Mold for forming spacers for flat panel displays

a technology for forming spacers and flat panels, which is applied in the direction of photomechanical equipment, instruments, transportation and packaging, etc., can solve the problems of reducing the quality of the fed, reducing the adhesion strength, and not allowing the precise alignment of the spacers with respect to the pixel array, so as to achieve superior properties and increase the adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Glass-Resist Adhesion

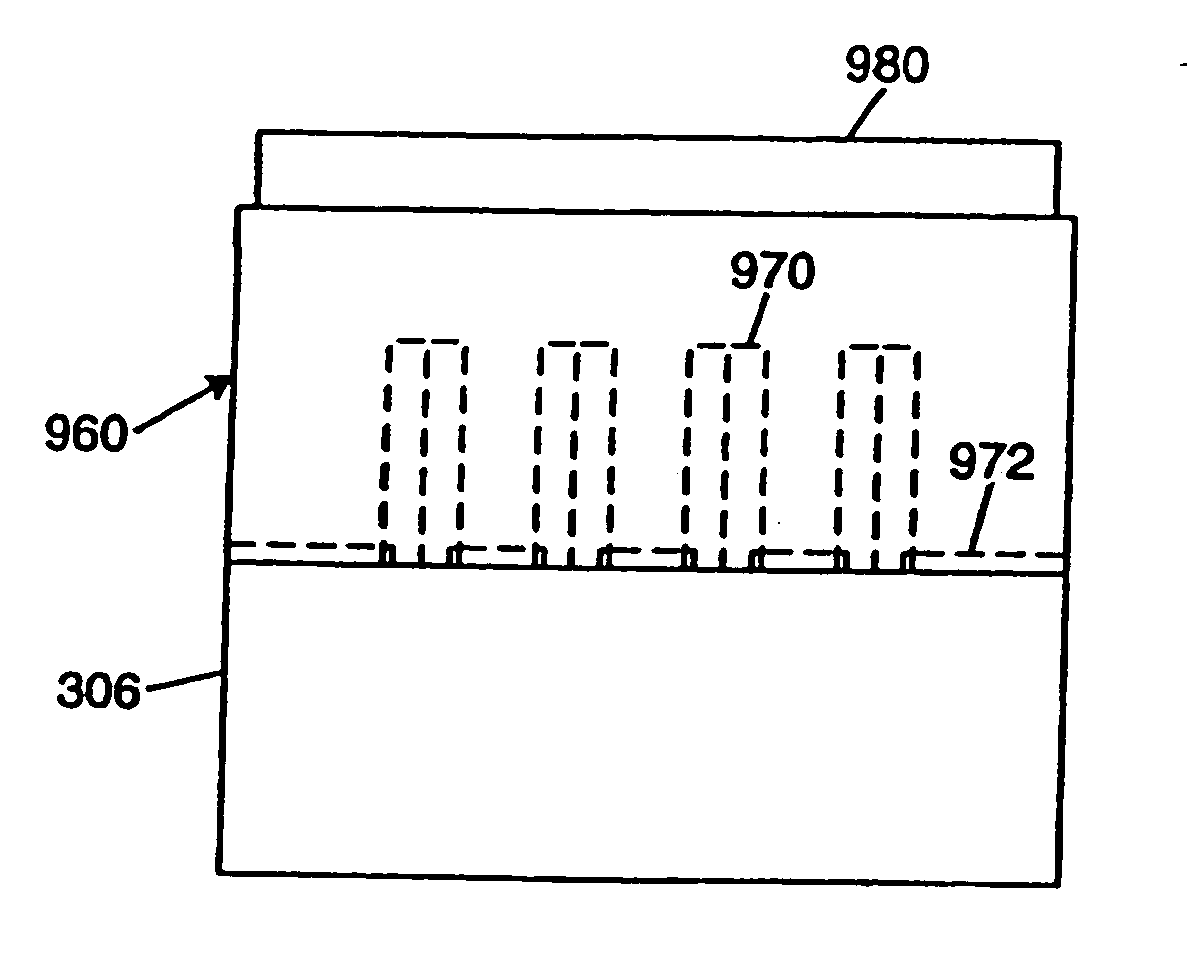

[0130] A mold fabricated from SU-8 can be formed as described herein. Briefly, a support, such as soda lime glass, is cleaned and coated with a thin film of SU-8 resist (e.g., about 50 μm), which is then flood-exposed to completely cure the SU-8 resist. A thicker film of the SU-8 resist is then applied (e.g., 200 to 600 μm), exposed with the desired photopattern, baked, and developed in a PGMEA solvent. Negative resist allows the process of coating, exposing and developing to be repeated, such that a complex 3D shape can be formed.

[0131] As described herein, adhesion of the SU-8 resist to a glass support can be poor, such that delamination occurs when the SU-8 resist exceeds a thickness of 200 μm. A search for possible priming methods was carried out in three broad categories: (1) cleaning processes that leave the surface hydrophilic; (2) cleaning processes that leave the surface hydrophobic; and (3) depositing several monolayers of molecules to promote adhesi...

example 2

Modification of SU-8

[0135] Propanediol and hexanediol were added to an SU-8 resist to determine the effects on the properties of the SU-8. As shown in FIGS. 13A-B, the photospeed of the propanediol / SU-8 mix and the hexanediol / SU-8 mix was faster than the photospeed of the SU-8 alone, and the adhesive strength of the propanediol / SU-8 mix with the support and the hexanediol / SU-8 mix with the support was better than the adhesive strength of the SU-8 alone.

example 3

Sol Gel Post-Mold Treatment

[0136] After the sol gel spacers are formed, they must be washed and dried, as described herein.

[0137] Washing the wet gels in deionized water can lead to swelling and cracking if care is not taken to balance the osmotic pressure between the solvent and the gel network. Sol gels will match the dilution of the ionic species it is immersed in by swelling or shrinking. Since the sol gels of the present invention contain a large amount of sodium and potassium, they will swell and rupture when placed in deionized water. When the sol gels of the present invention are washed in a solution of deionized water saturated with NaCl, they tend to shrink and expel water because the ion concentration gradient is higher outside the gel than inside. Thus, it has been found that a 1 to 10% solution of HCl in deionized water can effectively wash the sol gels of the present invention without swelling.

[0138] After washing, the gels must be dried. An increasing temperature c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com