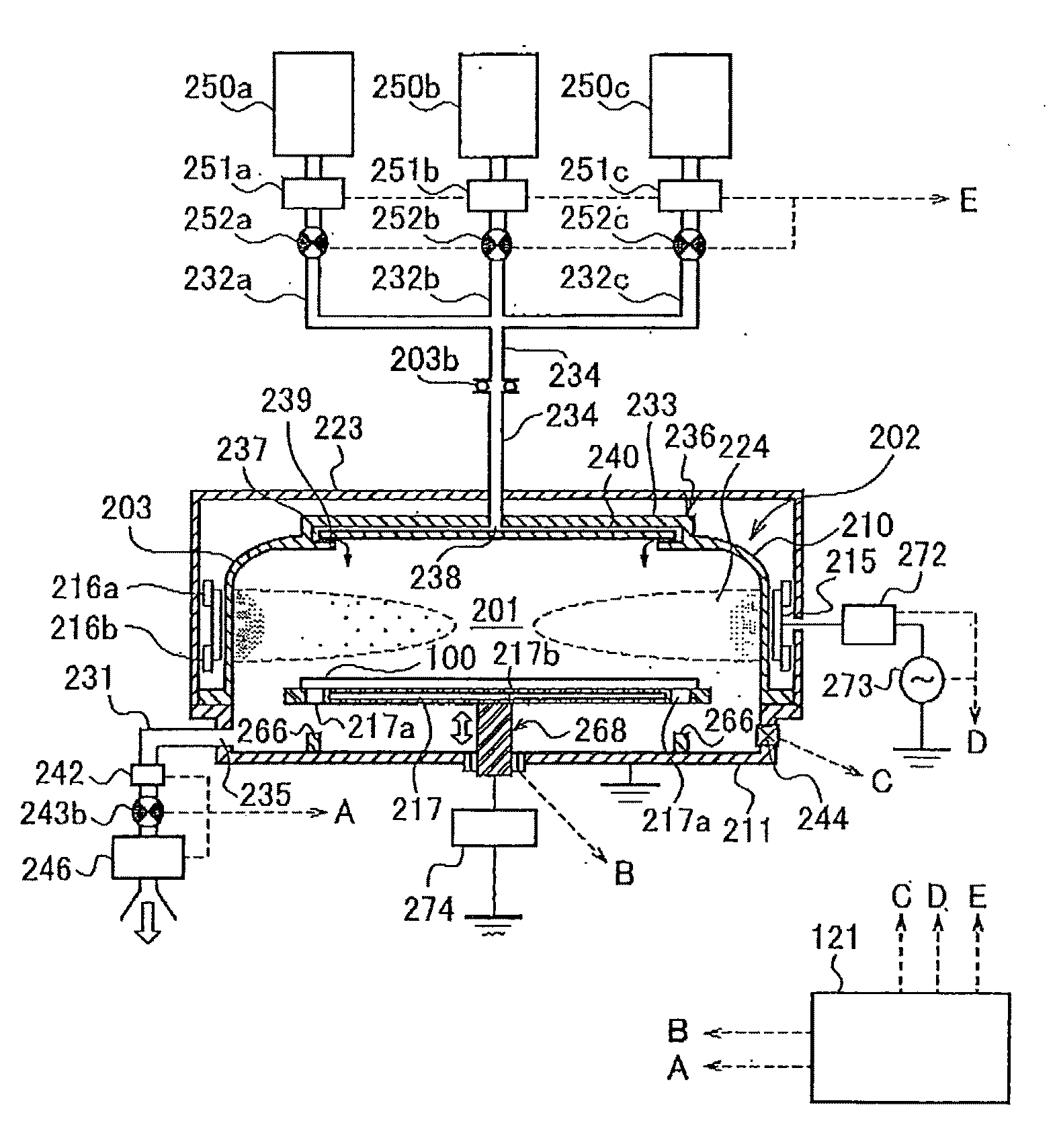

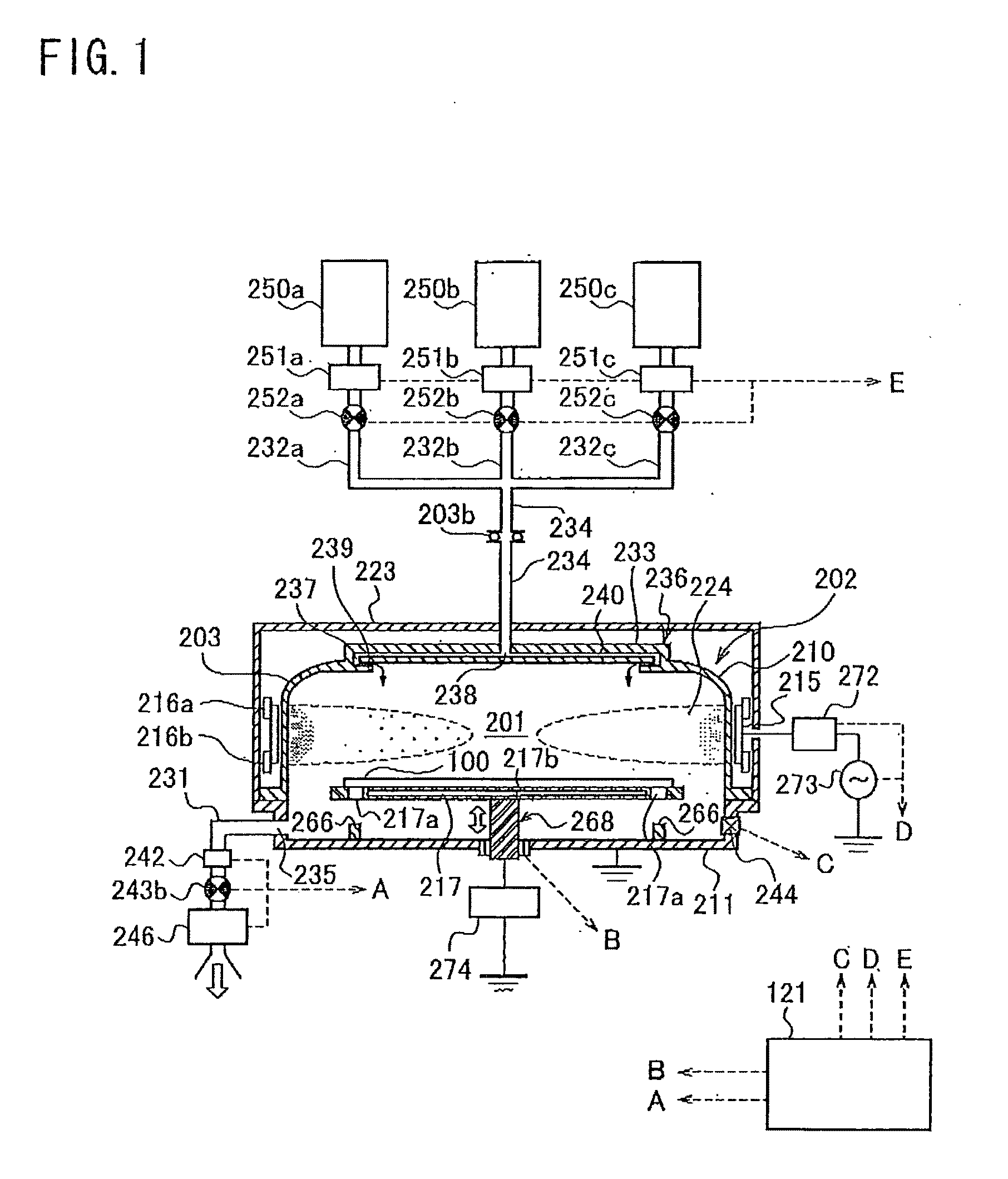

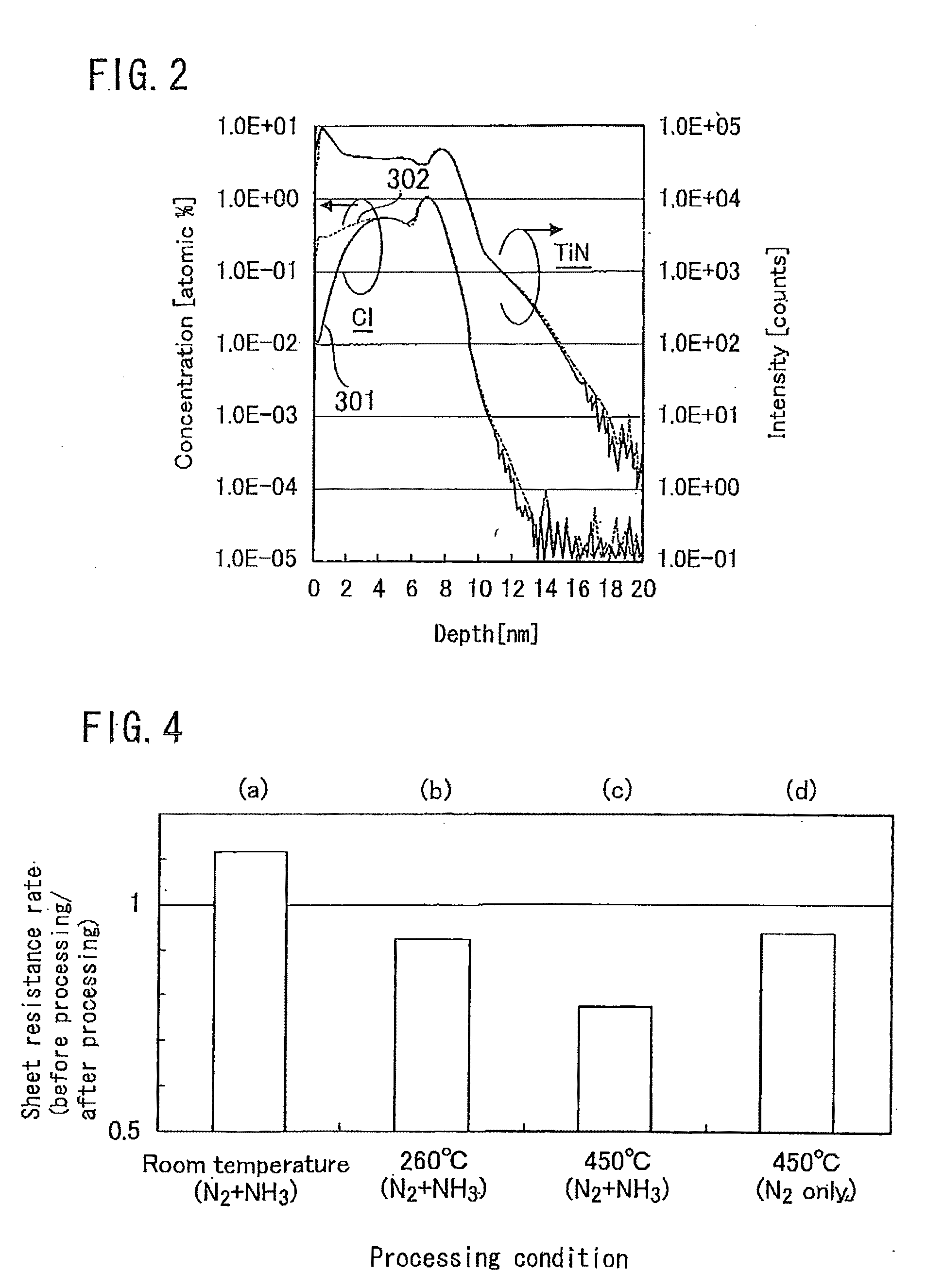

Substrate processing apparatus and manufacturing method of semiconductor device

ActiveUS20100317199A1Oxidation resistance be improveReduce residual amountElectric discharge tubesSemiconductor/solid-state device manufacturingOxygen atomSemiconductor

To reduce a residual amount of chlorine atoms and oxygen atoms in a metal nitride film, and improve oxidation resistance of the metal nitride, film, in a temperature range of not deteriorating the characteristics of other film adjacent to the metal nitride film. A substrate processing apparatus is provided, comprising: a processing chamber into which a substrate is loaded, having thereon a substrate containing oxygen atoms, chlorine atoms, and metal atoms; a substrate support part for supporting and heating the substrate in the processing chamber; a gas supply part for supplying nitrogen atoms-containing gas and hydrogen atoms-containing gas into the processing chamber; a gas exhaust part for exhausting inside of the processing chamber; a plasma generation part for exciting the nitrogen atoms-containing gas and the hydrogen atoms-containing gas supplied into the processing chamber; and a control part for controlling the substrate support part, the gas supply part, and the plasma generation part.

Owner:KOKUSA ELECTRIC CO LTD

Oxidation resistant indicator molecules

ActiveUS20080145944A1Improve oxidation resistanceOxidation resistance can be improvedMaterial analysis by observing effect on chemical indicatorGroup 3/13 element organic compoundsAromatic moietyBoronic acid

Compounds having enhanced oxidation stability are disclosed. The compounds have an aryl boronic acid residue having one or more electron withdrawing groups on the aromatic moiety which contains the boronic acid residue, such that the molecule has enhanced oxidation resistance as compared to a corresponding molecule without the one or more electron withdrawing groups.

Owner:SENSEONICS INC

Nanostructured low-Cr Cu-Cr coatings for high temperature oxidation resistance

ActiveUS20060177581A1Improve oxidation resistanceOxidation resistance can be improvedElectric discharge heatingVacuum evaporation coatingElectron beam physical vapor depositionIon beam

This invention is directed to a method of preventing oxidation of copper alloys at high temperatures by deposition of a nano-structured, low-chromium copper-chromium protective coating to copper-alloy components. The coatings of the present invention are applied by an ion beam assisted, electron beam physical vapor deposition and consist of copper and chromium particles having a diameter of about 10 nm. This invention also encompasses the coated copper-alloy components produced by the disclosed deposition methods.

Owner:SOUTHWEST RES INST

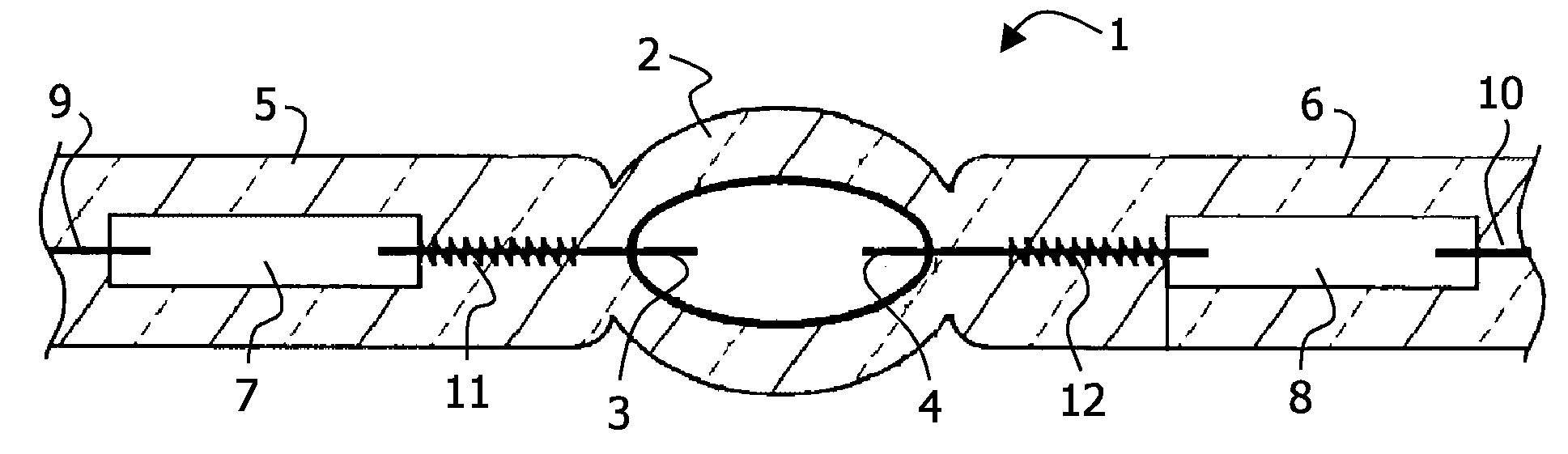

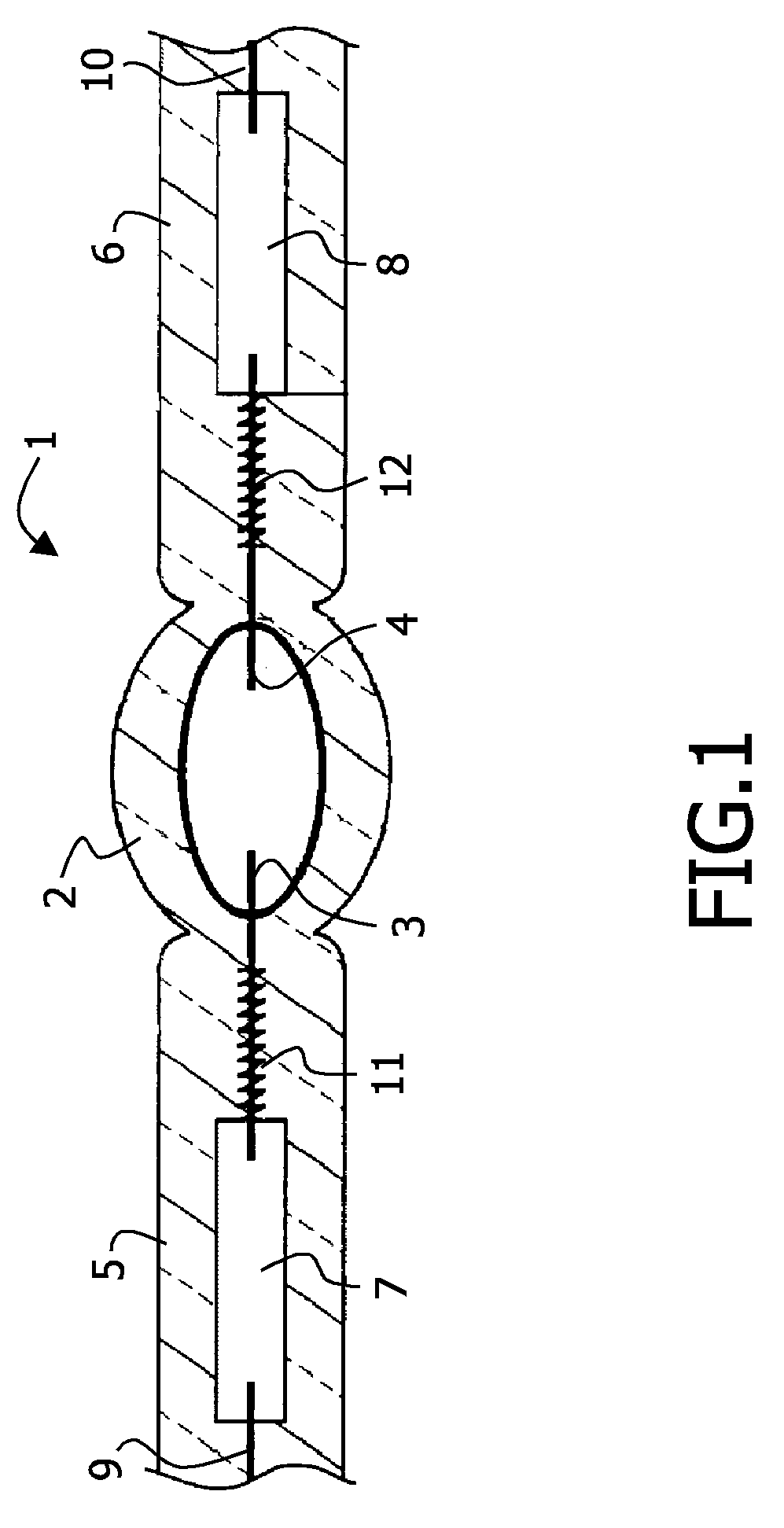

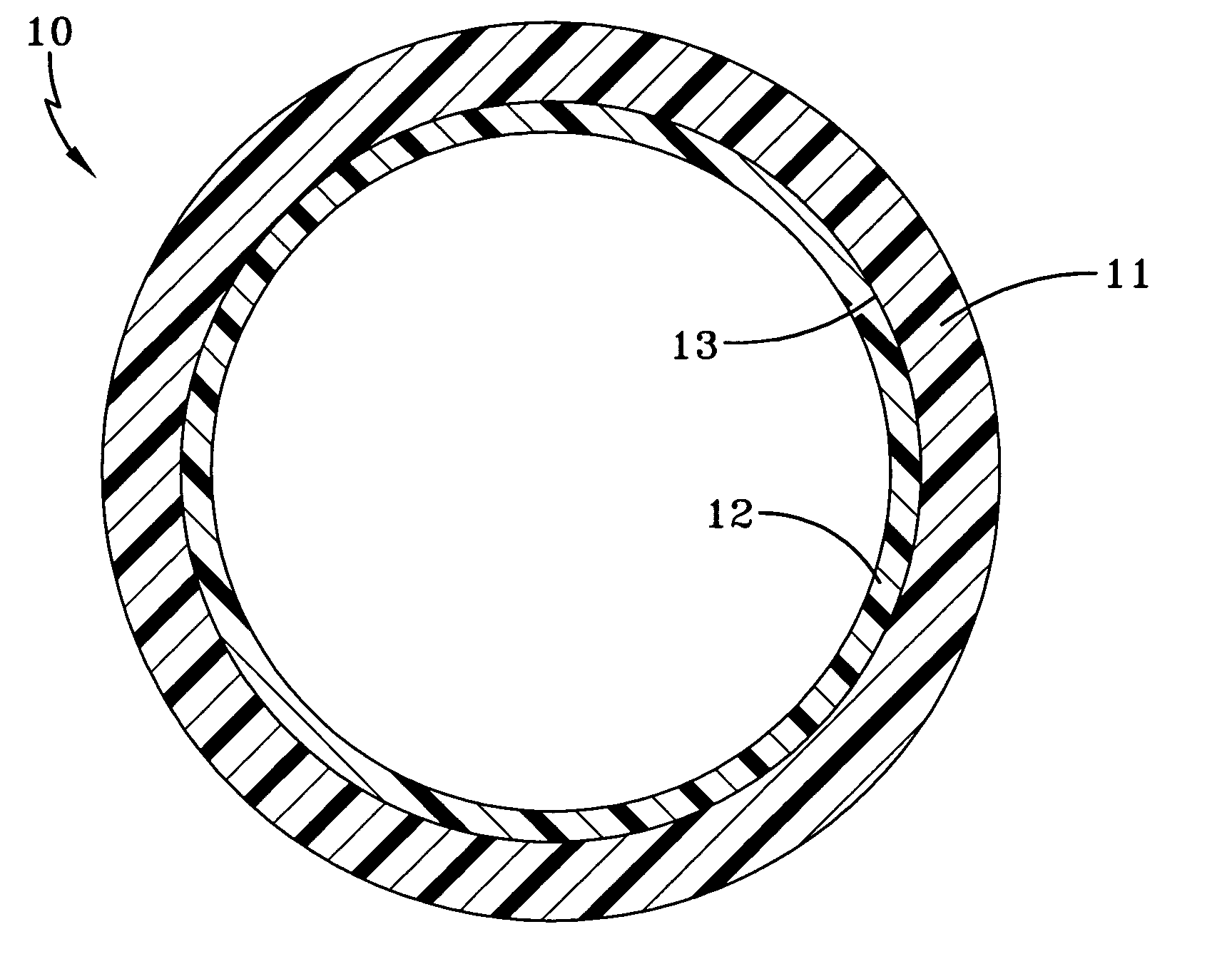

Lamp Having Molybdenum Alloy Lamp Components

InactiveUS20080203920A1Improve oxidation resistanceImprove corrosion resistanceHigh-pressure discharge lampsSolid cathode detailsRheniumIridium

The invention relates to a lamp (1) comprising a gastight vessel (2) embedding one or more feedthrough elements (7,8) electrically interconnecting an outer current conductor (9,10) and an inner current conductor (3,4) for operating said lamp. The feedthrough elements and / or the outer and inner current conductor are molybdenum alloy components containing at least one constituent from the group formed by rhenium and chromium in a quantity between 0.01 and 5% by weight; titanium in a quantity between 0.01 and 0.1% by weight; and aluminum, cobalt, gadolinium, hafnium, iridium, iron and zirconium in a quantity between 0.01 and 1% by weight of said alloy. The invention further relates to a method of manufacturing a lamp and a lamp component.

Owner:KONINKLJIJKE PHILIPS NV

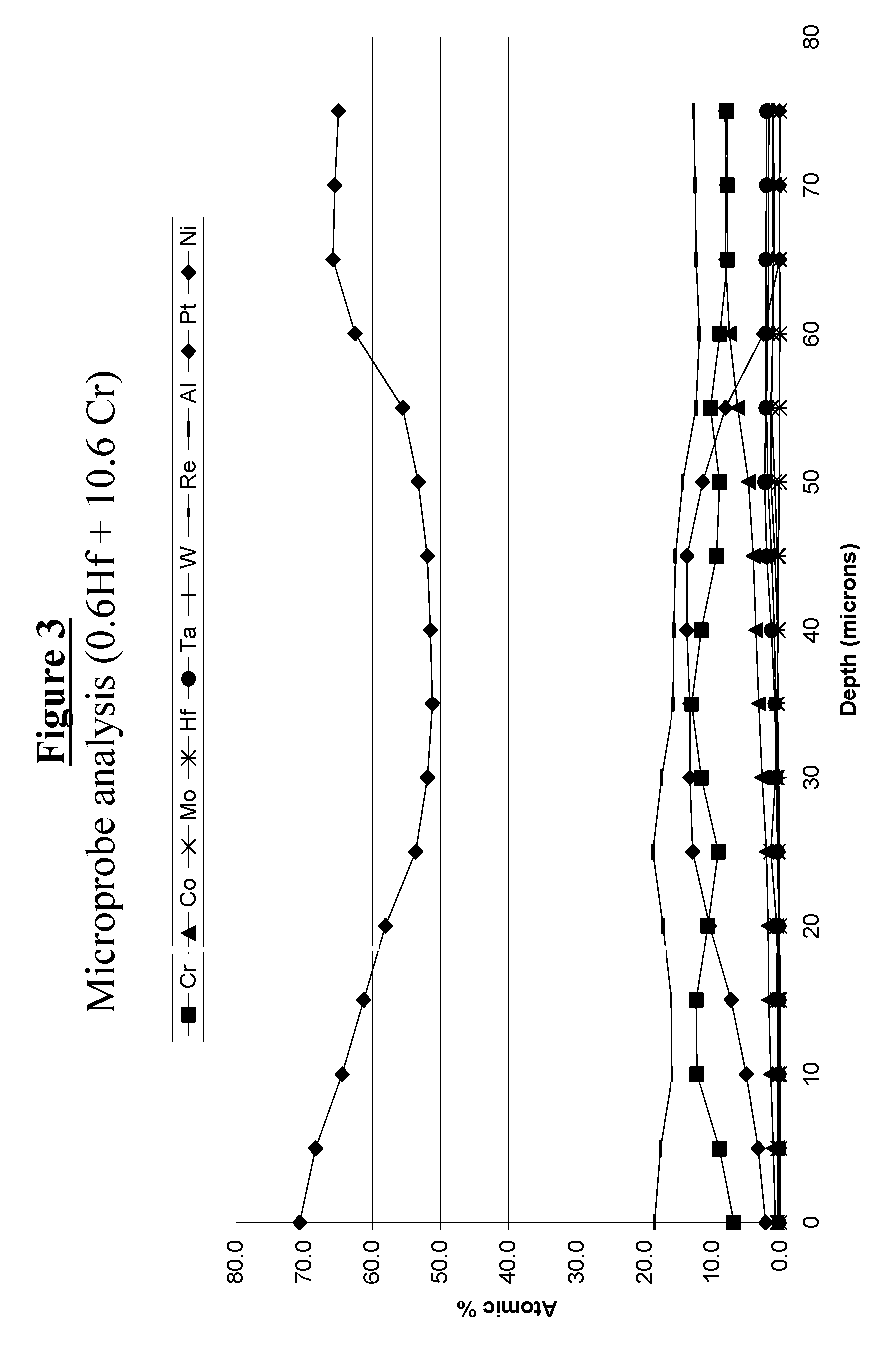

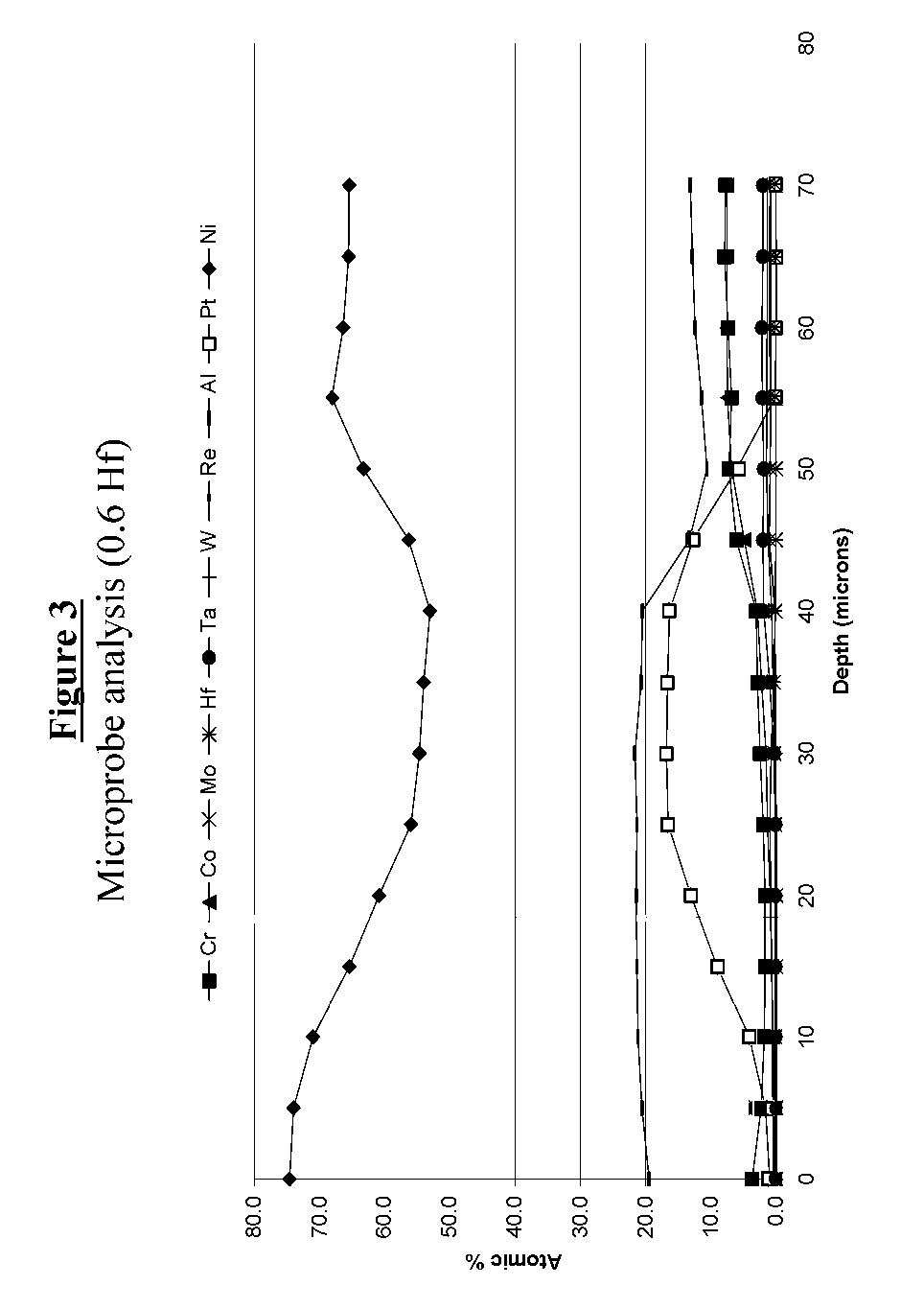

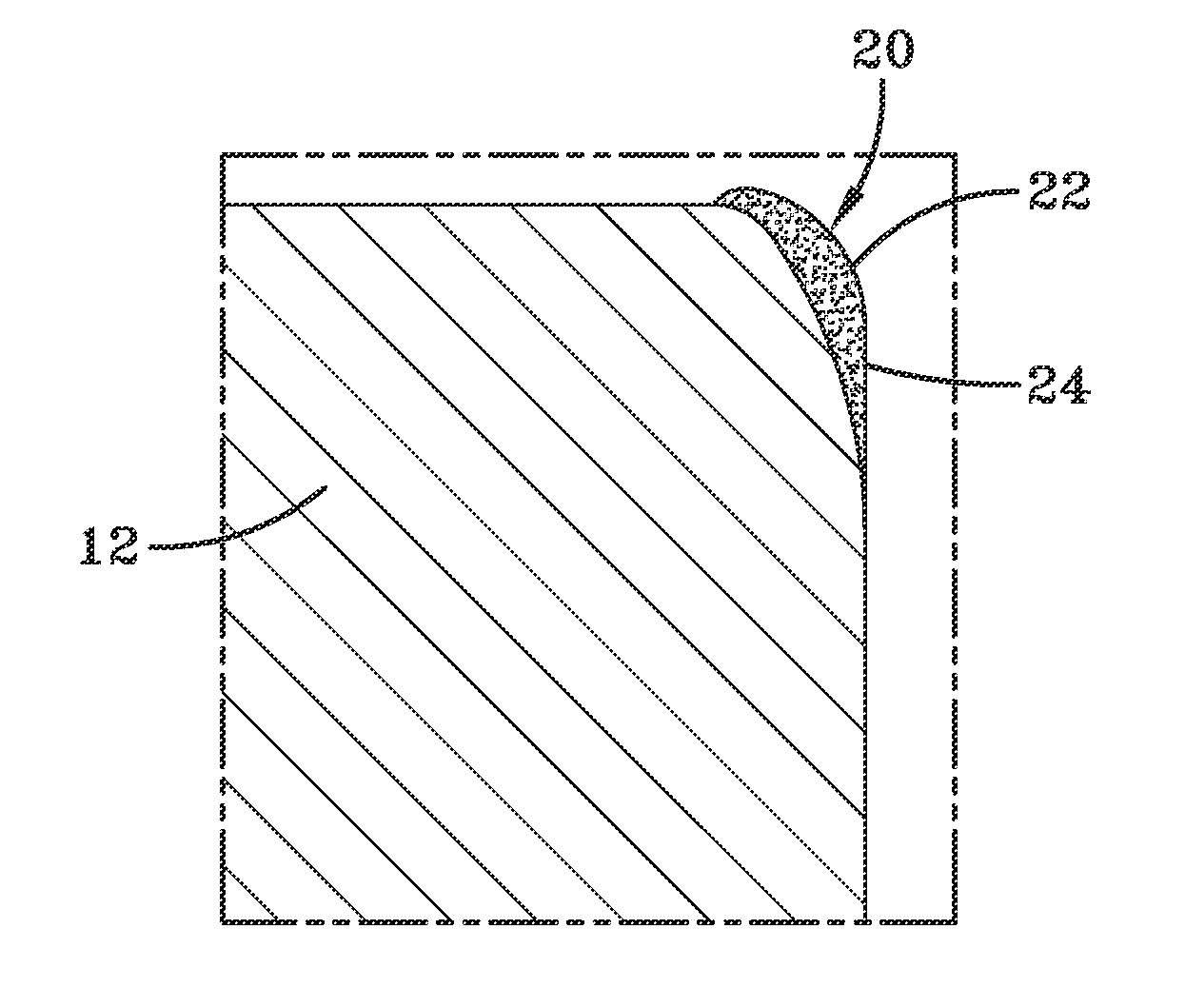

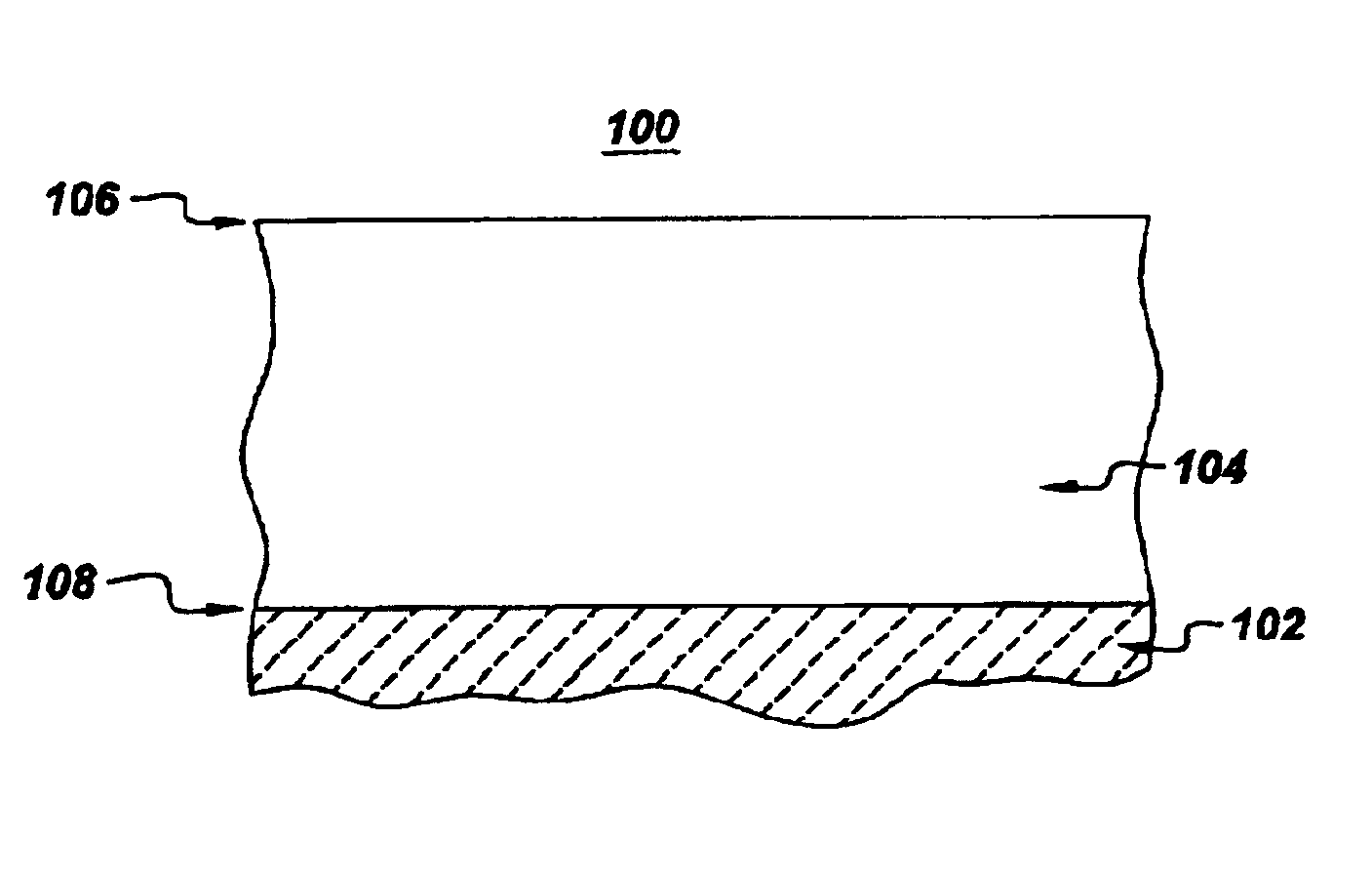

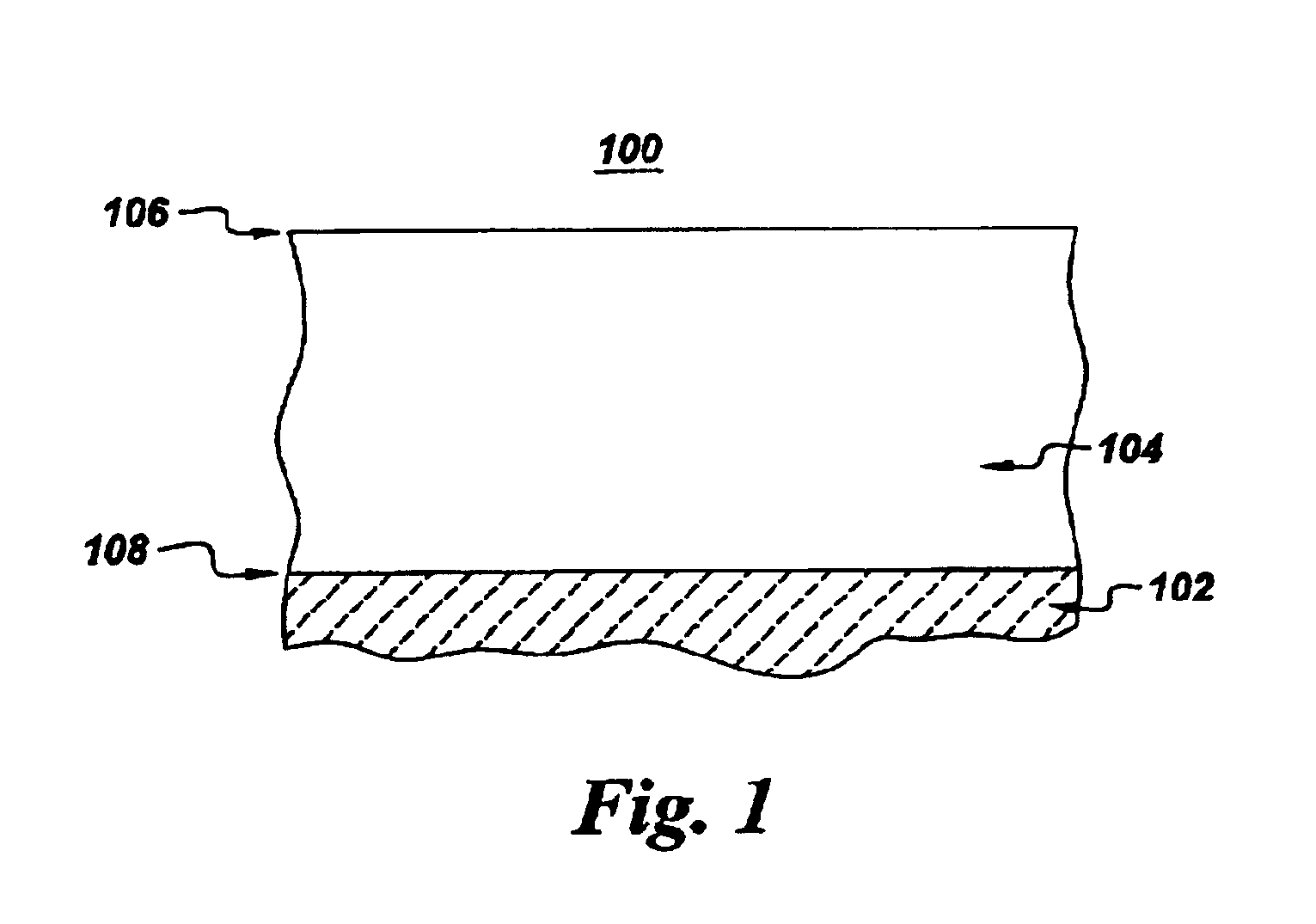

High-temperature articles and method for making

InactiveUS6746783B2Oxidation resistance can be improvedImprove the environmentMolten spray coatingVacuum evaporation coatingMetallic substrateMetallic Nickel

A coated article, a coating for protecting an article, and a method for protecting an article are provided. The article comprises a metallic substrate and a substantially single-phase coating disposed on the substrate, wherein the coating comprises nickel (Ni) and at least about 30 atomic percent aluminum (Al); the coating further comprises a gradient in Al composition, the gradient extending from a first Al concentration level at an outer surface of the coating to a second Al concentration level at an interface between the substantially single-phase coating and the substrate, wherein the first Al concentration level is greater than the second Al concentration level and the second concentration level is at least about 30 atomic percent Al.

Owner:GENERAL ELECTRIC CO

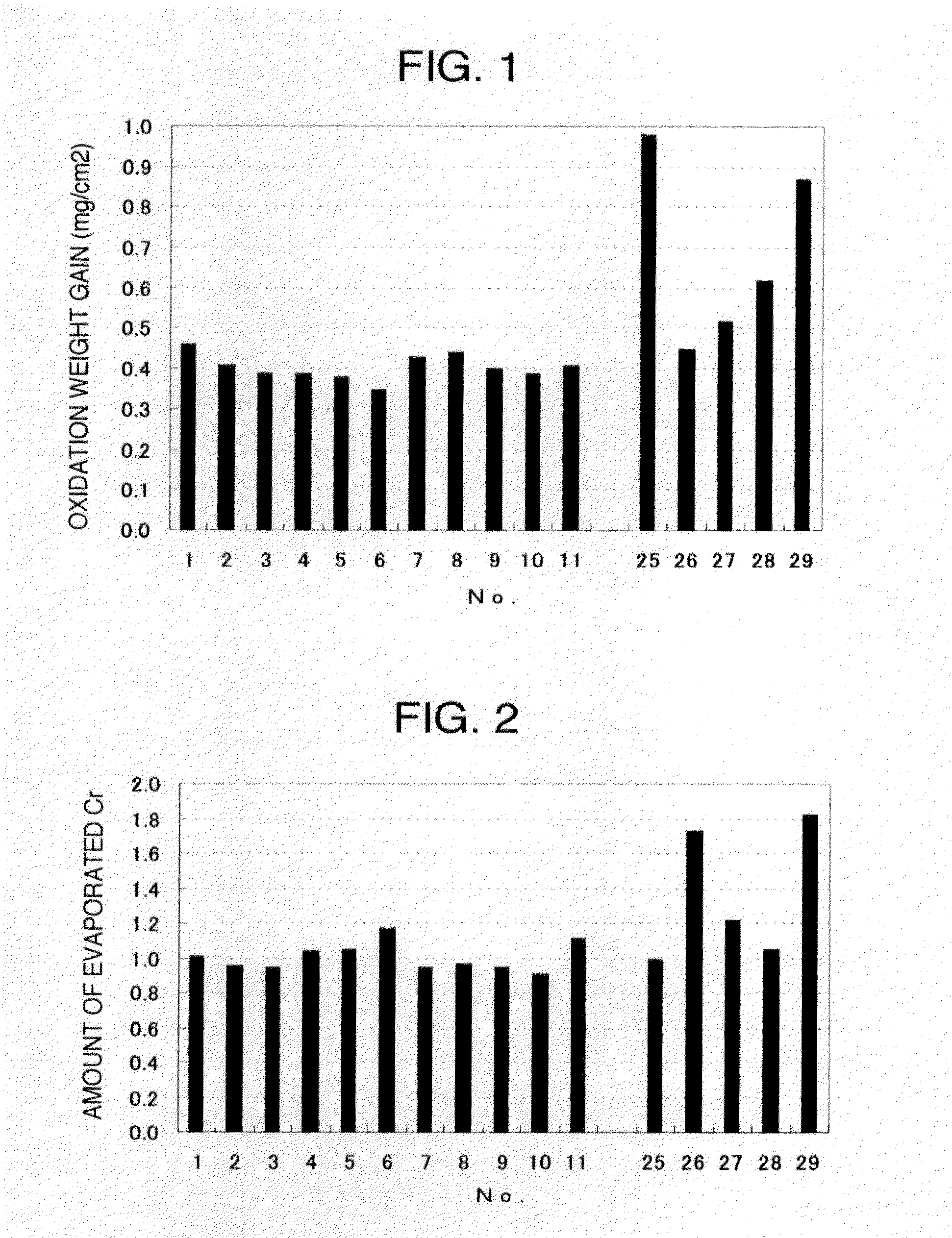

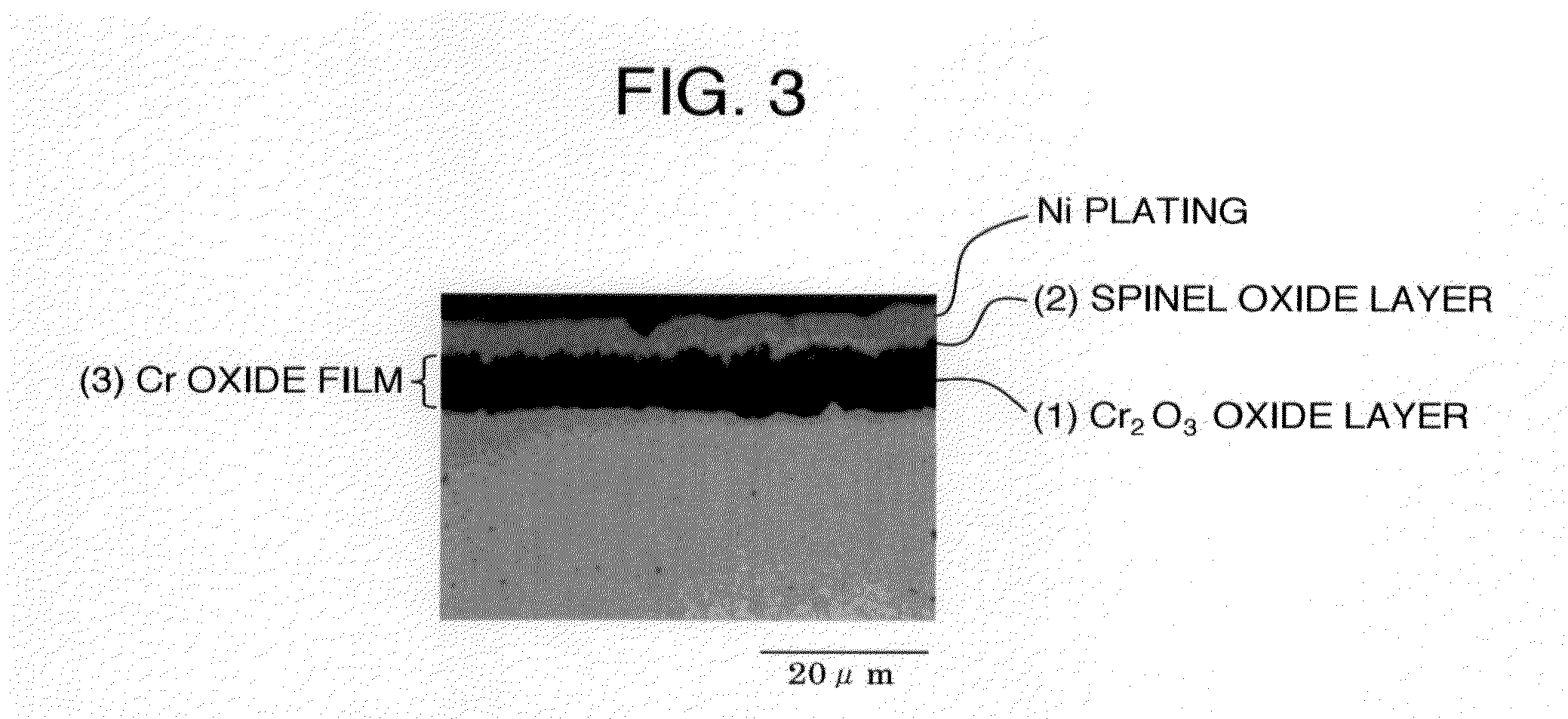

Steel for solid oxide fuel cell having excellent oxidation resistance

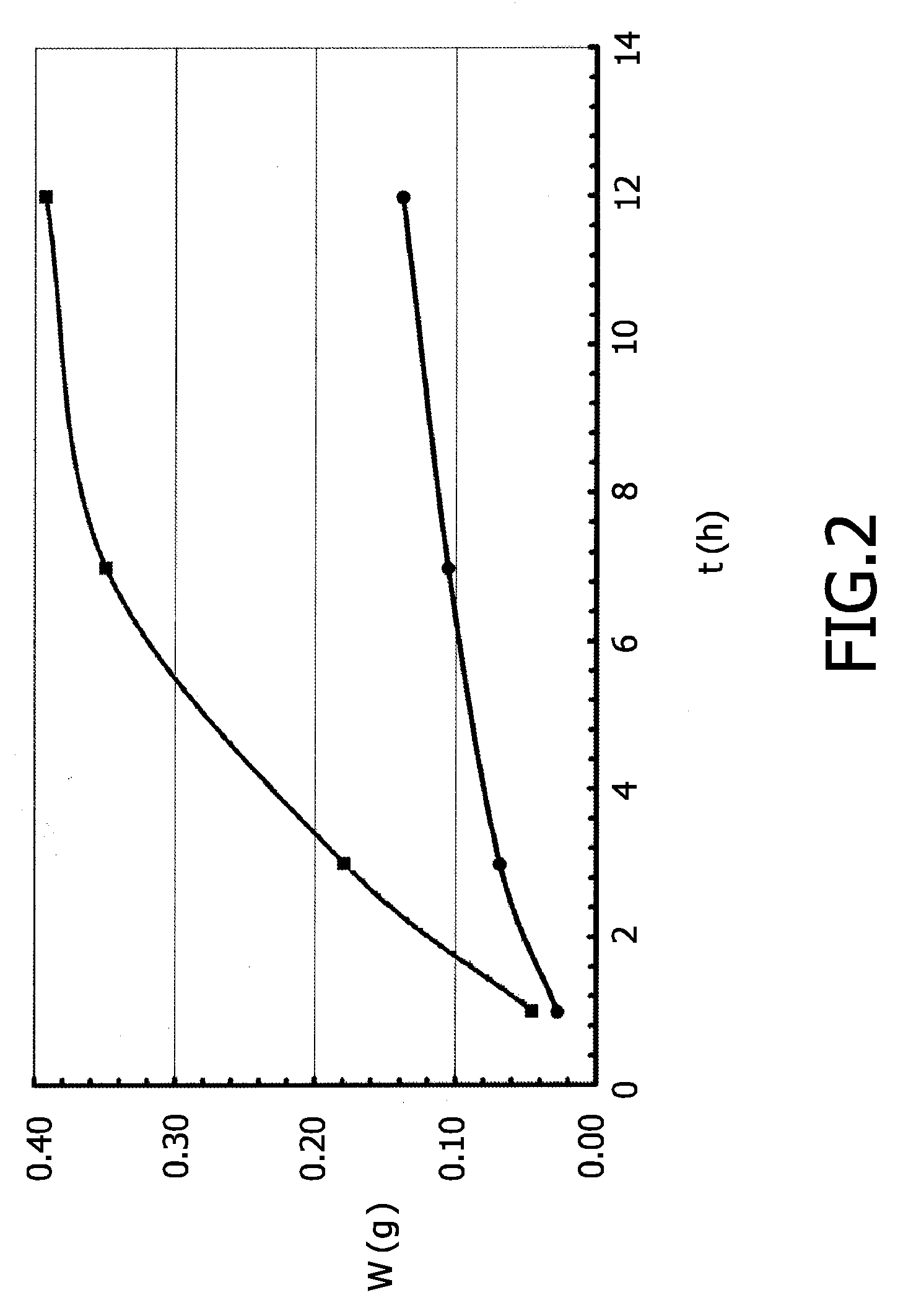

ActiveUS20120177530A1Oxidation resistance can be improvedReduce evaporationSolid electrolyte fuel cellsCollectors/separatorsFuel cellsEvaporation

Disclosed is steel for a solid oxide fuel cell, which has excellent oxidation resistance, reduces Cr evaporation, has good electrical conductivity and has a thermal expansion coefficient similar to that of a ceramic component such as an electrolyte or an electrode. Specifically disclosed is steel for solid oxide fuel cells, which has excellent oxidation resistance and contains, in mass %, 0.1% or less of C, 0.2% or less of Al, 0.2% or less of Si, 0.4% or less of Mn, 16.0-28.0% of Cr, 1.5% or less of Ni, 1.0% or less of REM and / or Zr in total, 1.0-3.0% of W, and more than 0.2% but 4.0% or less of Cu, with the balance made up of Fe and unavoidable impurities.

Owner:HITACHI METALS LTD

High-temperature articles and method for making

InactiveUS20040001965A1Improve the immunityImprove the environmentMolten spray coatingVacuum evaporation coatingMetallic substrateMaterials science

A coated article, a coating for protecting an article, and a method for protecting an article are provided. The article comprises a metallic substrate and a substantially single-phase coating disposed on the substrate, wherein the coating comprises nickel (Ni) and at least about 30 atomic percent aluminum (Al); the coating further comprises a gradient in Al composition, the gradient extending from a first Al concentration level at an outer surface of the coating to a second Al concentration level at an interface between the substantially single-phase coating and the substrate, wherein the first Al concentration level is greater than the second Al concentration level and the second concentration level is at least about 30 atomic percent Al.

Owner:GENERAL ELECTRIC CO

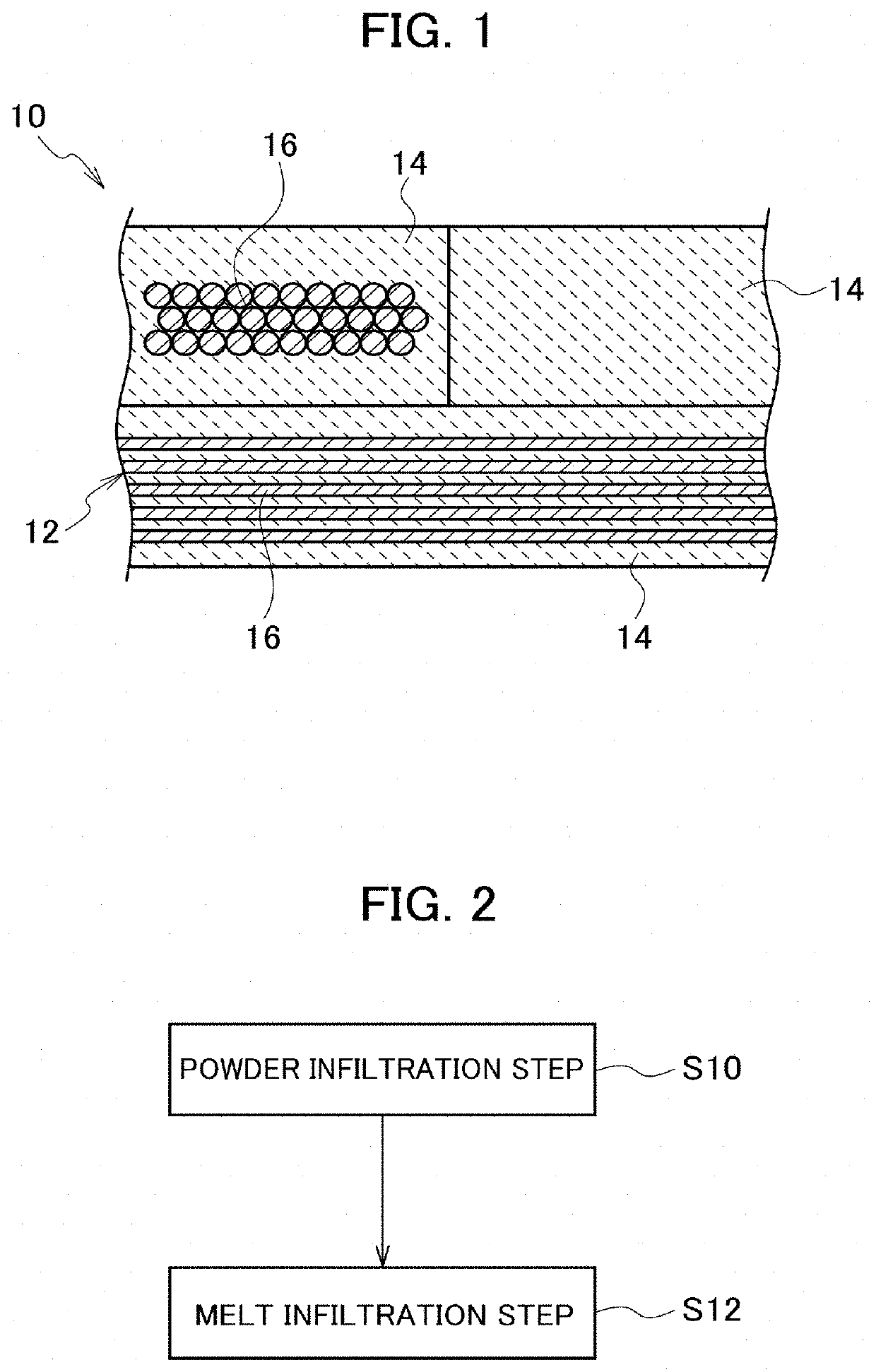

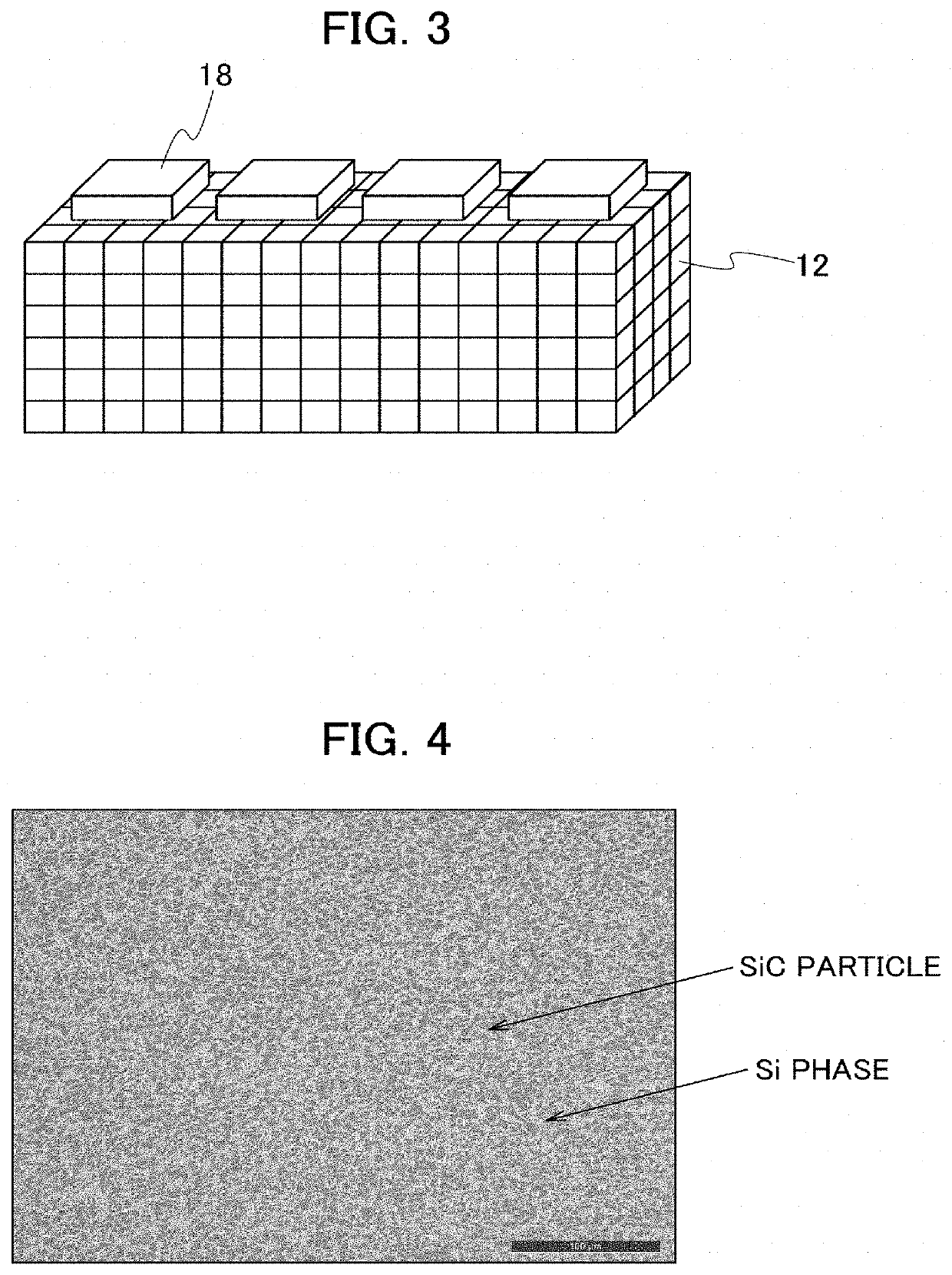

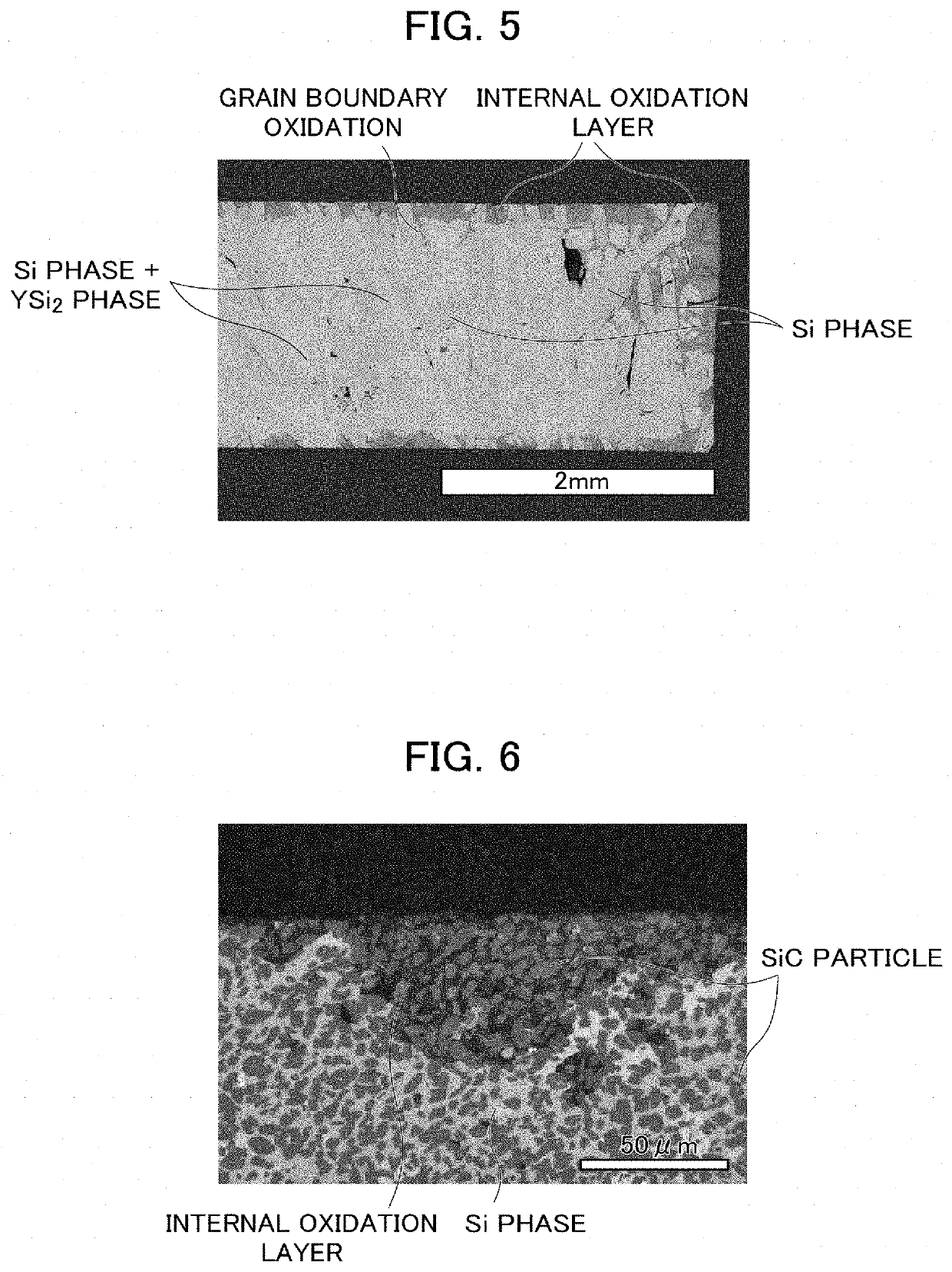

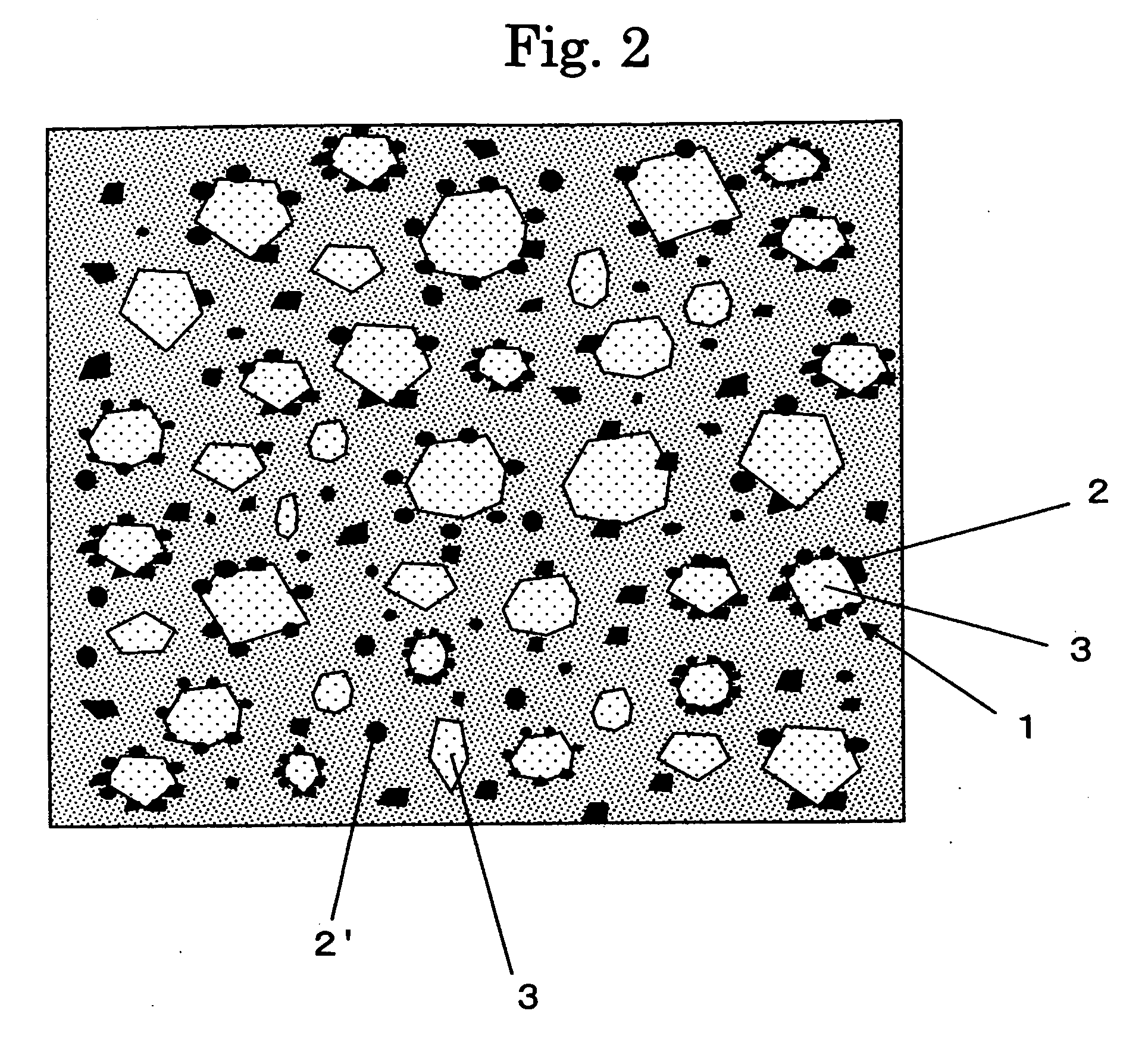

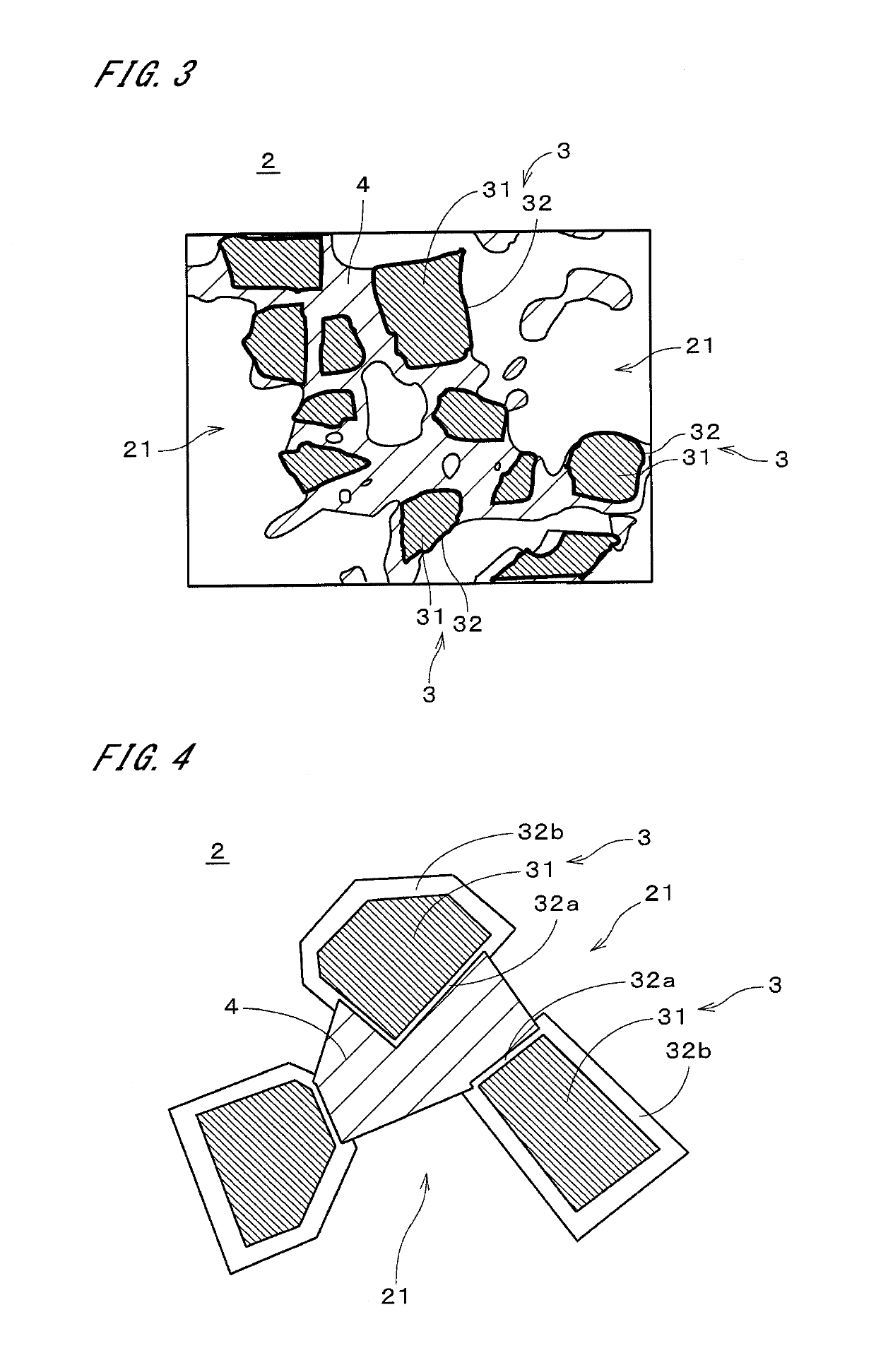

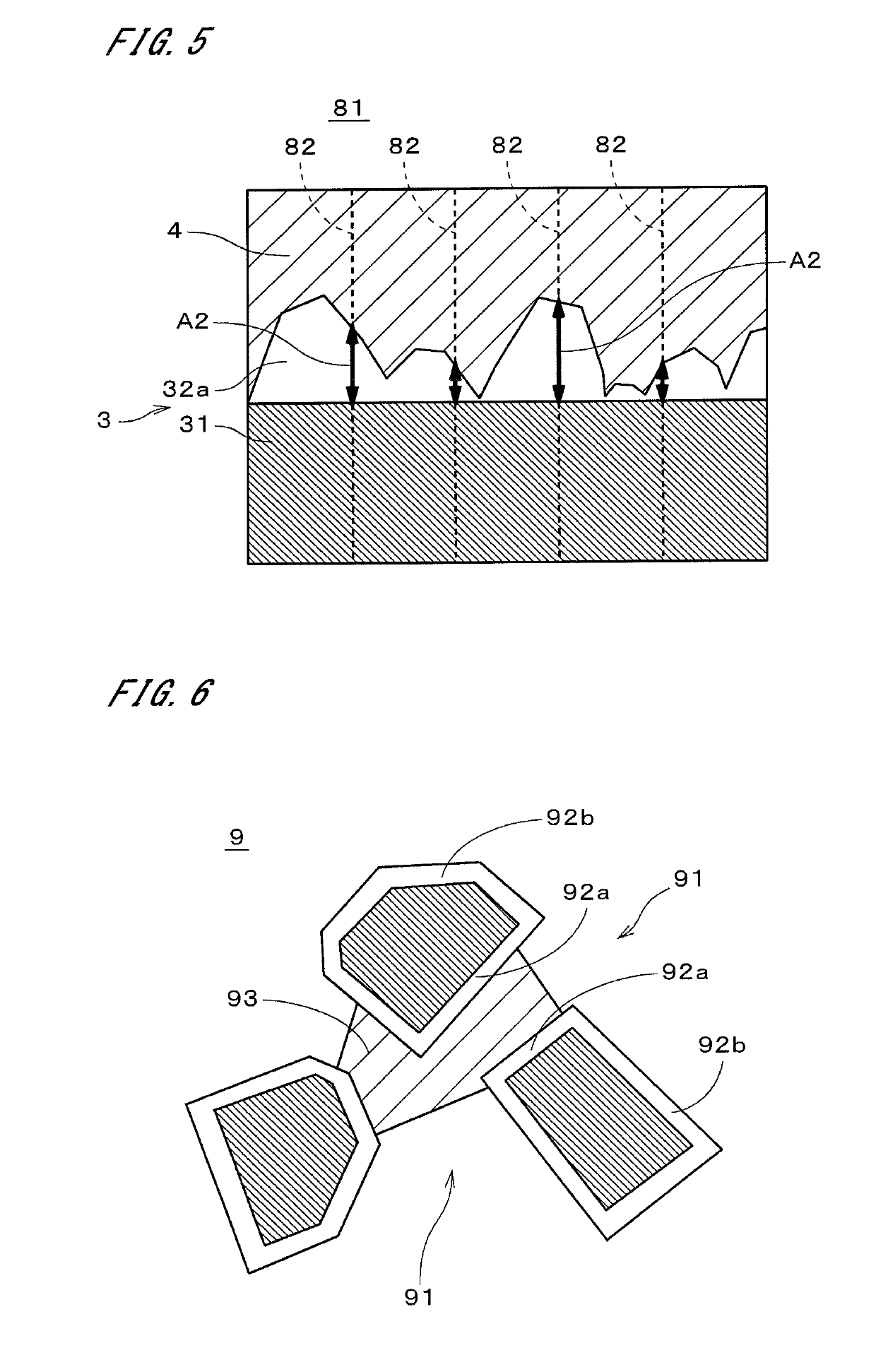

Ceramic matrix composite and method of manufacturing the same

A ceramic matrix composite includes a substrate which contains a fibrous body made of silicon carbide fiber, and a matrix which is formed in the substrate, and which contains silicon carbide and a silicon material made of silicon or a binary silicon alloy.

Owner:IHI CORP

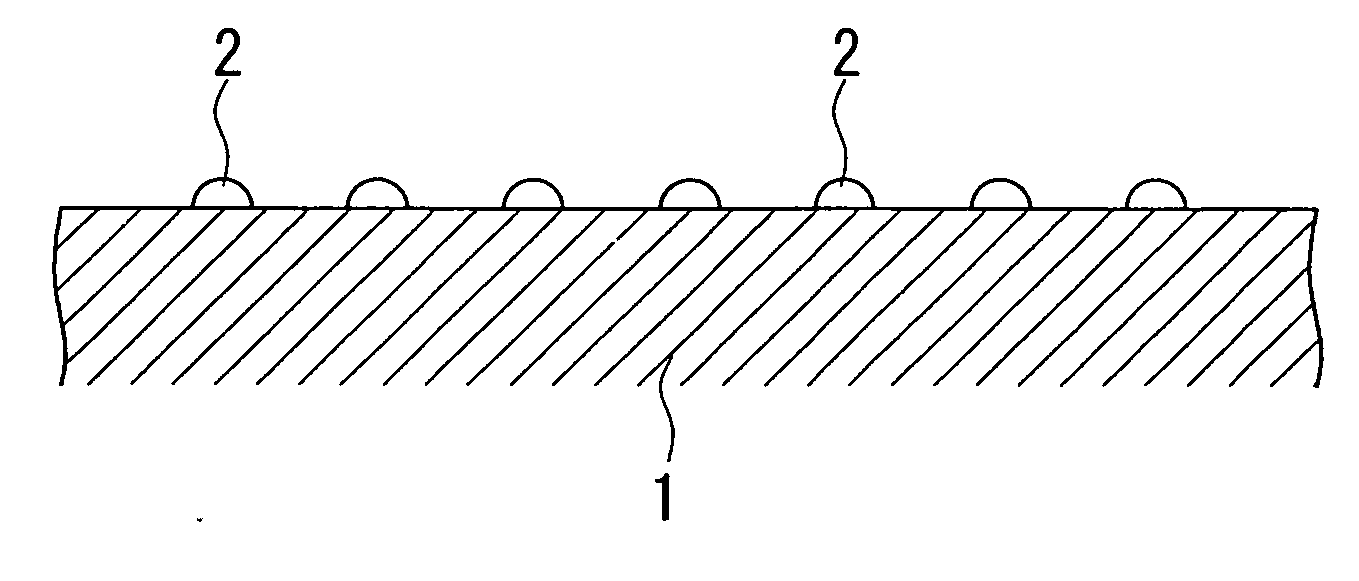

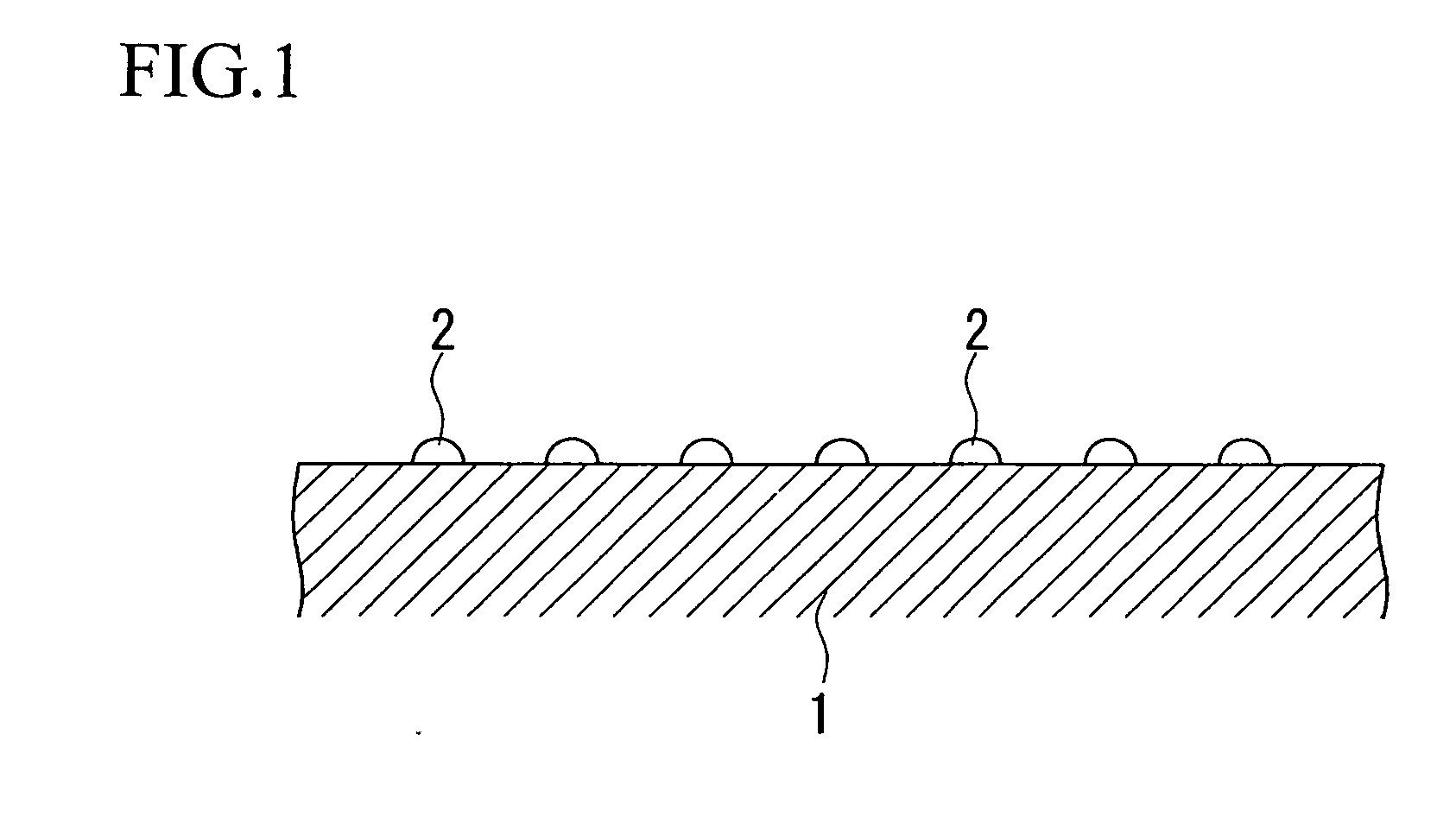

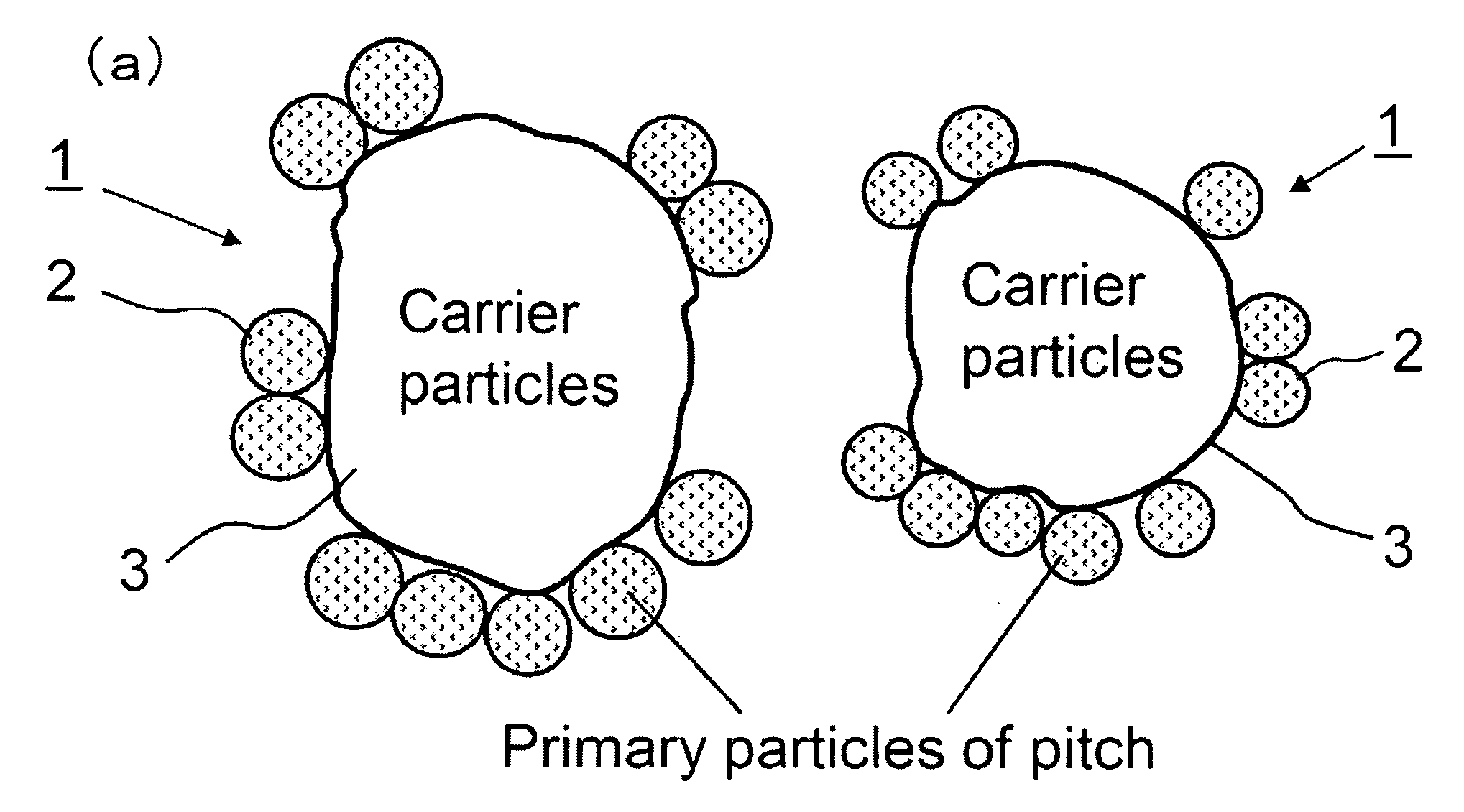

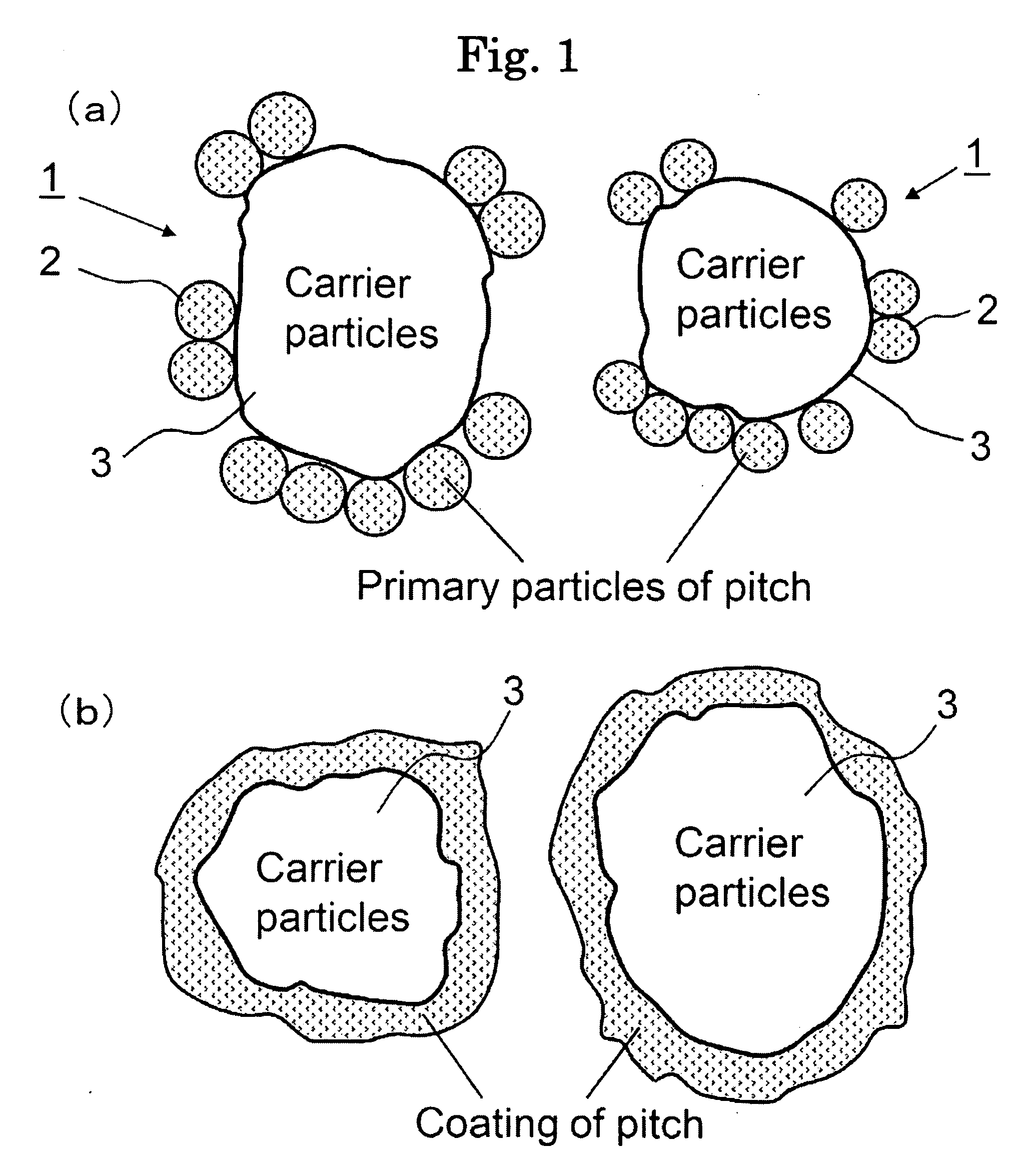

Carbon-Containing Refractory, Production Method Thereof, and Pitch-Containing Refractory Raw Material

InactiveUS20090044723A1Improve corrosion resistanceHigh strengthNon-woven fabricsBuilding insulationsRefractoryYoung's modulus

A configuration in which particles of pitch 2 having a softening point in the range of 70 to 200° C. and a diameter equal to or smaller than 30 μm are held on the surfaces of particles of a refractory raw material 3 having a diameter equal to or smaller than 50 μm is employed. This pitch-containing refractory raw material 1 can be used with the pitch being in a fine-particle form without any aggregation even after the long-term storage. Using it as a part of a raw material formulation allows the fine particles of pitch to be uniformly dispersed during the mixing or kneading process. The resulting carbon-containing refractory has an excellent corrosion resistance. It also provides suppressed increase in the Young's modulus while maintaining the level of strength, thereby being excellent in thermal spalling resistance even with the carbon content ratio being low.

Coatings for molybdenum-based substrates

InactiveUS20070231595A1Oxidation resistance can be improvedImprove the immunityLiquid surface applicatorsMolten spray coatingOxygenBoron

A coating for a molybdenum-based substrate that may be a bi-layer coating. The lower layer may include a first molybdenum coating compound, such as Mo5Si3, doped with from about 0 to about 10% boron and / or silicon. The upper layer may include a second molybdenum coating compound, such as MoSi2, doped with from about 0 to about 20% silicon and / or aluminum. The bi-layer coating forms a protective SiO2 surface upon high temperature exposure in oxygen-containing atmospheres. The coating is capable of providing long-term oxidation resistance to molybdenum-based substrates up to about 1400° C. An additional thermal layer may be included.

Owner:SIEMENS ENERGY INC

Reduced temperature and pressure powder metallurgy process for consolidating rhenium alloys

InactiveUS7270782B2Oxidation resistance can be improvedReduce pressureBearing componentsSliding contact bearingsRheniumHigh pressure

Pressure powder metallurgy process for consolidating refractory or rhenium alloys using a reduced temperature and elevated pressure. Rhenium metal has high temperature strength and wear resistance but has a very high melting point as a pure metal and thus is difficult to use as a coating for many alloys having lower melting points. The reduced temperature and elevated pressure alloying process of the rhenium allows it to be used as a coating for other metal alloys, such as nickel and steel alloys, providing some high temperature and wear resistance due to the properties of the rhenium material in the coating.

Owner:HONEYWELL INT INC

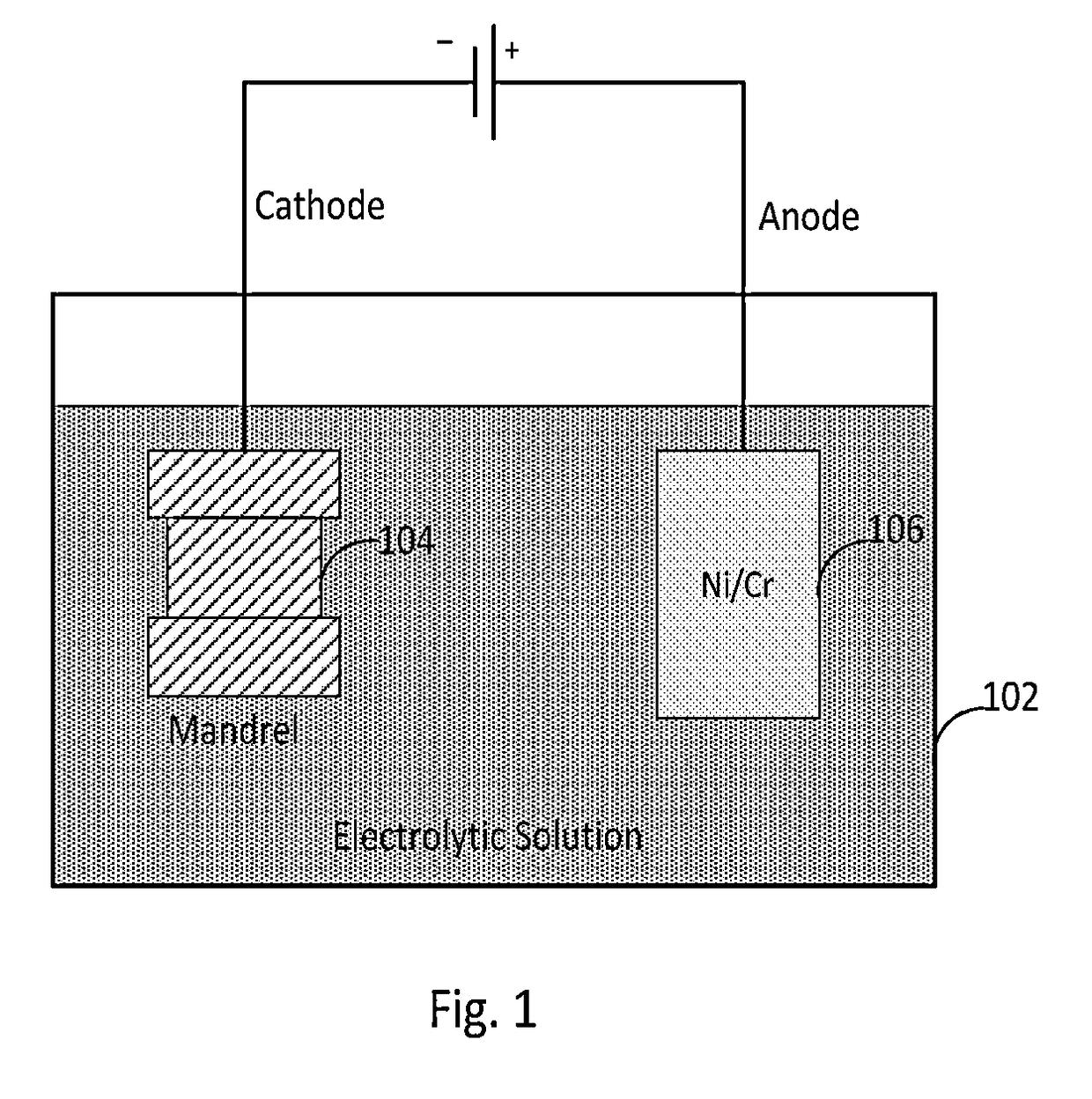

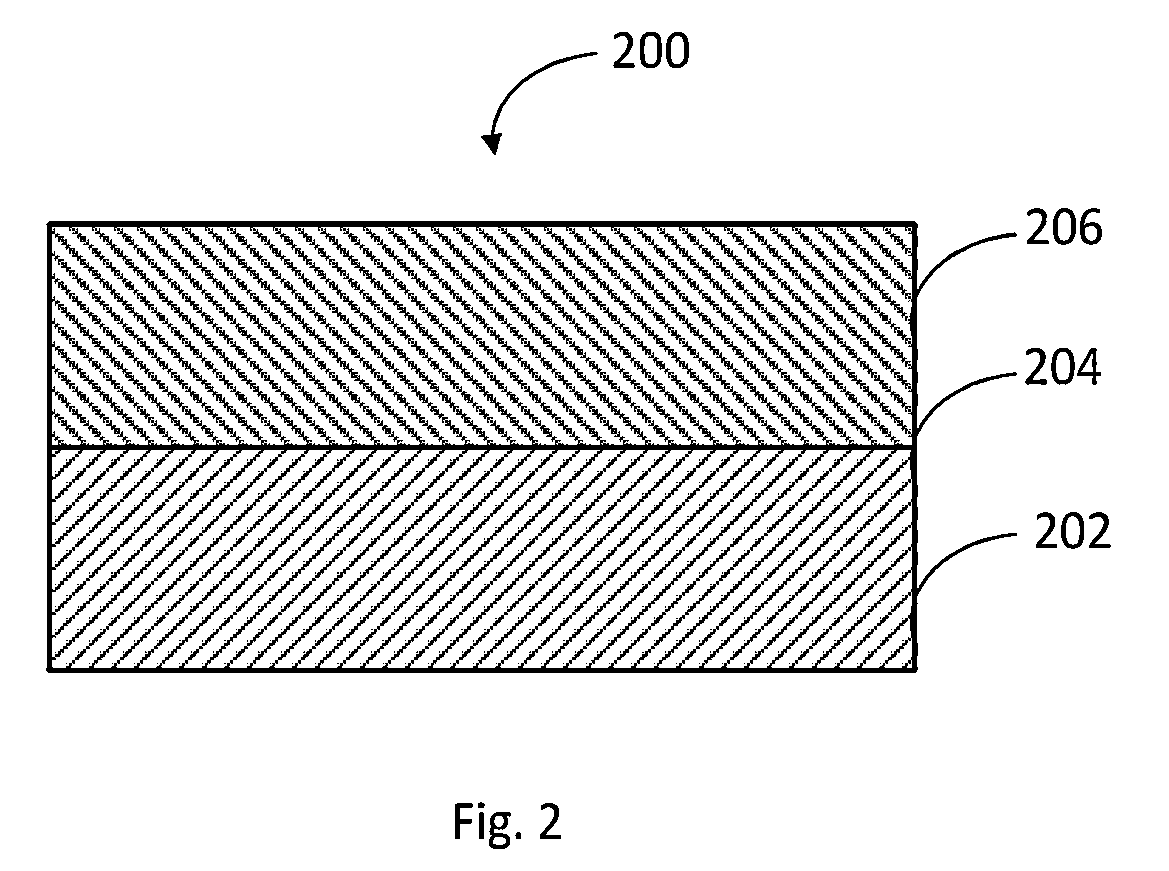

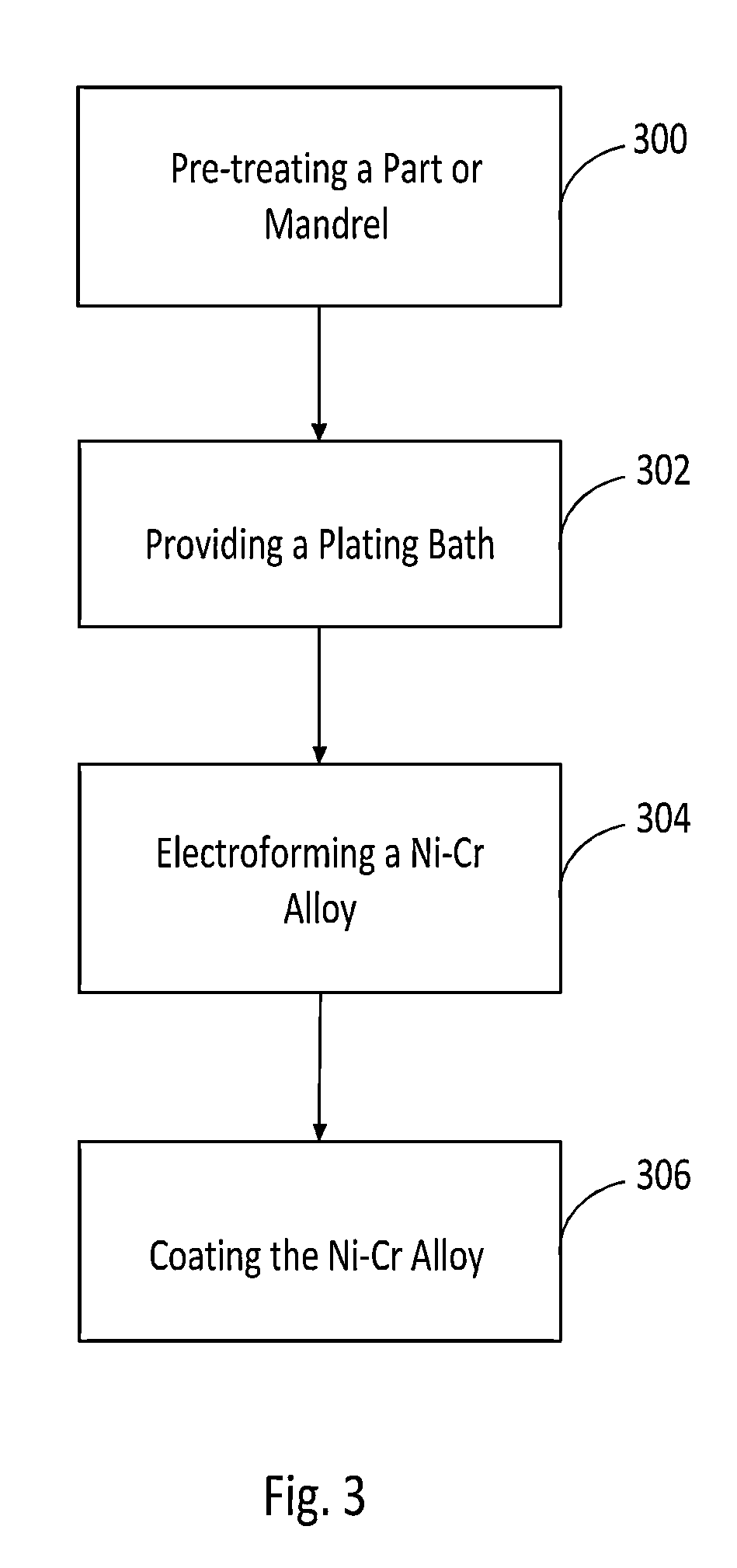

Electroformed nickel-chromium alloy

ActiveUS20190072683A2Oxidation resistance can be improvedSeismic data acquisitionBlade accessoriesNichromeChromium(III) chloride

An article comprising a turbine component formed of a nickel-chromium (Ni—Cr) alloy including from 2 to 50 wt % chromium balanced by nickel is disclosed. The Ni—Cr alloy is thicker than at least 125 μm to make a self-supporting turbine component, and the turbine component includes a rotor blade, a stator, or a vane. The Ni—Cr alloy is electroformed on a mandrel by providing an external supply of current to an anode and a cathode in a plating bath containing a solvent, a surfactant, and an ionic liquid including choline chloride, nickel chloride, and chromium chloride.

Owner:RTX CORP

Surface hardened carbon material and process of manufacturing

InactiveUS6893601B2Oxidation resistance can be improvedElectric discharge heatingLayered productsNitrogen atmosphereAluminium

A carbon material is formed by heat-treating a carbonaceous material in a reaction mix of oxides of boron and boron nitride in a nitrogen atmosphere to temperatures of 1600 to 2000° C. The surface of the carbonaceous material is transformed into a carbon material that is resistant to oxidation to temperatures of 900° C., enabling machined components to be utilized for weeks at that temperature. The carbon material is also stable in inert or vacuum environments to temperatures in the range of 1500 to 2000° C., enabling its use as aluminum evaporative boats and the like.

Owner:EQUITY ENTERPRISES

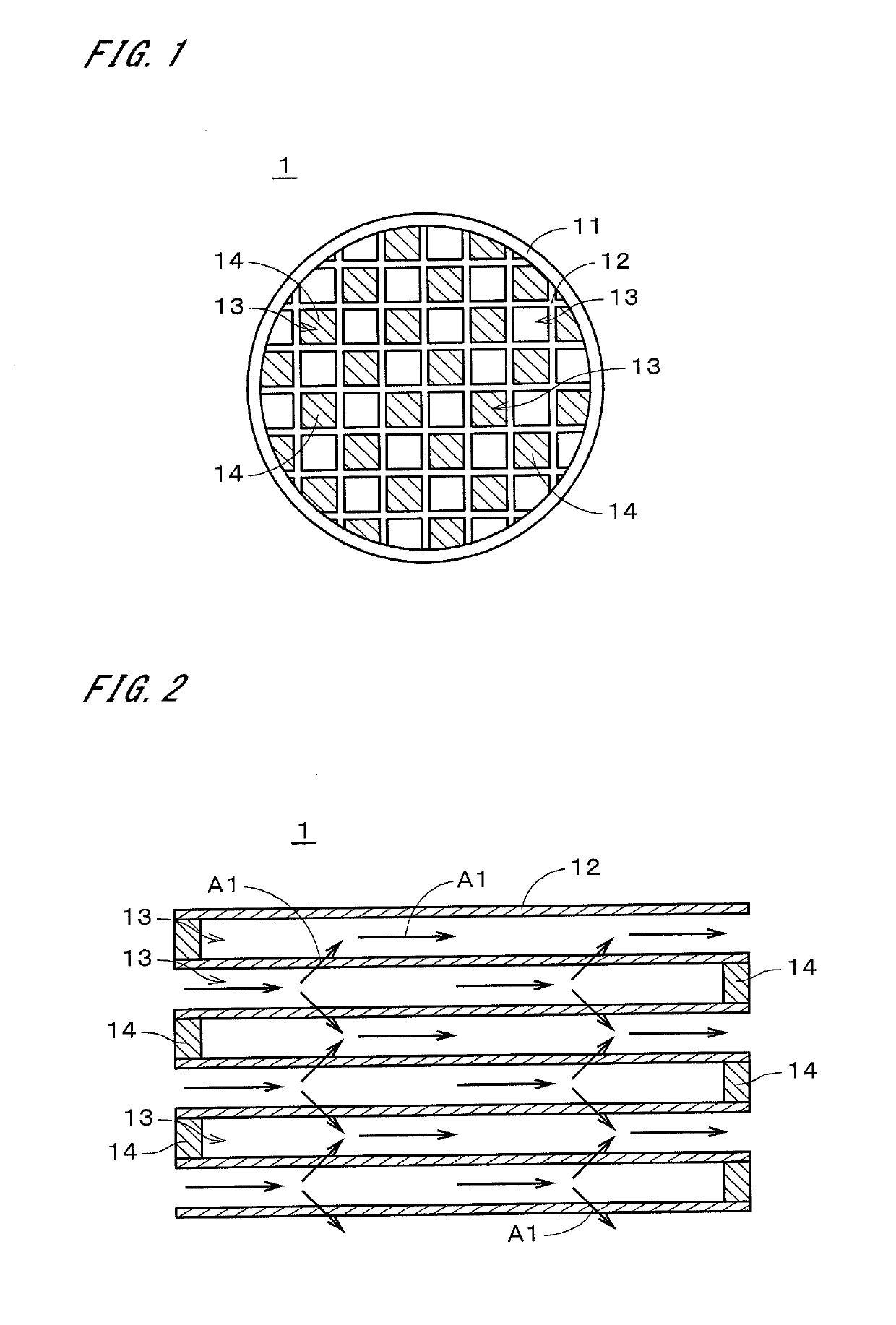

Porous material, cell structure, and method of producing porous material

ActiveUS20190292104A1Reduce thermal expansion coefficientImprove oxidation resistanceInternal combustion piston enginesThin material handlingCordieriteMaterials science

A porous material includes aggregate particles and a binding material. In the aggregate particles, oxide films containing cristobalite are provided on surfaces of particle bodies that are silicon carbide particles or silicon nitride particles. The binding material contains cordierite and binds the aggregate particles together in a state where pores are provided therein. The mass ratio of the cordierite to the whole of the porous material is in the range of 10 to 40 mass %. The oxide films that exist between the particle bodies and the binding material have a thickness less than or equal to 0.90 μm.

Owner:NGK INSULATORS LTD

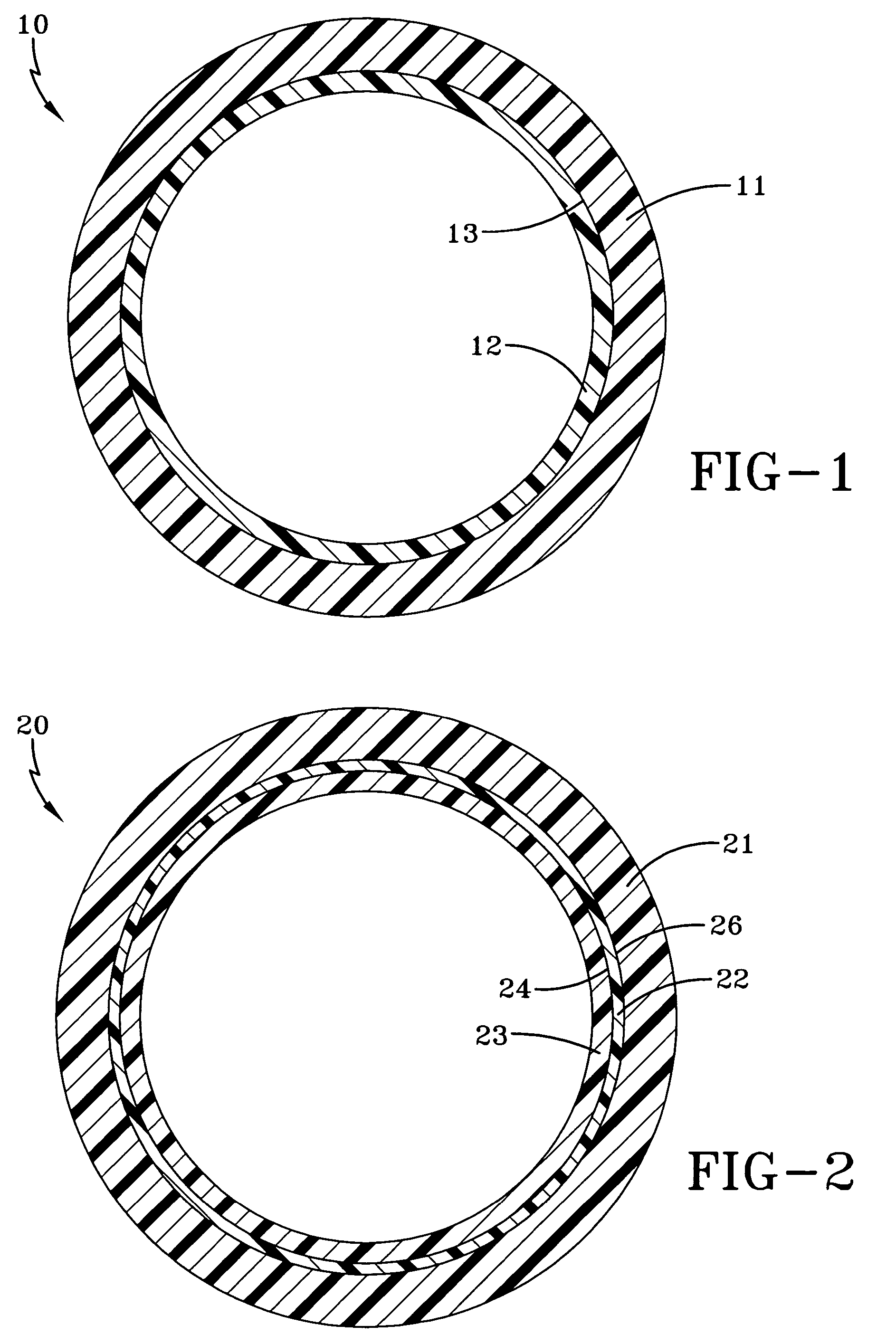

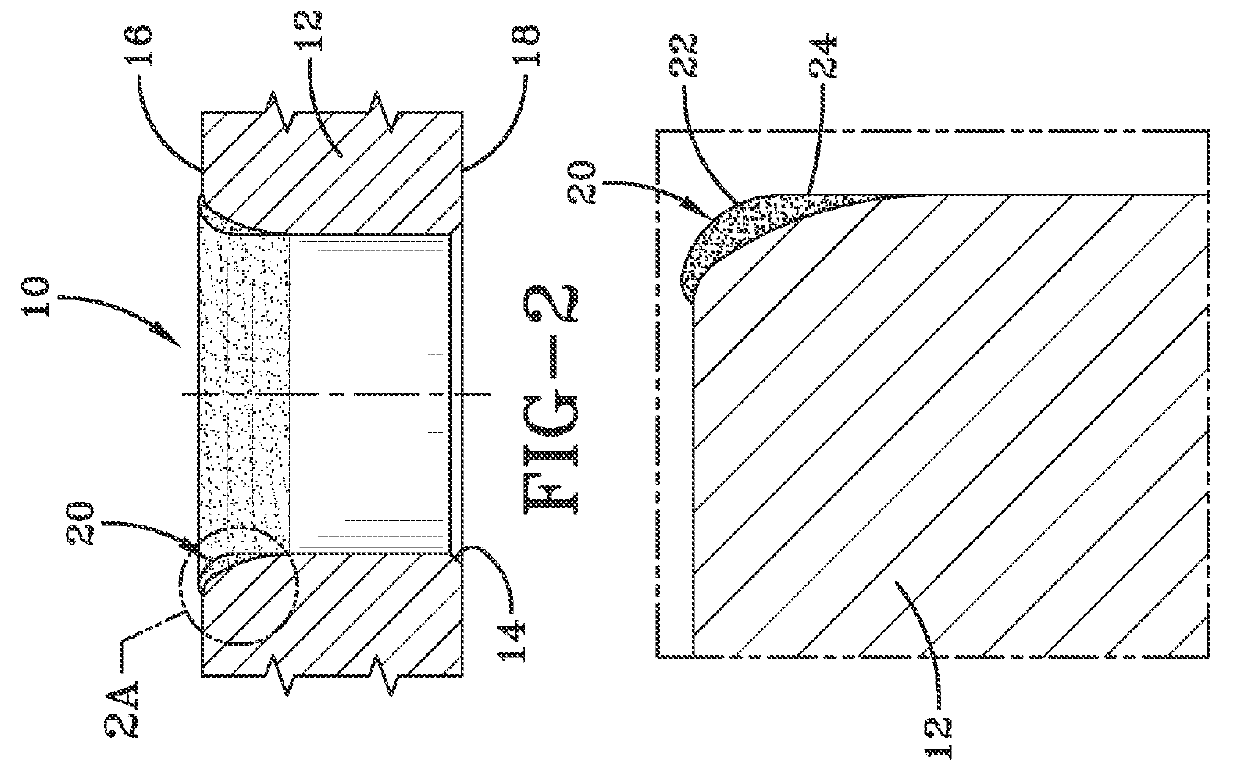

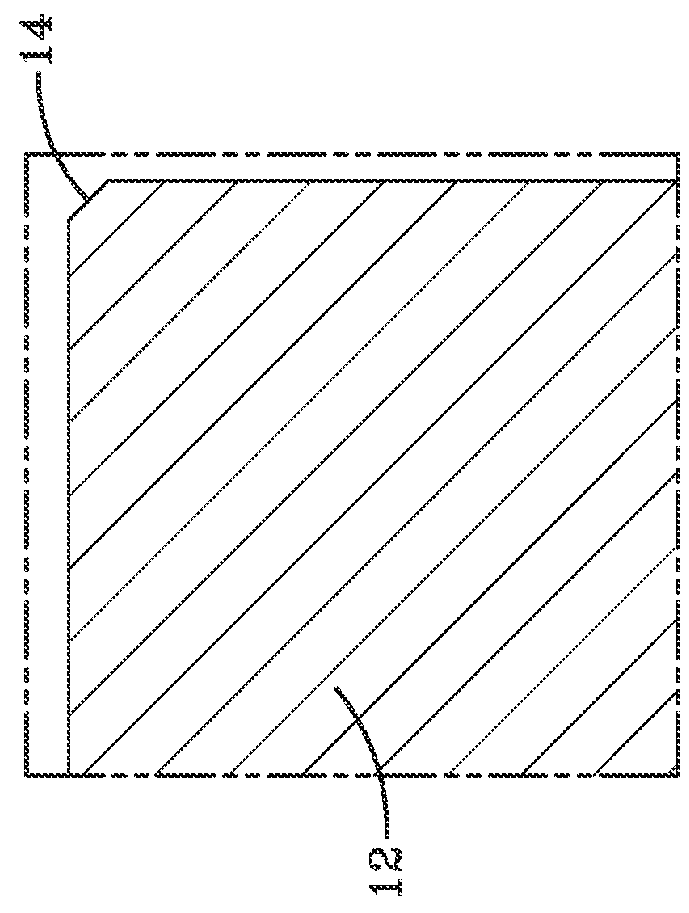

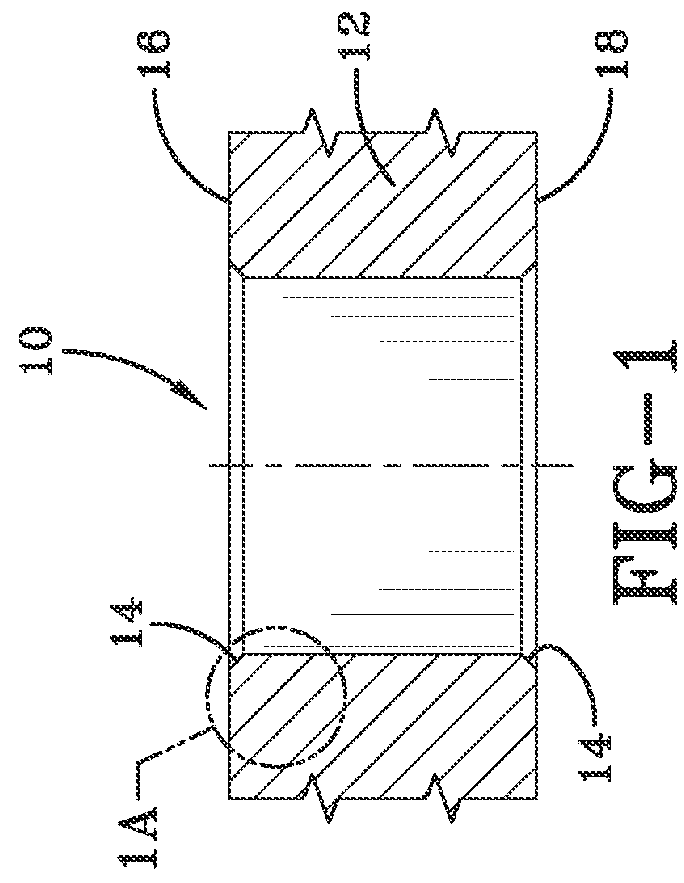

Polyefinic pipe having a chlorinated polyolefinic hollow core

InactiveUS7160593B2Improve oxidation resistanceEasy squeezeClosuresClosure using stoppersPolyolefinAdditive ingredient

Owner:NOVEON INC

Electrospark deposition process for oxidation resistant coating of cooling hole

InactiveUS20160031033A1Oxidation resistance can be improvedImprove the immunityEngine fuctionsBlade accessoriesConductive materialsOxidation resistant

A method of providing an oxidation resistant coating is disclosed. The method includes providing a substrate having a first surface and cooling holes. A portable coating device includes electro-spark deposition (ESD) equipment and an ESD torch connected with the ESD equipment. The ESD torch has an inert gas source and a rotary electrode conductive material. The rotary electrode is positioned within the ESD torch, and is shielded by an inert gas. The rotary electrode applies a compositionally controlled protective coating to the first surface of the substrate. Then the rotary electrode is inserted into the cooling hole and generates an electrospark between rotary ESD electrode and the substrate to form a rounded edge and deposit a coating of electrode material alloy at a cooling hole edge.

Owner:GENERAL ELECTRIC CO

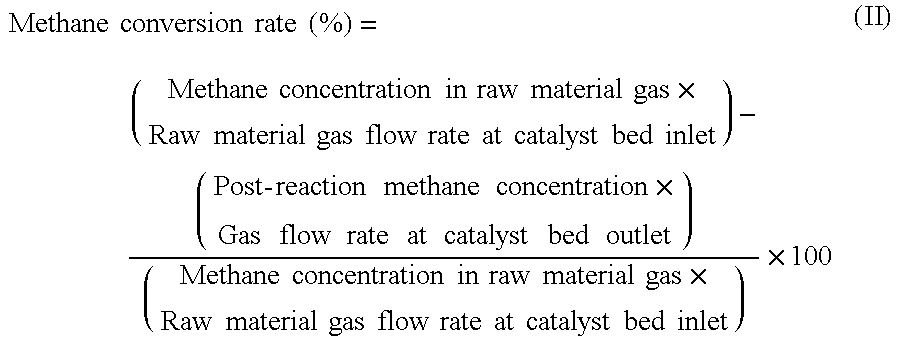

Composite oxide for hydrocarbon reforming catalyst, process for producing the same, and process for producing syngas using the same

A composite oxide for a hydrocarbon reforming catalyst which maintains the catalytic activity at a high level over a long period of time, a process for producing the catalyst, and a process for producing syngas using the catalyst, are provided. The composite oxide for a hydrocarbon reforming catalyst is obtained by a process including preparing a mixed solution for impregnation which contains catalytic active components of Co, or Co and Ni, one or more oxidation resistance enhancing components selected from the elements of Group 3B and the elements of Group 6A of the Periodic Table, and one or more additive metal components selected from Ca and Mg; impregnating a carrier formed from a porous molded body selected from magnesia and a composite of magnesia and calcia, with the mixed solution for impregnation; drying the impregnated carrier; and calcining the dried carrier in an oxidizing atmosphere.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com