Patents

Literature

32results about How to "More resilient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

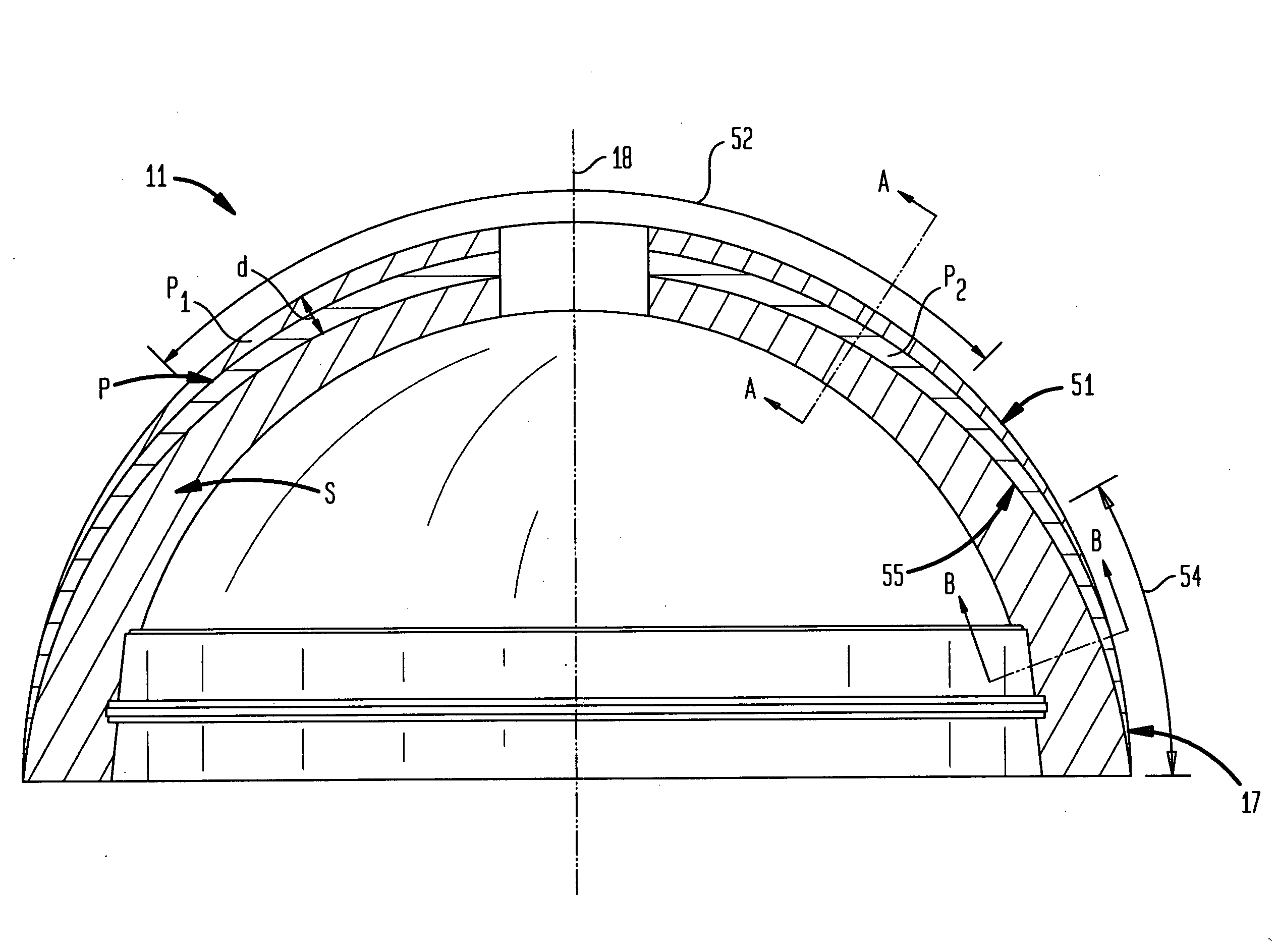

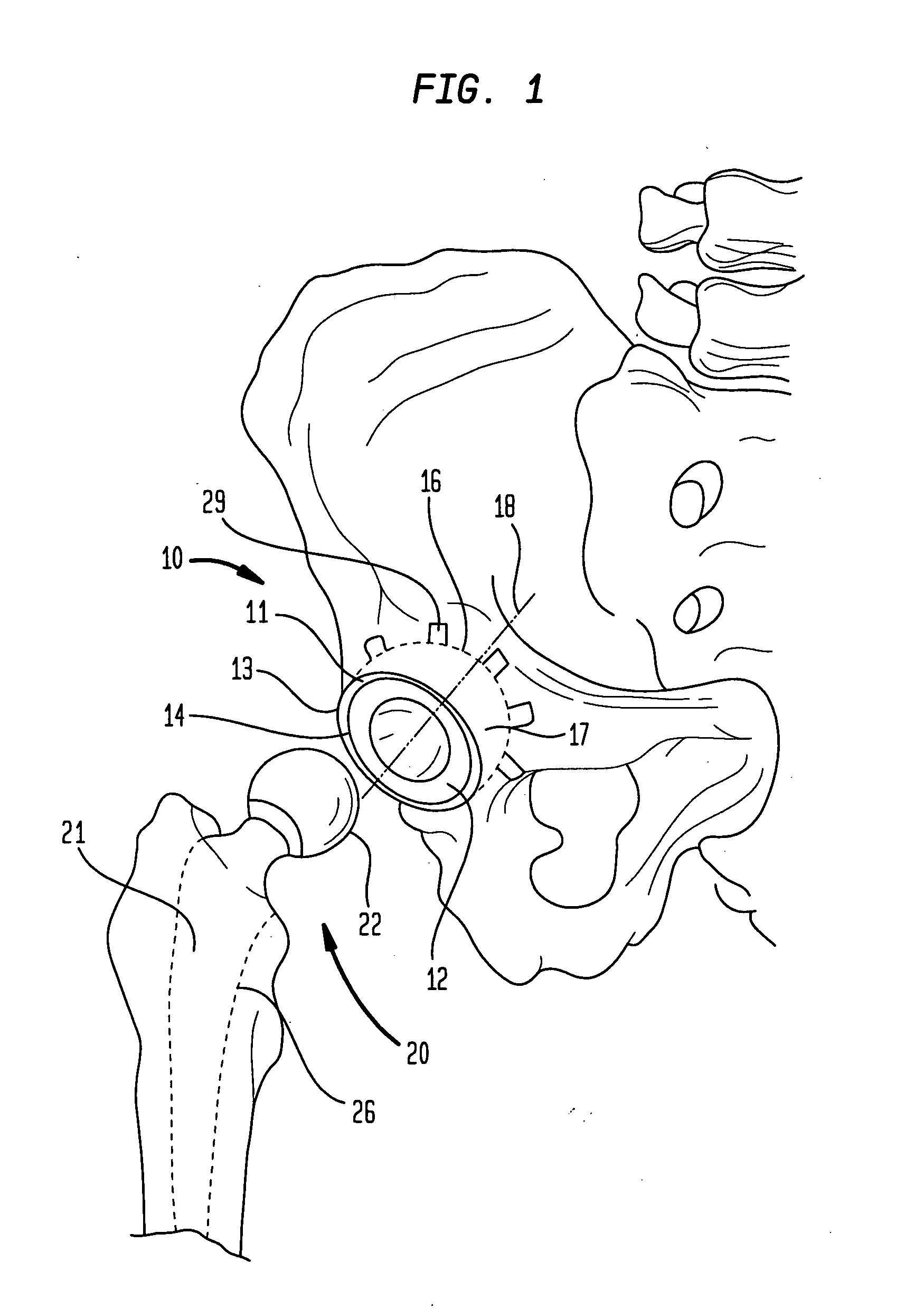

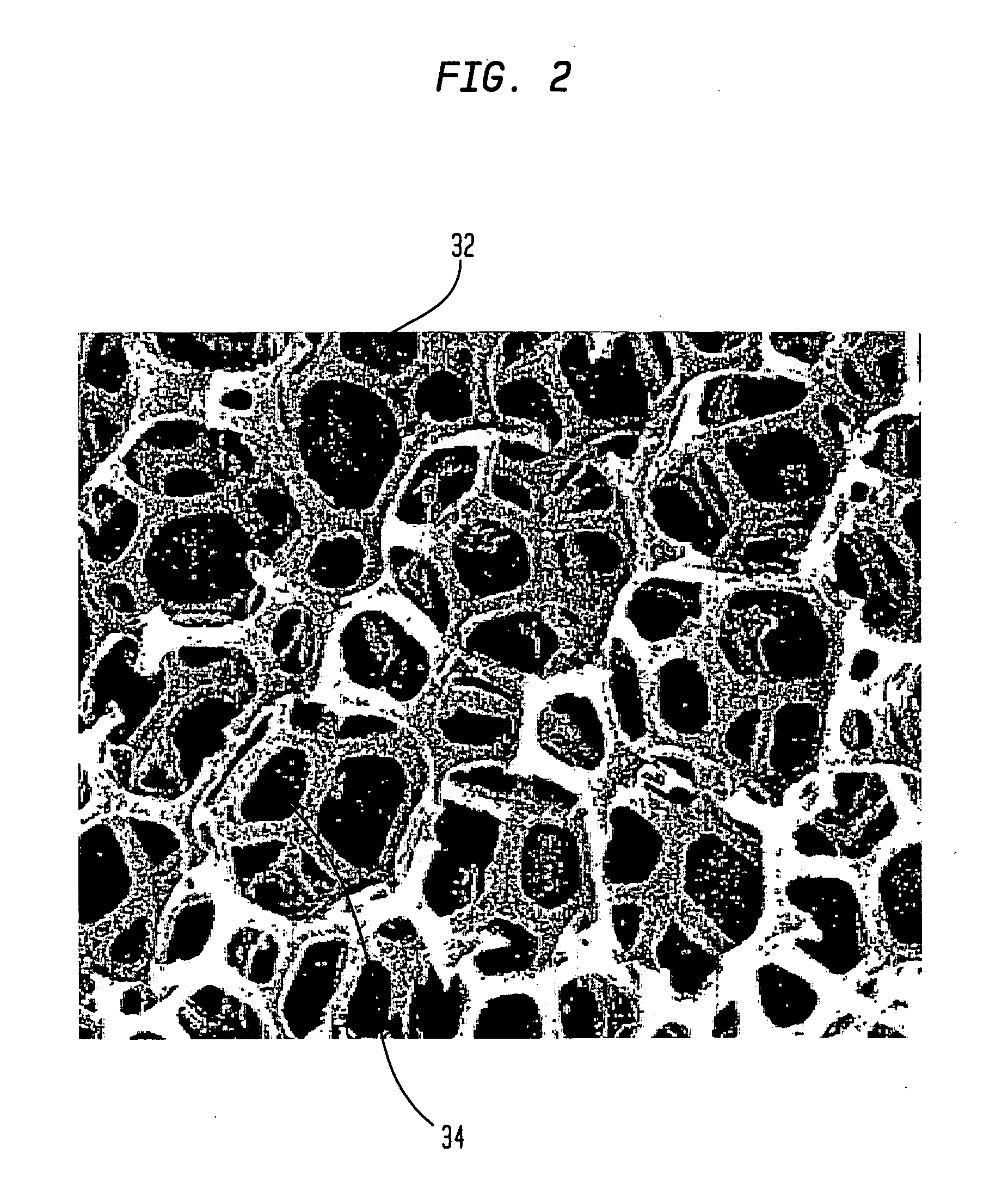

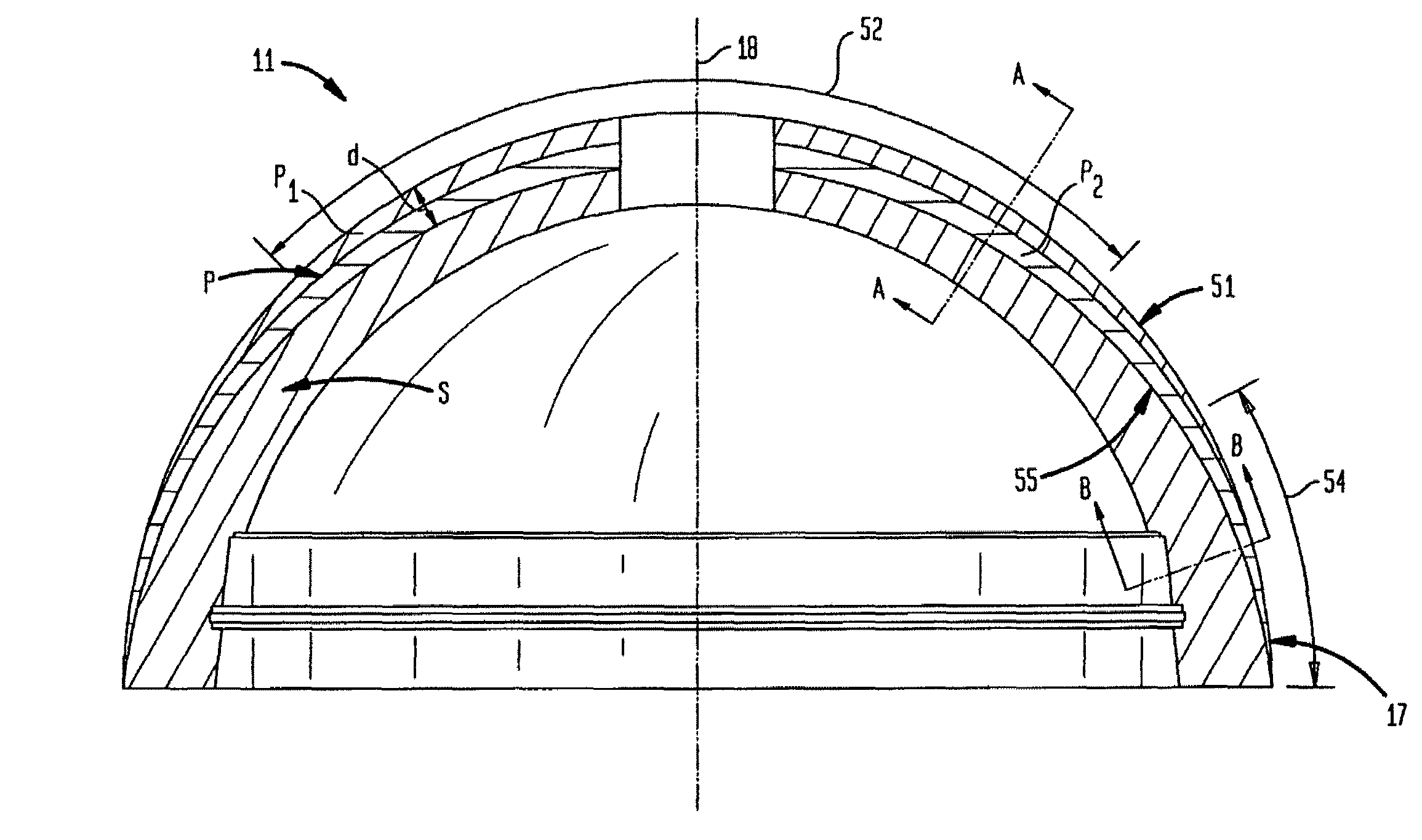

Gradient porous implant

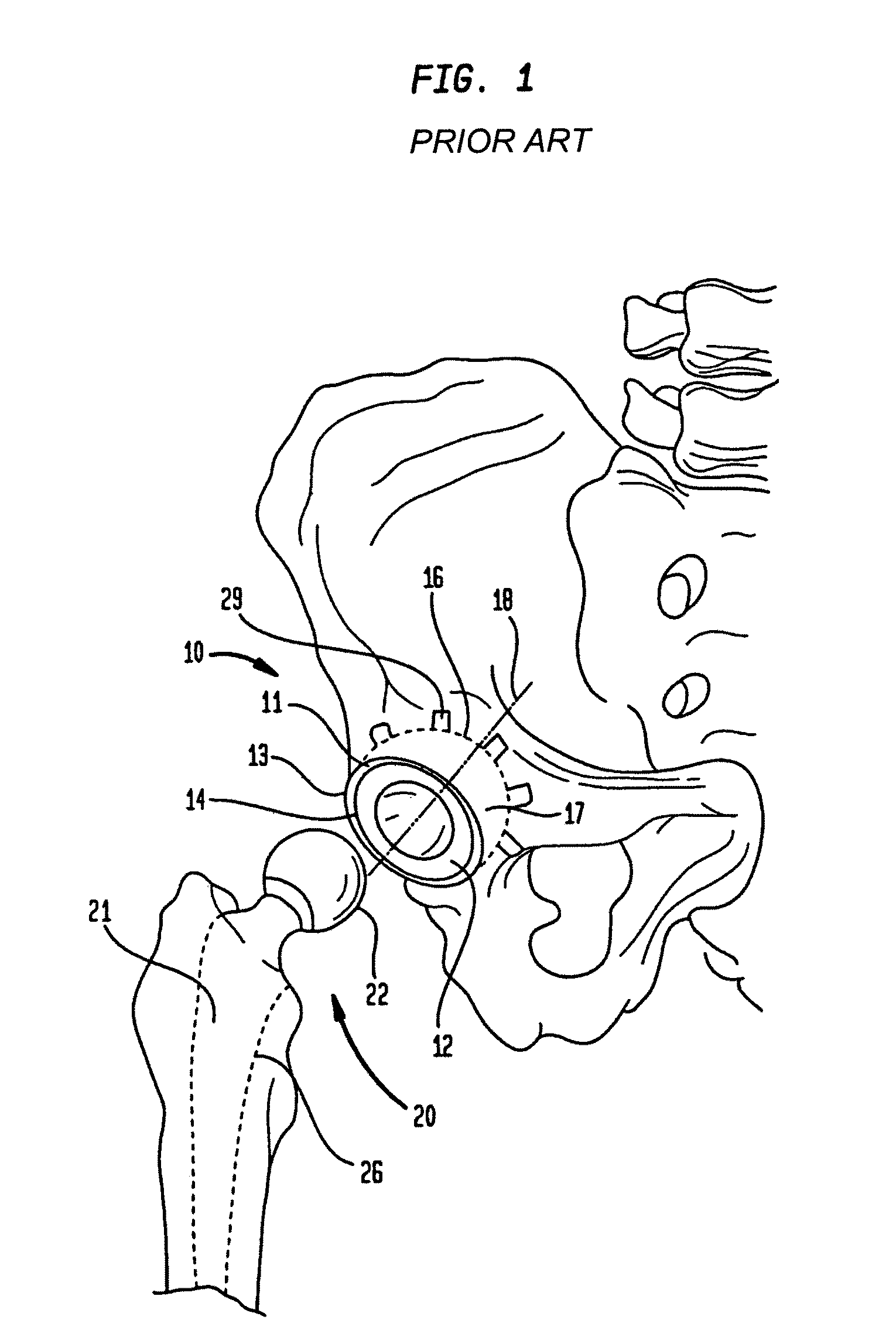

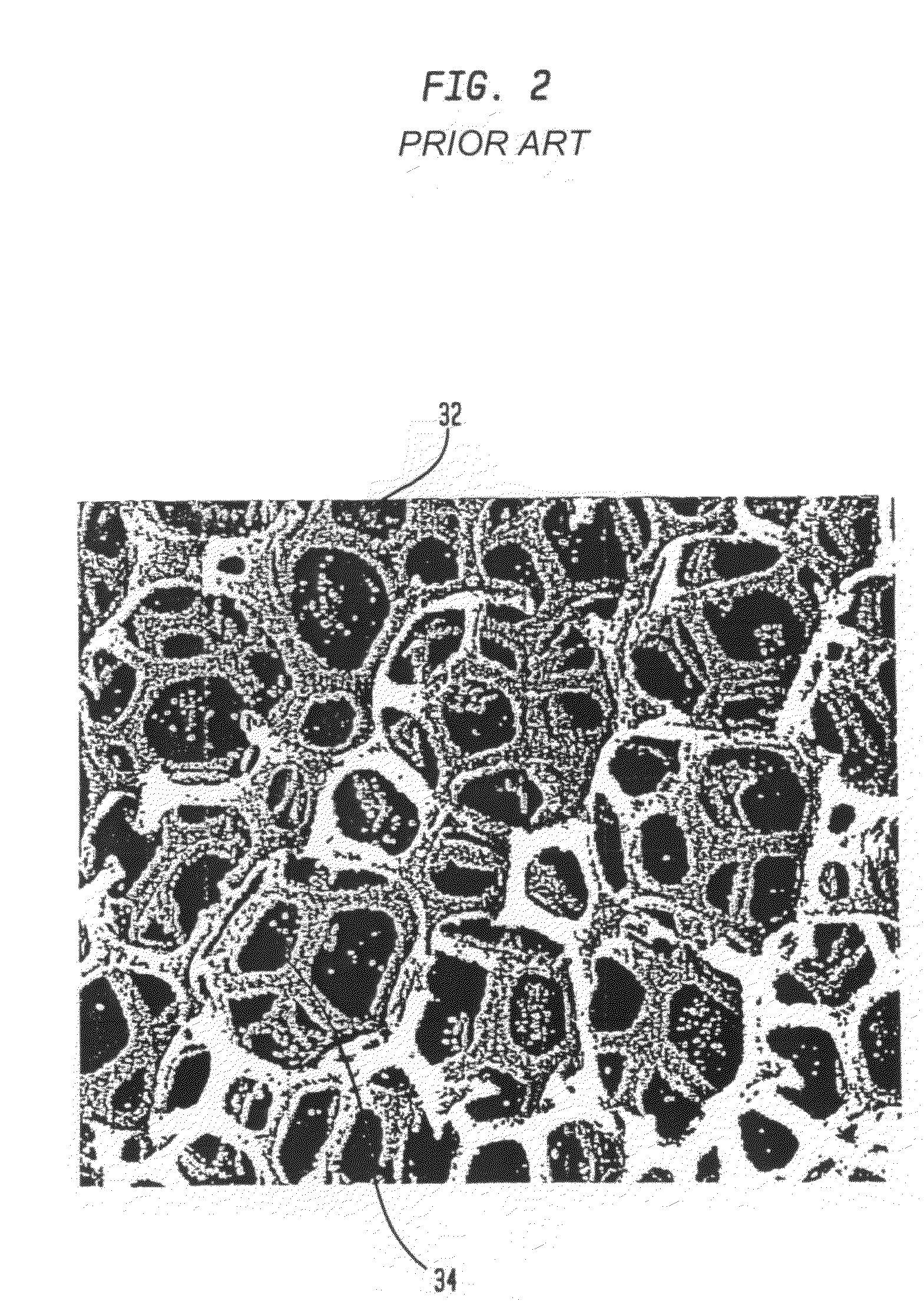

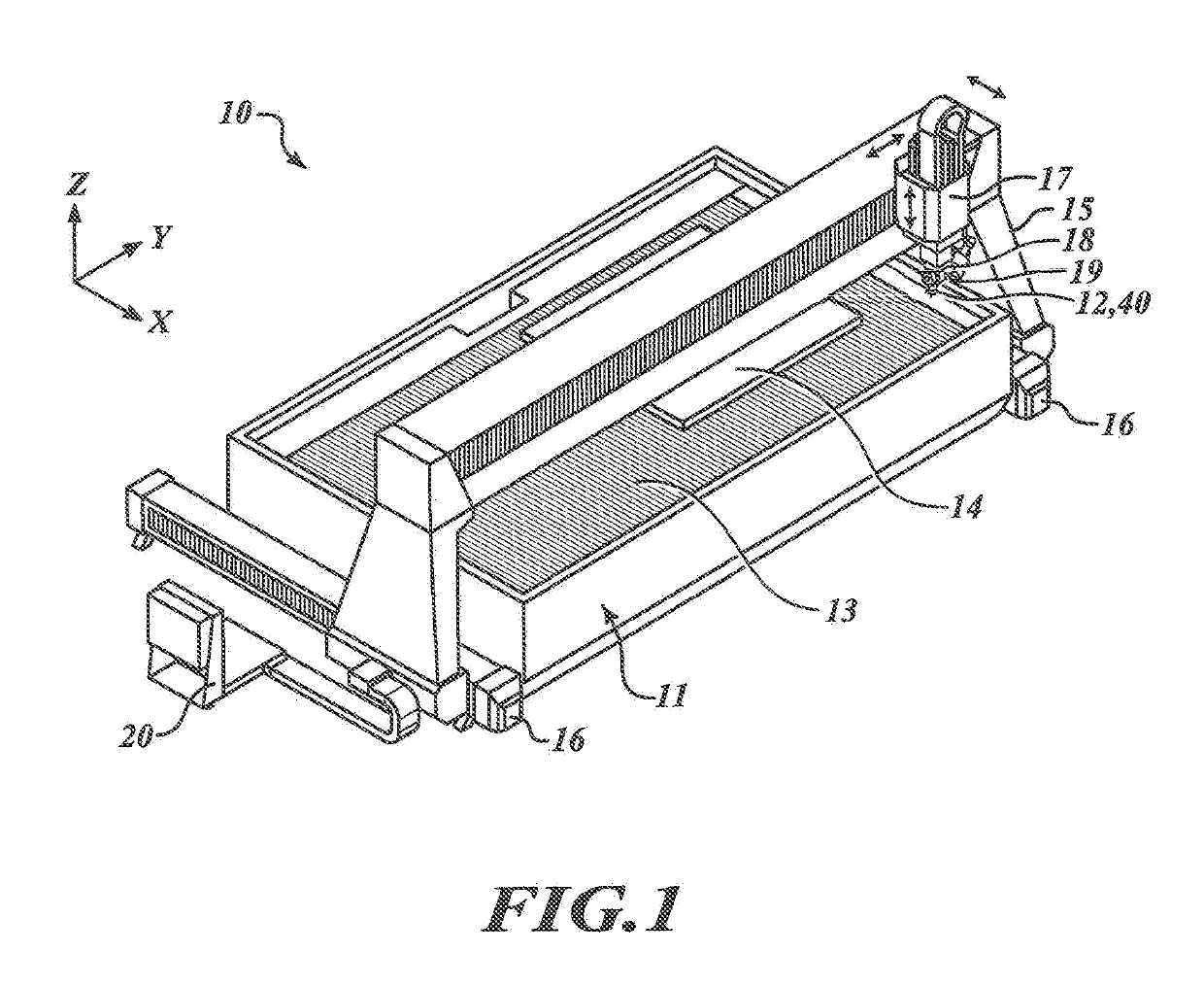

ActiveUS20070150068A1Optimize performanceOptimizes various mechanical and biological requirements of the implants performanceAdditive manufacturing apparatusBone implantPorous metalMedical treatment

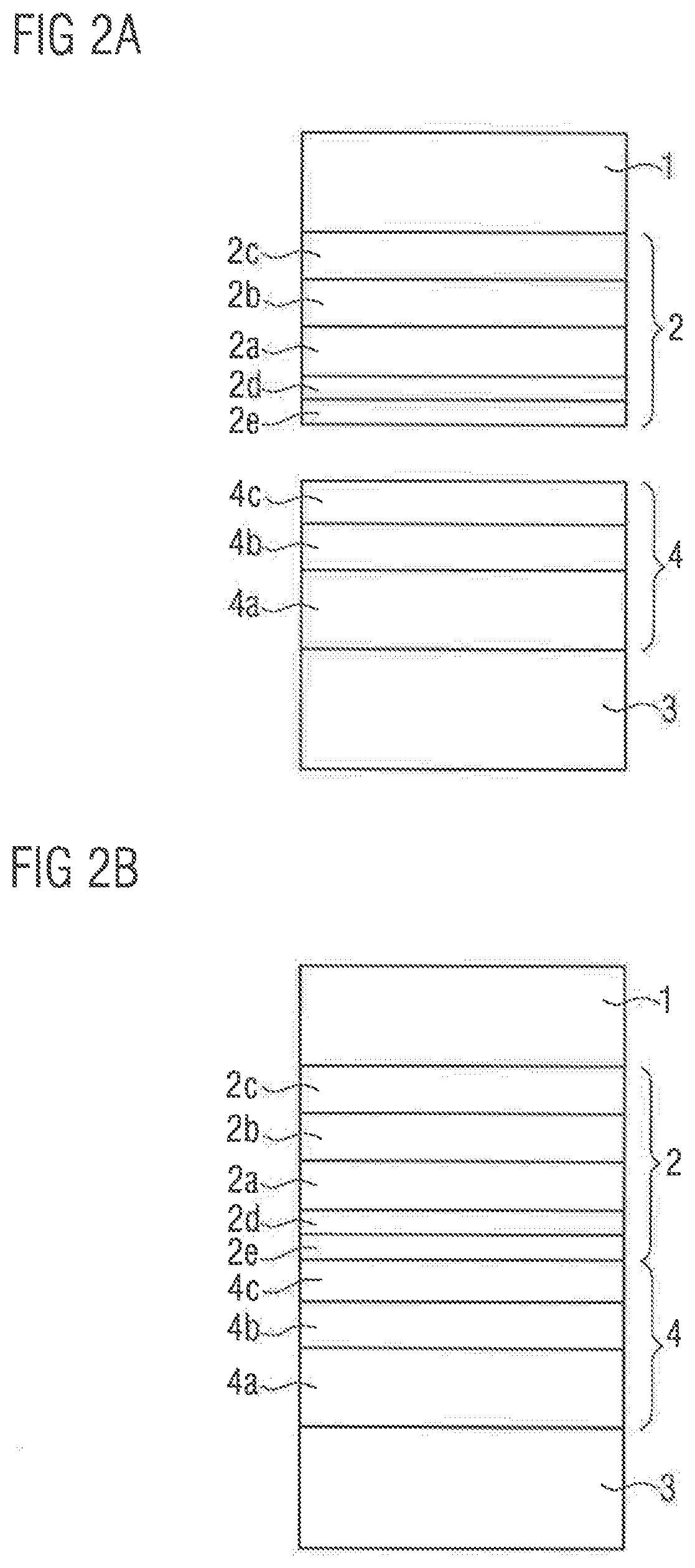

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

Gradient porous implant

ActiveUS7578851B2Optimizes various mechanical and biological requirements of the implants performanceIncreasing the thicknessAdditive manufacturing apparatusBone implantPorous implantMedical device

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

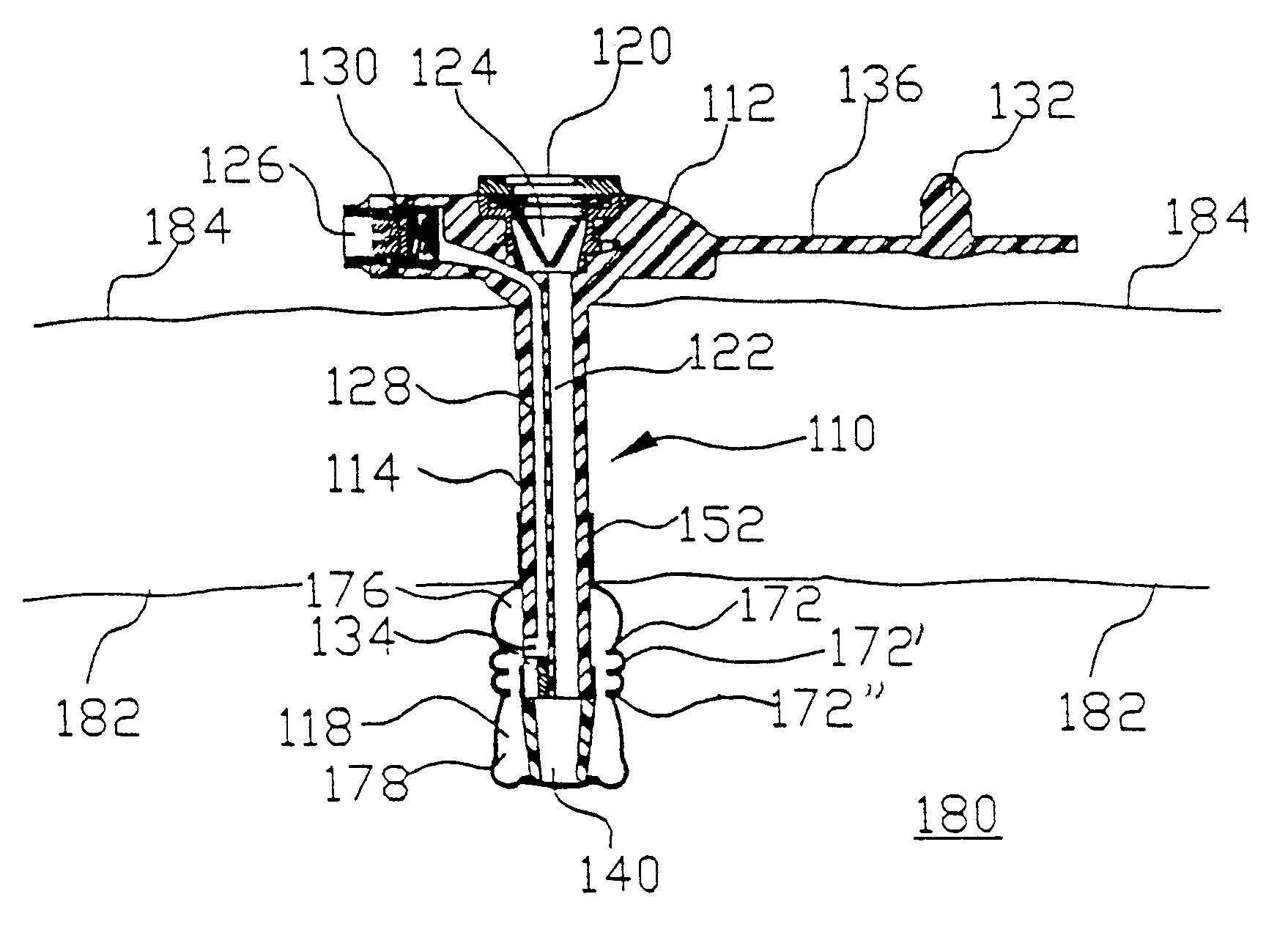

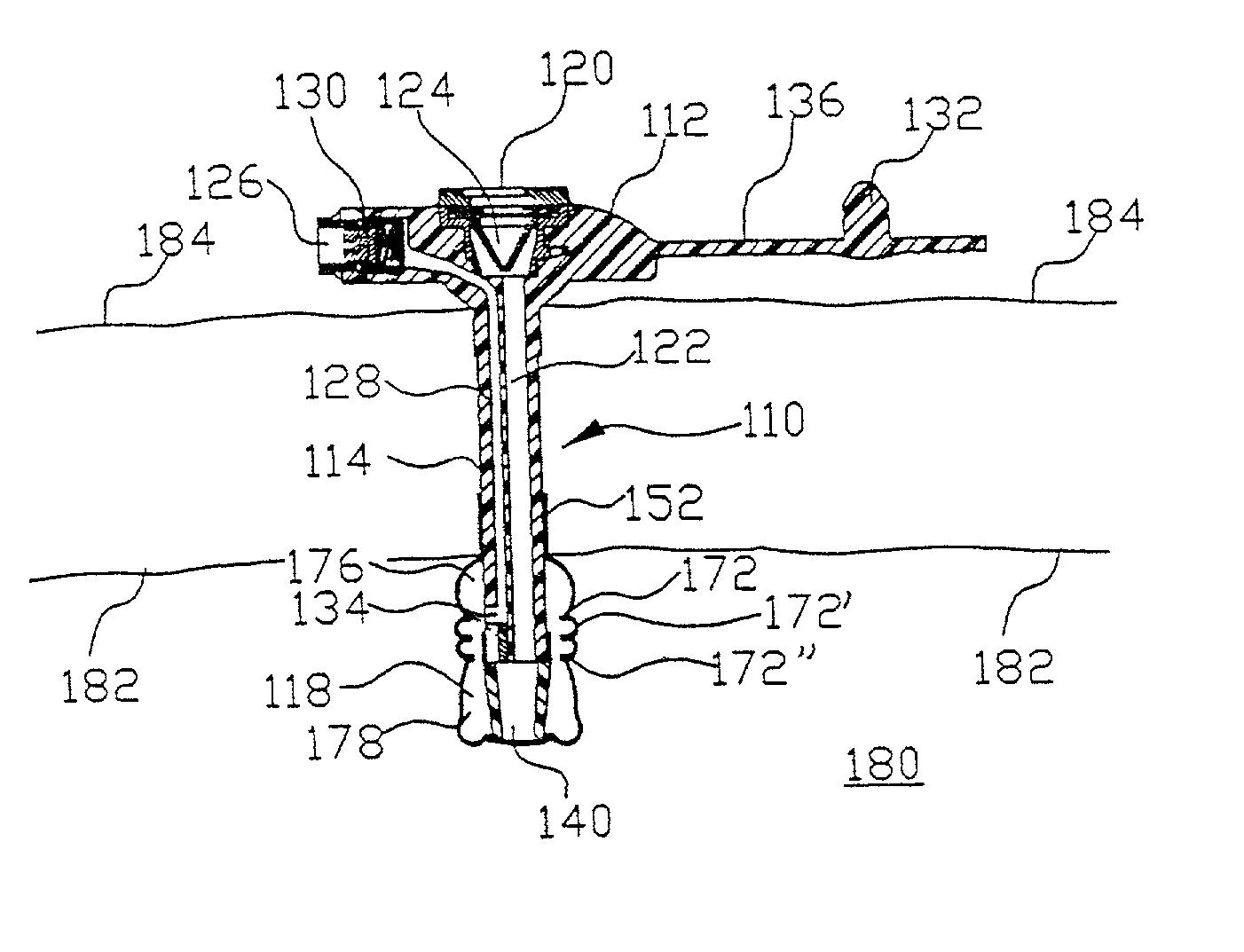

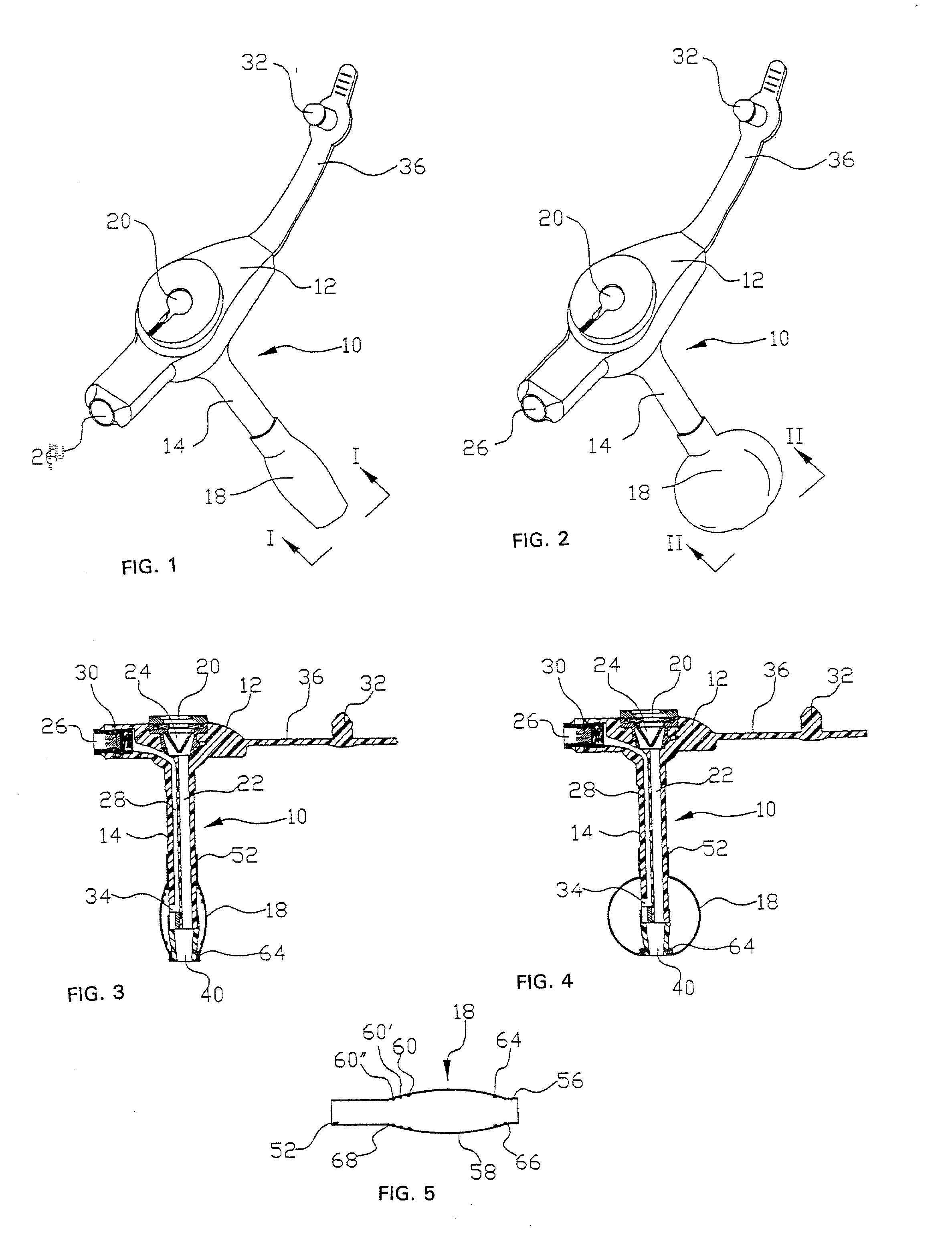

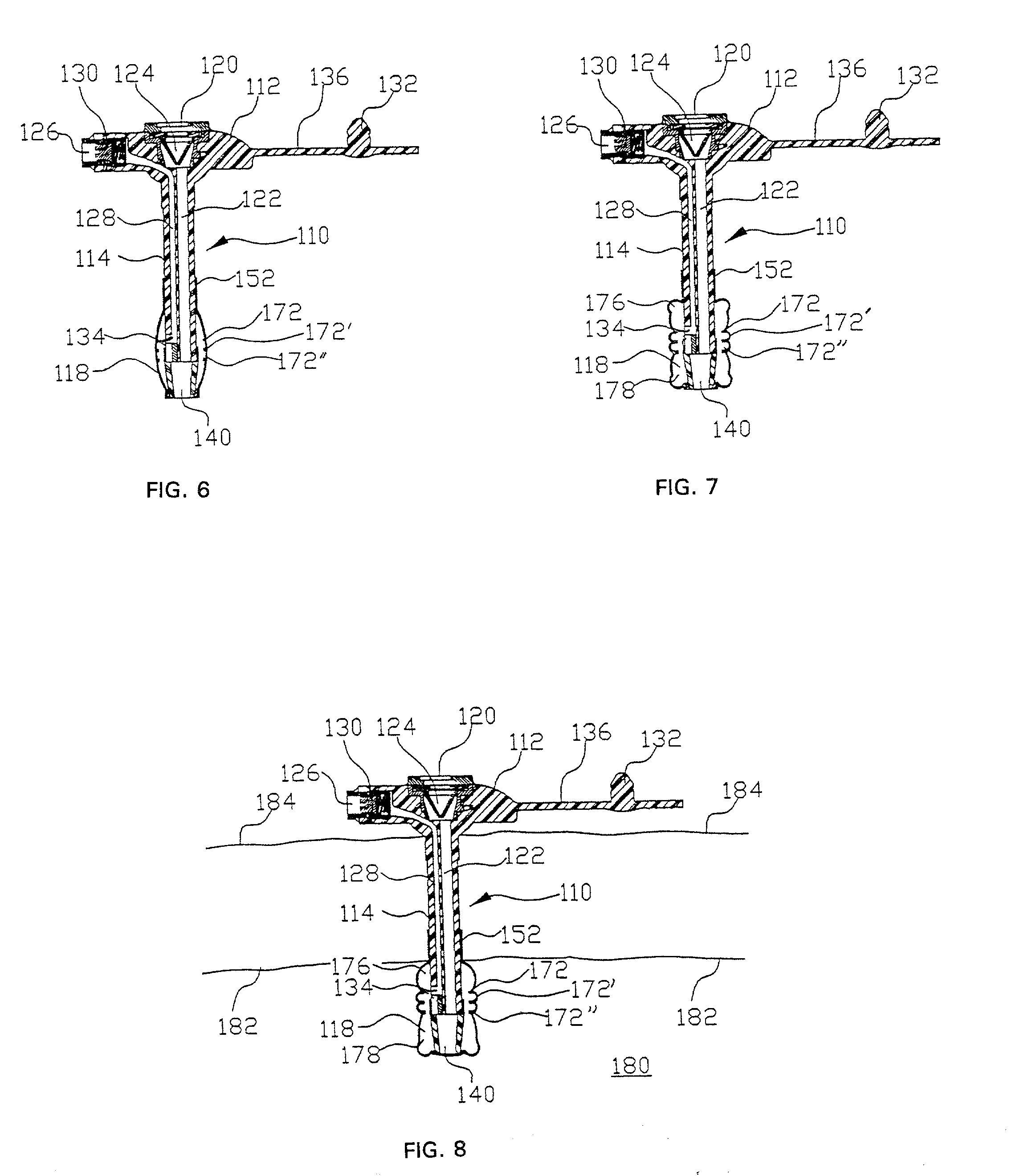

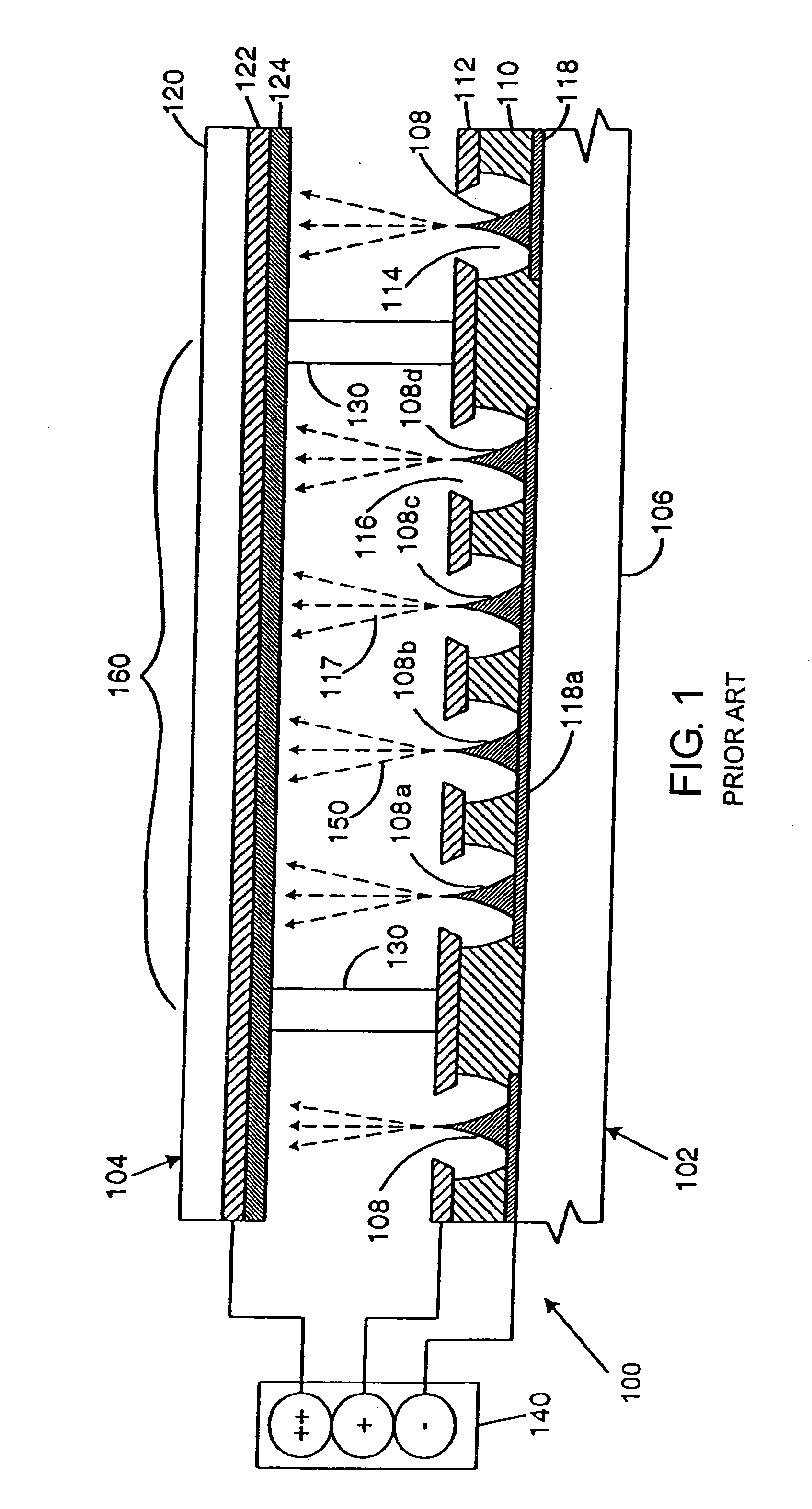

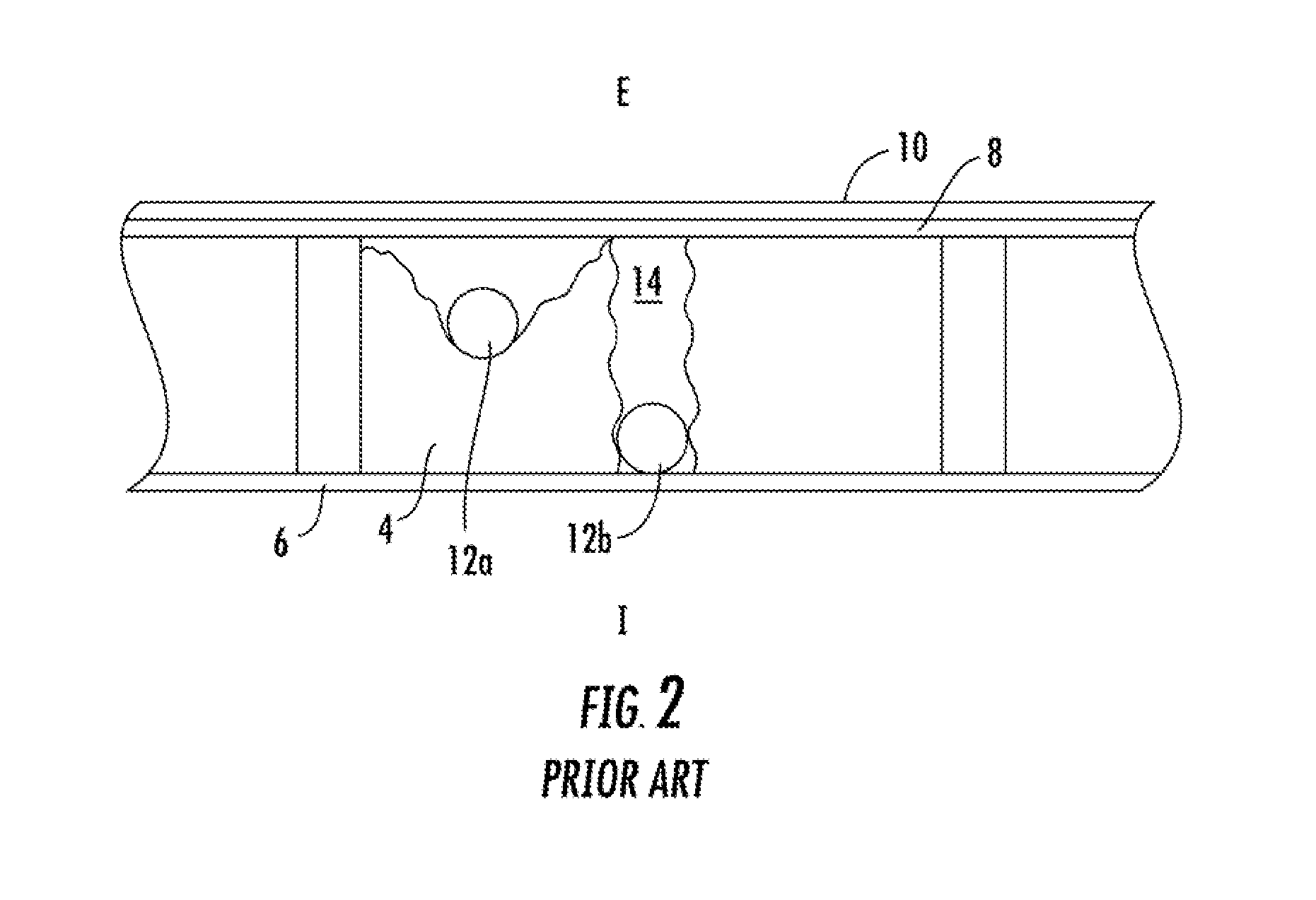

Catheter with distally distending balloon

InactiveUS6264631B1Avoid stimulationIncrease surface areaSurgeryMedical devicesEnteral feedingsBalloon catheter

A balloon catheter having a balloon disposed upon an elongate shaft near a relatively rigid distal insertion tip, a fluid lumen for fluid communication with a body cavity and an inflation lumen for fluid communication with the balloon. The balloon holds the catheter tip within a body cavity such as the stomach for long-term enteral feeding. The balloon is configured such that upon inflation, the balloon distends distally to cover the distal tip thus insulating it from sensitive anatomy.

Owner:KIMBERLY-CLARK WORLDWIDE INC

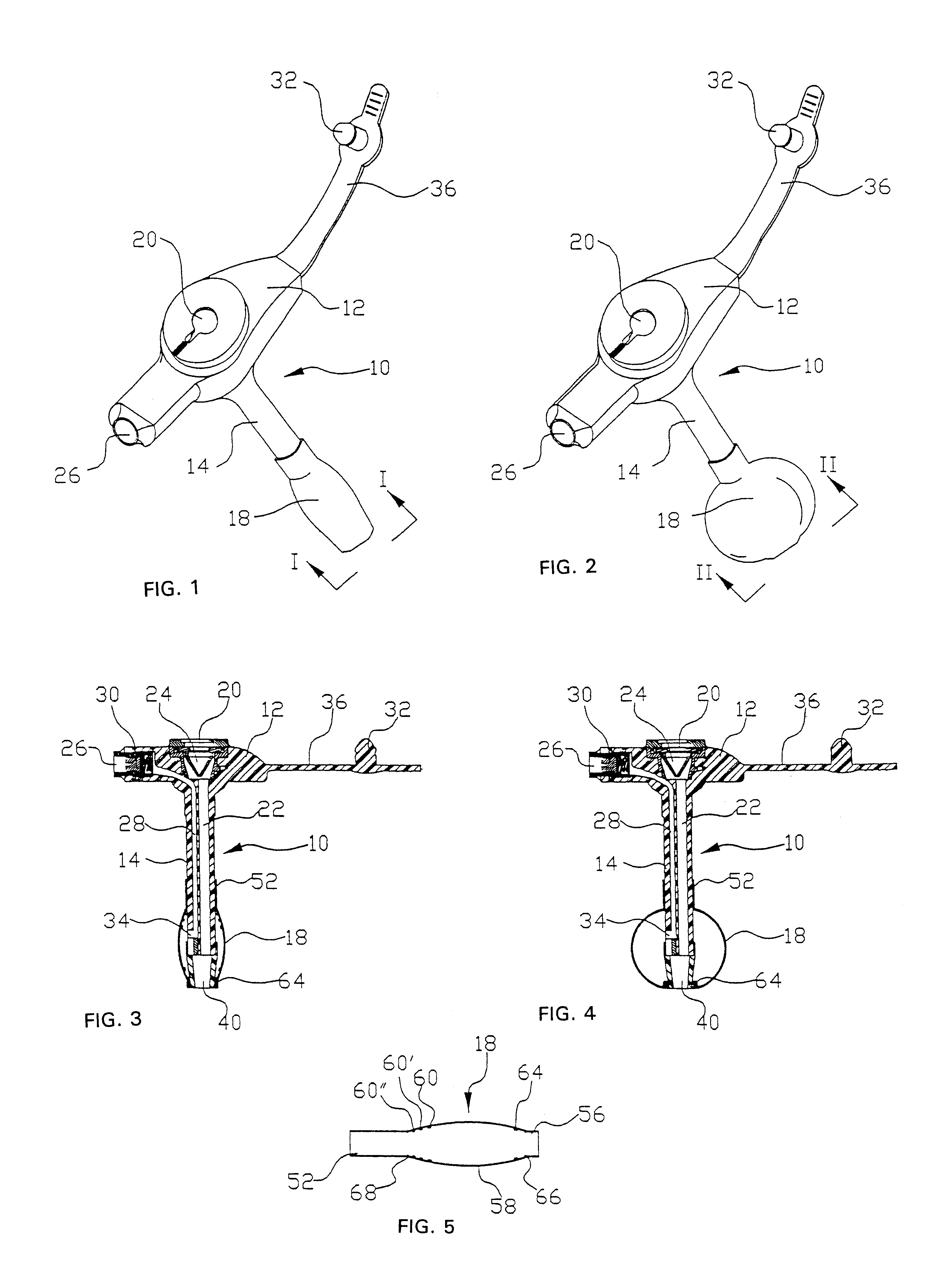

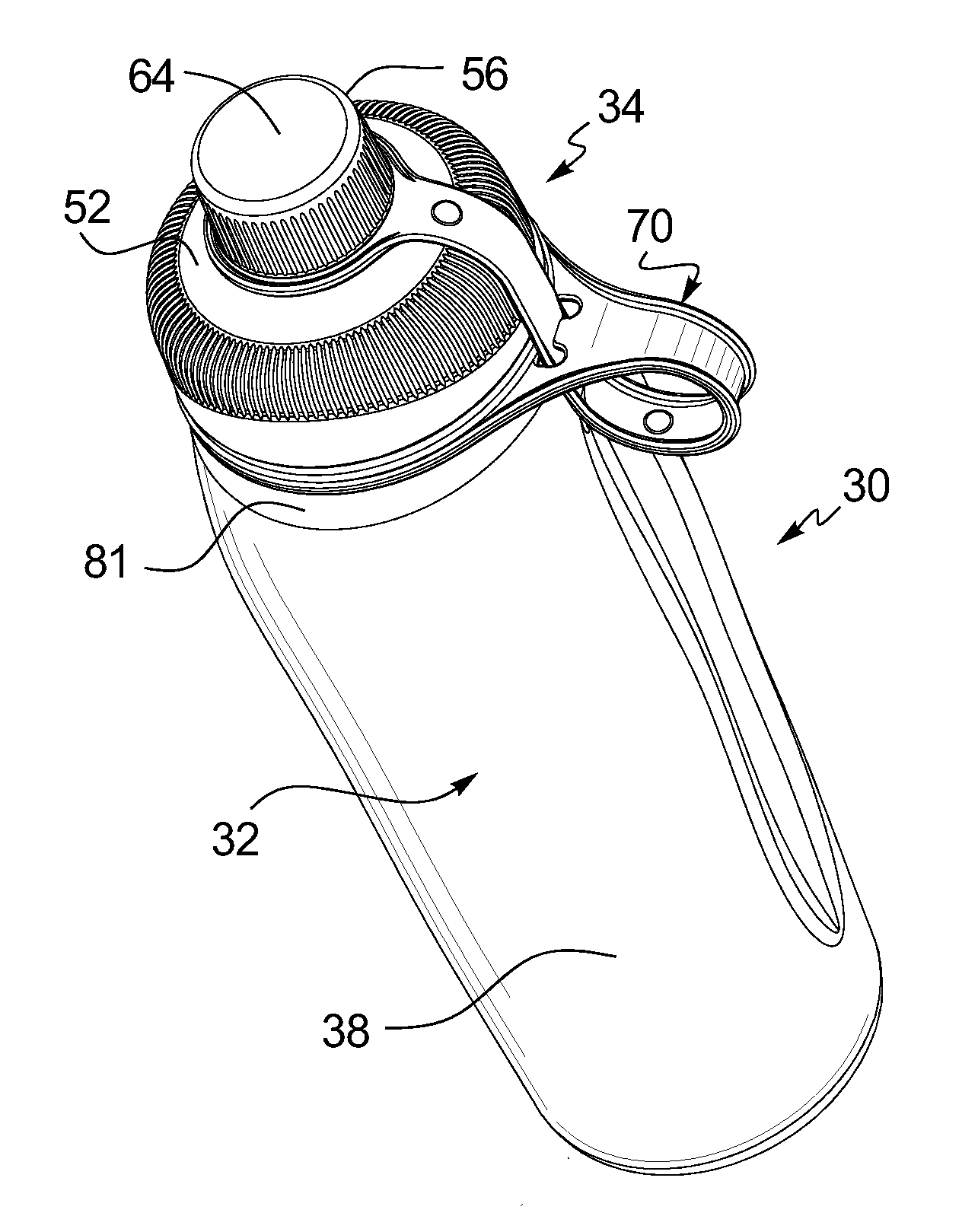

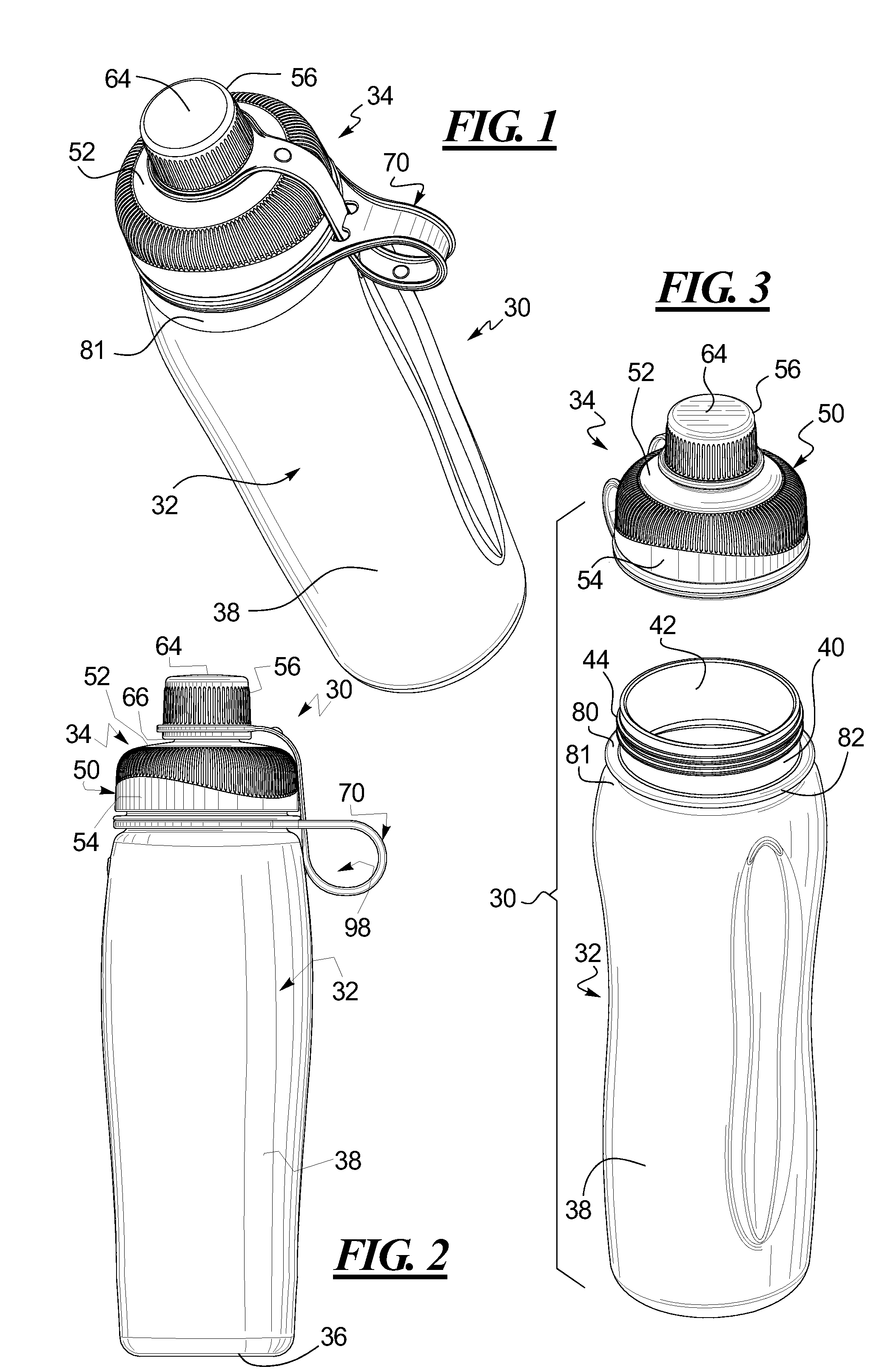

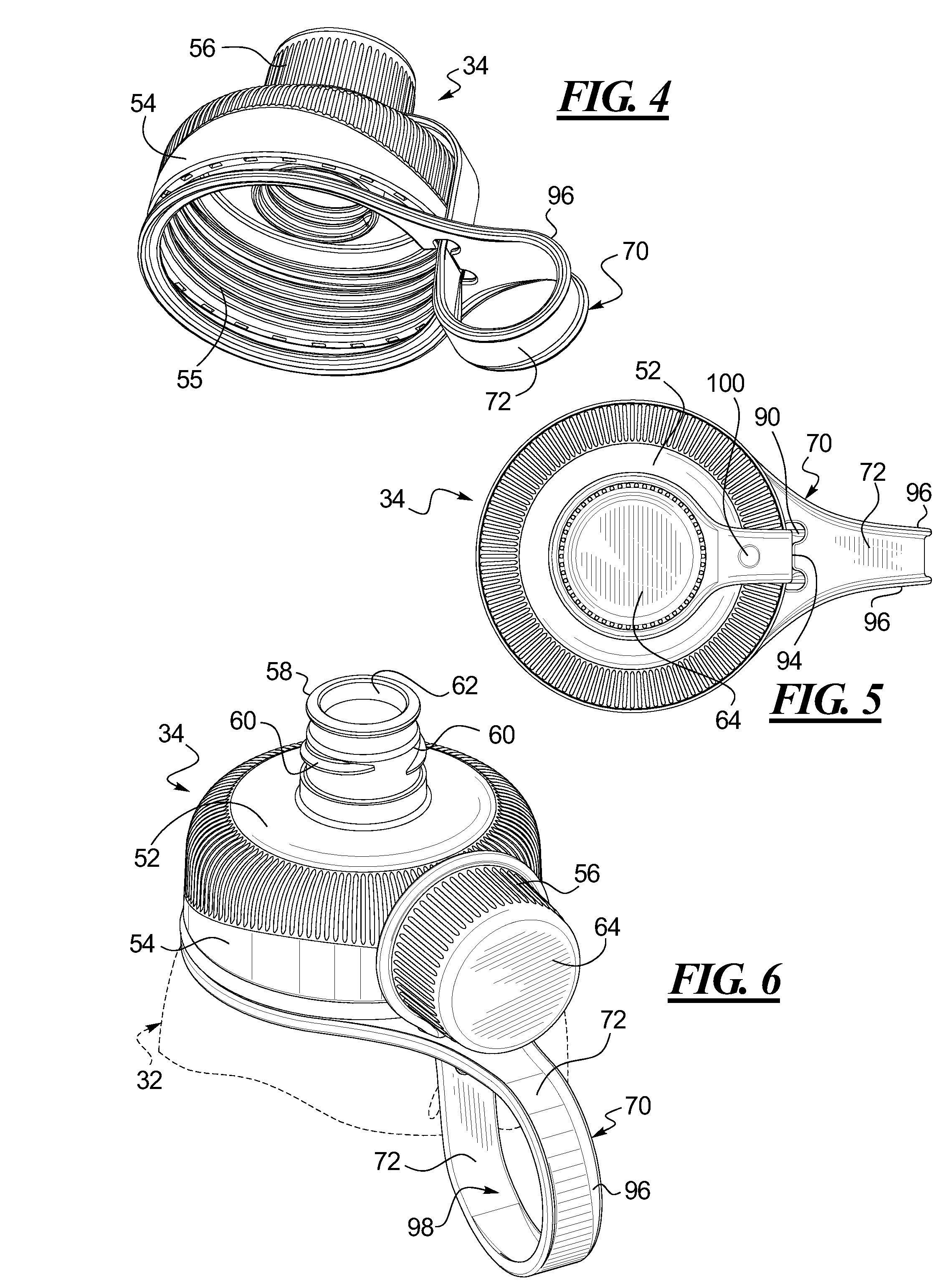

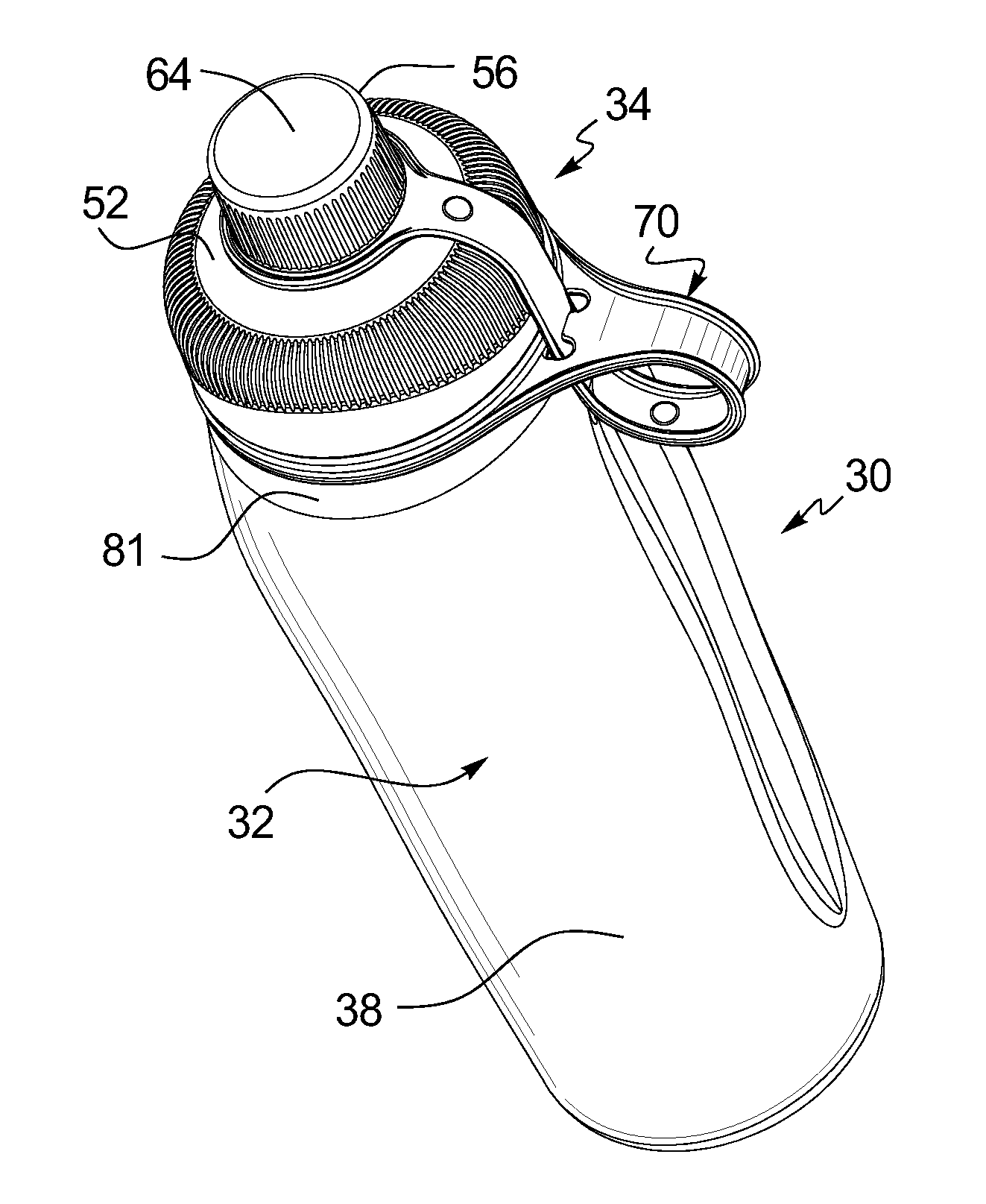

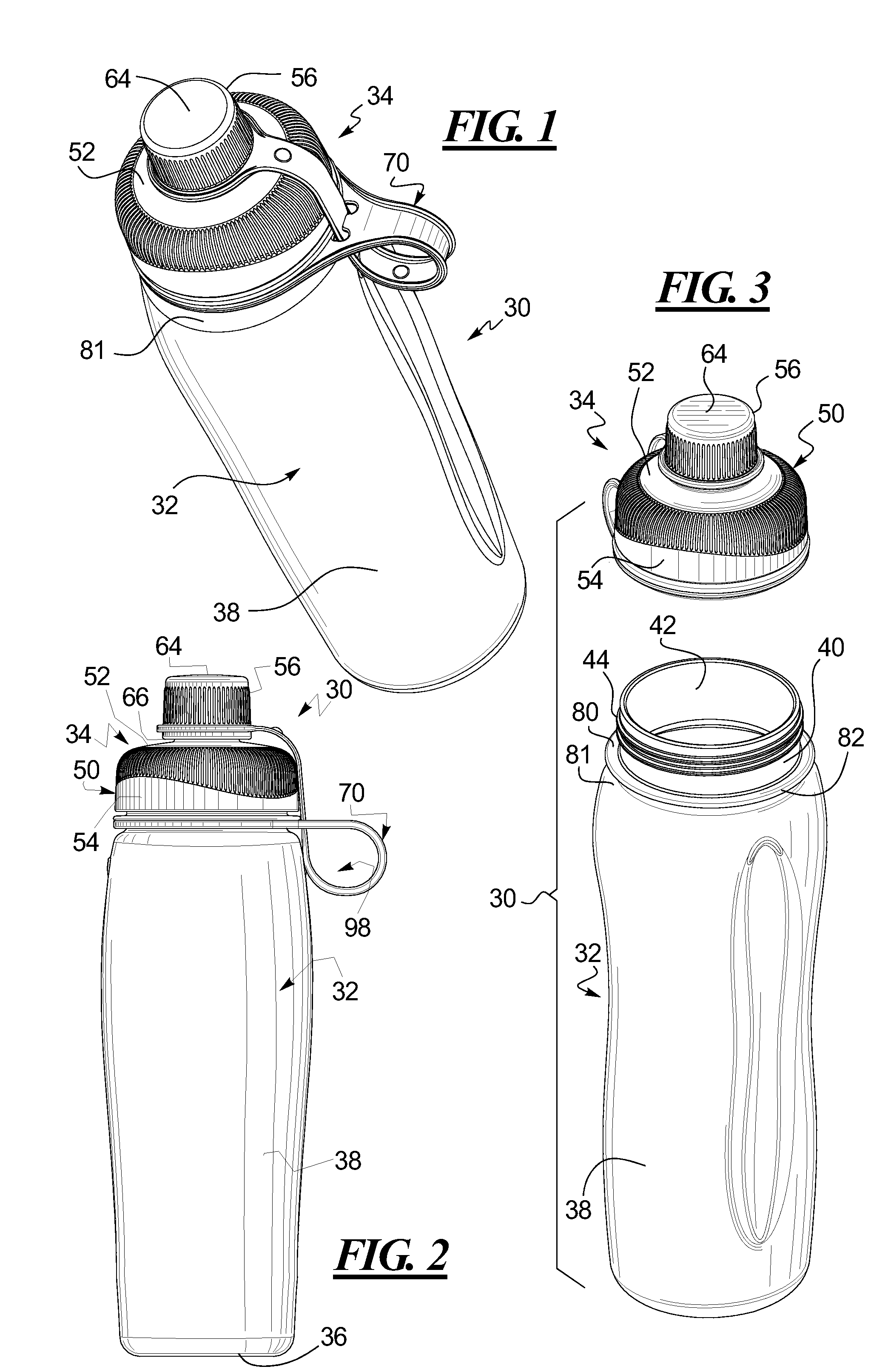

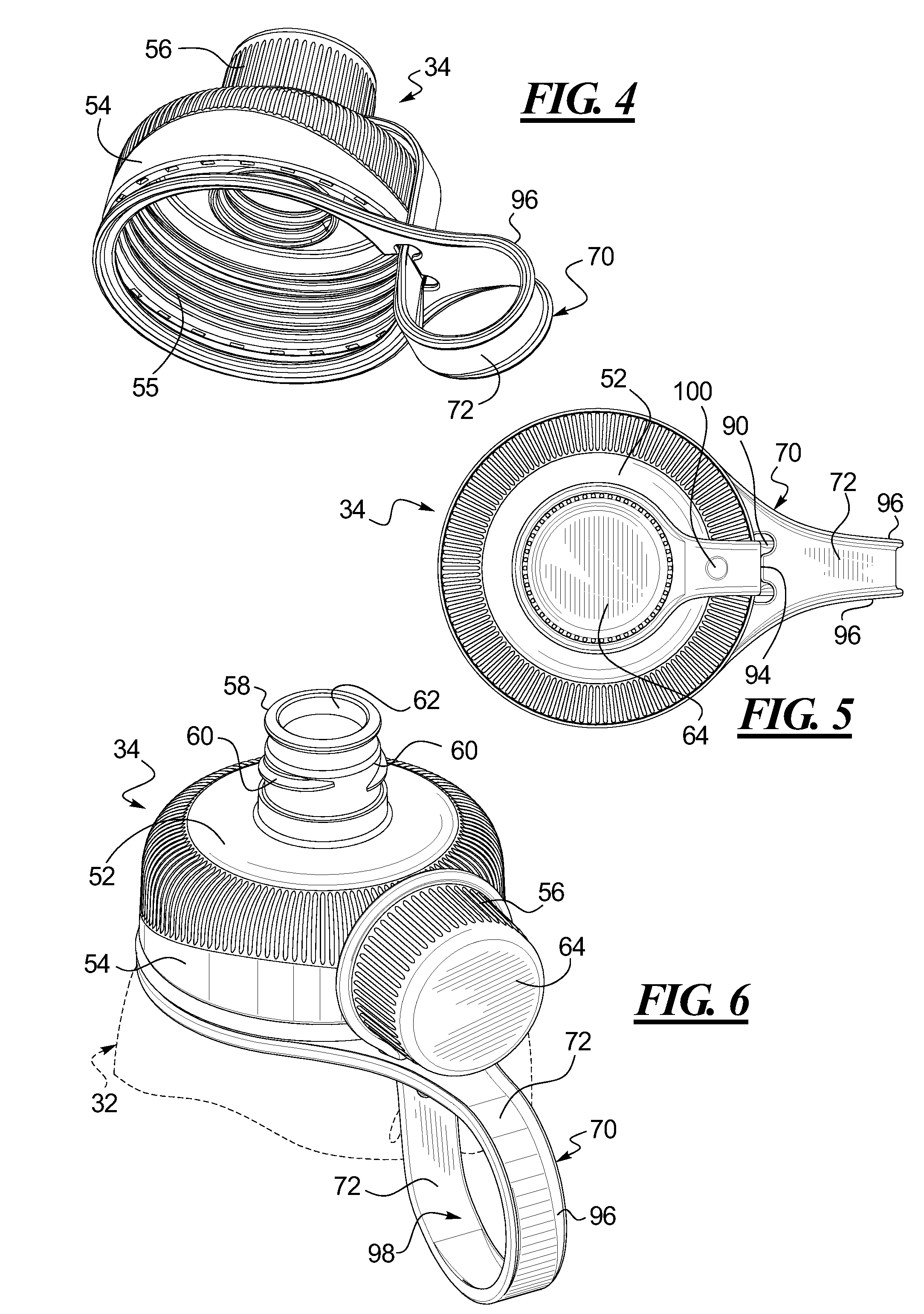

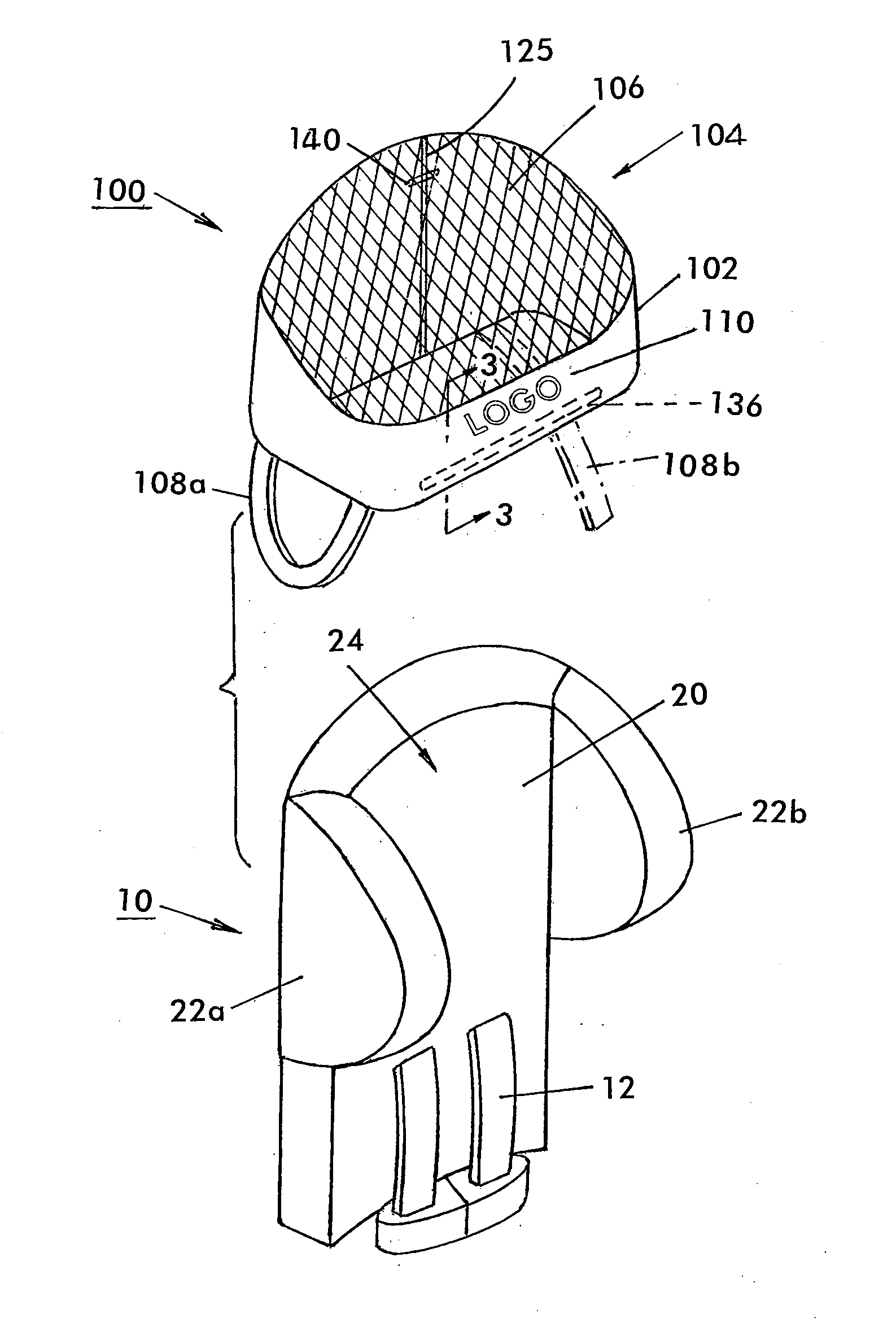

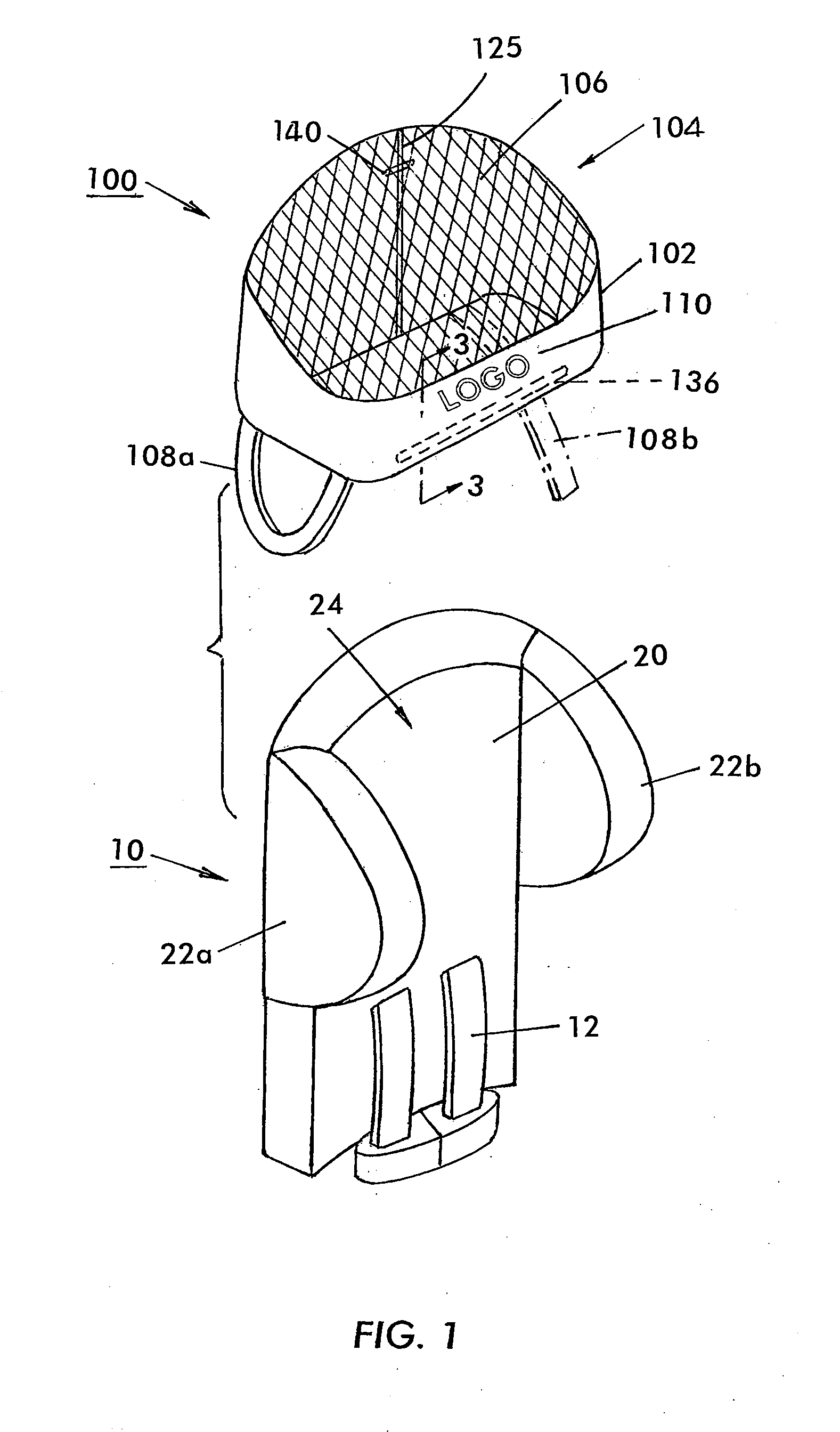

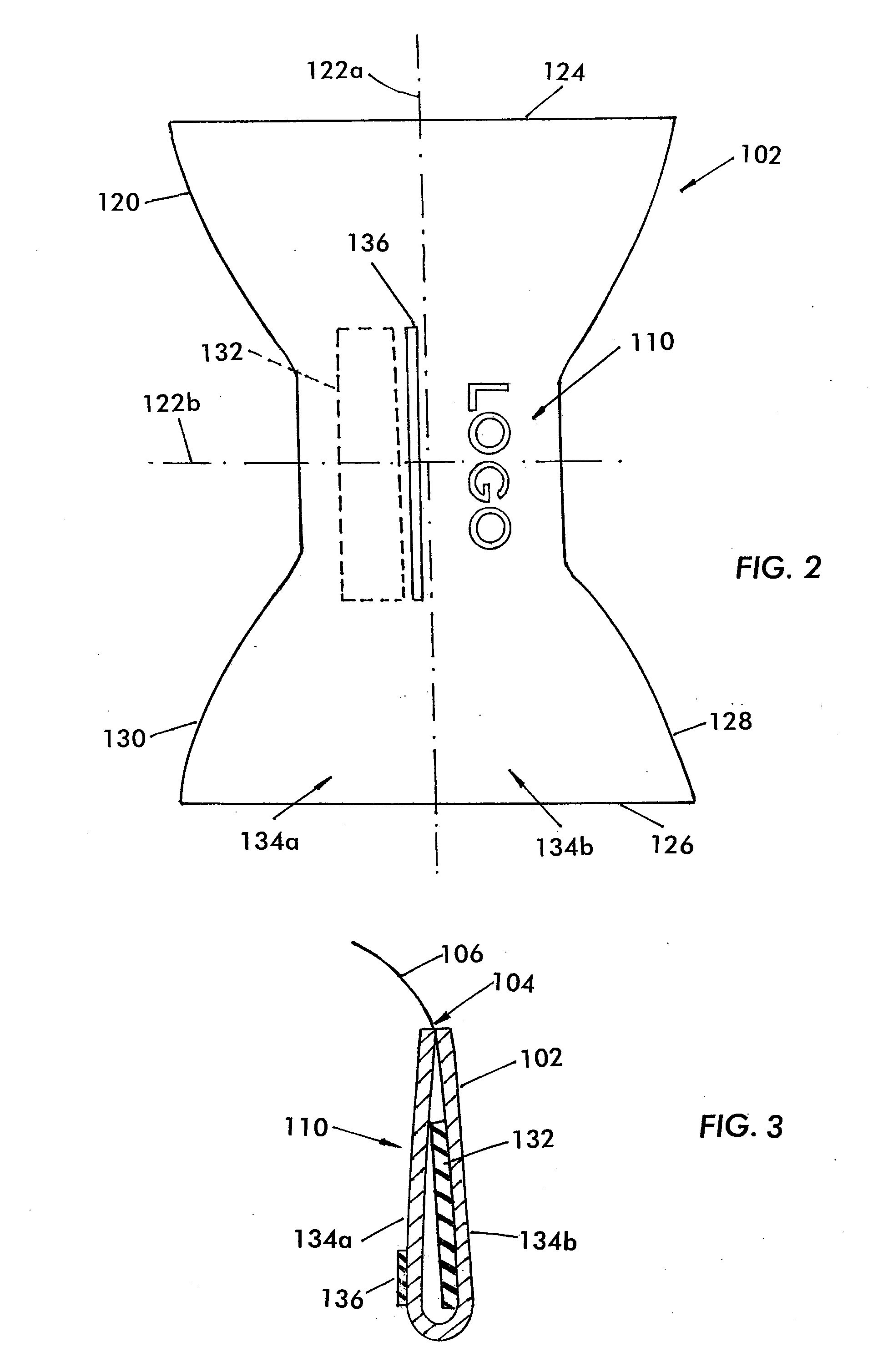

Container Cap with Tether

A drinking container has a bottle with an open top, a cap assembly attachable to the bottle to cover the open top, and a drinking spout with a top opening on the cap assembly. A spout cover is removably fitted on the top opening of the drinking spout. A flexible tether is connected to the spout cover and to the cap assembly or the bottle. The tether is looped unto itself permitting the spout cover and a portion of the tether to be extended to reach the top opening and to be retracted withdrawing the spout cover to a position remote from the drinking spout.

Owner:RUBBERMAID

Container cap with tether

A drinking container has a bottle with an open top, a cap assembly attachable to the bottle to cover the open top, and a drinking spout with a top opening on the cap assembly. A spout cover is removably fitted on the top opening of the drinking spout. A flexible tether is connected to the spout cover and to the cap assembly or the bottle. The tether is looped unto itself permitting the spout cover and a portion of the tether to be extended to reach the top opening and to be retracted withdrawing the spout cover to a position remote from the drinking spout.

Owner:IGNITE USA

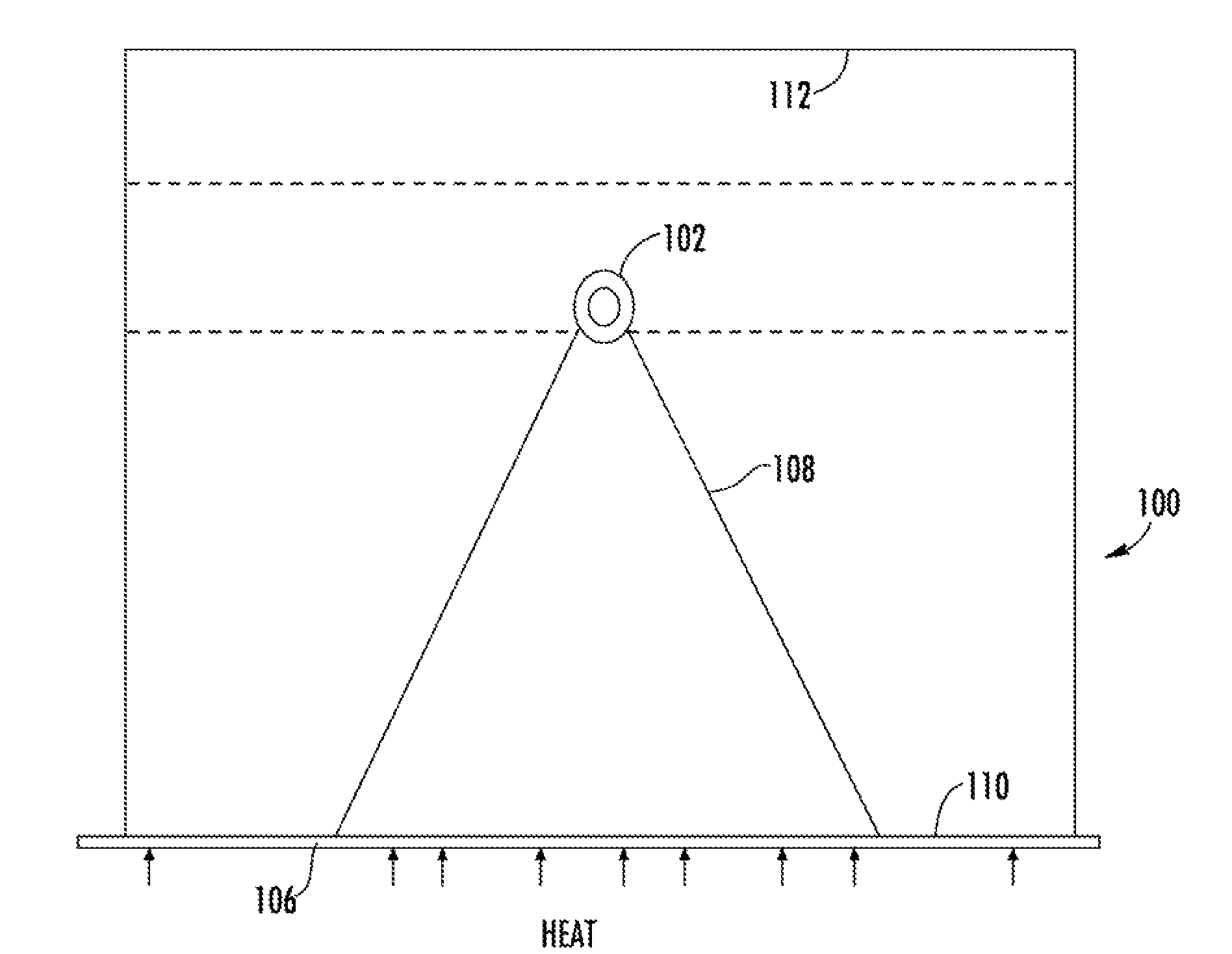

Thermally modified carbon blacks for various type applications and a process for producing same

InactiveUS20050063892A1Oxidation resistance can be improvedReduced metal and ash contentPigmenting treatmentMaterial nanotechnologyModified carbonOxidation resistant

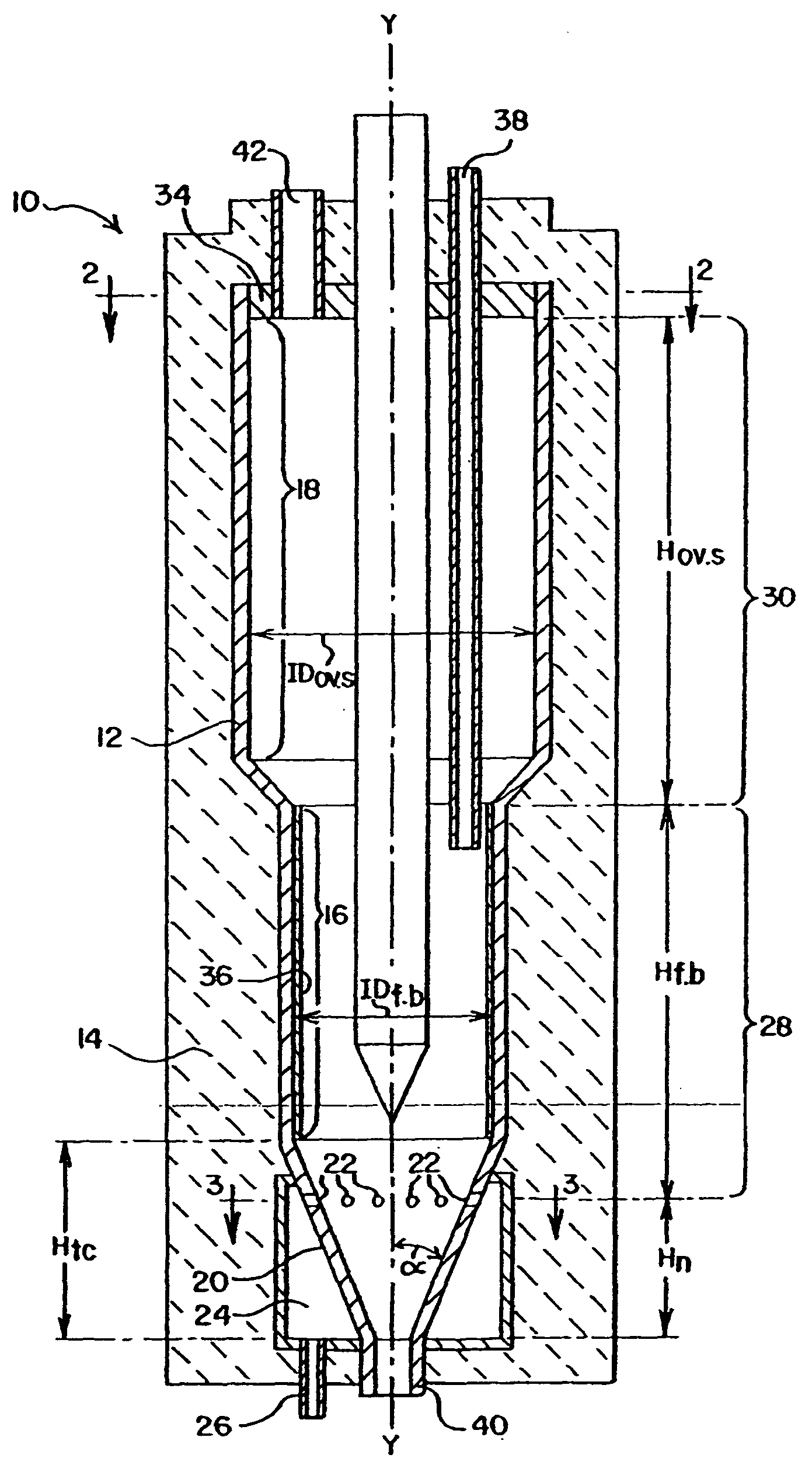

An electro thermal fluidized bed furnace is adapted to be used in a process for continuously heat treating of fine particulate matter, such as carbon black material, by continuously introducing a non-reactive fluidizing gas through the nozzles of the furnace at a pre-determined rate, continuously introducing untreated carbon black material through the feed pipe of the furnace at a predetermined rate so that it forms a fluidized bed, energizing the electrode so as to heat the fluidized bed, and continuously collecting the treated carbon black from the discharge pipe. The carbon black collected from the discharge pipe exhibits properties of having the PAHs and sulfur removed, the carbon black has been graphitized, the moisture pick-up by the carbon black has been eliminated and the carbon black is more oxidation resistant, Furthermore, the resultant furnace carbon backs have a particle size of 7-100 nm and an oil absorption number of 50-300 ml / 100 g., while the thermal blacks have a particle size of 200-500 nm and an oil absorption number of less than 50 ml / 100 g. All of these properties result in thermally modified carbon blacks having such properties and of such purity so as to provide improved performance properties in food contact type applications, moisture cured polymer systems, zinc-carbon dry cell battery applications, and semi-conductive wire and cable applications.

Owner:COLUMBIAN CHEM CO +1

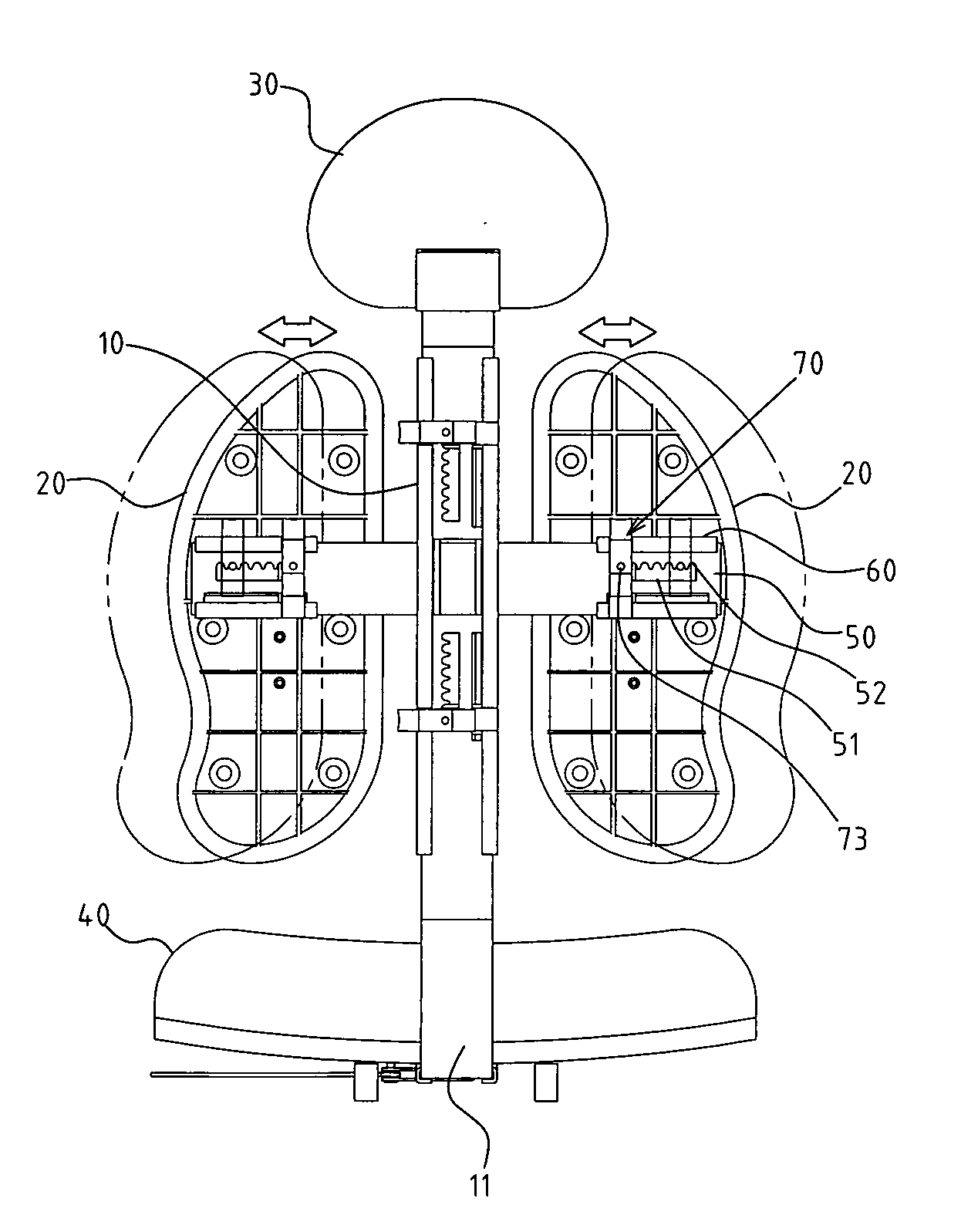

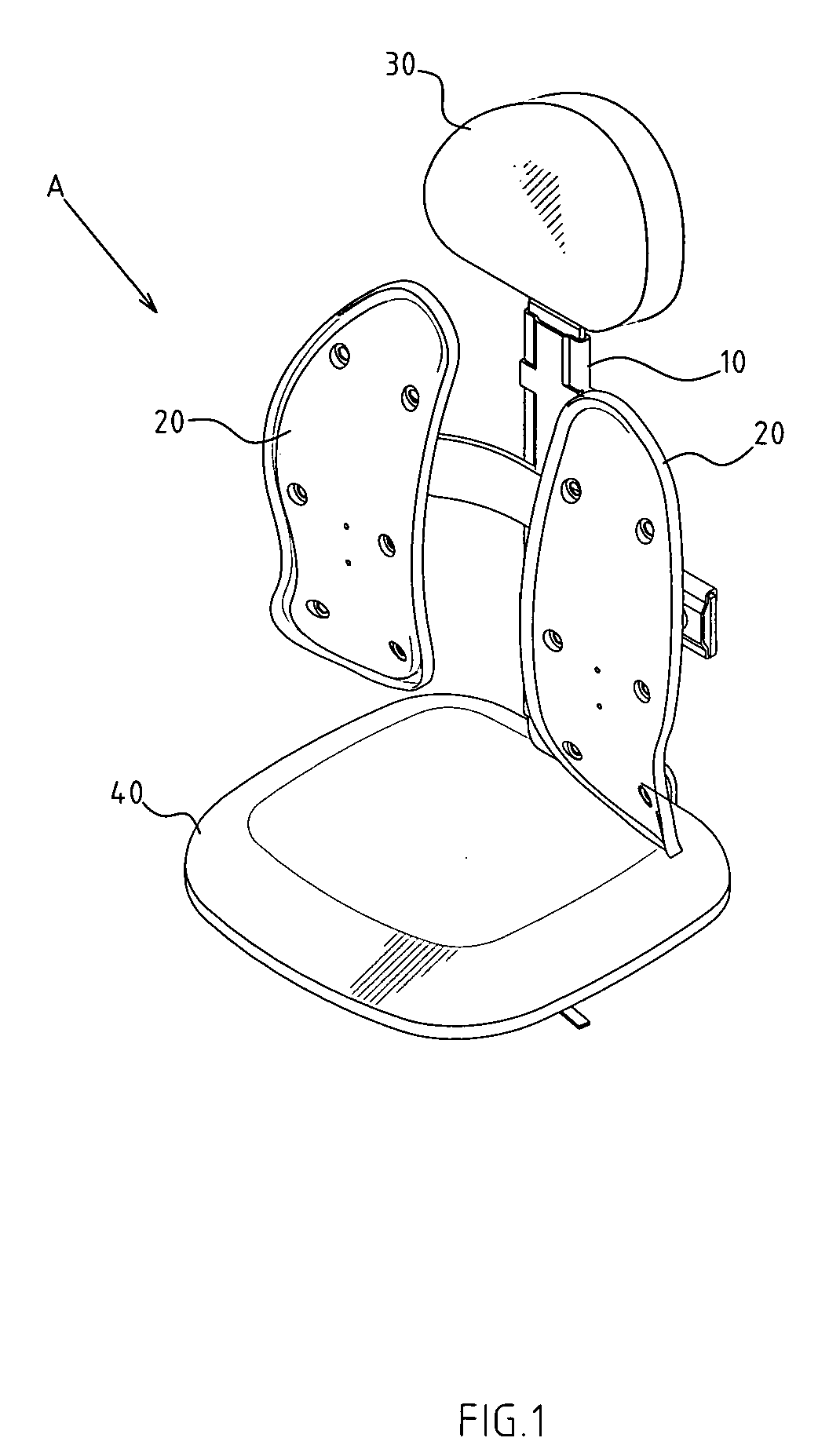

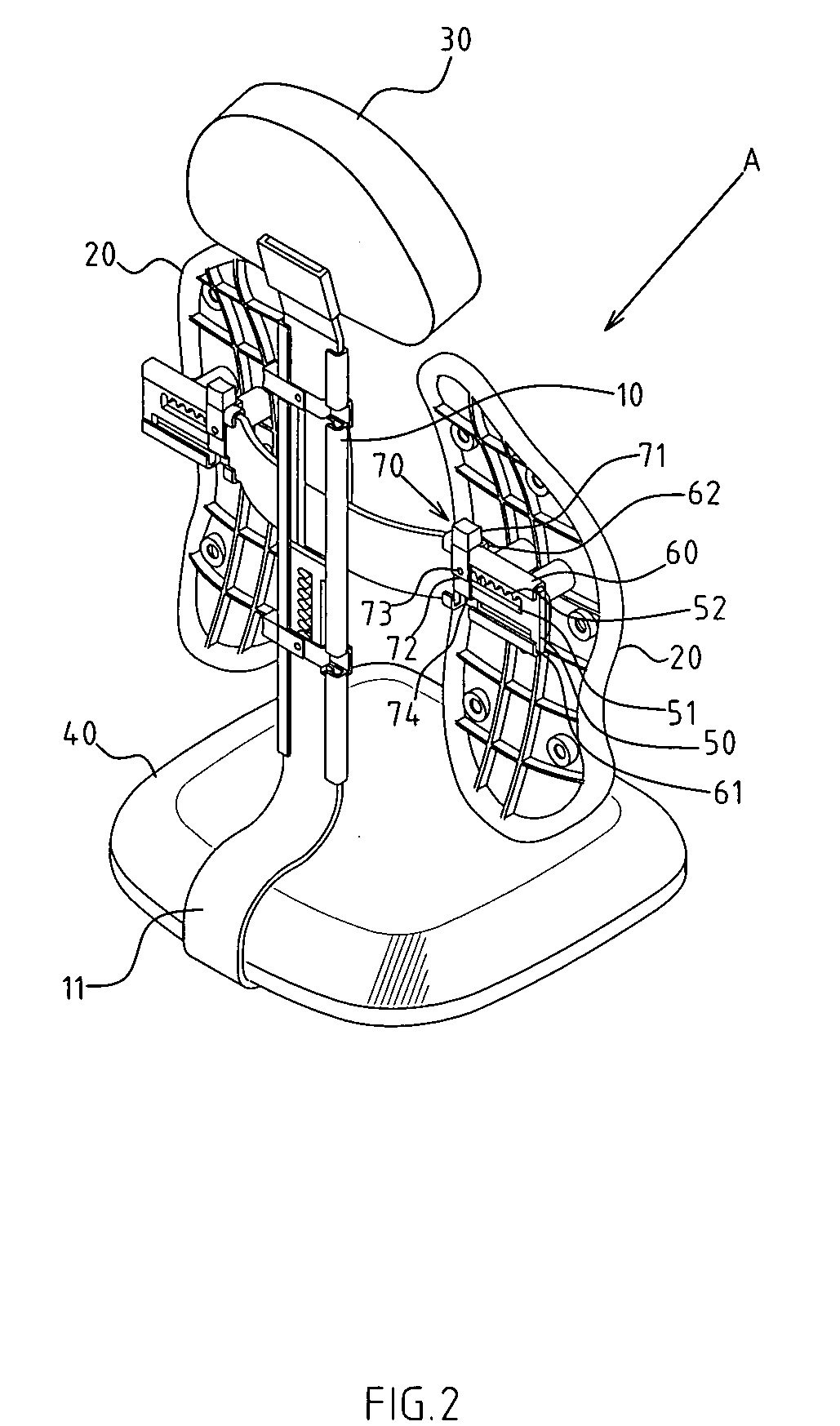

Adjustment structure of chair backrests

Owner:HUNG CHING LIN

Catheter with distally distending balloon

InactiveUS20020032407A1Avoid stimulationIncrease surface areaSurgeryDilatorsEnteral feedingsBalloon catheter

A balloon catheter having a balloon disposed upon an elongate shaft near a relatively rigid distal insertion tip, a fluid lumen for fluid communication with a body cavity and an inflation lumen for fluid communication with the balloon. The balloon holds the catheter tip within a body cavity such as the stomach for long-term enteral feeding. The balloon is configured such that upon inflation, the balloon distends distally to cover the distal tip thus insulating it from sensitive anatomy.

Owner:KIMBERLY-CLARK WORLDWIDE INC

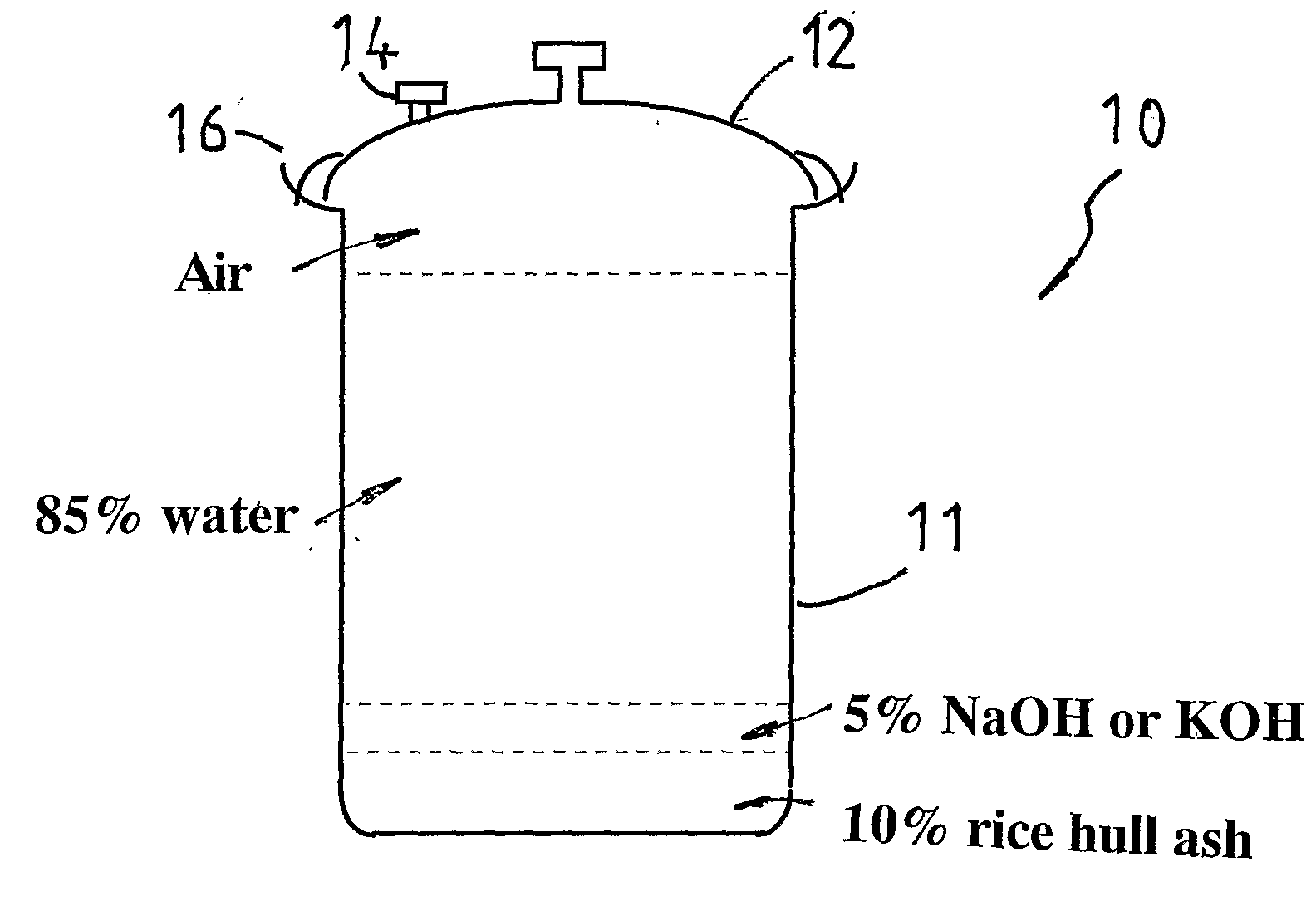

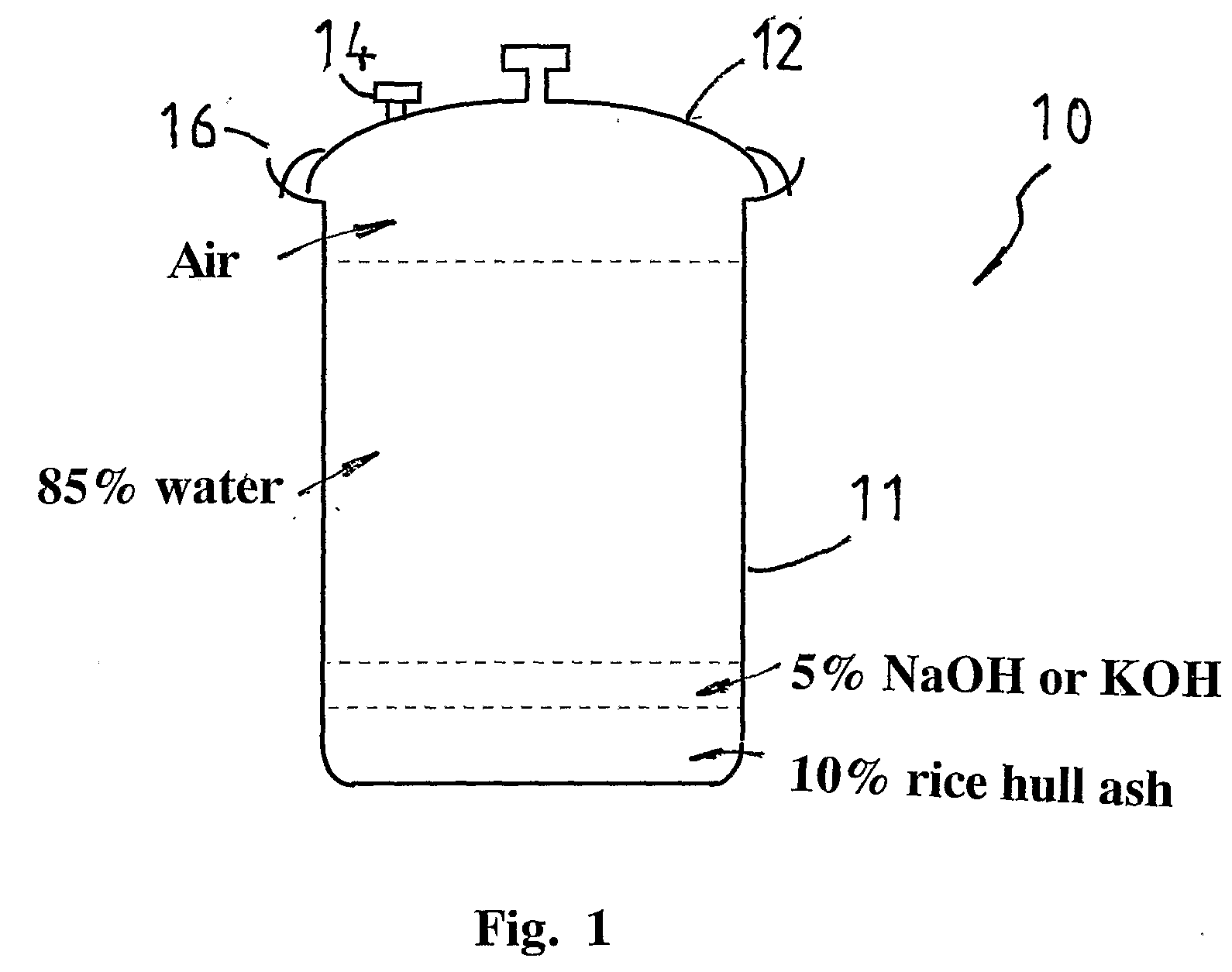

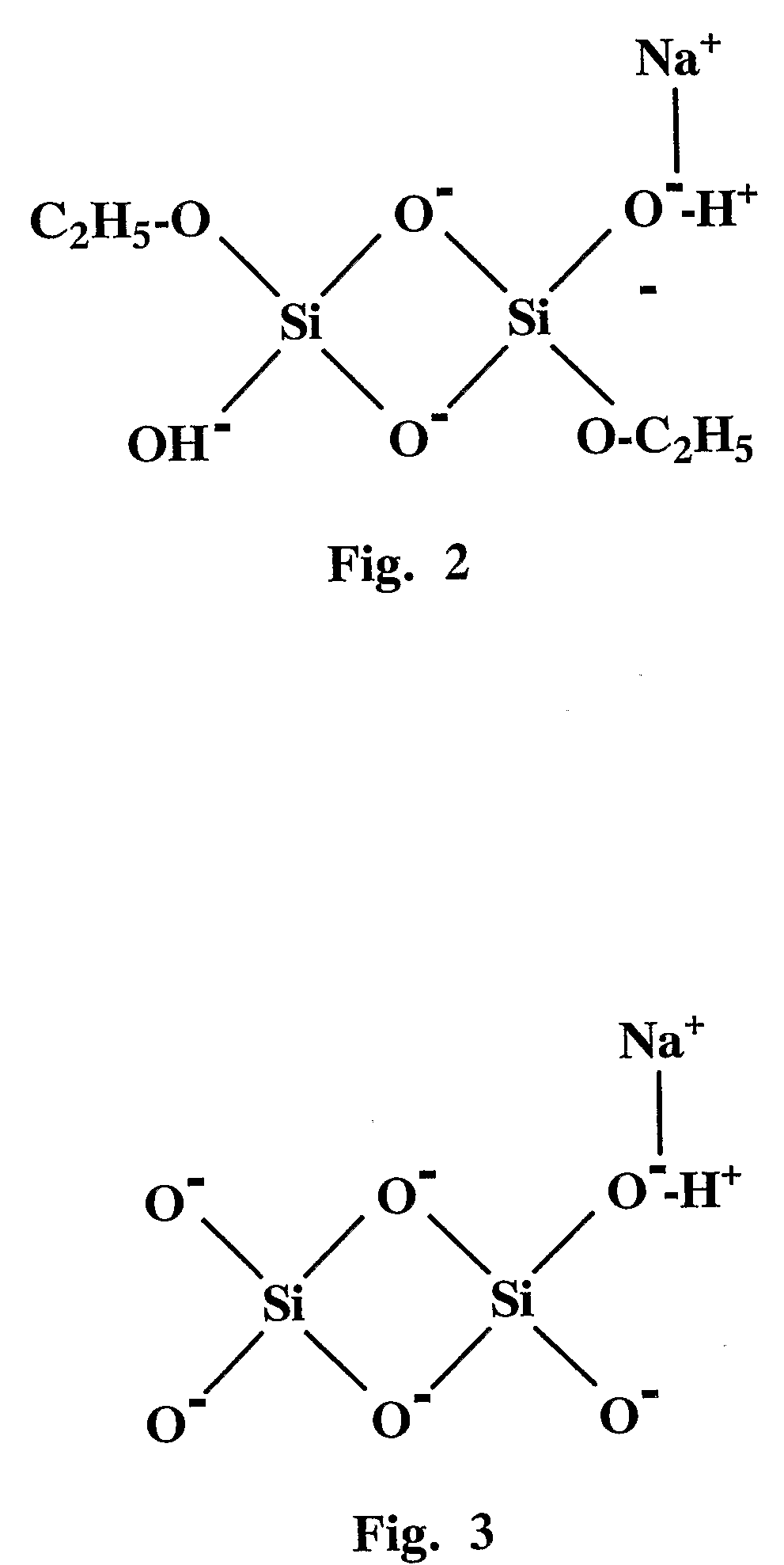

Soluble Biogenic Silica and Application Using Same

InactiveUS20080286383A1Improve adhesionPromote rapid formationBiocideSilicaSilicon dioxideBiogenic silica

A process of preparing a biogenic silica comprising the steps of incinerating a silica bearing organic source at a temperature up to 1200° C. and allowing the incinerated silica organic source to cool; adding the incinerated and cooled silica bearing organic source to an alkaline solution that has either been preheated to a temperature up to about 65° C. or to be heated with the added organic source to a temperature up to about 65° C., the alkaline solution being contained in a vessel and having a pH up to 14; applying heat so that the added organic source and the alkaline solution in the vessel are at a temperature between 100° C. and up to about 300° C. for 1 to 4 hours, thereby forming an aqueous biogenic silica and undissolved impurities derived from the added organic source; and extracting the aqueous biogenic silica from the vessel. The extracted silica can be solidified into a solid form.

Owner:NUNN GARRY ROBERT

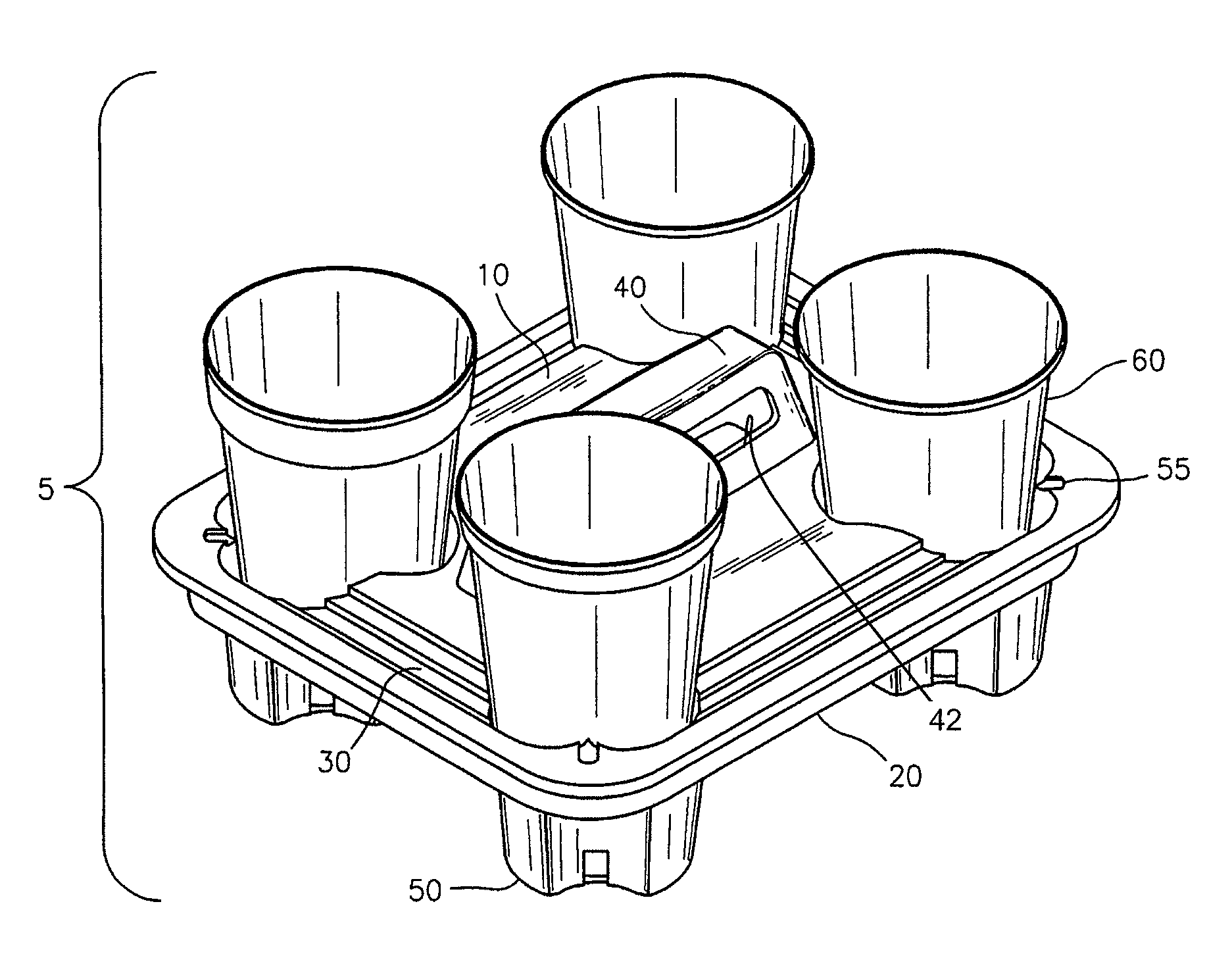

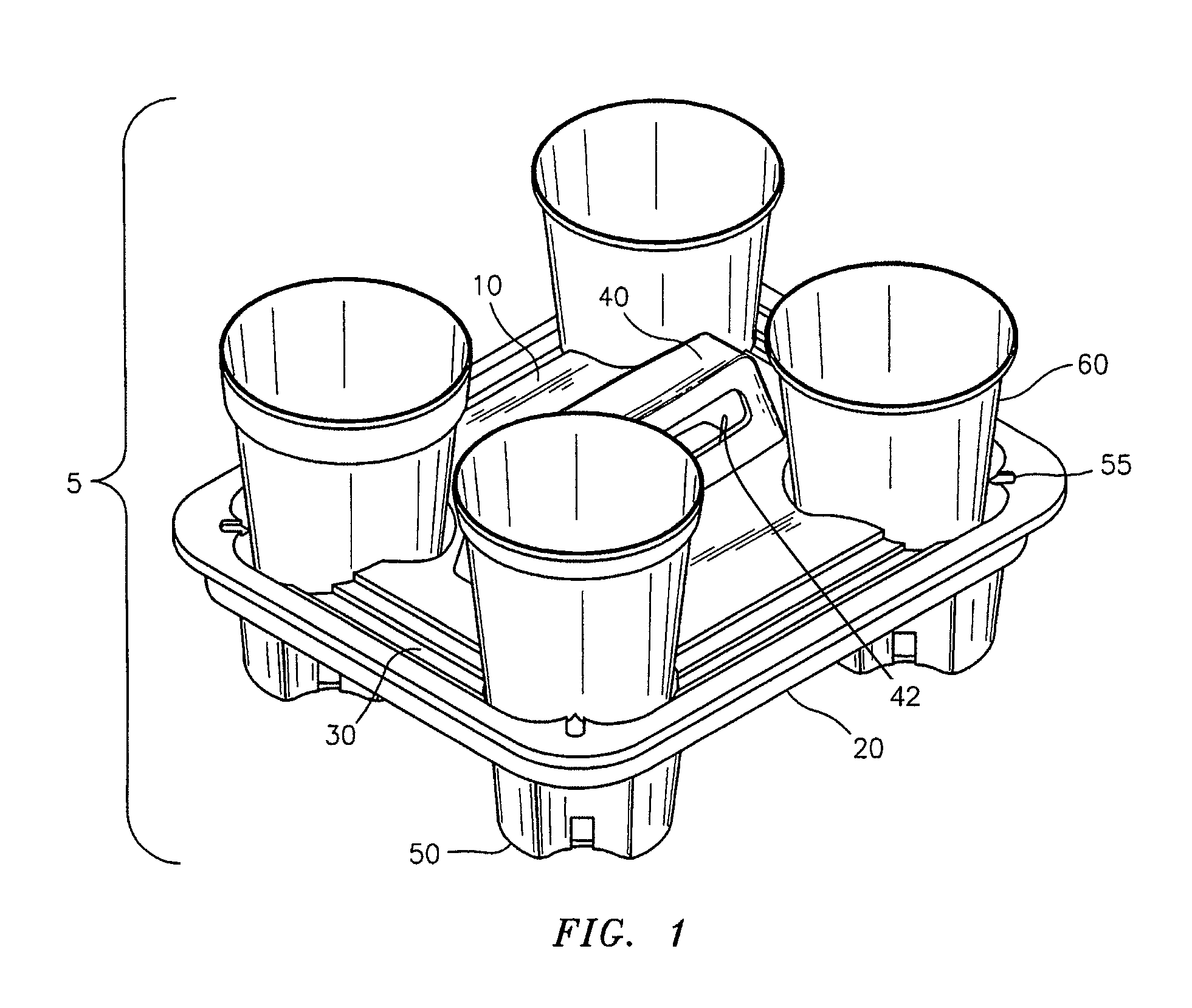

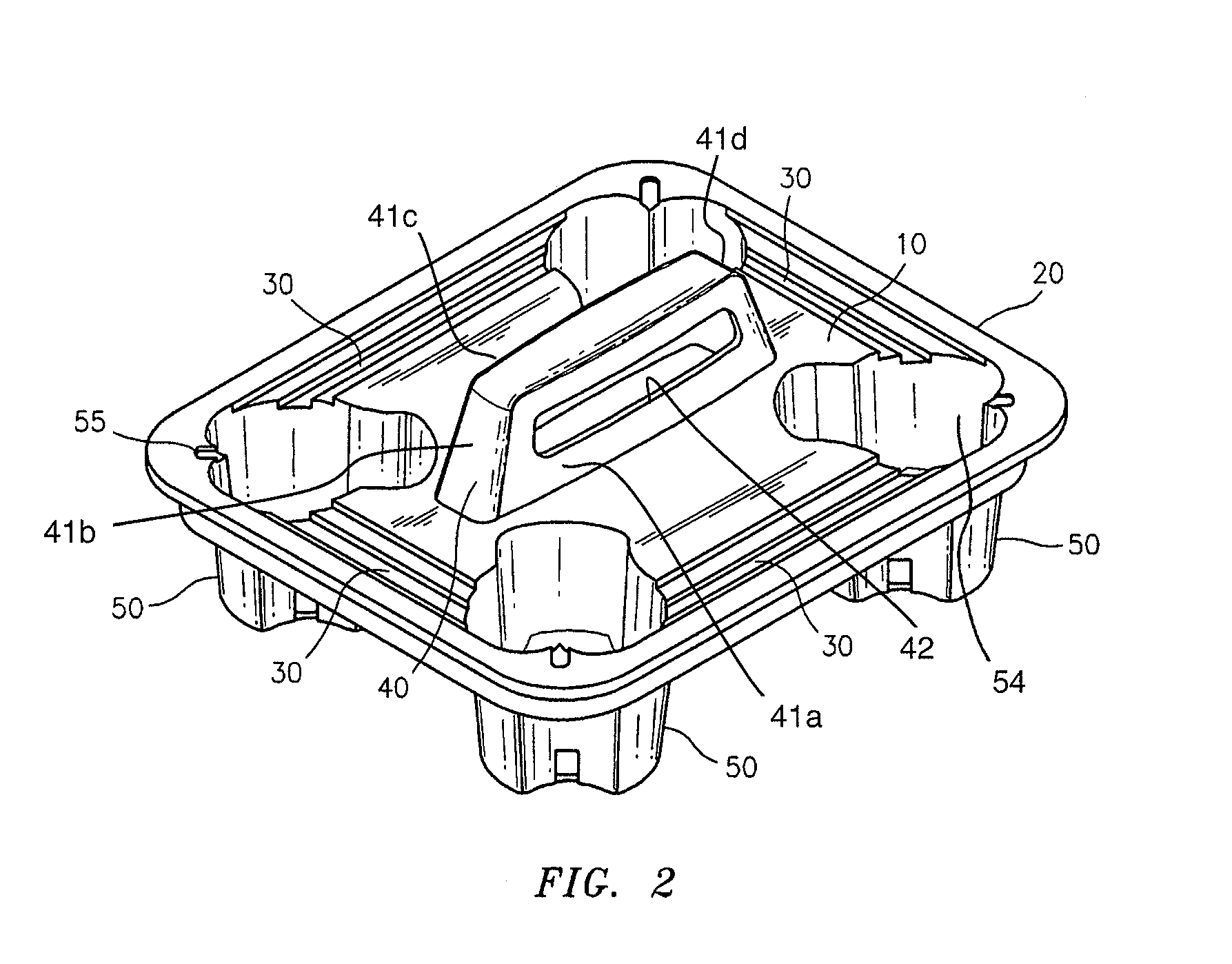

Beverage cup carrier

InactiveUS8146737B2Improve securityImprove stabilityFlexible coversWrappersMolded pulpMechanical engineering

A disposable beverage cup carrier is preferably made from molded pulp, plastic or other resilient material capable of withstanding the force of four filled beverage cups while carried by integral carrying handle and preventing collapsing of the carrier and resultant spillage of the hot or cold beverage. The beverage cup carrier has a top surface, generally square in shape, of sufficient diameter capable of accommodating a integral ergonomically carrying handle. The beverage cup carrier is capable of holding one to four cups of various sizes and shapes of beverage containers providing a safe and sturdy means during transportation preventing spillage. The integral carrying handle positioned in the center of the top surface allows the user to carry up to four beverage containers with one hand providing enhanced safety and allowing a free hand for purposes of opening the door of one's automobile. The larger surface area of the top surface to accommodate the carrying handle further provides more stability to the carrier. The beverage cup carrier is a unitary mold and is capable of nesting with a plurality of similar beverage cup carriers. The top surface is attached to a peripheral rim by a plurality of annular rib components. The peripheral rim having four rounded corners at which points are positioned sockets to receive the beverage cups. The sockets extending downwardly about five inches in depth from a bottom surface containing stabilizing components within an internal wall of the sockets to provide stability by exerting an external force against the beverage container during use.

Owner:DAGOSTINO ROBERT J

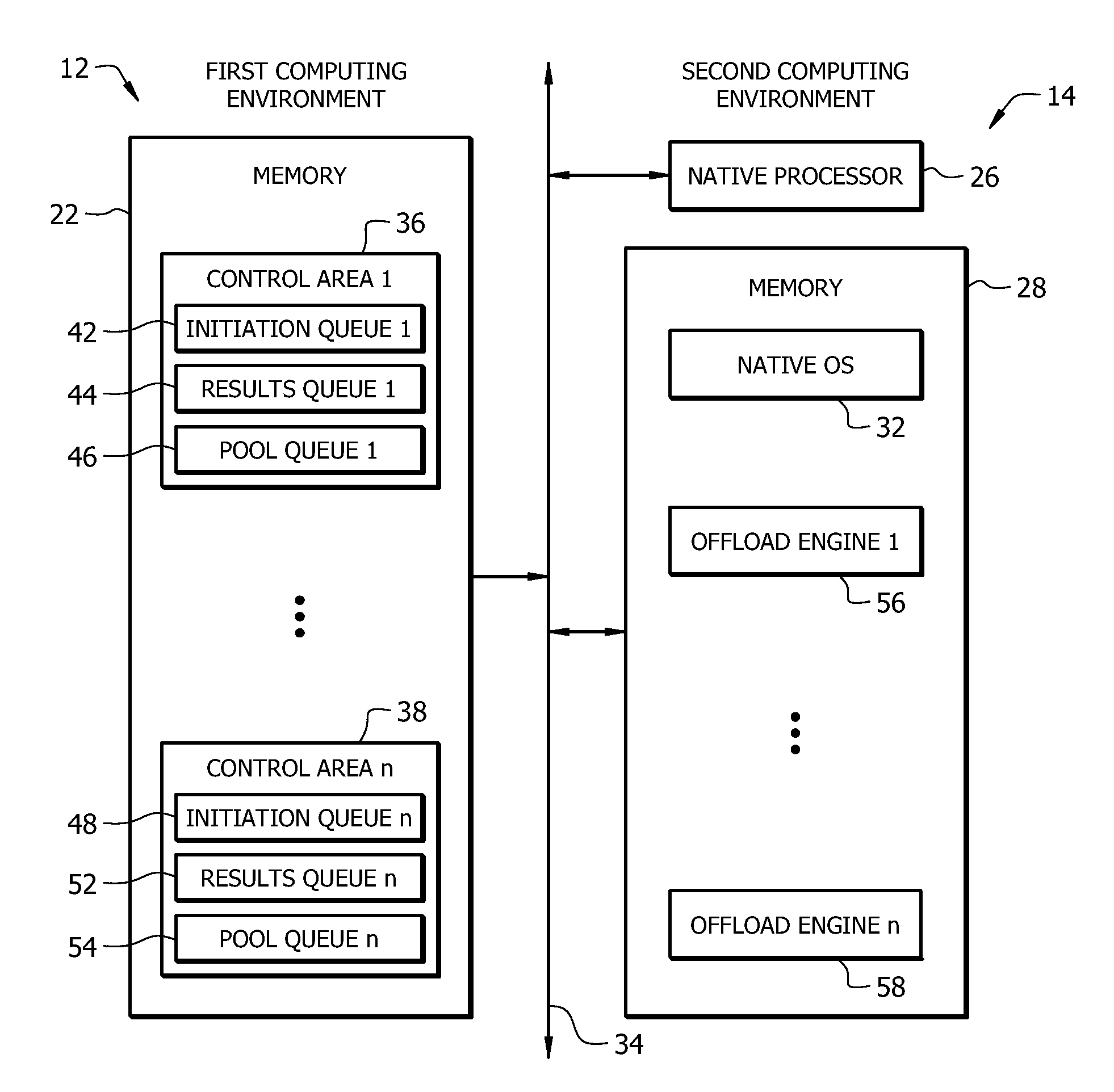

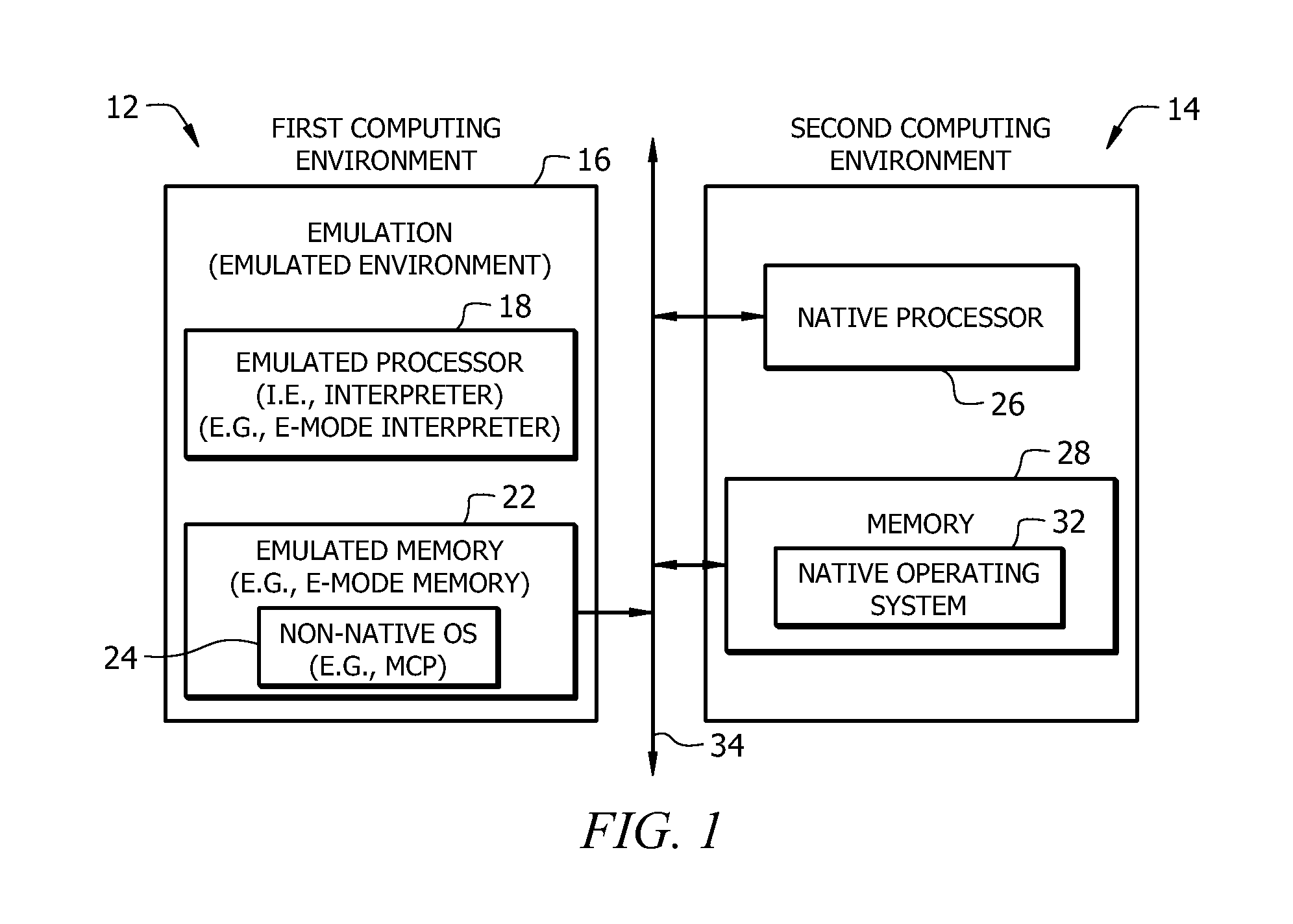

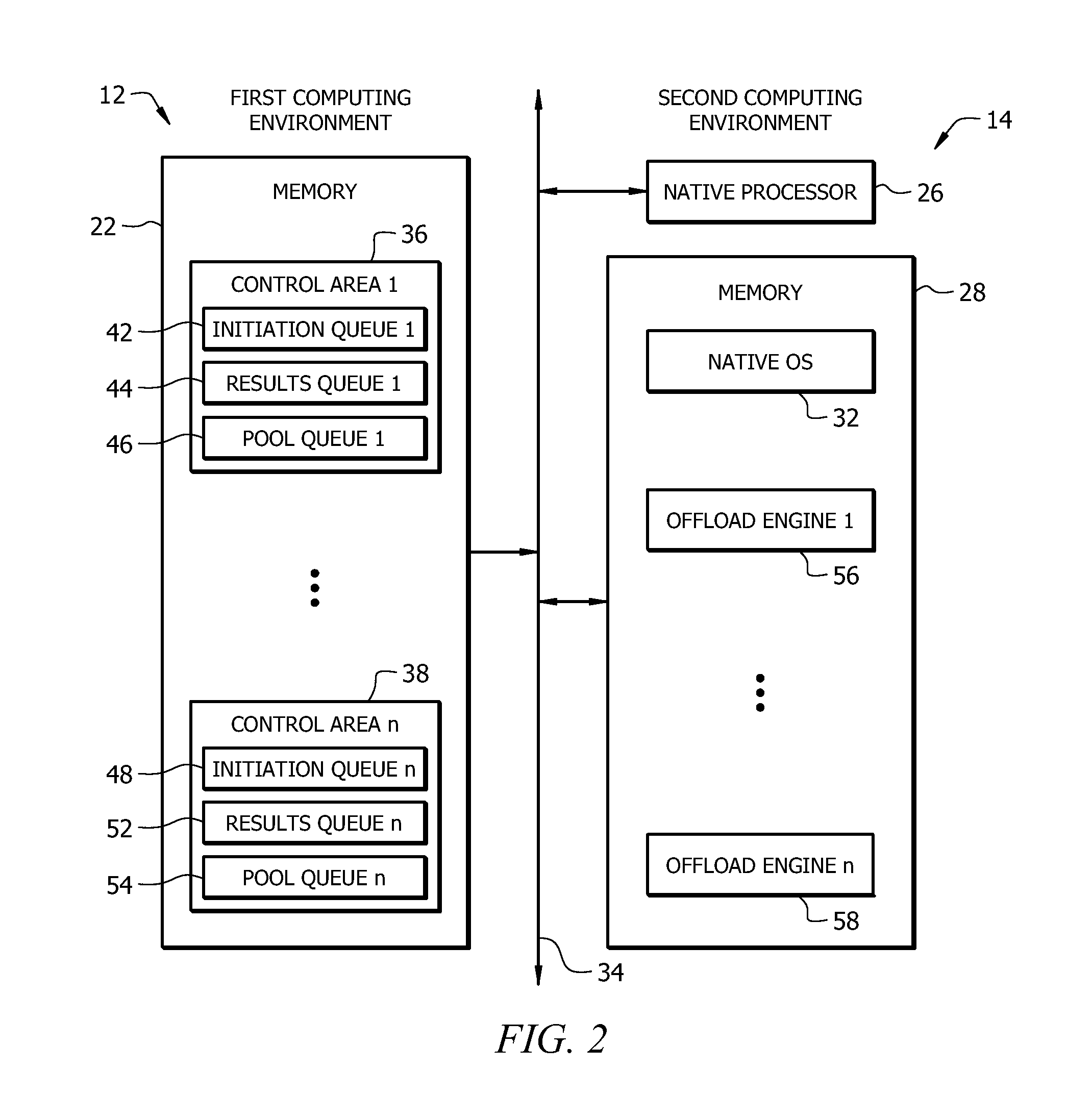

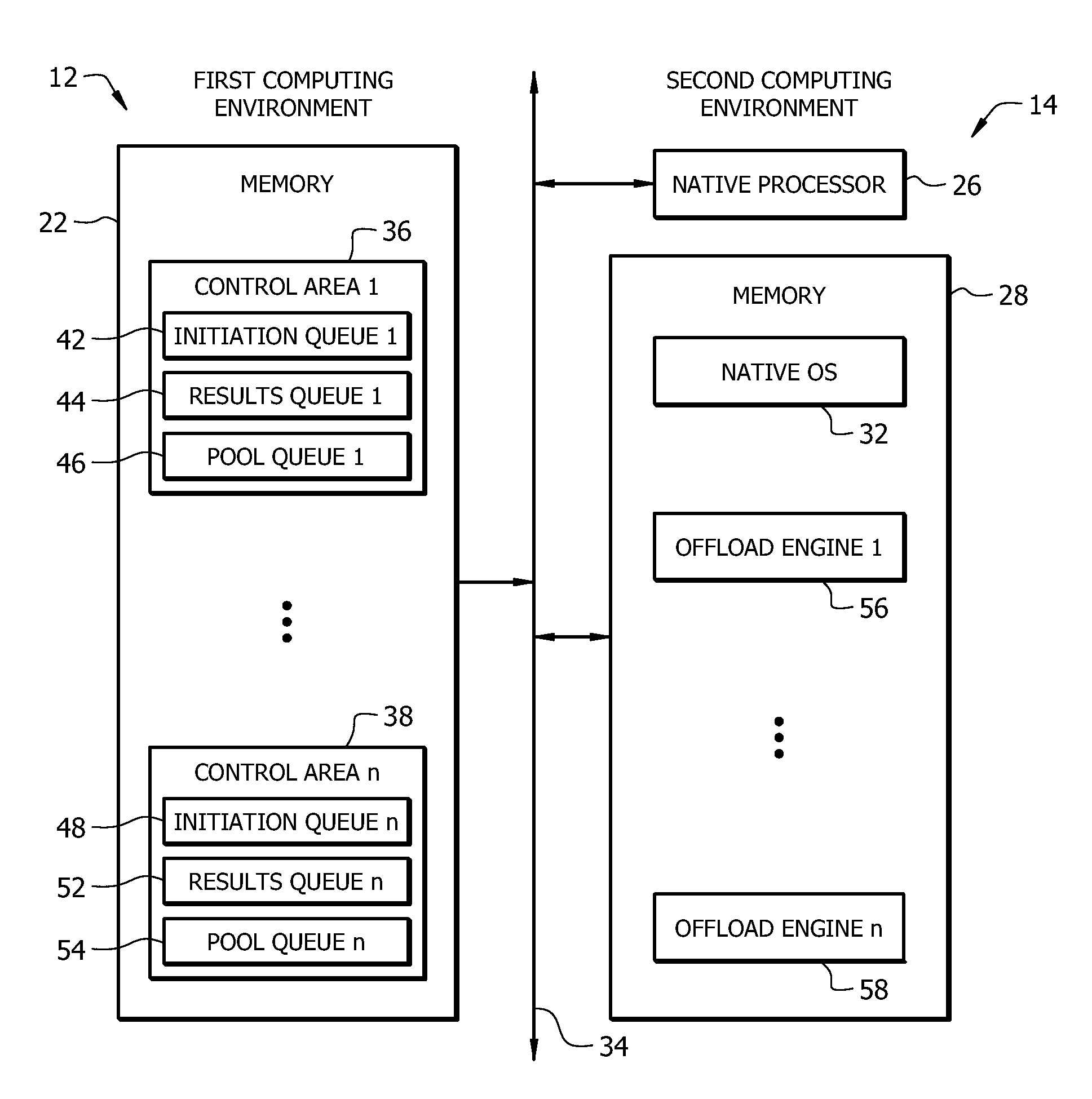

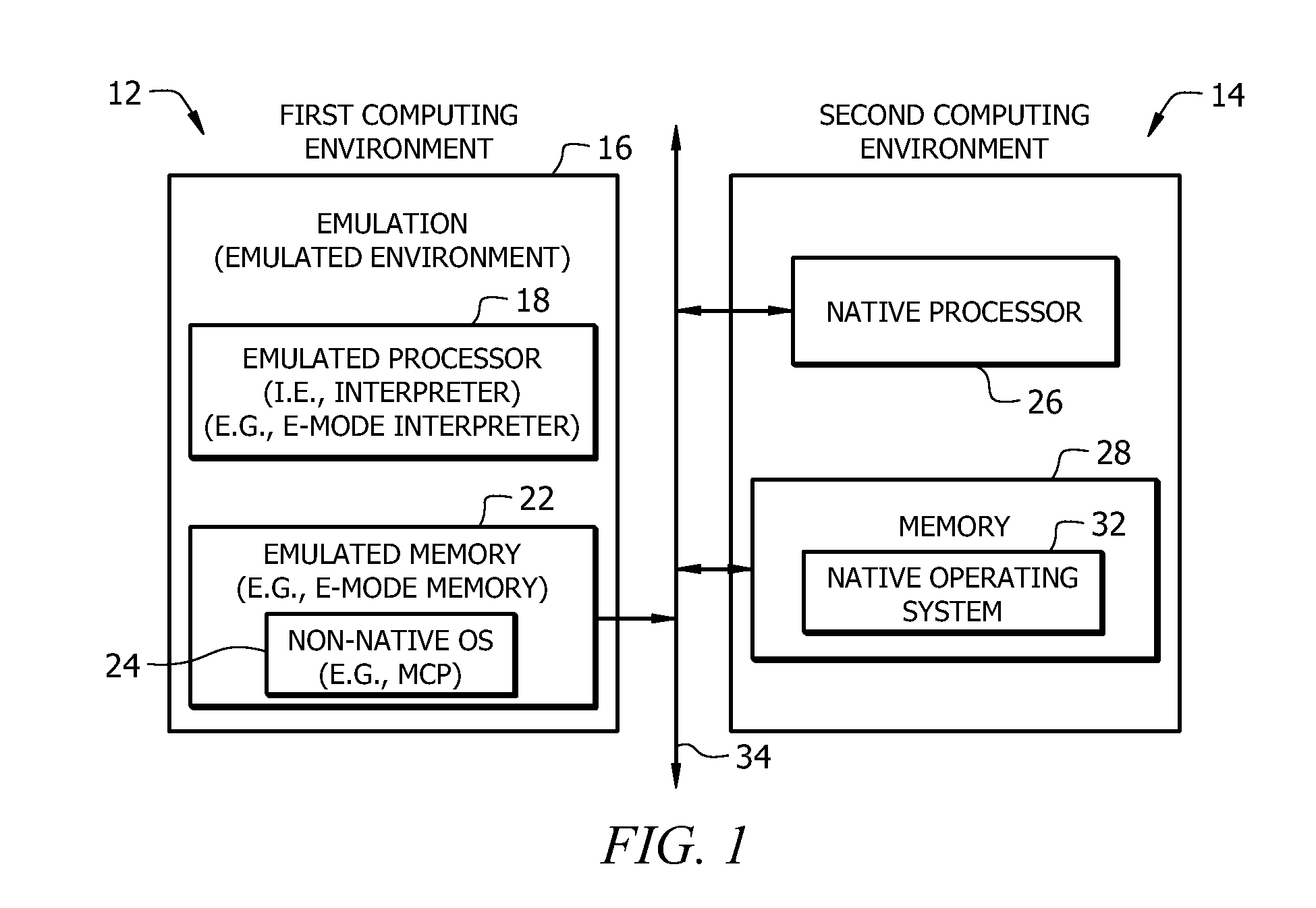

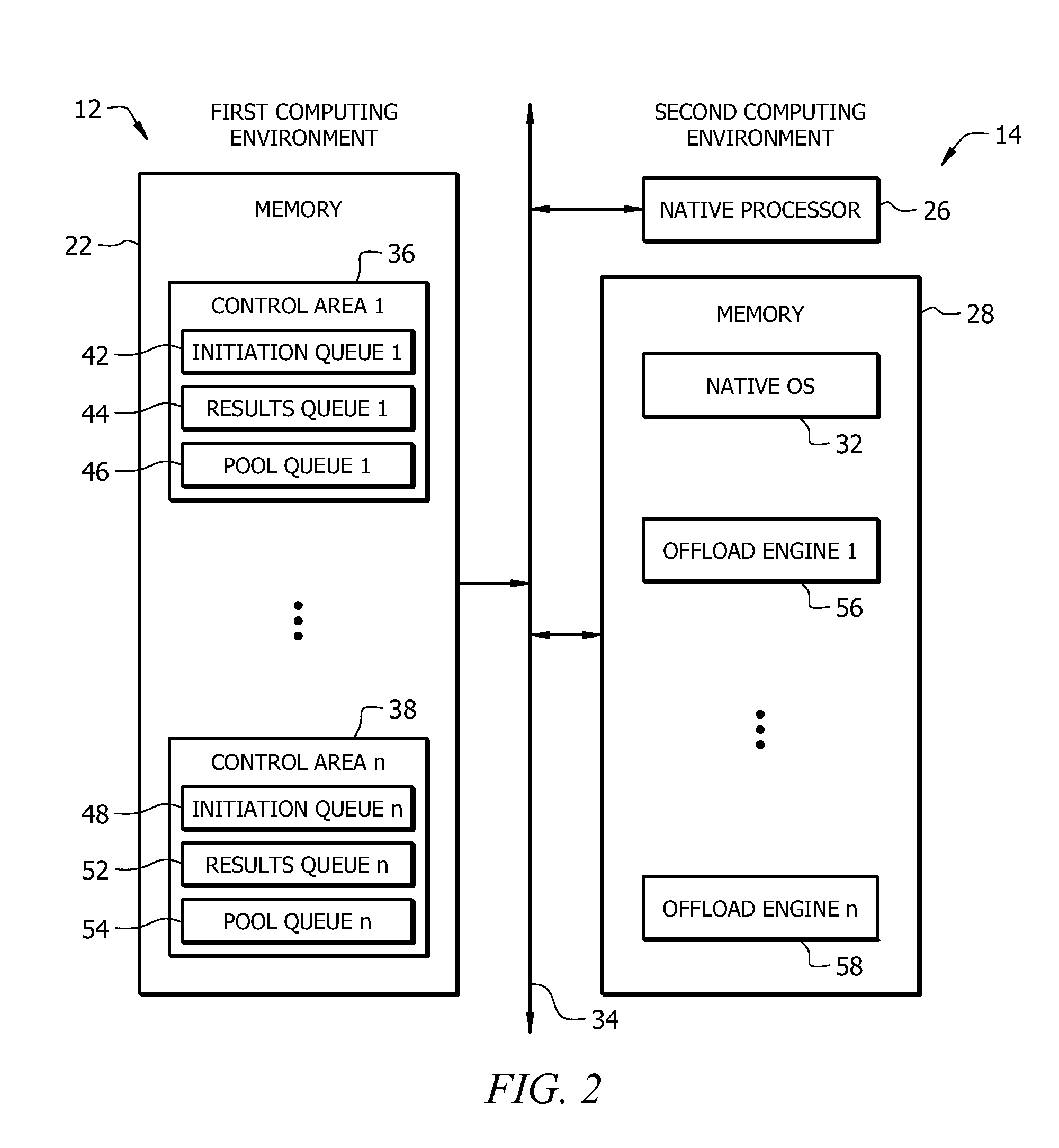

Method and system for offloading processing tasks to a foreign computing environment

InactiveUS20110154334A1More reliableMore resilientProgram control using stored programsMultiprogramming arrangementsOperating system

A method and apparatus for offloading processing tasks from a first computing environment to a second computing environment, such as from a first interpreter emulation environment to a second native operating system within which the interpreter is running. The offloading method uses memory queues in the first computing environment that are accessible by the first computing environment and one or more offload engines residing in the second computing environment. Using the queues, the first computing environment can allocate and queue a control block for access by a corresponding offload engine. Once the offload engine dequeues the control block and performs the processing task in the control block, the control block is returned for interrogation into the success or failure of the requested processing task. The offload engine is a separate process in a separate computing environment, and does not execute as part of any portion of the first computing environment.

Owner:UNISYS CORP

Head restraint

Owner:DEMARAS VERONICA

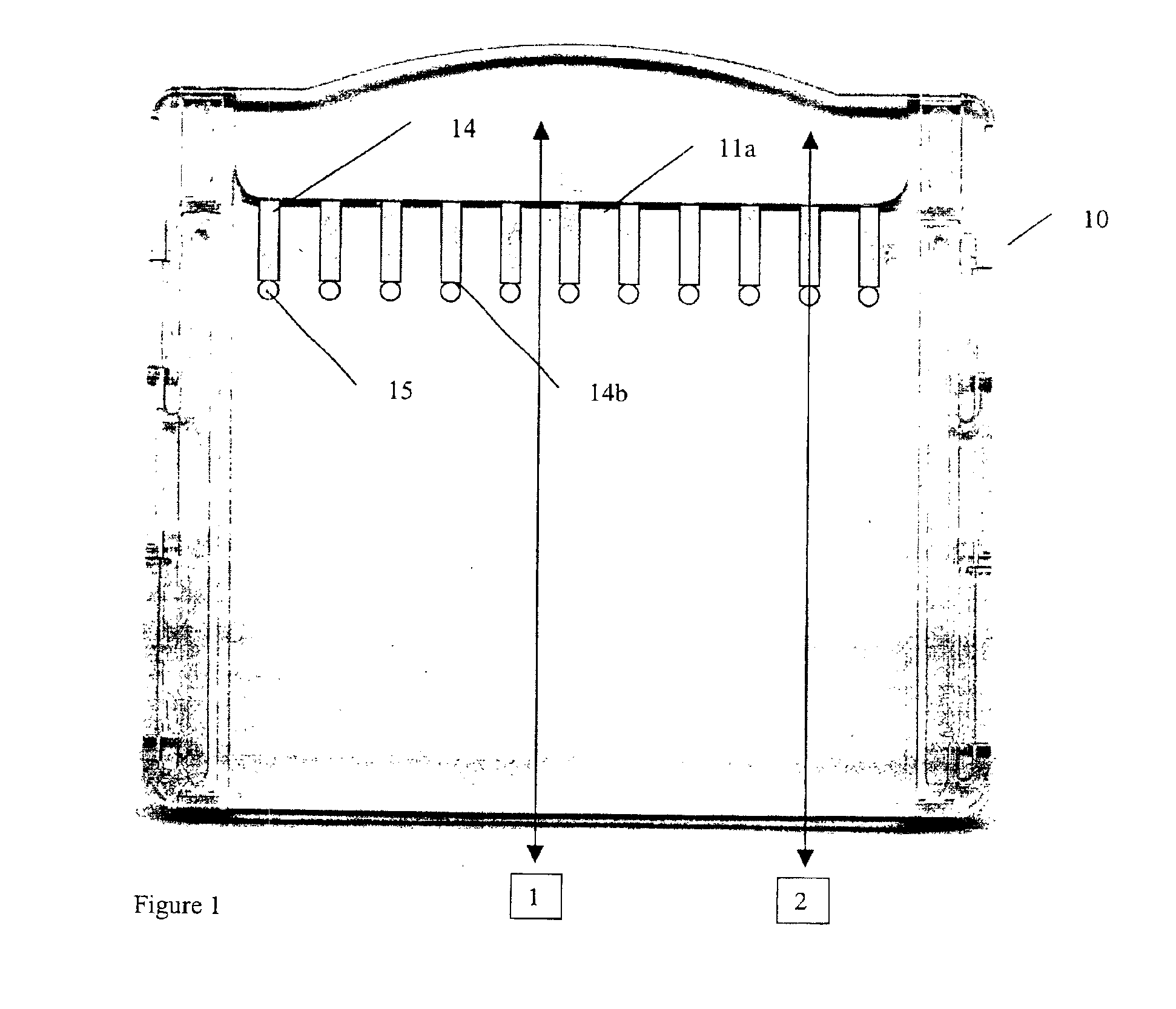

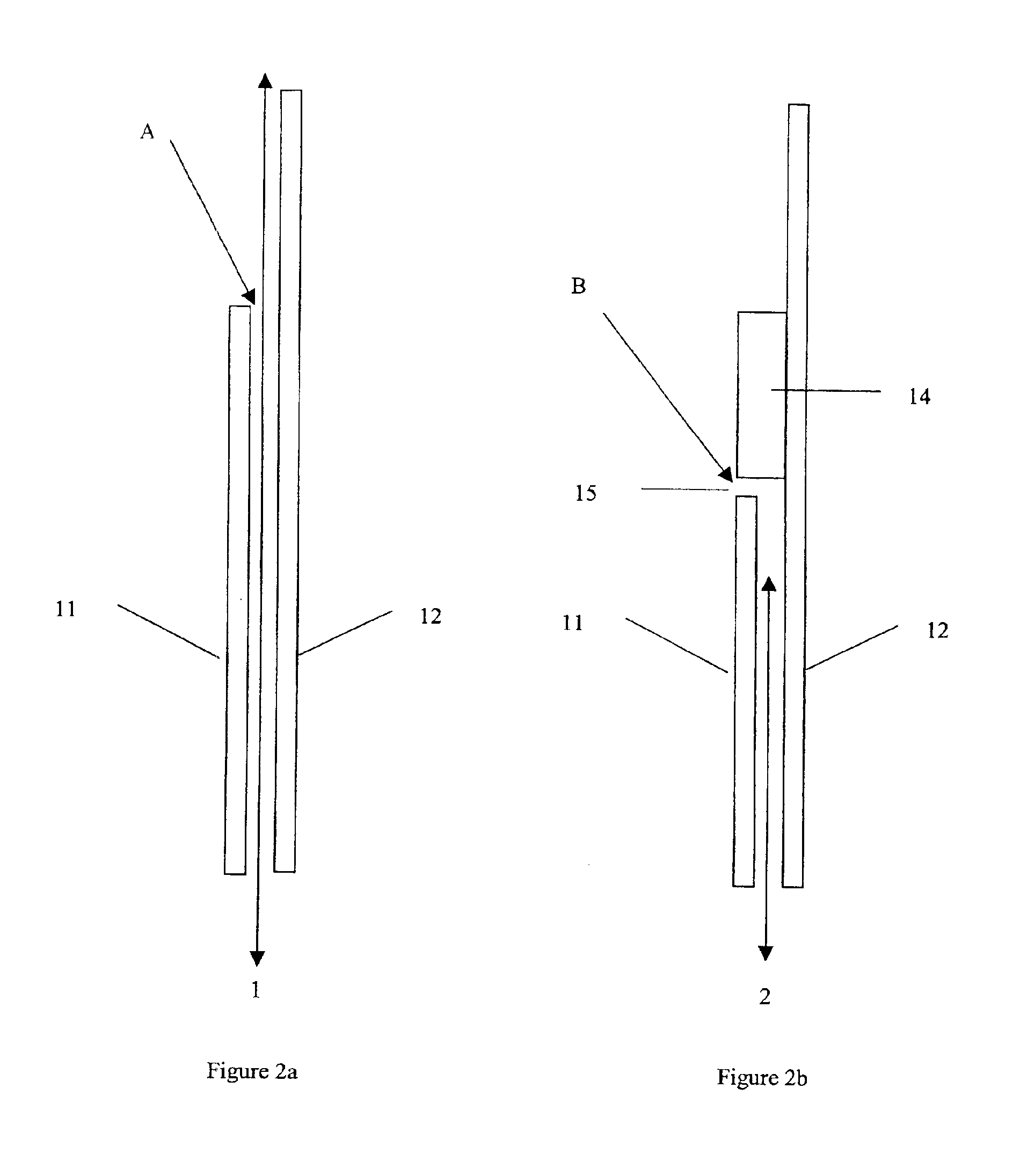

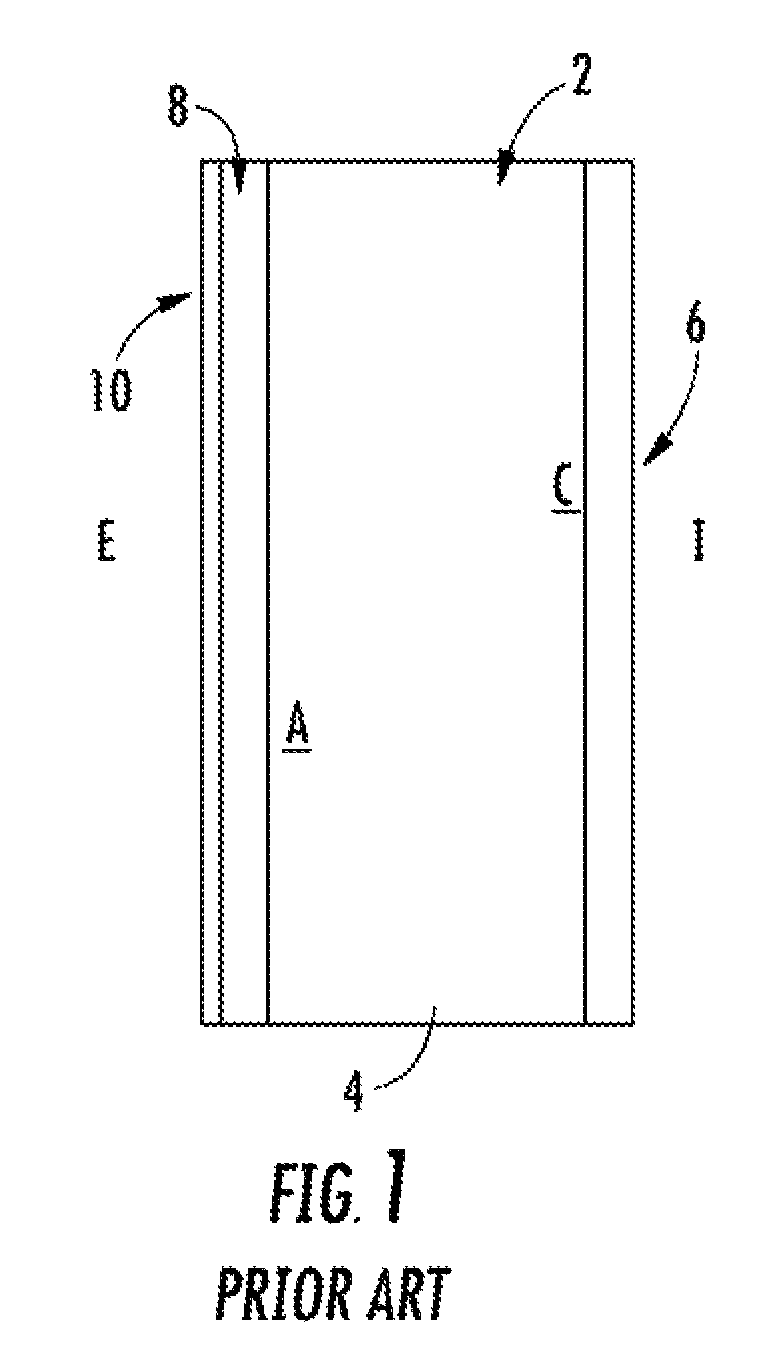

Cassette for electrophoretic gels

InactiveUS6878257B2Avoid spreadingMore resilientSludge treatmentVolume/mass flow measurementElectrophoresisMagnetic tape

An improved cassette for use in the formation of an electrophoretic gel comprises two plates with substantially planar walls having two sides and two ends so arranged in a side by side spaced apart array to form a gel receiving space between them. A plurality of dividing ribs on one or each of the walls extend from a first end of the wall or walls substantially parallel to at least one of the sides thereof to a rib base end. The ribs extend into the space so as to subdivide at least one end of the space into a plurality of substantially parallel wells. A plurality of holes extend through at least one of the walls of the cassette located at or adjacent the base of the dividing rib and aligned with the rib. The arrangement of holes allow sufficient current flow to replace that lost due to the dividing ribs. The structure retains the advantage of having solid dividing walls which are considerably more resilient than dividing walls made from fingers of gel even when reinforced with pegs or projections and yet by virtue of the provision of a hole at the base of the ribs allows sufficient current flow at the base of each rib that the current flow through the space is substantially uniform, thus preventing spreading of the bands as they form in the body of the gel.

Owner:DYCENT BIOTECH SHANGHAI CO LTD

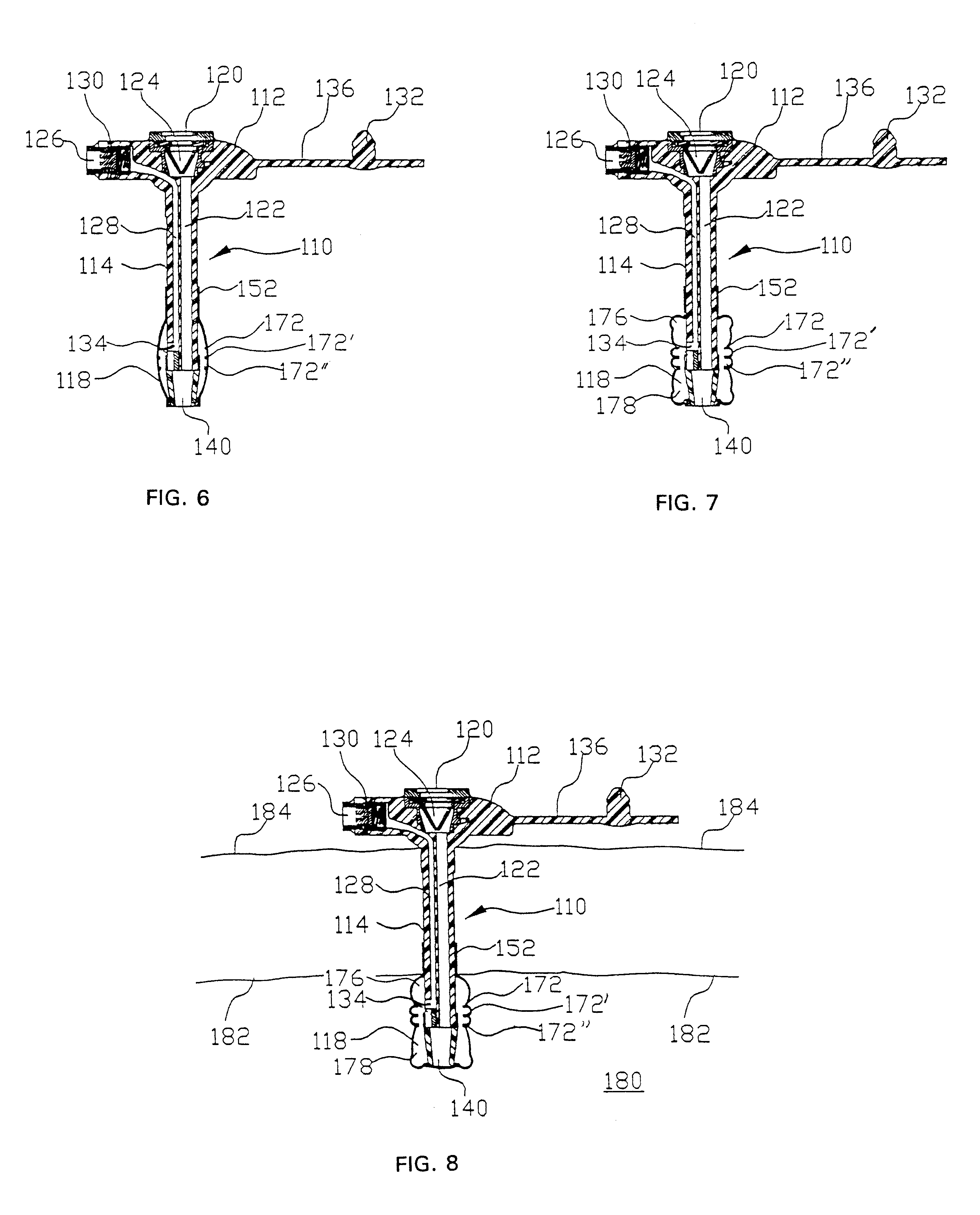

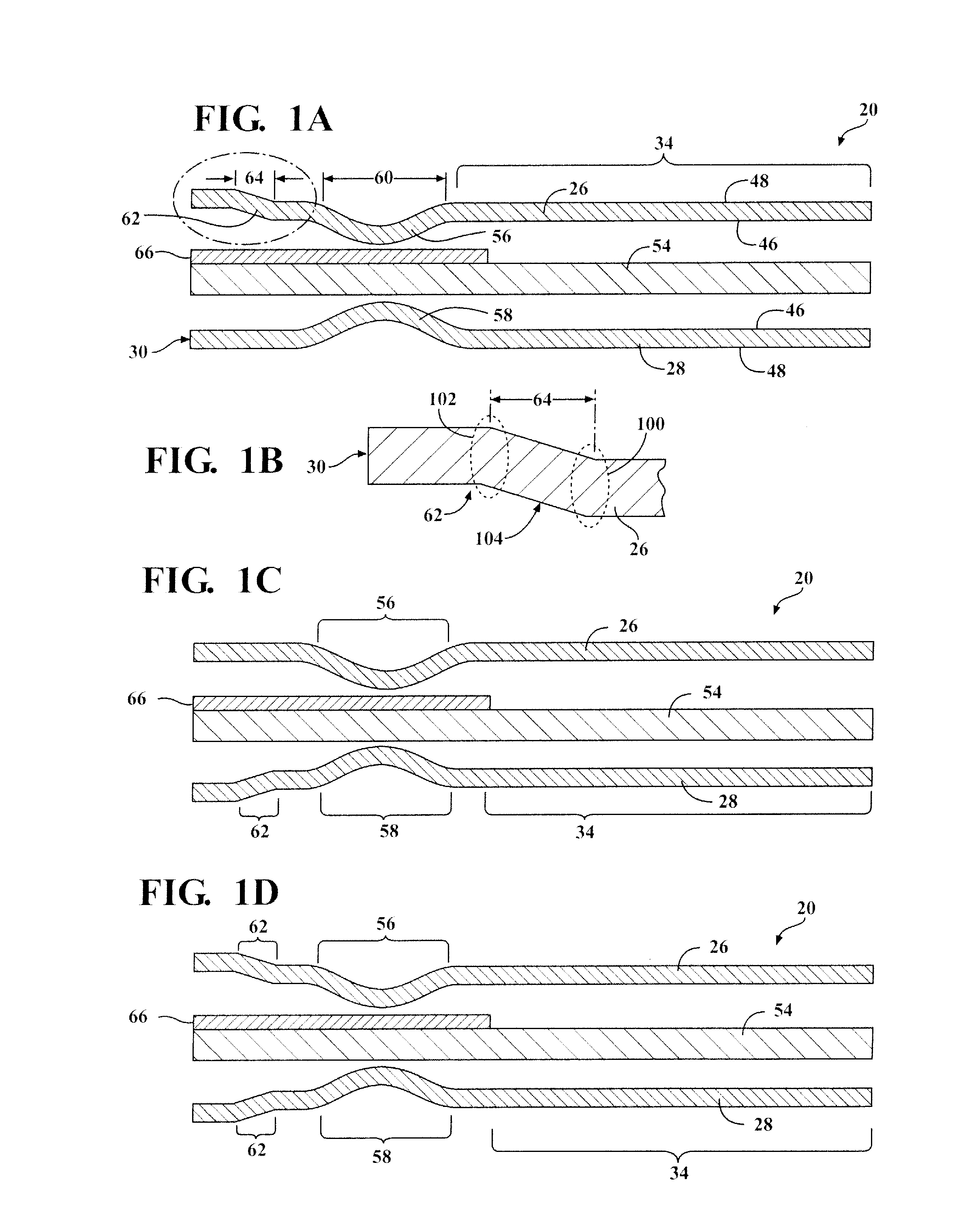

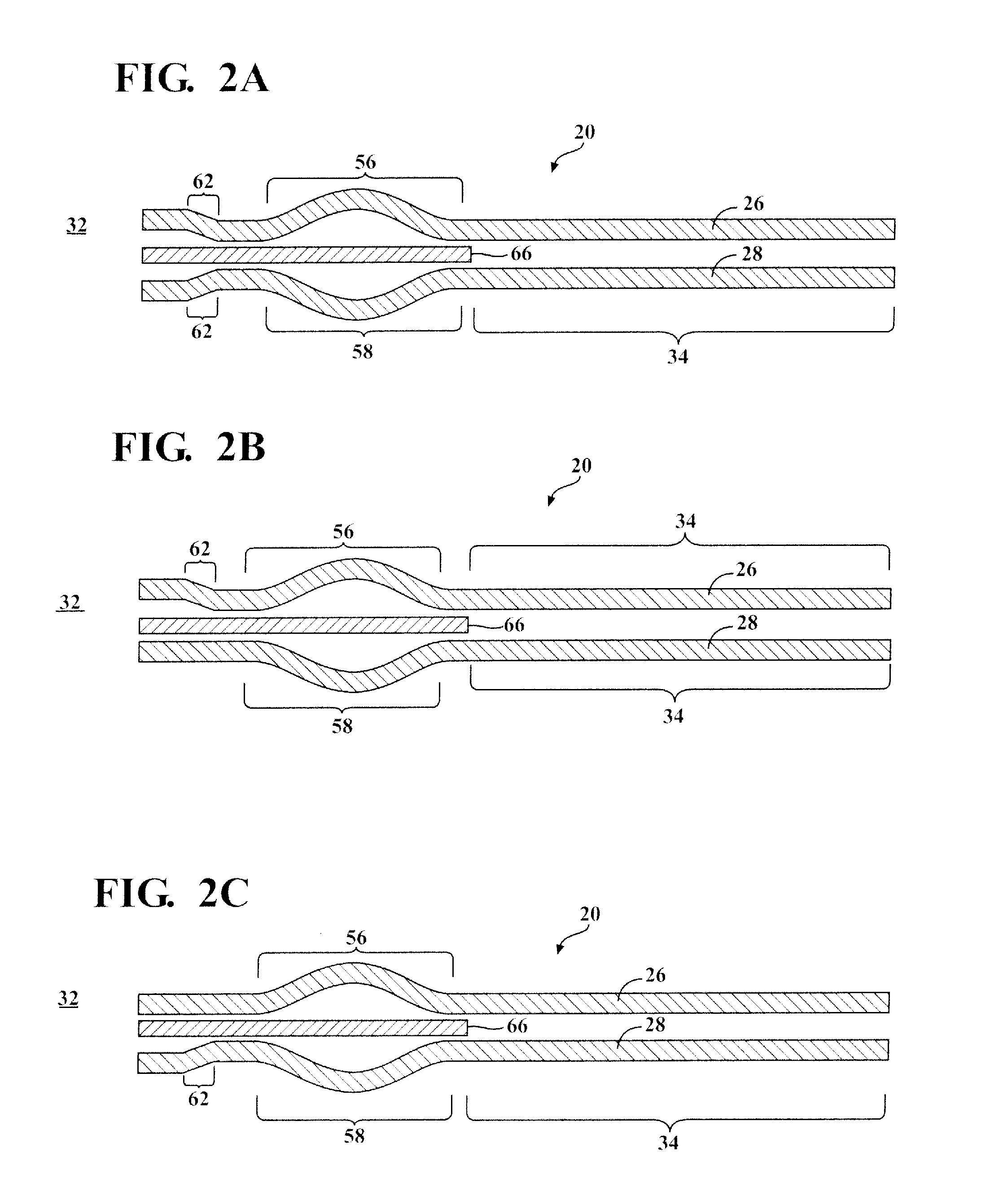

Elastic sealing member radially inwardly of primary sealing bead

InactiveUS20140265156A1More resilientDeformation of sealEngine sealsSealing arrangements for enginesEngineeringMechanical engineering

A gasket assembly having a secondary elastic sealing bead positioned radially inwardly of the primary sealing bead. The secondary sealing bead extends circumferentially about the aperture and radially inwardly of the primary sealing bead. A stopper layer is disposed adjacent at least a portion of the gasket layer and extends radially from the outboard region to the inboard edge to radially overlap the secondary sealing bead and the primary sealing bead. The secondary sealing bead has an “S-type” structure and provides increased gasket resiliency adjacent the inboard edge.

Owner:FEDERAL MOGUL MOTORPARTS LLC

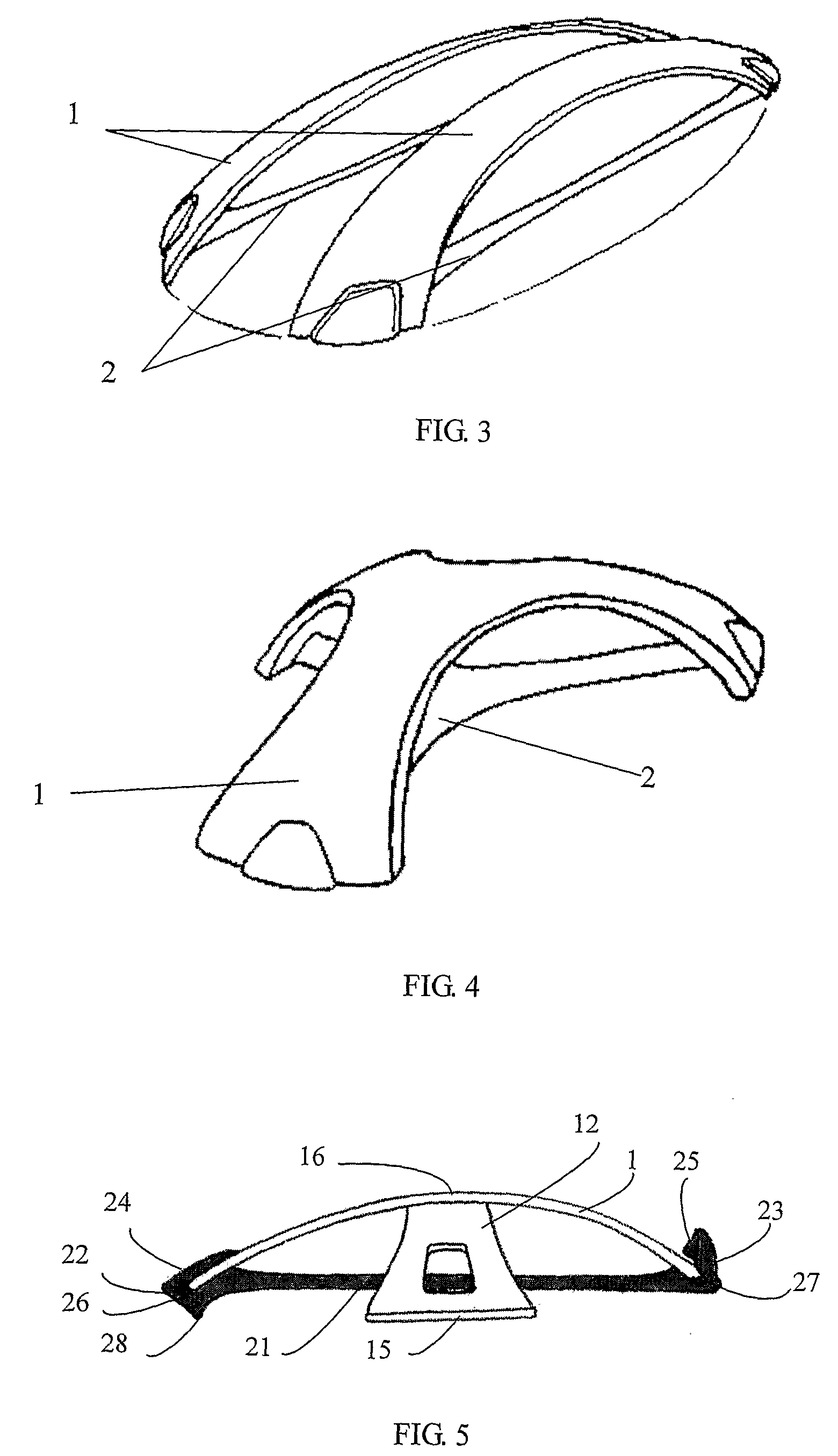

Adjustable shock attenuating means for footwear and footwear using the same

Owner:LI NING SPORTS SHANGHAI

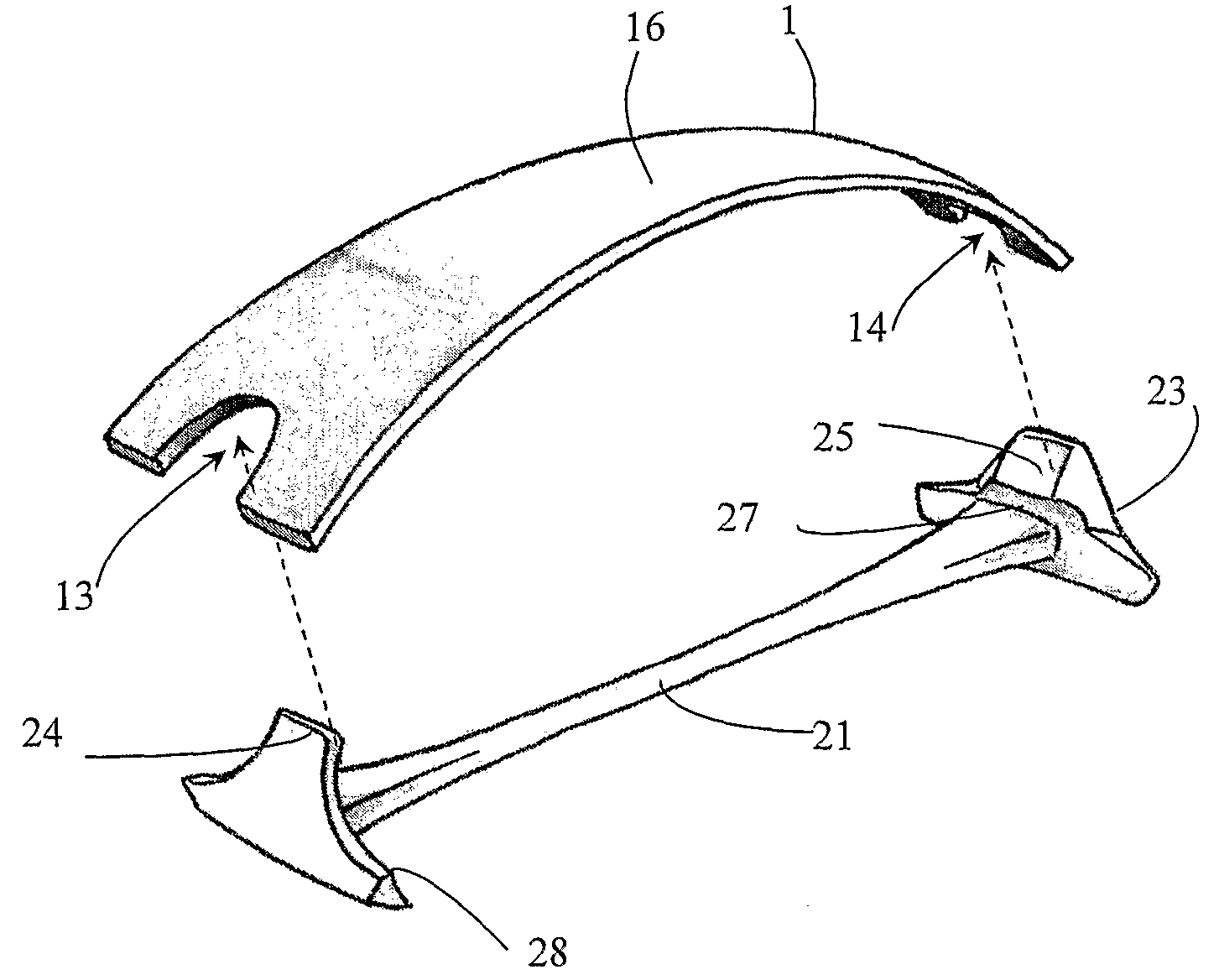

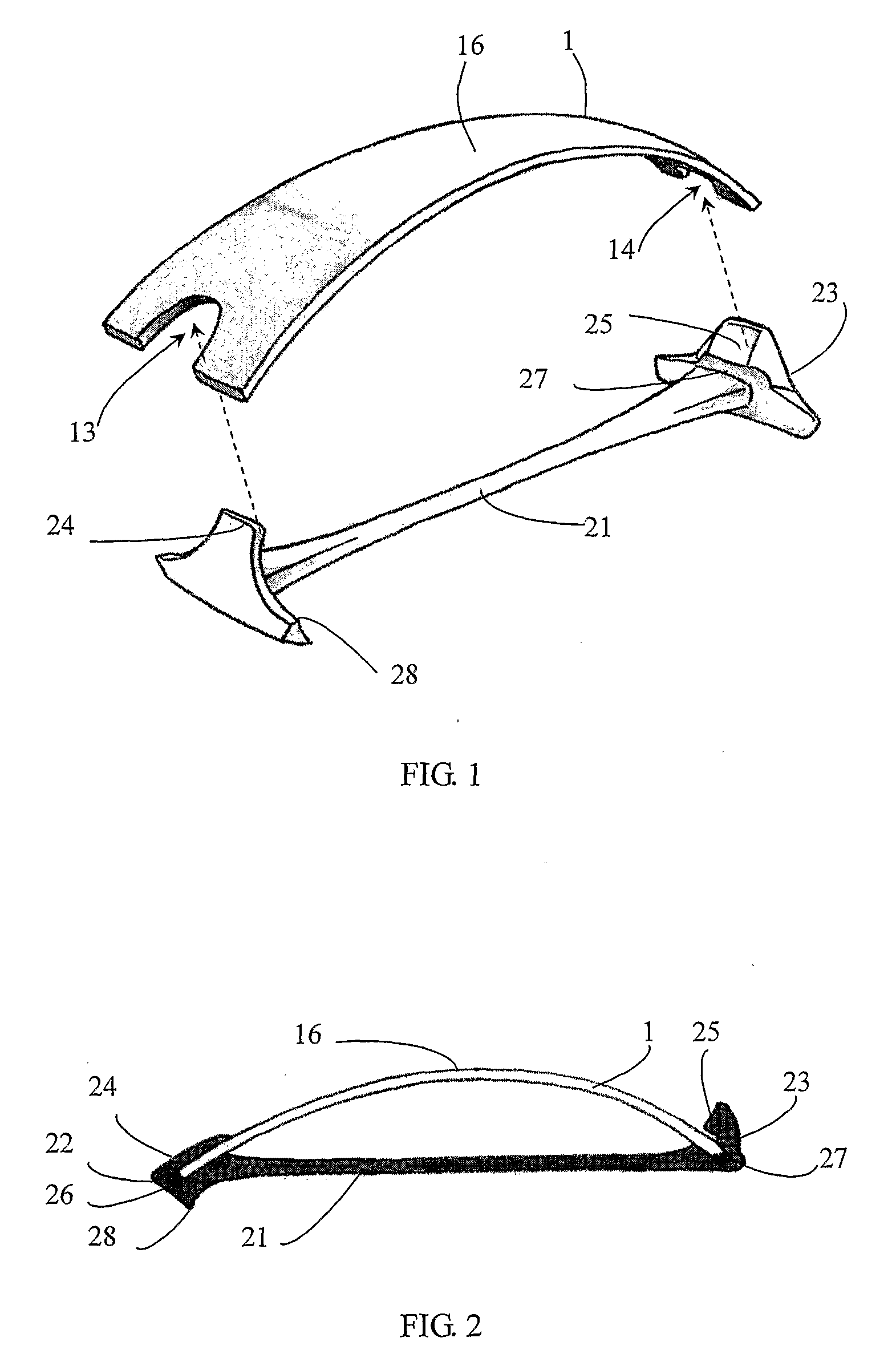

Adjustable Shock Attenuating Means for Footwear and Footwear Using the Same

An adjustable shock attenuating means comprises at least one arch element (1) and at least one tensile element (2) arranged between any two positions at a concave surface of the element (1) or between two ends of the arch element (1). This means further comprises at least one additional arch element (12) arranged intersecting with the arch element (1) or arranged with the arch element (1) side by side. The arch element (1) has a U-shaped cut-out (13, 14) at its two ends respectively and the tensile element (2) correspondingly has a connecting piece (23, 24) at its two ends respectively to be coupled with the U-shaped cut-outs (13, 14) of the arch element (1) with which the tensile element (2) is coupled with the arch element (1).

Owner:LI NING SPORTS SHANGHAI

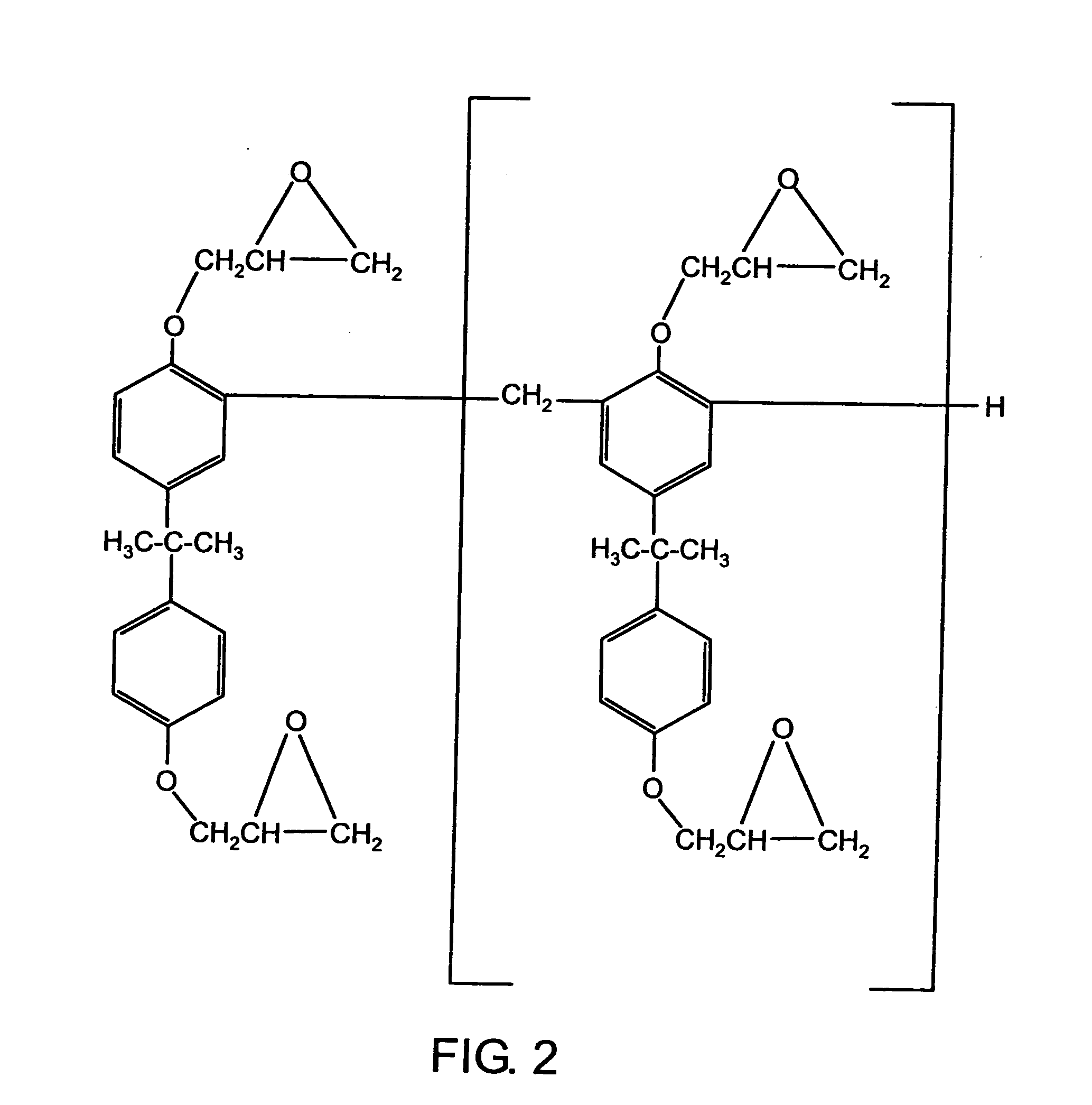

Light transmitting copolymers

InactiveUS20150024158A1Good dimensional stabilityControlled absorptionSynthetic resin layered productsMonocomponent copolyamides artificial filamentCLARITYNylon 6

A copolymer which can be formed from a mixture of nylon 6,12 and nylon 6,10 along with other possible components. The nylon copolymer is not only clear (transparent) but also exhibits high dimensional stability in varying environments, limited water absorption, good wear resistance, the ability to accommodate large amounts of glass fillers, and is more resilient and tougher than either nylon 6,10 or nylon 6, 12. Moreover, the crystallinity rate of this combination of homopolymers is reduced to further improve clarity and transparency.

Owner:SHAKESPEARE CO

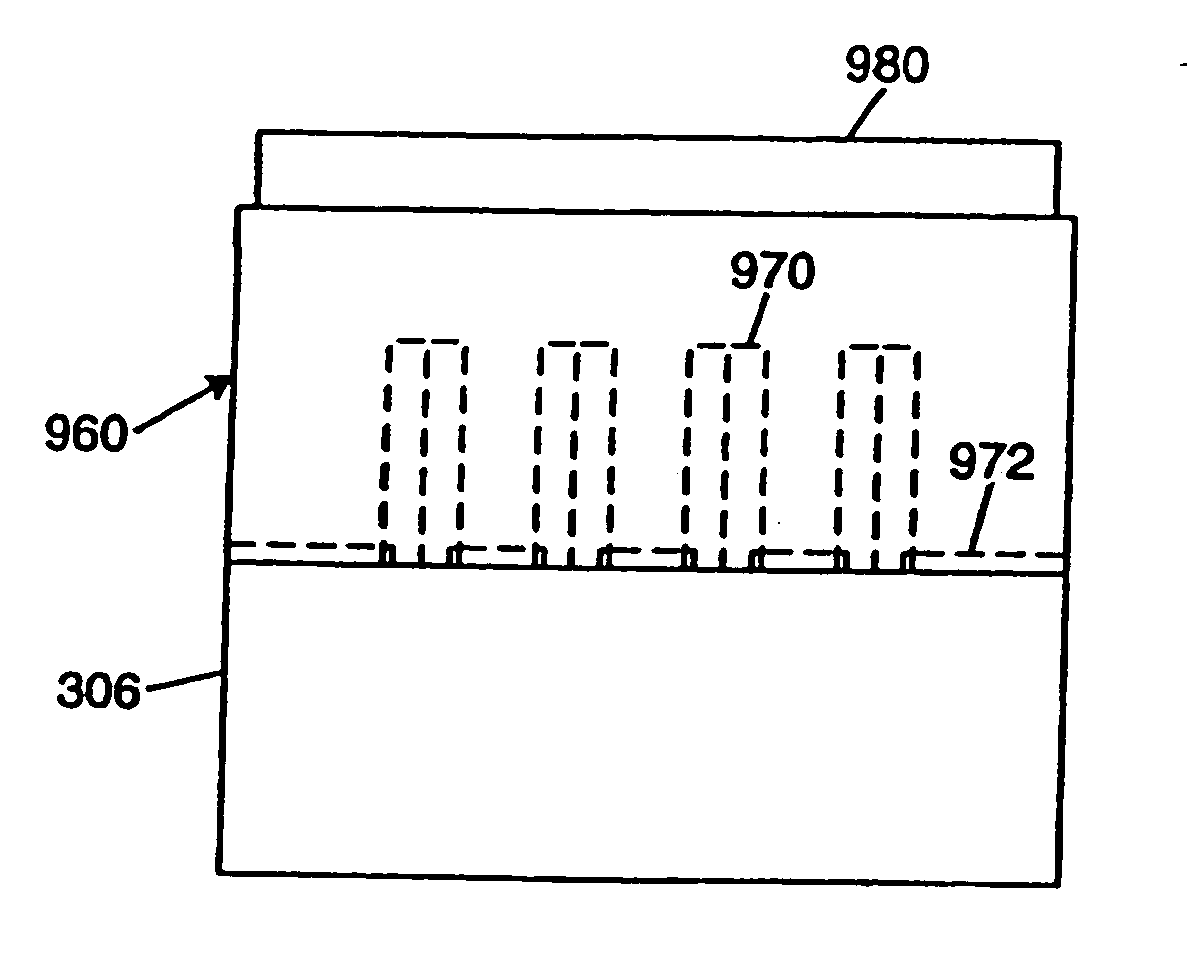

Mold for forming spacers for flat panel displays

InactiveUS20060139561A1Improve abilitiesLess brittleElectric discharge tubesPhotomechanical apparatusPotassium silicateDisplay device

The present invention describes thick film photolithographic molds, methods of making thick film photolithographic molds, and methods of using thick film photolithographic molds to form spacers on a substrate. The thick film photolithographic molds preferably comprise an epoxy bisphenol A novolac resin. The present invention also describes sol gel spacers comprising sodium silicates and potassium silicates. The thick film photolithographic molds and sol gel spacers of the present invention can be used in flat panel displays, such as field emission displays and plasma displays.

Owner:HOFMANN JAMES J +3

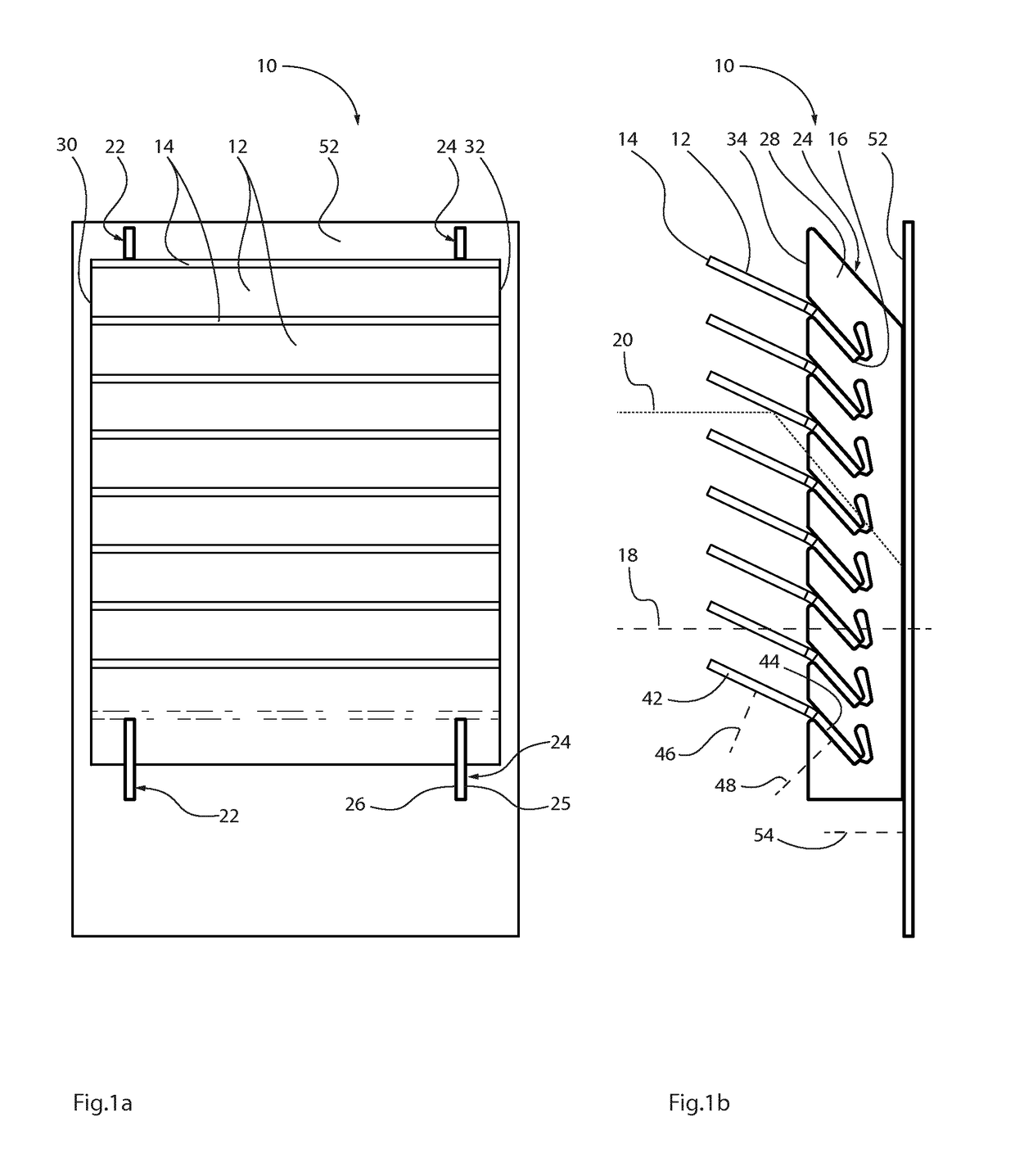

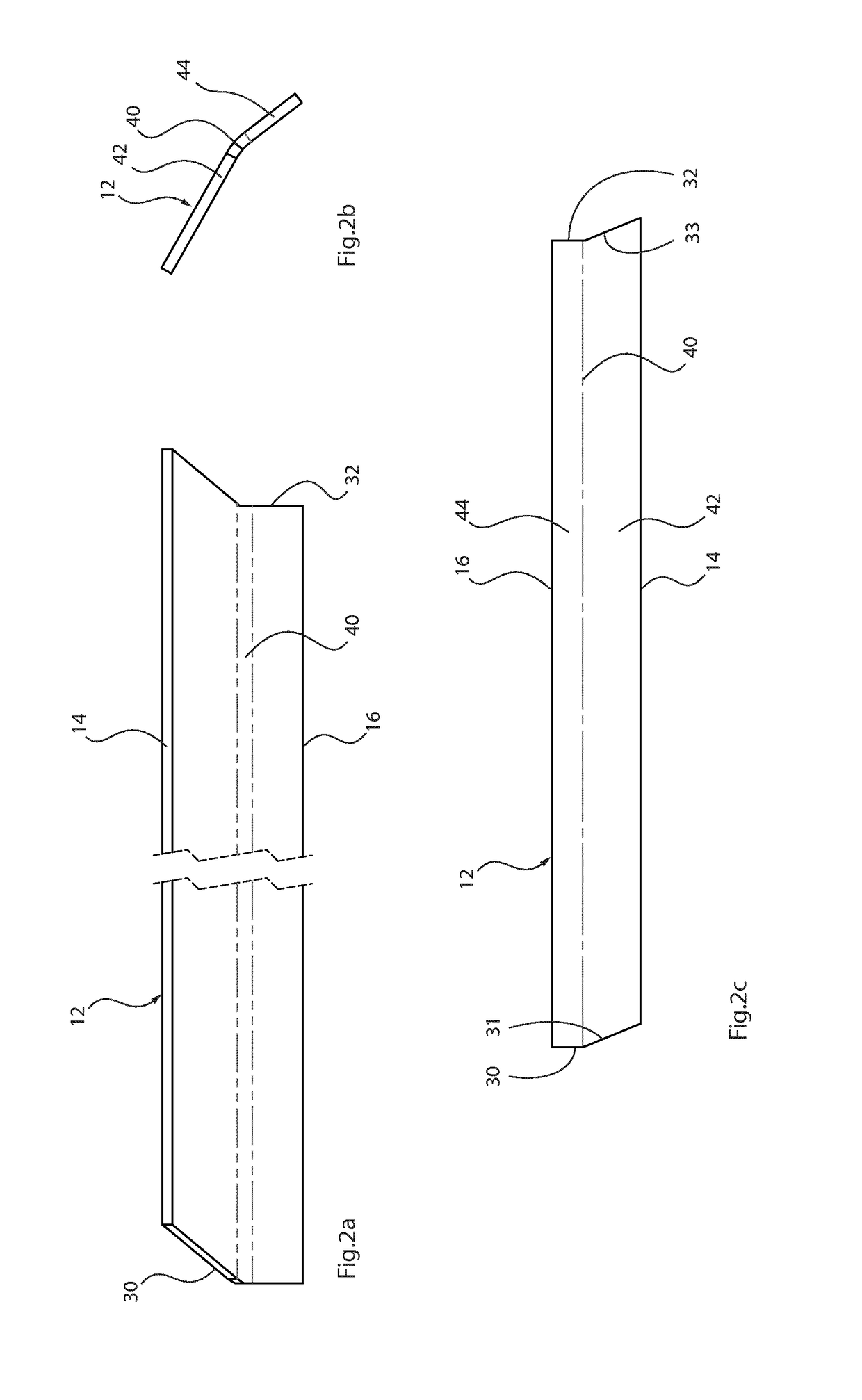

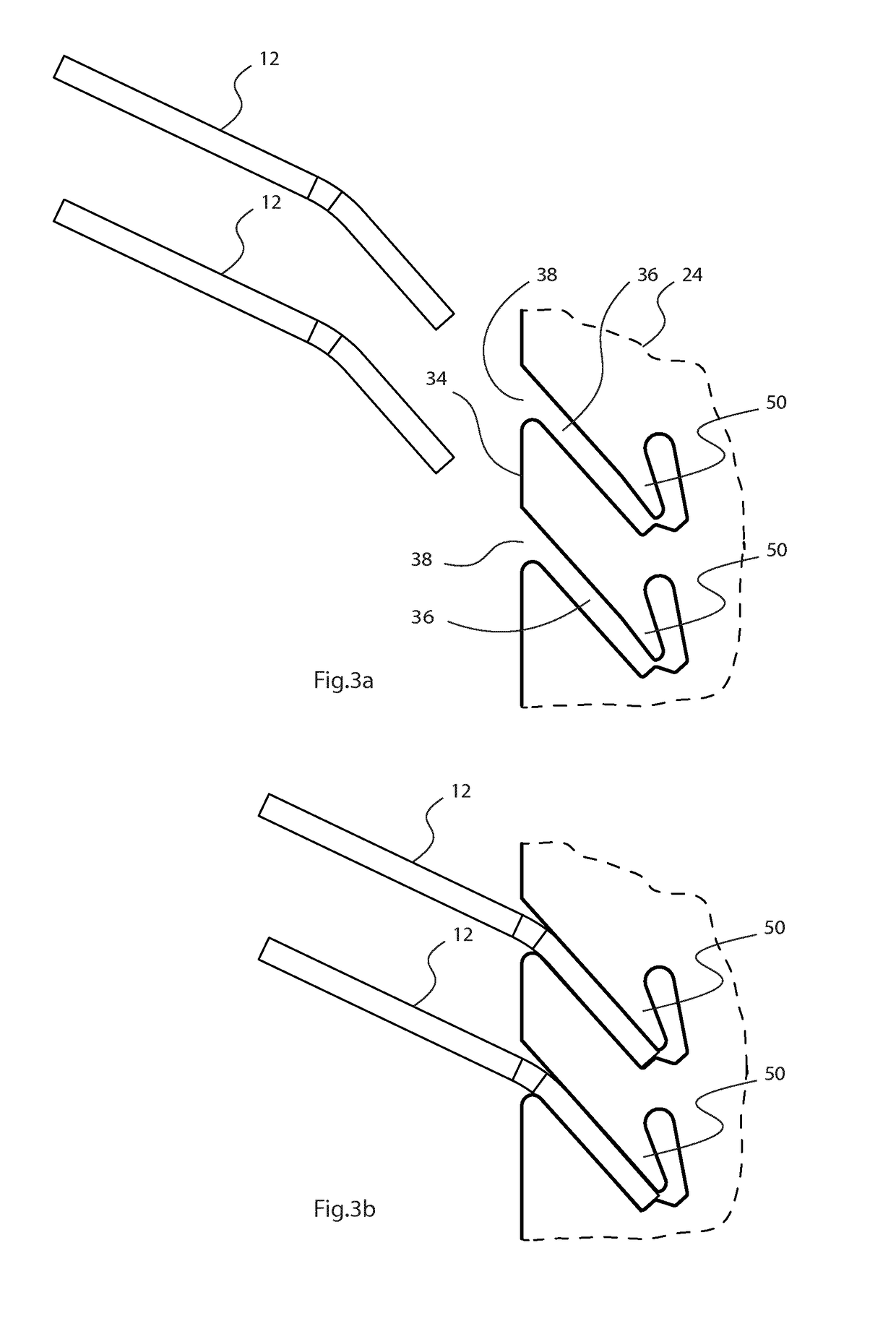

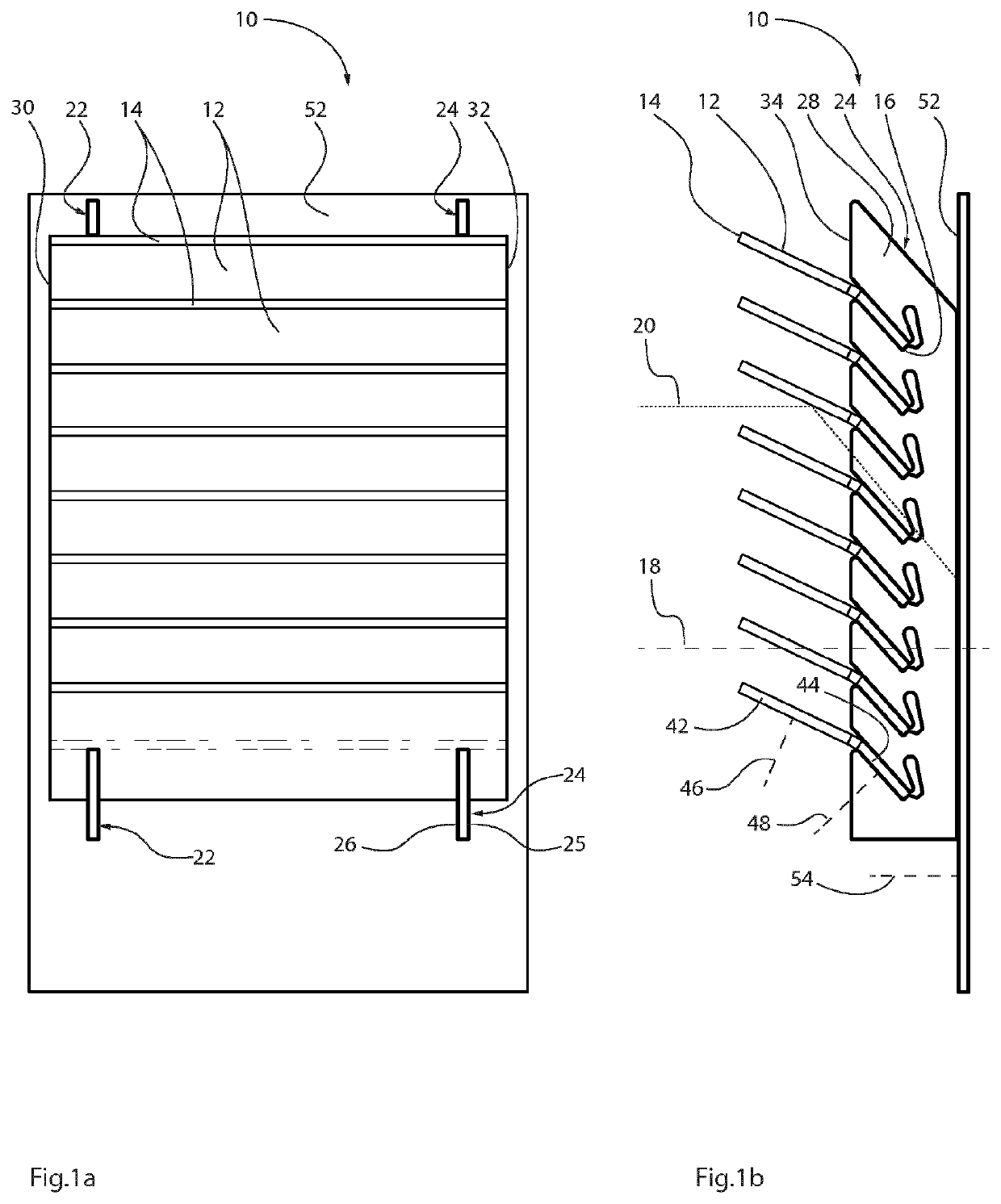

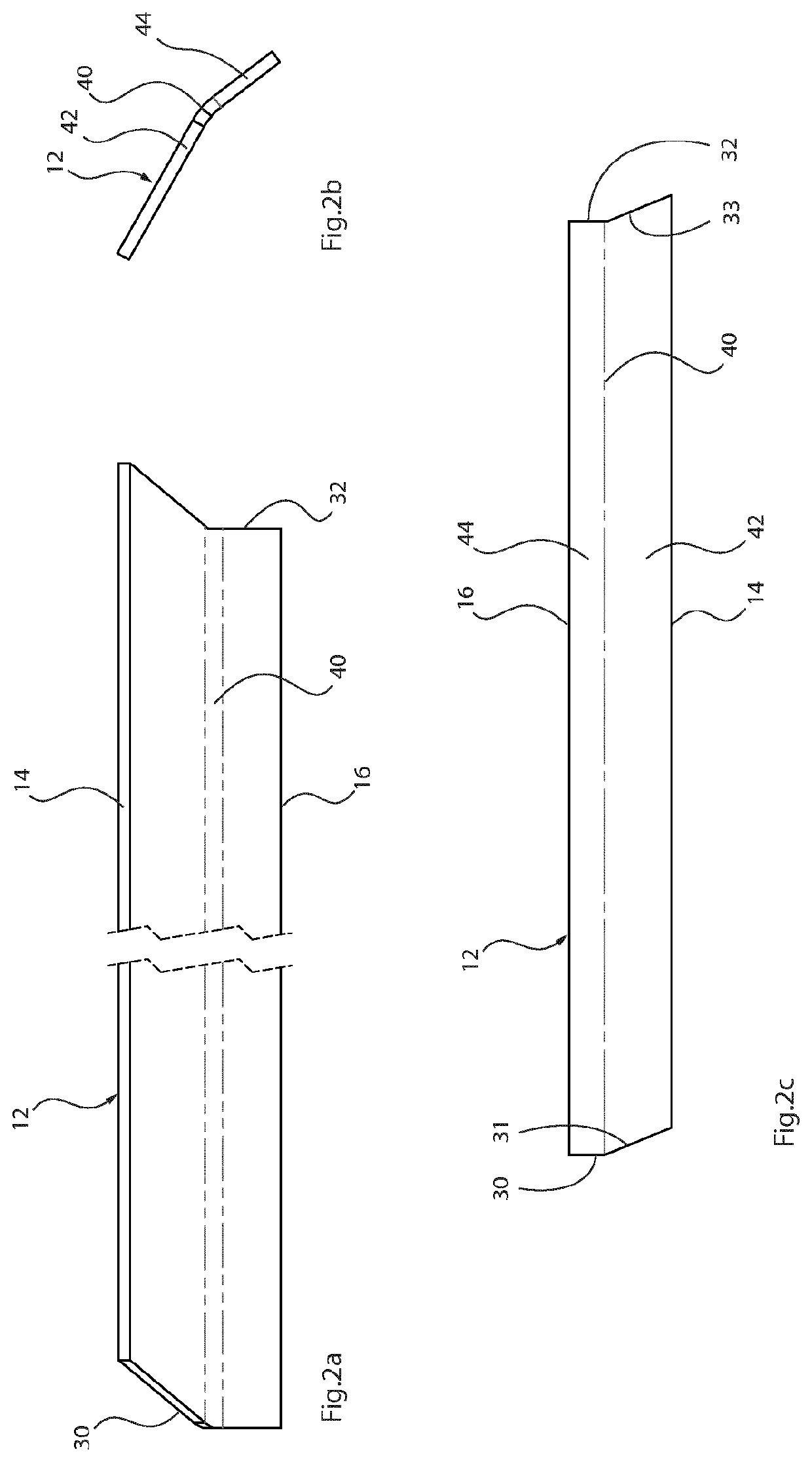

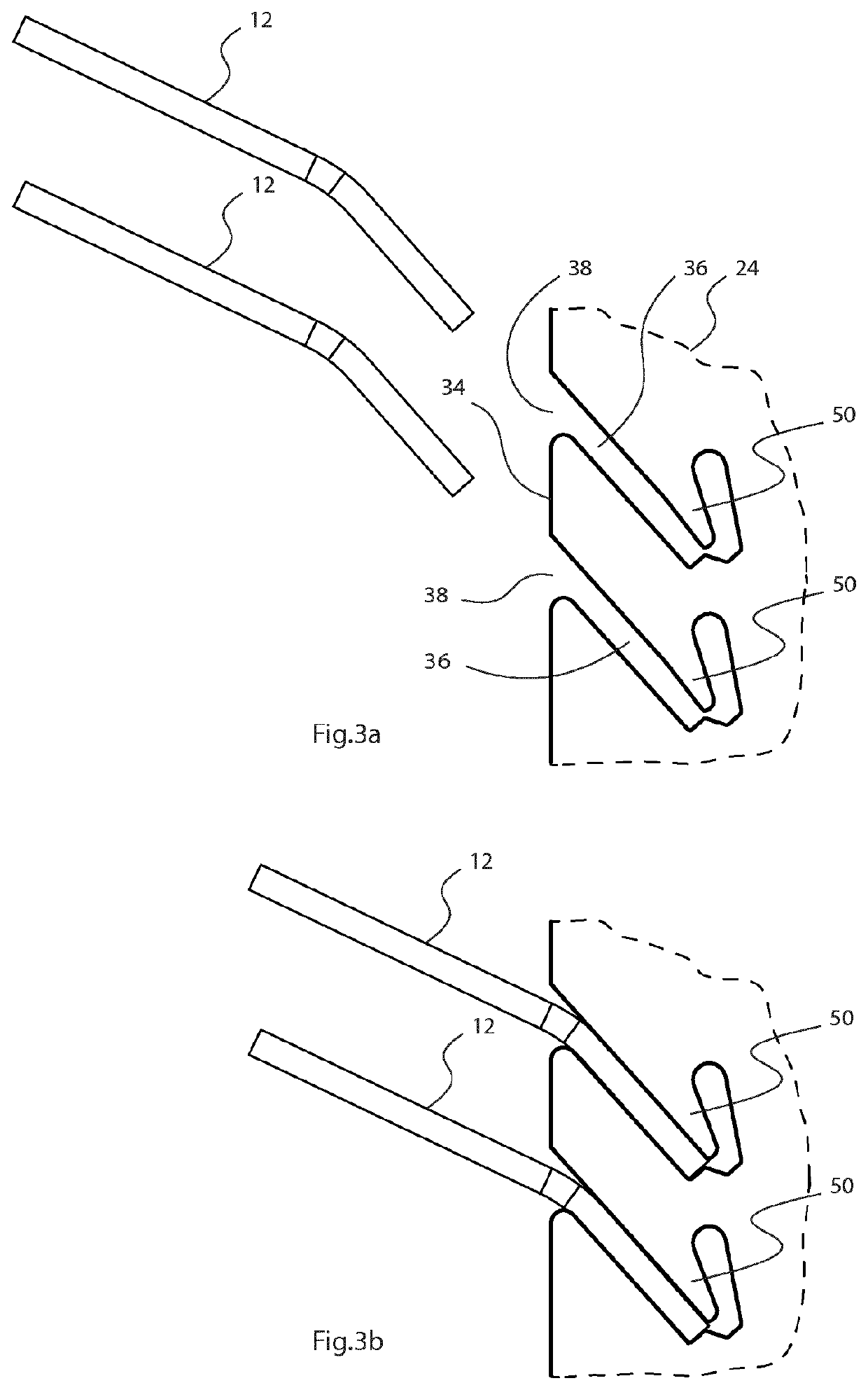

Frameless bullet trap

ActiveUS20190078861A1Compact structureReduce maintenanceArmourBullet catchersTrajectory of a projectileClassical mechanics

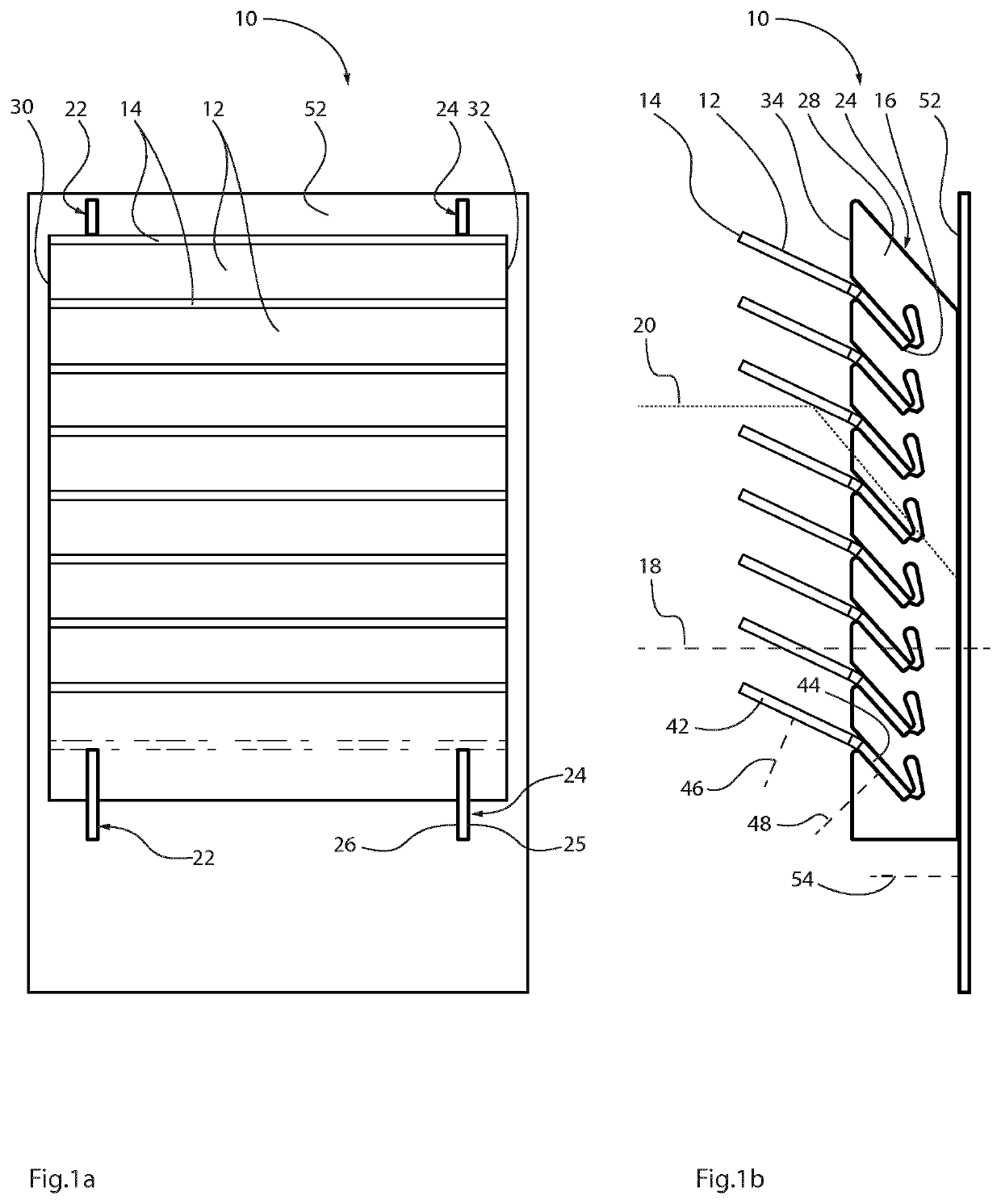

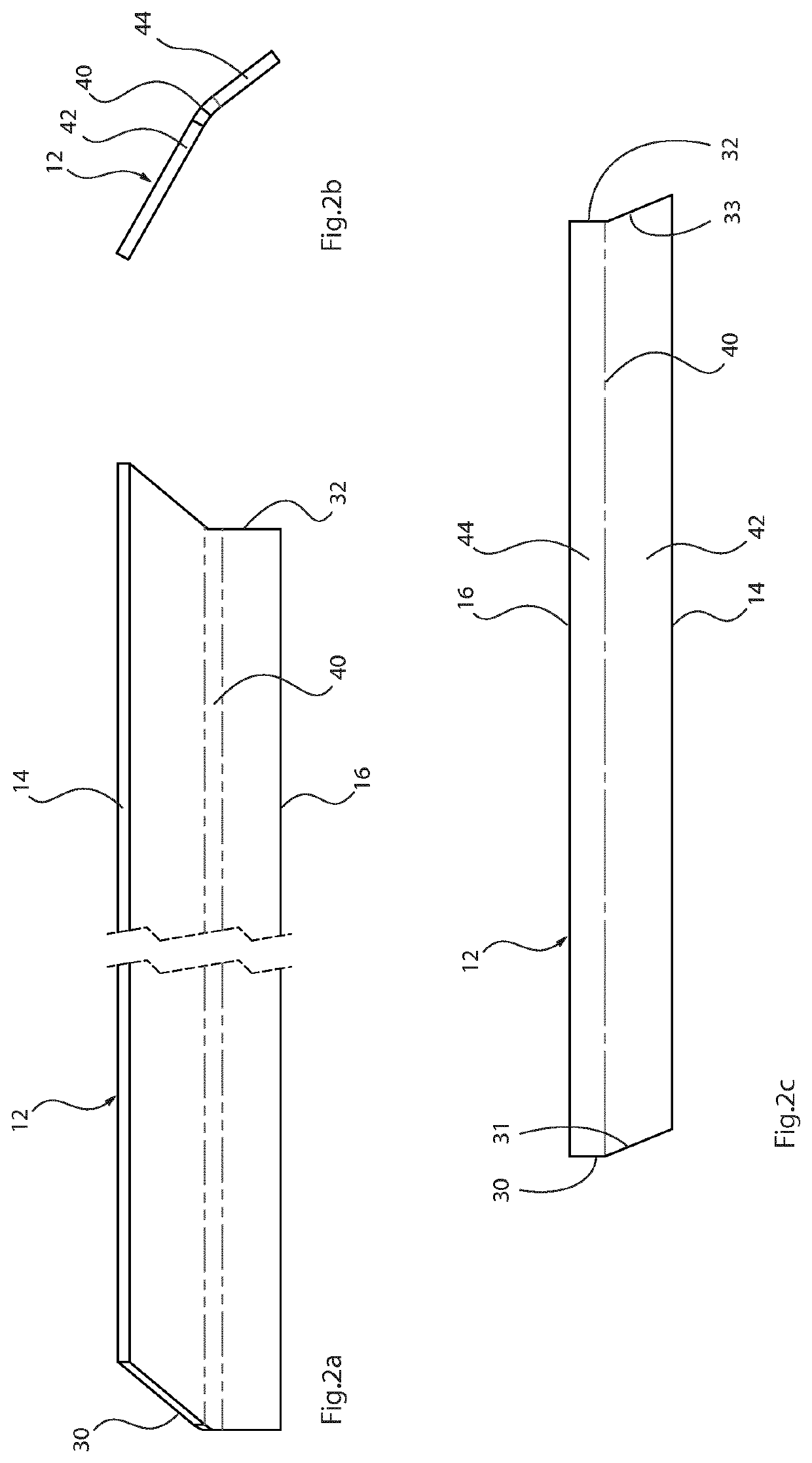

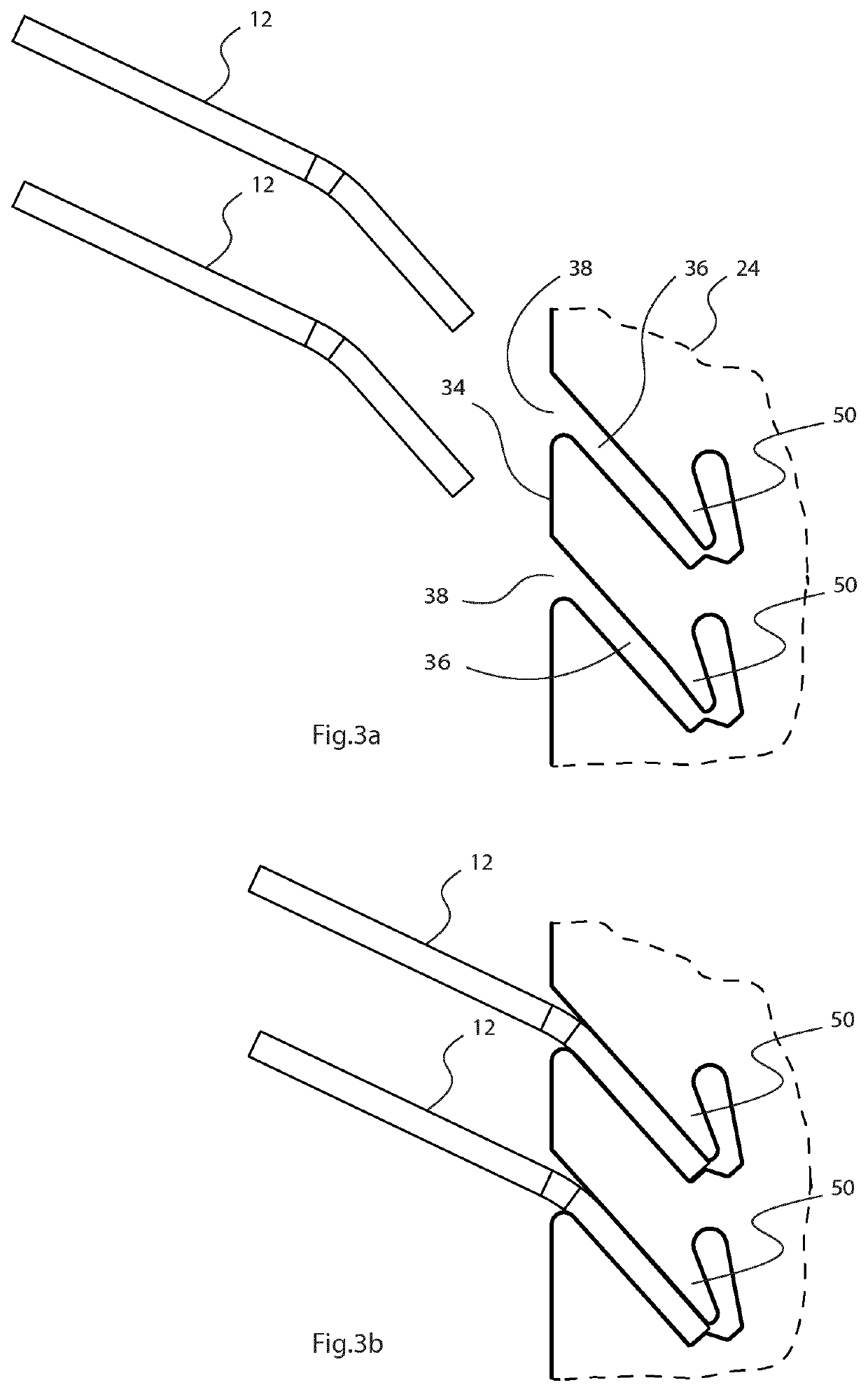

The invention relates to a slat arrangement for redirecting the trajectory of a bullet. The slat arrangement has a plurality of elongated steel slats, and each elongated steel slat has a longitudinal front edge and a longitudinal back edge stretching between a first end and a second end. The slat arrangement also has a support structure for supporting the plurality of steel slats. The steel slats are positioned in a louver-like fashion for changing the direction of a bullet following a trajectory along the normal of the slat arrangement. The support structure is connected to each steel slat at the back edge of the steel slat and between the first end and the second end of the steel slat.

Owner:ODIN TARGET

Frameless bullet trap

ActiveUS20200232771A1Reduce riskImprove the immunityArmour platesBullet catchersTrajectory of a projectileClassical mechanics

A slat arrangement for redirecting the trajectory of a bullet has a plurality of elongated steel slats, and each elongated steel slat has a longitudinal front edge and a longitudinal back edge stretching between a first end and a second end. The steel slats are positioned in a louver-like fashion for changing the direction of a bullet following a trajectory along the normal of the slat arrangement. A support structure is connected to each steel slat at the back edge of the steel slat, between the first end and the second end of the steel slat.

Owner:ODIN TARGET

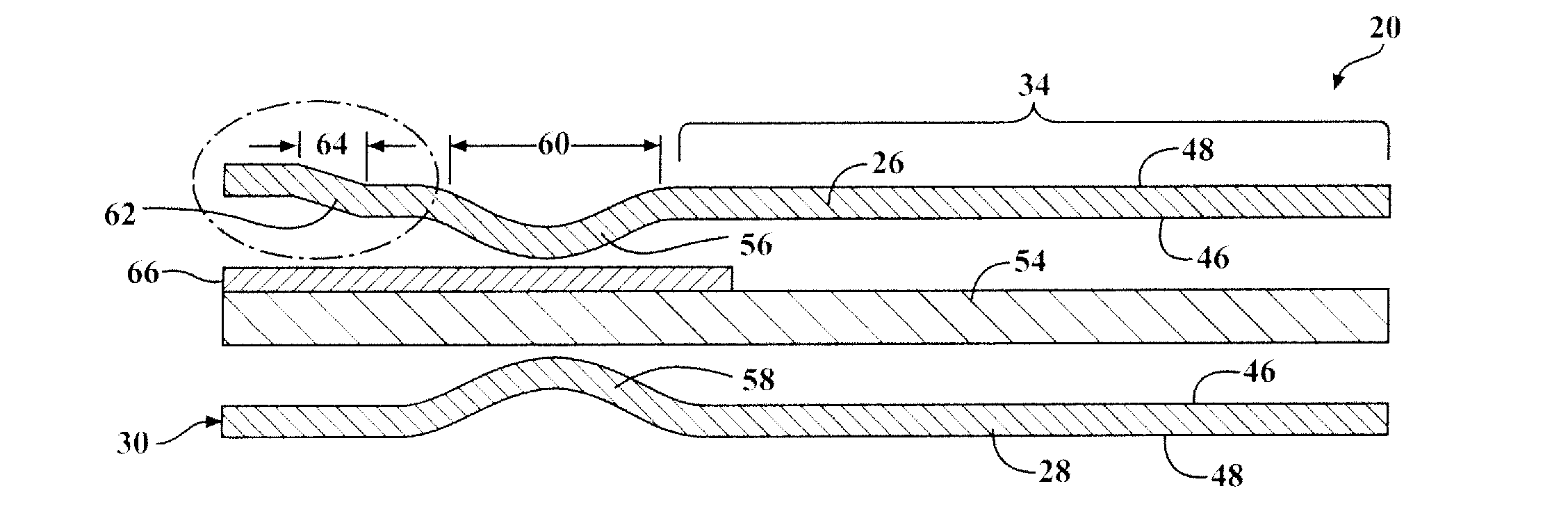

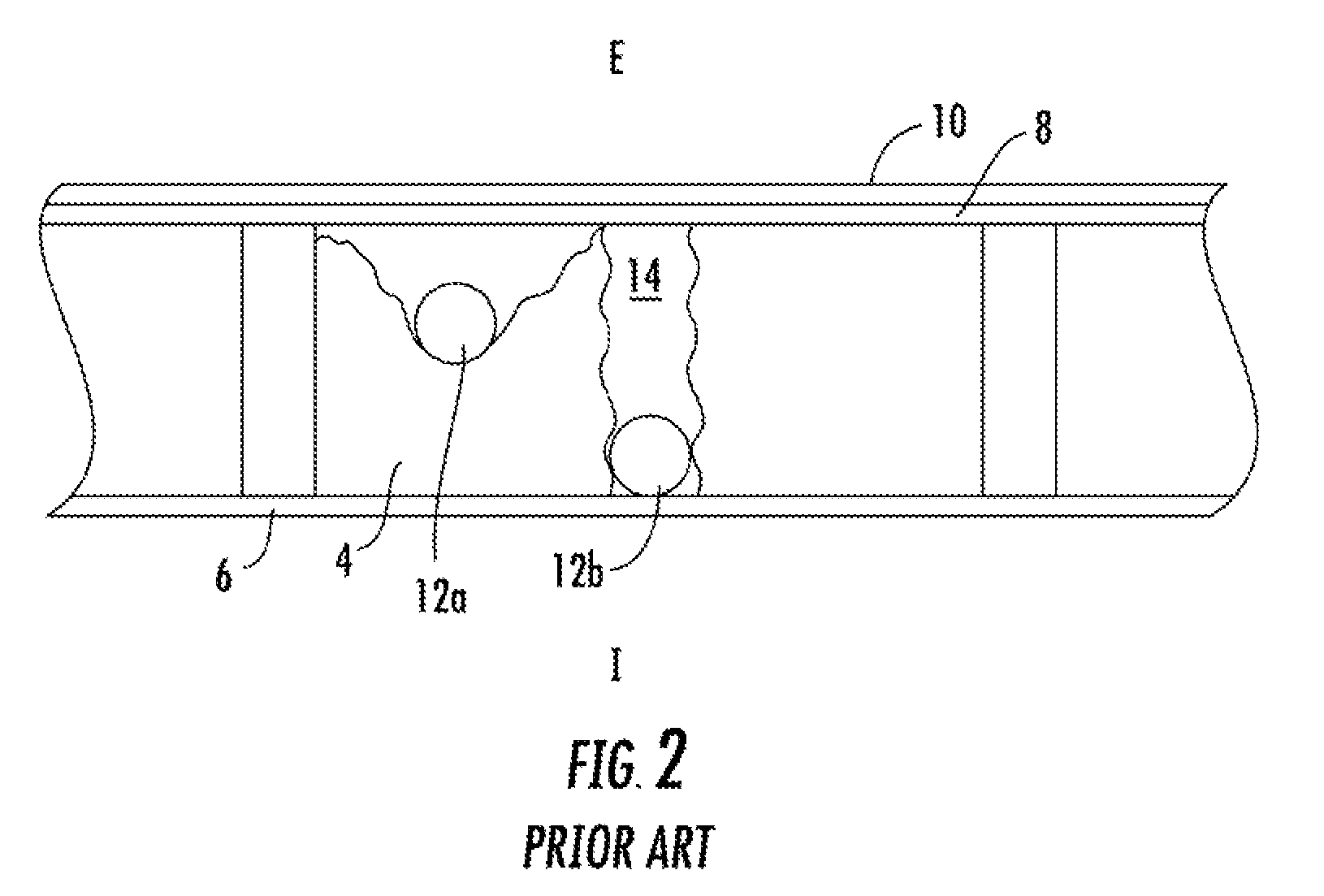

Pipe insulation system

InactiveUS8555574B2Improve flowLess prone to displacementThermal insulationPipesHeat flowNatural convection

A modular shell system of a hard insulation material fabricated in a geometric shape that encapsulates a pipe in insulation is provided. In an attic installation for example, the entire insulation component is inserted over a pipe and into the space between the building structural wood framing members resting on the interior sheathing below. By placing a series of these interlocking insulating modules along a pipe that is run perpendicular to the building construction members, the piping is encapsulated in a continuous insulating system along its entire length. This design facilitates natural heat flow into the pipe with an open pipe slot cavity in the insulating module that allows natural convection heat to pass up through the elongated piping slot, allowing it to come into contact with this piping.

Owner:INSULATION SYST

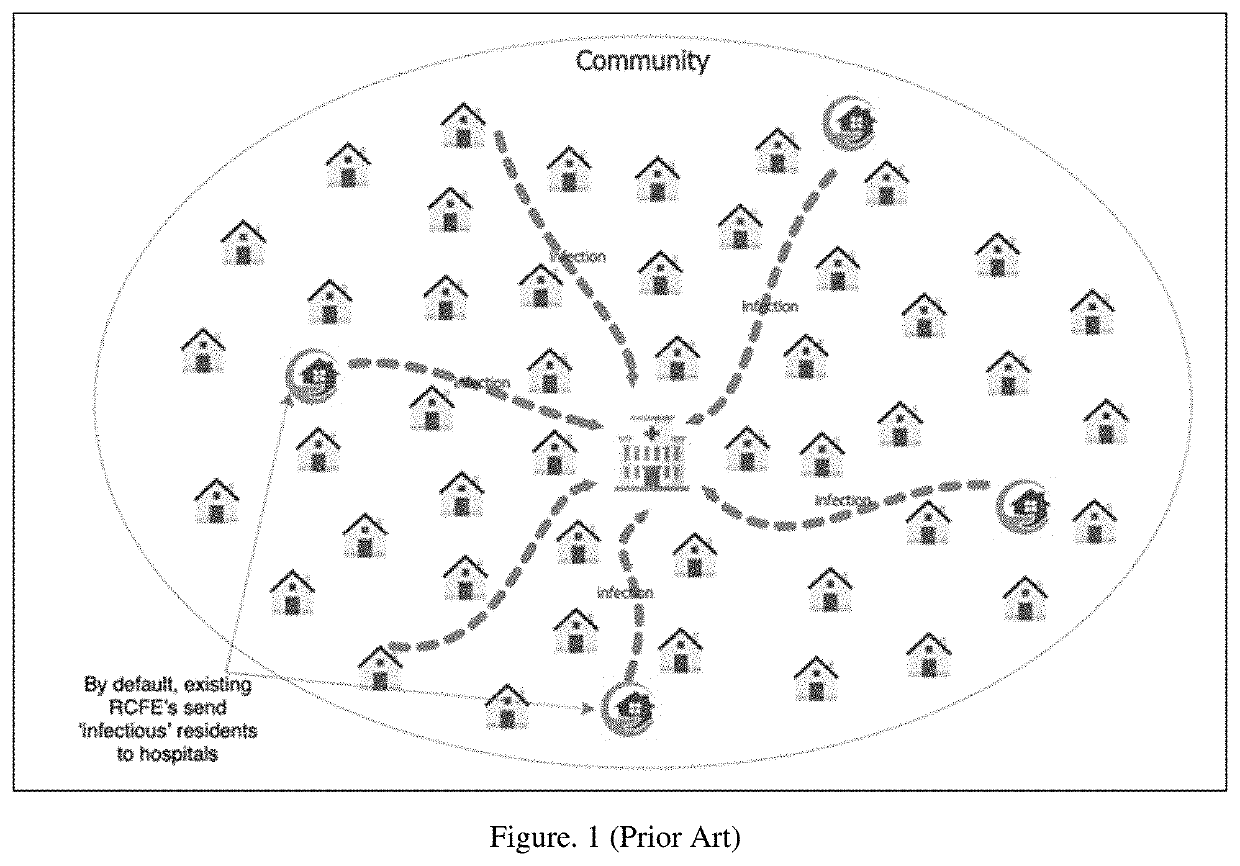

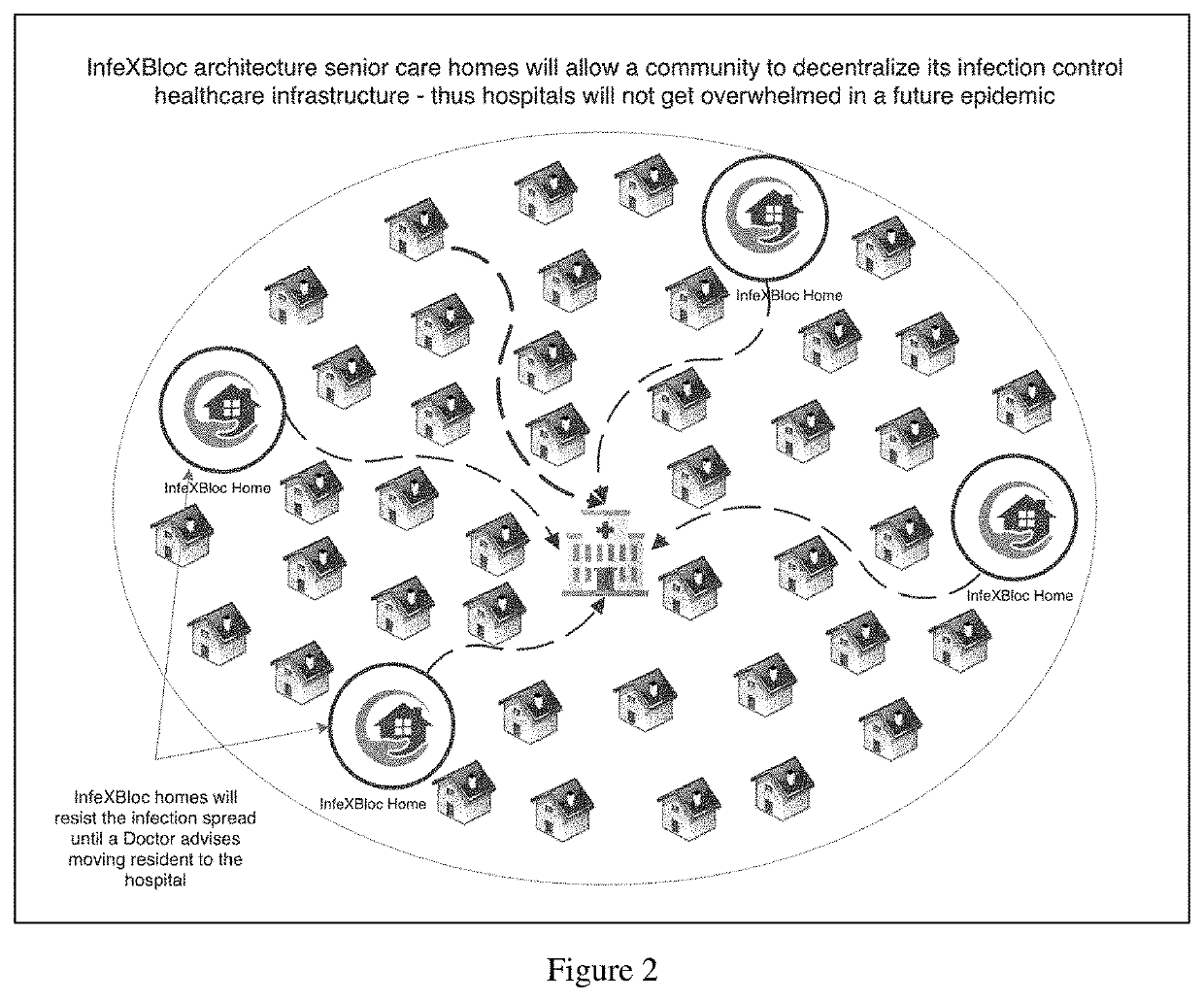

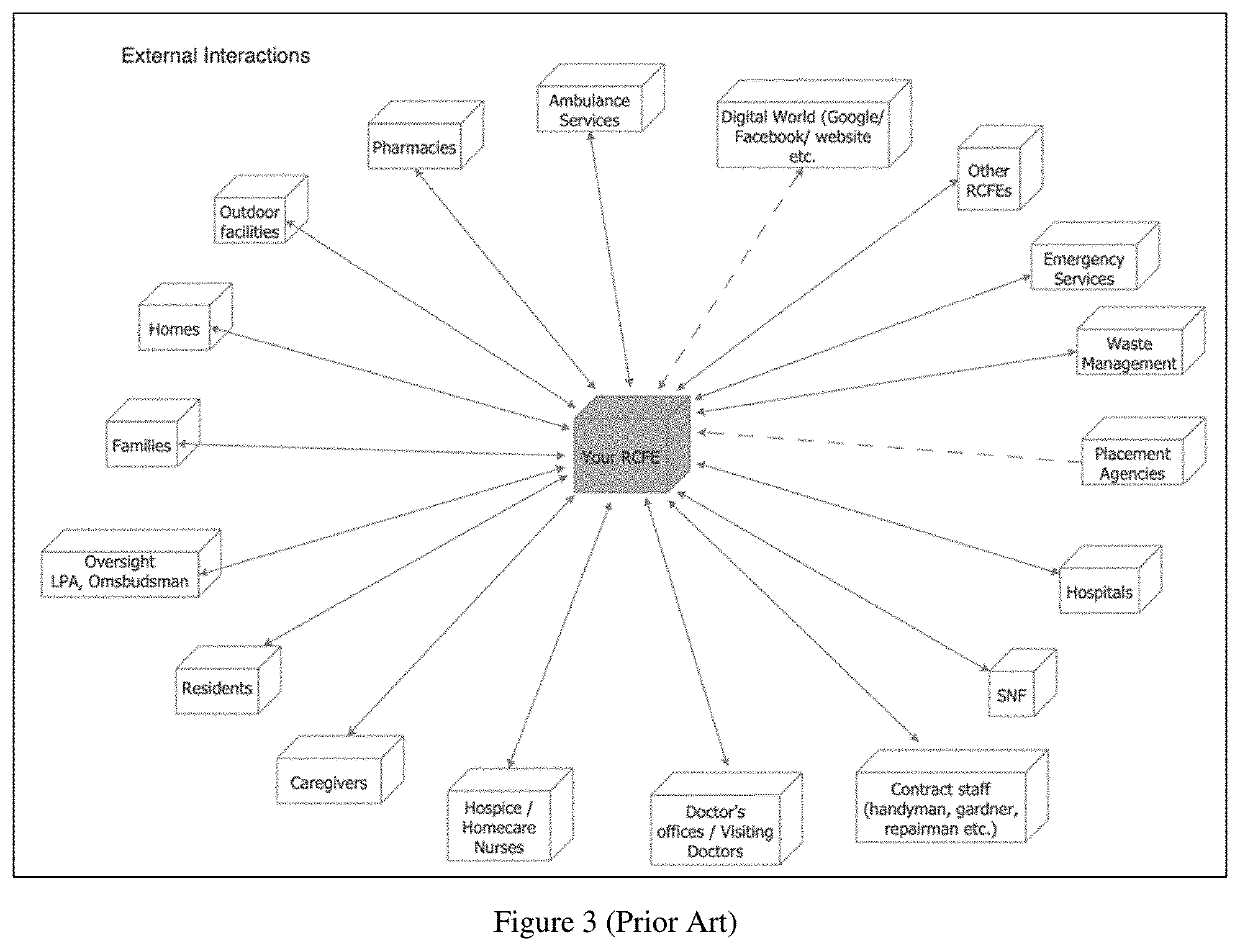

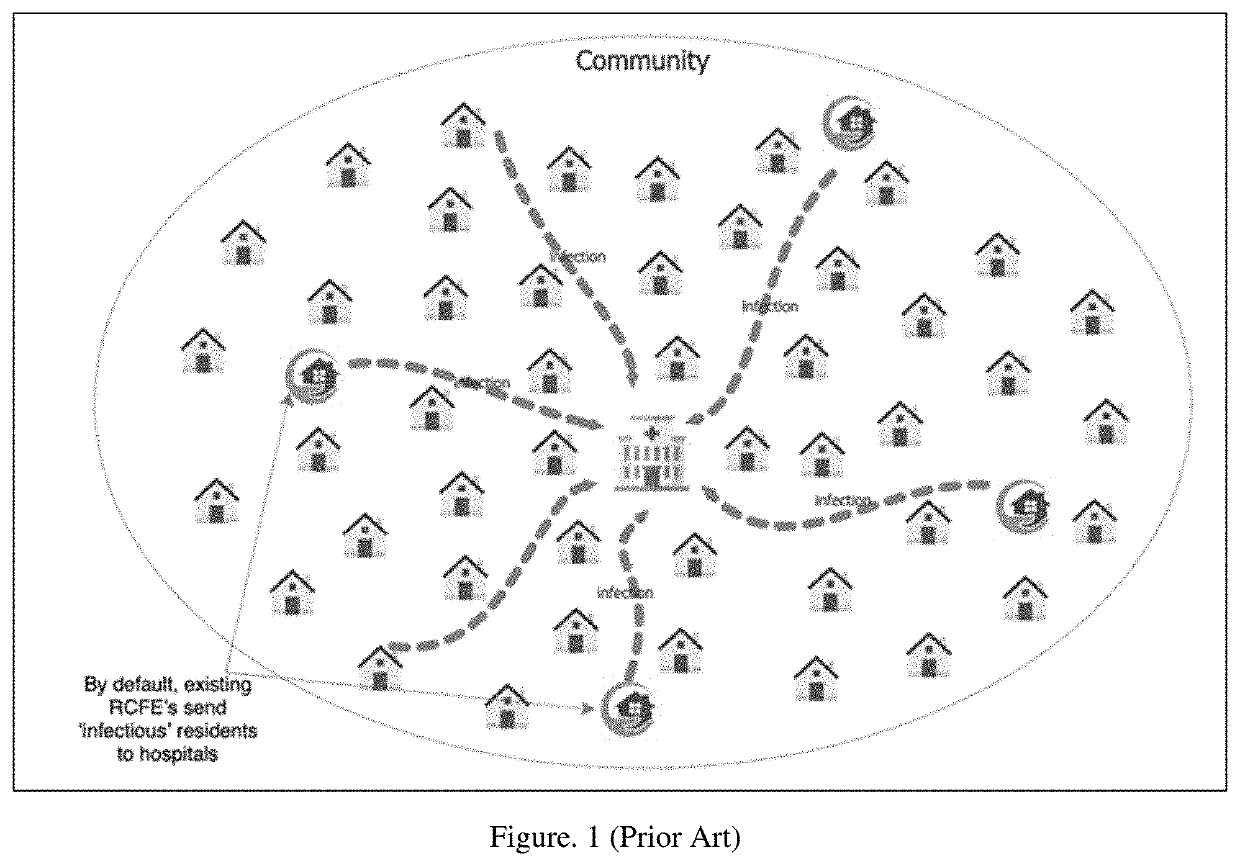

Methods for administering residential care facility

InactiveUS20220005592A1Environment safetyNew informationVoting arrangementHealth-index calculationResidential careEmergency medicine

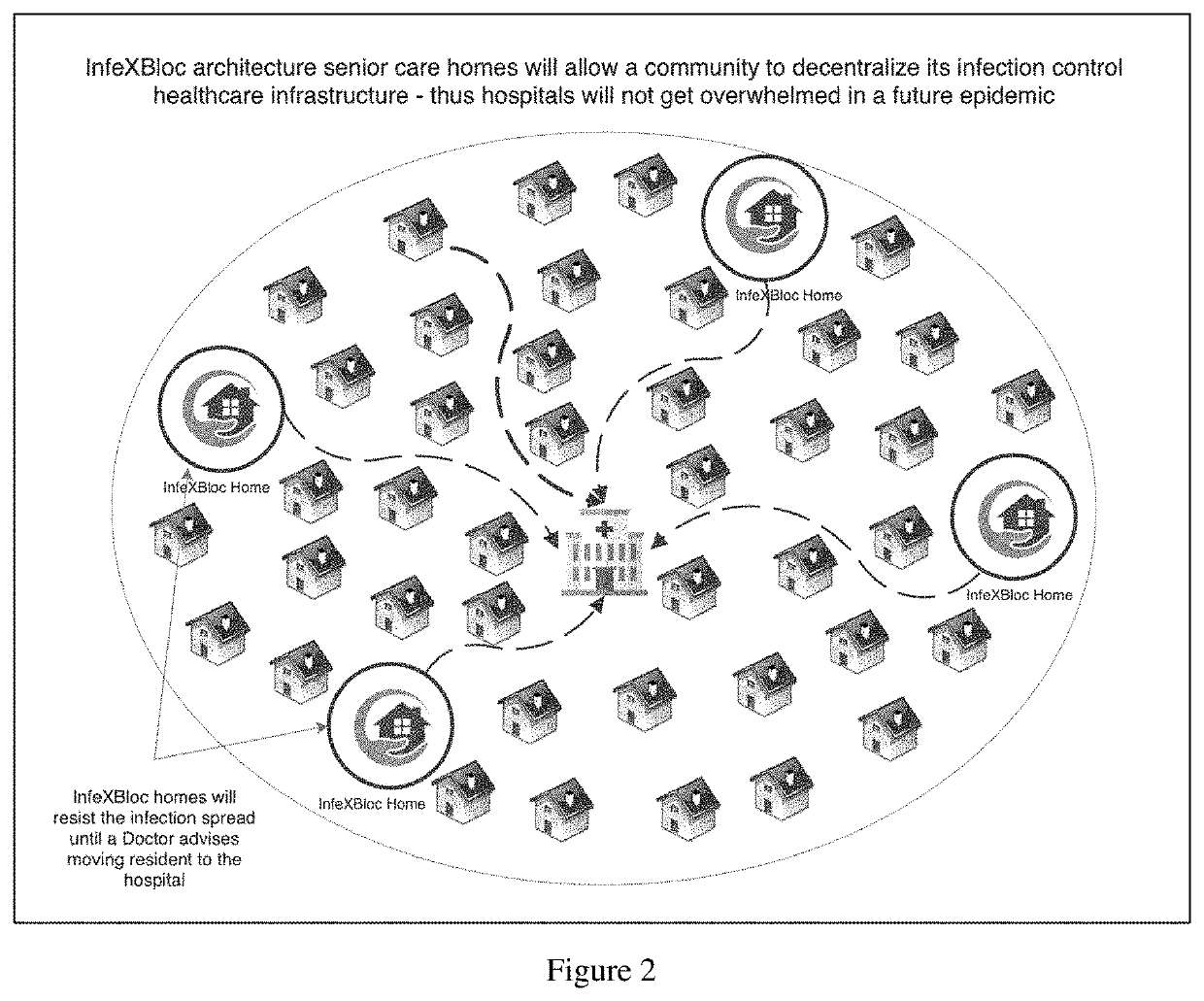

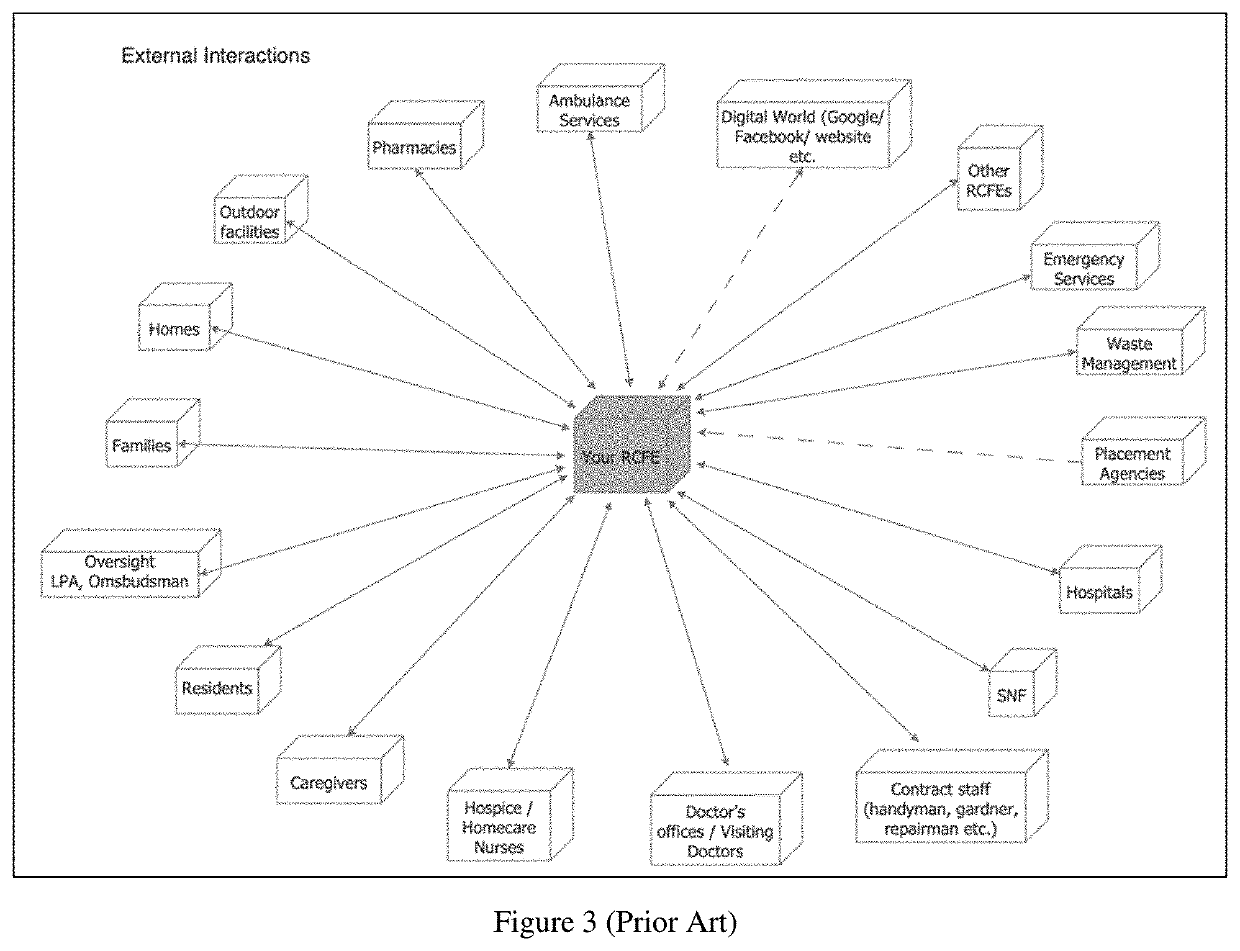

Assisted Living facility administration methods are disclosed for effectively preventing infection spread. A decentralized architecture and innovative systems including InfeXPASS™ (a certified designation of a person's health status), InfeXCON™ (a facility's real-time risk designation), a InfeXBloc™ Scorecard system (rating of facilities' implemented infection safety measures), and a InfeXSIM™ system to depict the simulation of an operating facility are provided to increase resistance to infection transmission while retaining the residential setting.

Owner:PRATIBHA CREATIVE RESOURCES LLC

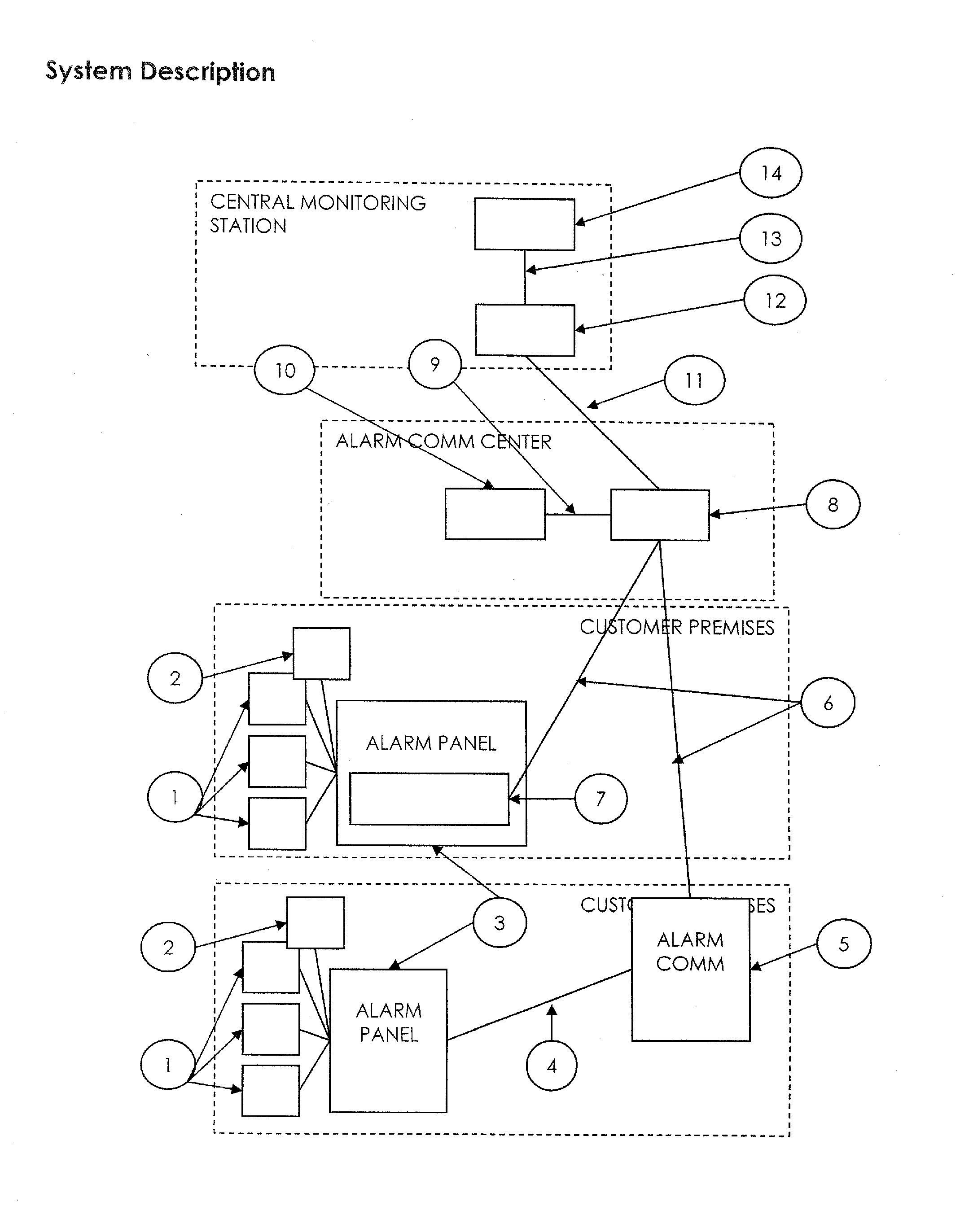

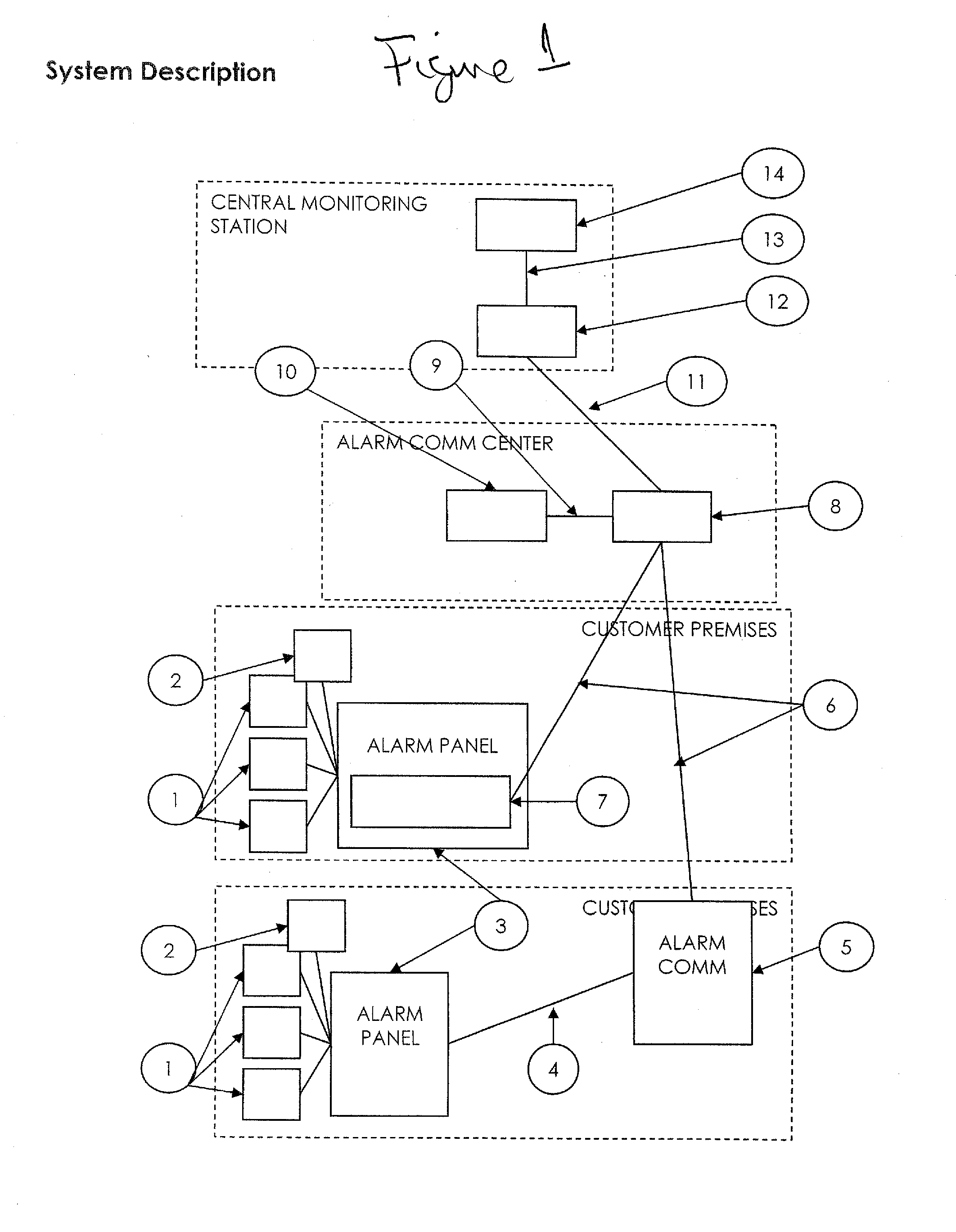

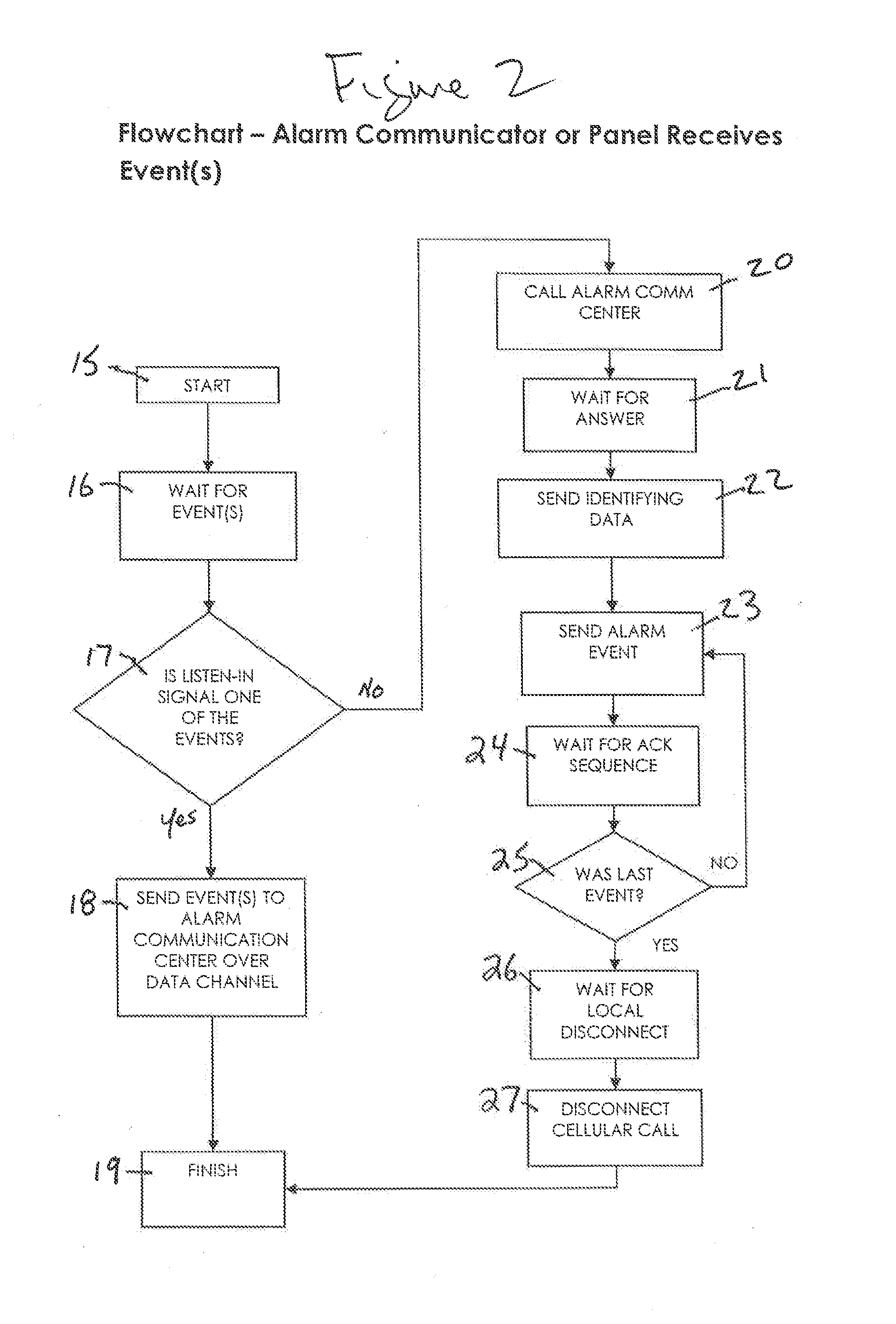

In-band voice with security signaling

InactiveUS20130189943A1More resilientAvoid transmissionEmergency connection handlingTelephonic communicationComputer networkTechnical standard

The present invention includes an aspect directed to in-band voice capabilities with security signaling. For sessions that do not involve voice, the signaling data can be sent to the alarm communication center using a data channel, without using a voice channel. In other aspects, the protocol used to transmit alarm events from the alarm device to the alarm communication center resembles industry-standard alarm format, but differs in specific ways that recognize both advantages and disadvantages of the cellular medium. In yet other aspects, the invention may use a timeout in order to ensure orderly resource management in the case of a communication failure.

Owner:TELULAR

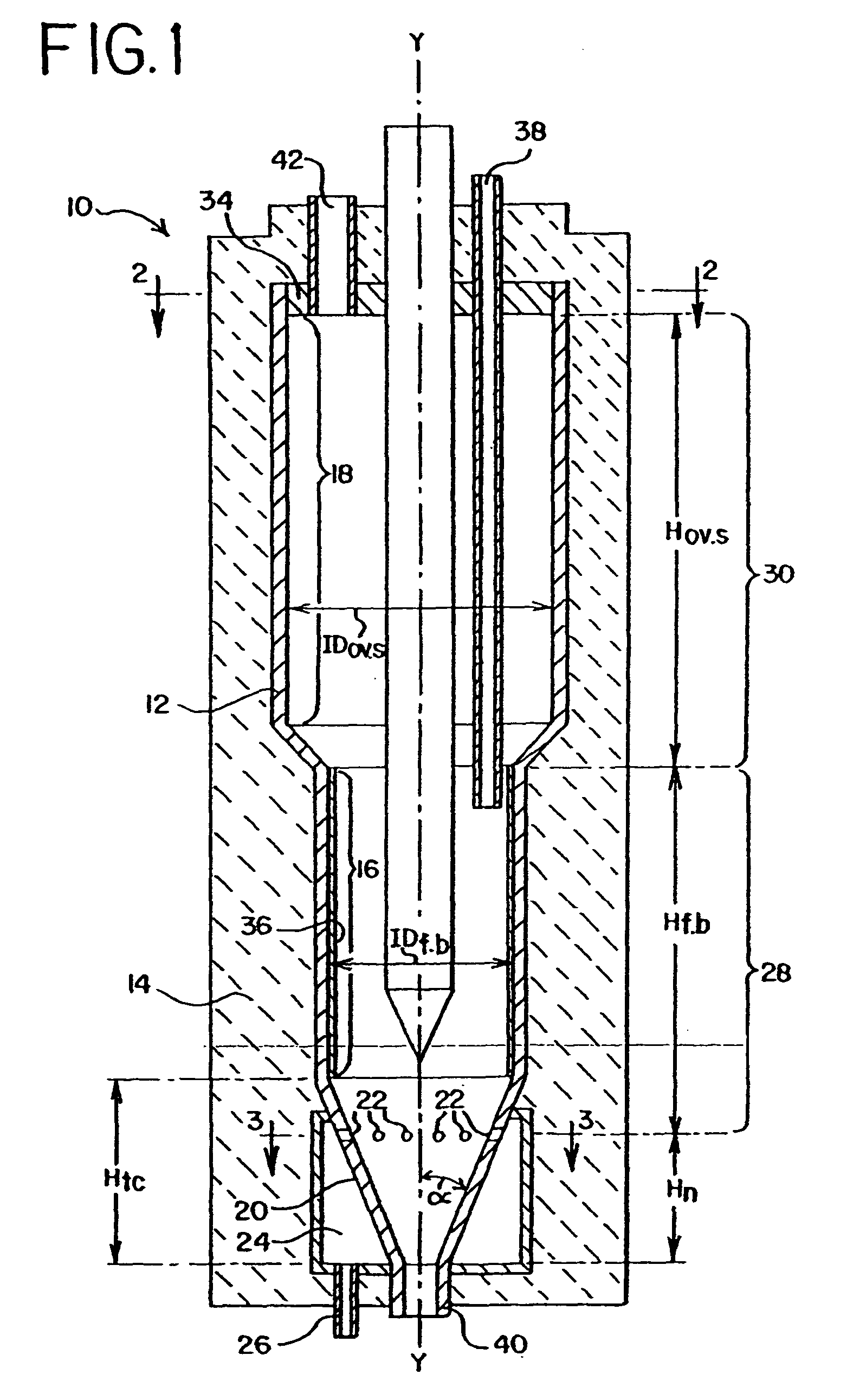

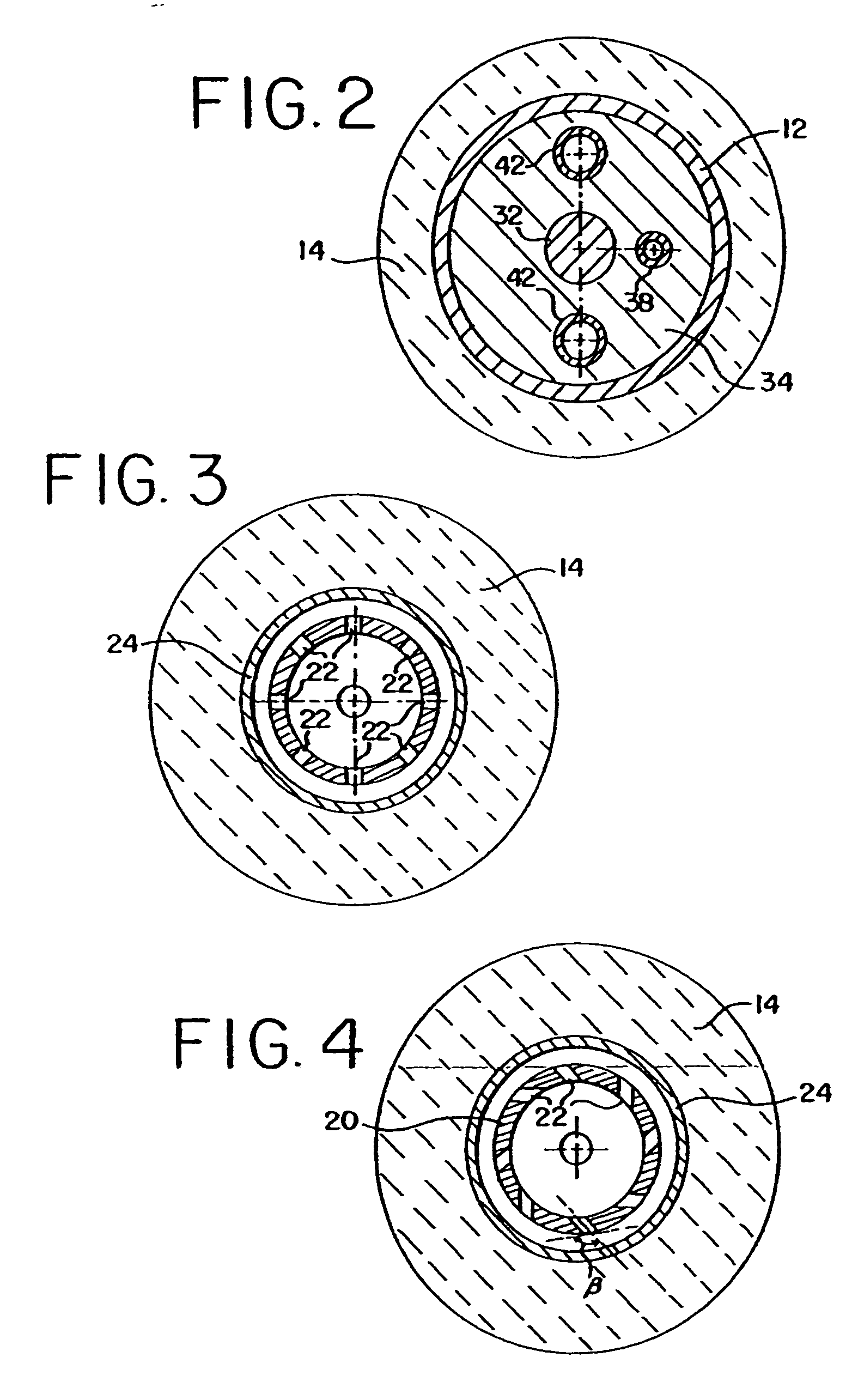

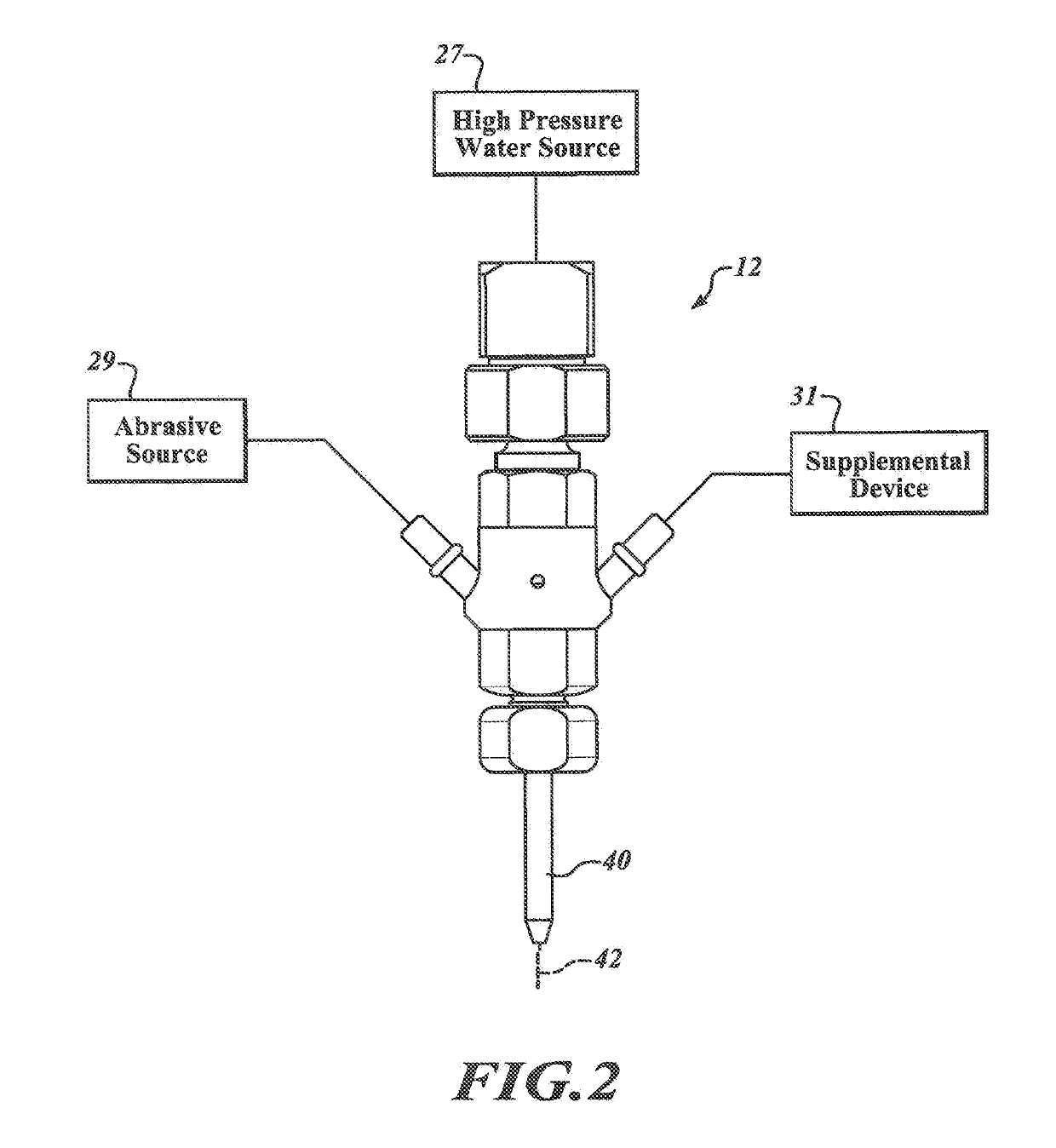

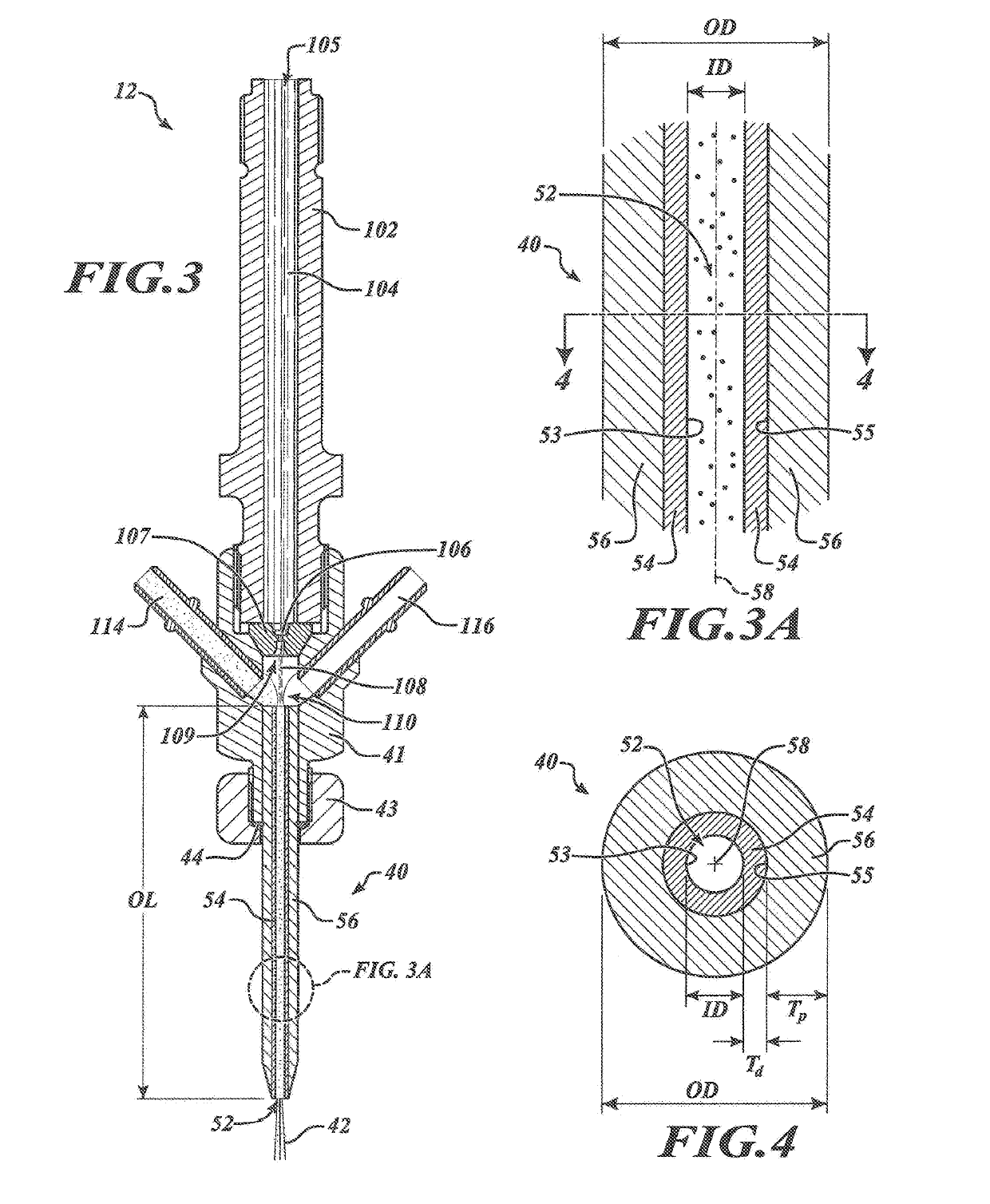

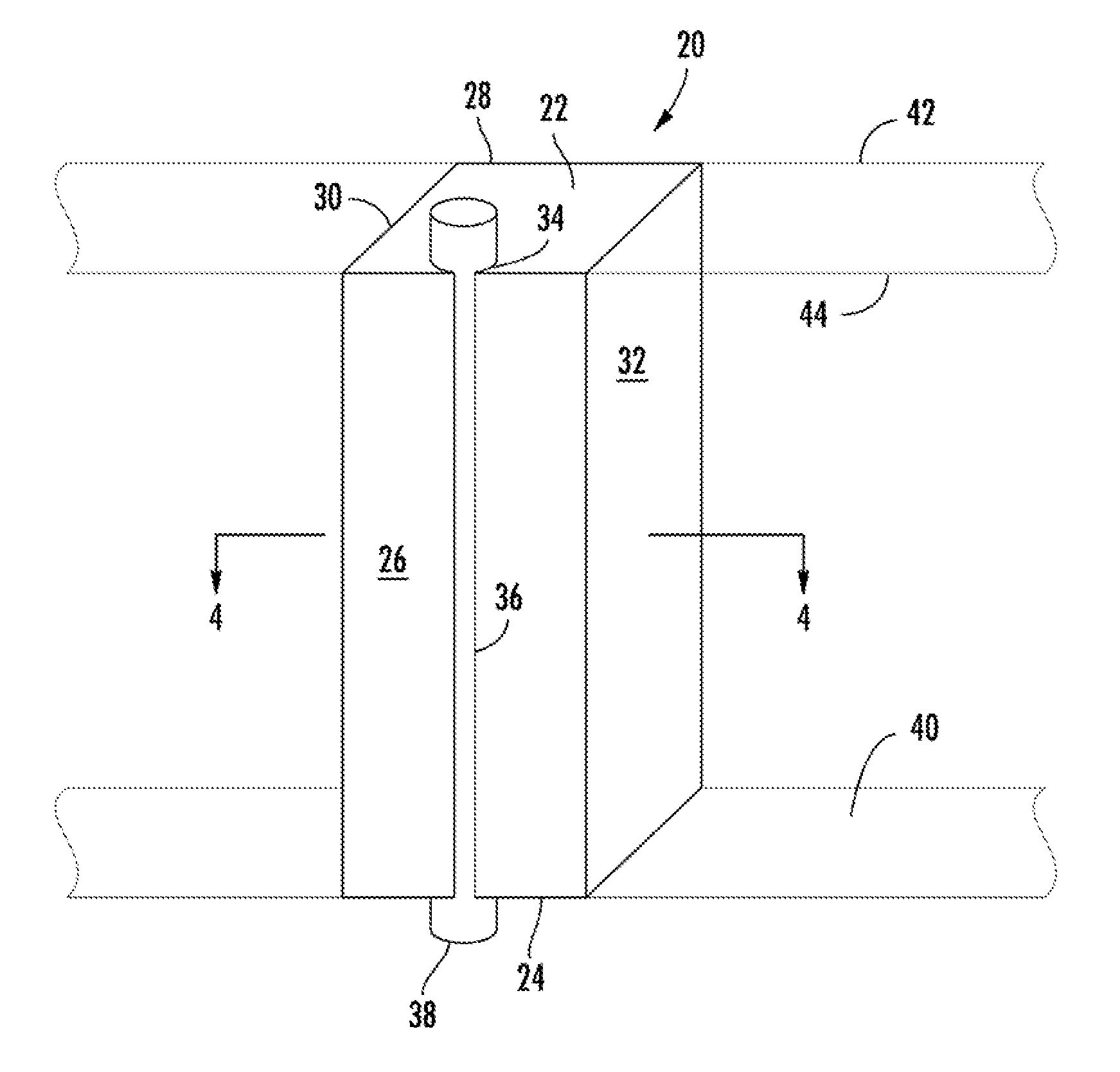

Fluid jet nozzles and methods of making same

PendingUS20190184523A1Function increaseEasy to manufactureMolten spray coatingBlast gunsDirect metal laser sinteringManufacturing technology

Reinforced diamond nozzles and methods of making the same for fluid jet cutting applications are provided. An example method includes forming or providing a tubular diamond body having a jet passage extending therethrough and establishing a protective casing around the tubular diamond body so that an entirety or substantially an entirety of an outer circumferential surface area of the tubular diamond body is directly contacted and reinforced by the protective casing. Establishing the protective casing around the tubular diamond body may include thermal spraying, casting, direct metal laser sintering, or other fabrication techniques.

Owner:FLOW INT

Pipe insulation system

InactiveUS20120023844A1Improve flowLess prone to displacementThermal insulationPipesHeat flowNatural convection

A modular shell system of a hard insulation material fabricated in a geometric shape that encapsulates a pipe in insulation is provided. In an attic installation for example, the entire insulation component is inserted over a pipe and into the space between the building structural wood framing members resting on the interior sheathing below. By placing a series of these interlocking insulating modules along a pipe that is run perpendicular to the building construction members, the piping is encapsulated in a continuous insulating system along its entire length. This design facilitates natural heat flow into the pipe with an open pipe slot cavity in the insulating module that allows natural convection heat to pass up through the elongated piping slot, allowing it to come into contact with this piping.

Owner:INSULATION SYST

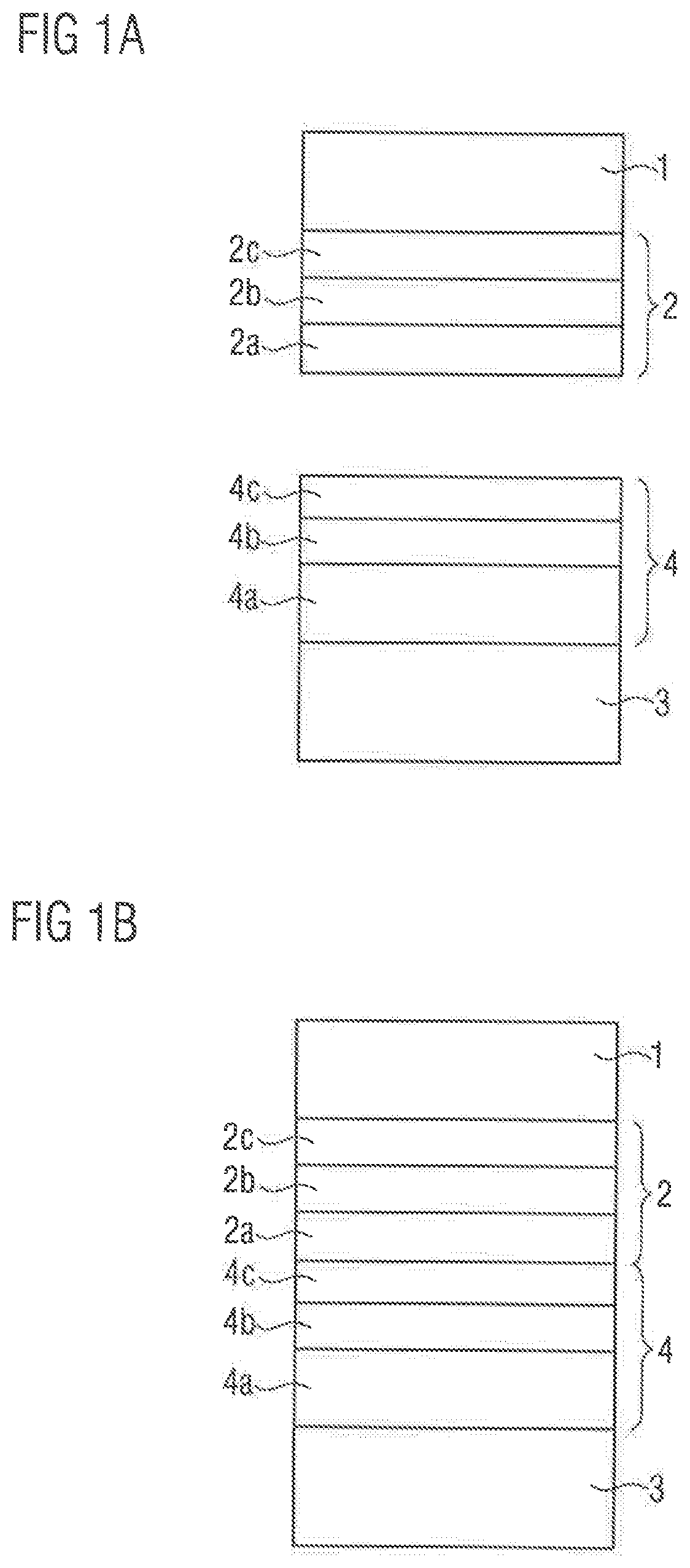

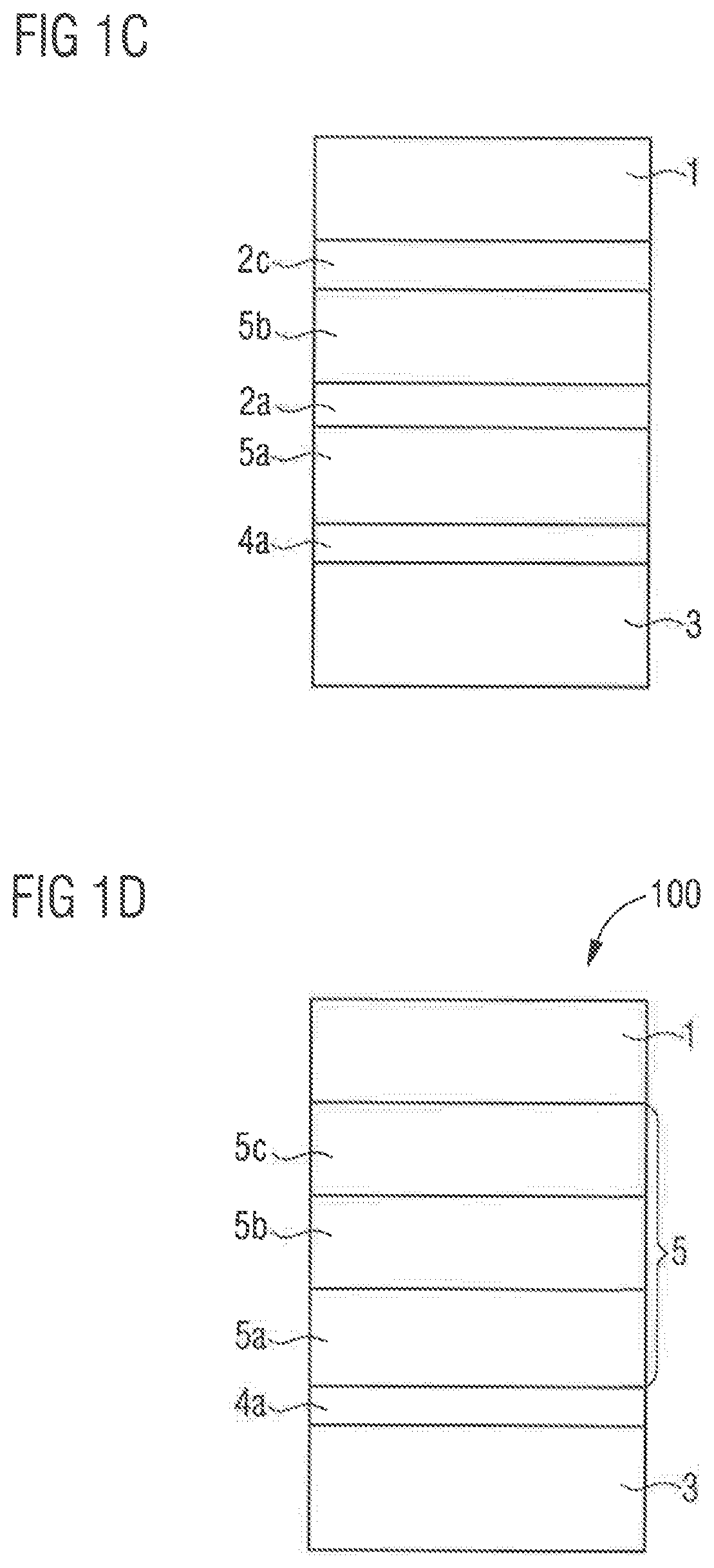

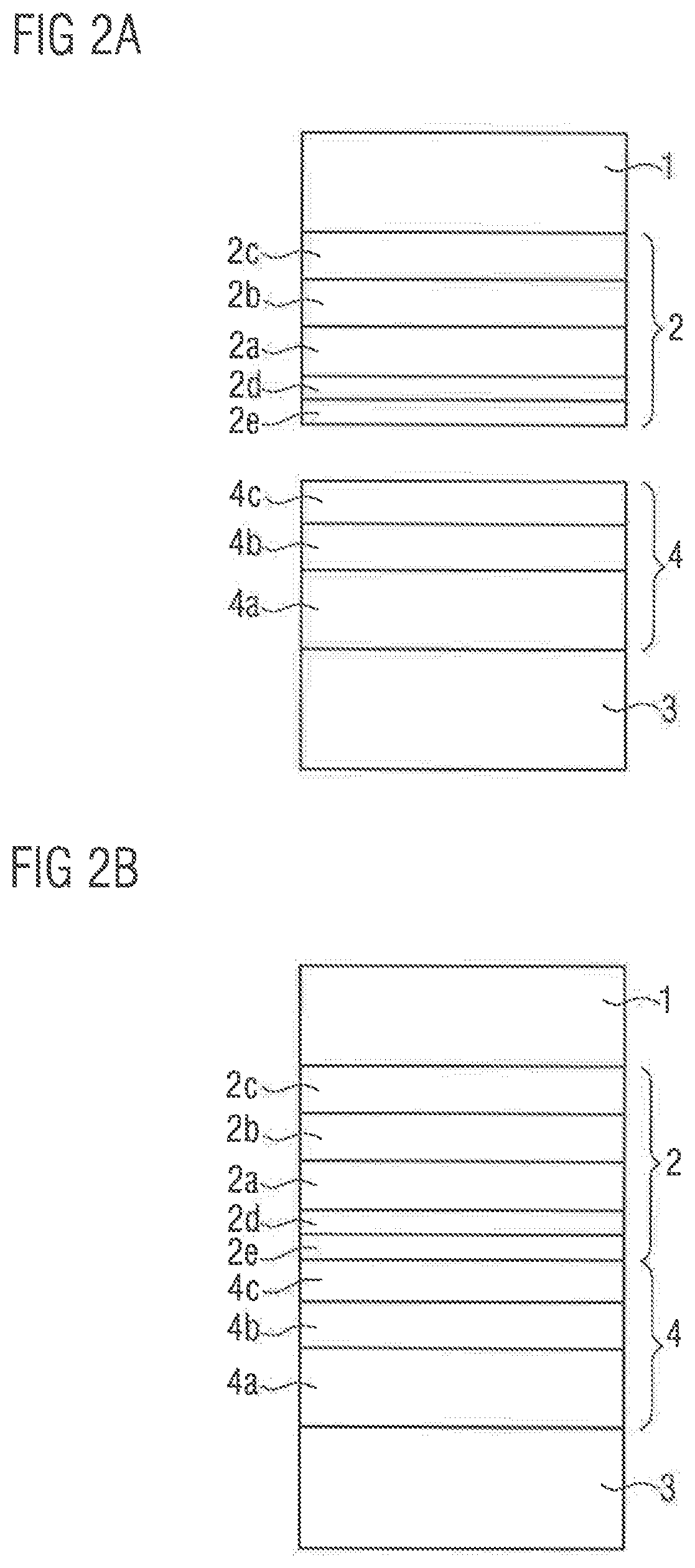

Method for fastening a semiconductor chip on a substrate, and electronic component

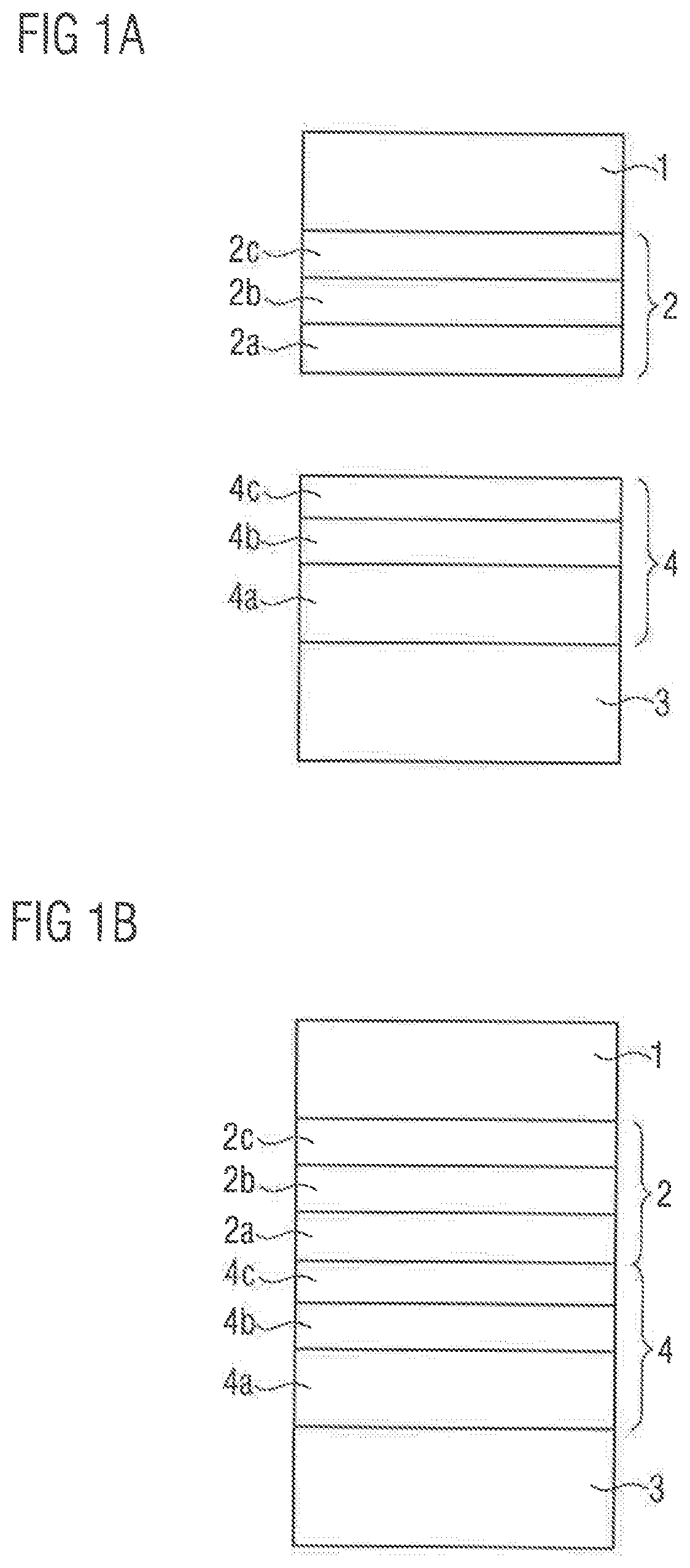

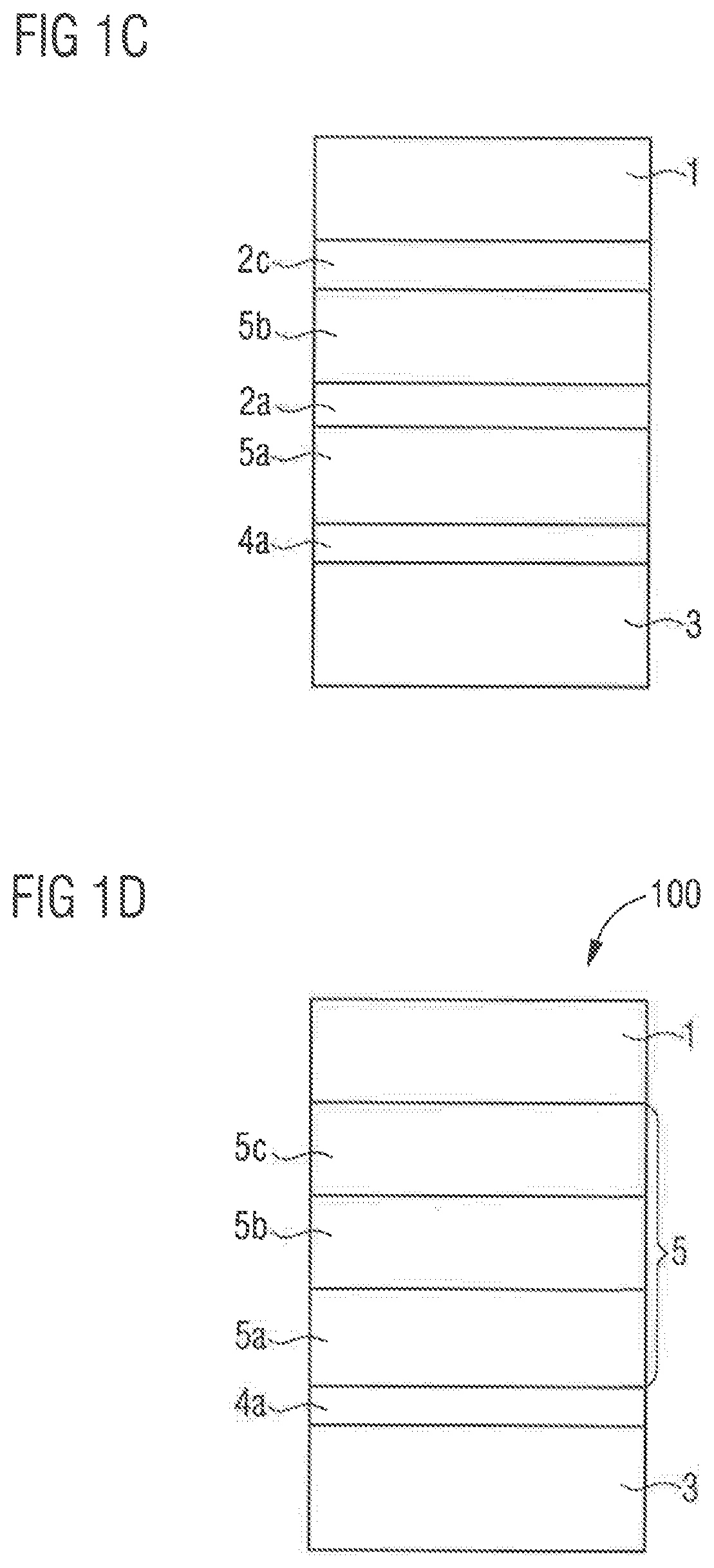

ActiveUS11315898B2Low melting pointSimple compositionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A method for fastening a semiconductor chip on a substrate and an electronic component are disclosed. In an embodiment a method includes providing a semiconductor chip, applying a solder metal layer sequence on the semiconductor chip, providing a substrate, applying a metallization layer sequence on the substrate, applying the semiconductor chip on the substrate via the solder metal layer sequence and the metallization layer sequence and heating the applied semiconductor chip on the substrate for fastening the semiconductor chip on the substrate. The solder metal layer may include a first metallic layer comprising an indium-tin alloy, a barrier layer arranged above the first metallic layer and a second metallic layer comprising gold arranged between the barrier layer and the semiconductor chip, wherein an amount of substance of the gold in the second metallic layer is greater than an amount of substance of tin in the first metallic layer.

Owner:OSRAM OLED

Method and system for offloading processing tasks to a foreign computing environment

ActiveUS8161494B2More reliableMore resilientMultiprogramming arrangementsMultiple digital computer combinationsOperational systemOperating system

A method and apparatus for offloading processing tasks from a first computing environment to a second computing environment, such as from a first interpreter emulation environment to a second native operating system within which the interpreter is running. The offloading method uses memory queues in the first computing environment that are accessible by the first computing environment and one or more offload engines residing in the second computing environment. Using the queues, the first computing environment can allocate and queue a control block for access by a corresponding offload engine. Once the offload engine dequeues the control block and performs the processing task in the control block, the control block is returned for interrogation into the success or failure of the requested processing task. The offload engine is a separate process in a separate computing environment, and does not execute as part of any portion of the first computing environment.

Owner:UNISYS CORP

Methods for administering residential care facility

InactiveUS20220005591A1Avoid spreadingEnvironment safetyVoting arrangementEpidemiological alert systemsResidential careInfection transmission

Assisted living facility administration methods are disclosed for effectively preventing infection spread. A decentralized architecture and innovative systems including MedVisa™ (a certified designation of a person's health status), InfeXCON™ (a facility's real-time risk designation), a InfeXBloc™ Scorecard system (rating of facilities' implemented infection safety measures) are provided to increase resistance to infection transmission while retaining the residential setting.

Owner:PRATIBHA CREATIVE RESOURCES LLC

Method for Fastening a Semiconductor Chip on a Substrate, and Electronic Component

ActiveUS20200211997A1Low melting pointSimple compositionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A method for fastening a semiconductor chip on a substrate and an electronic component are disclosed. In an embodiment a method includes providing a semiconductor chip, applying a solder metal layer sequence on the semiconductor chip, providing a substrate, applying a metallization layer sequence on the substrate, applying the semiconductor chip on the substrate via the solder metal layer sequence and the metallization layer sequence and heating the applied semiconductor chip on the substrate for fastening the semiconductor chip on the substrate. The solder metal layer may include a first metallic layer comprising an indium-tin alloy, a barrier layer arranged above the first metallic layer and a second metallic layer comprising gold arranged between the barrier layer and the semiconductor chip, wherein an amount of substance of the gold in the second metallic layer is greater than an amount of substance of tin in the first metallic layer.

Owner:OSRAM OLED

Frameless bullet trap

Owner:ODIN TARGET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com