Electroformed nickel-chromium alloy

a nickel-chromium alloy and electro-forming technology, applied in the field of electro-forming nickel-chromium alloys, can solve the problems of poor oxidation resistance, poor high temperature creep resistance of nickel, and the failure of conventional plating chemistry to achieve the formation of ni-cr alloys, etc., and achieve the effect of increasing the oxidation resistance of nickel-based alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

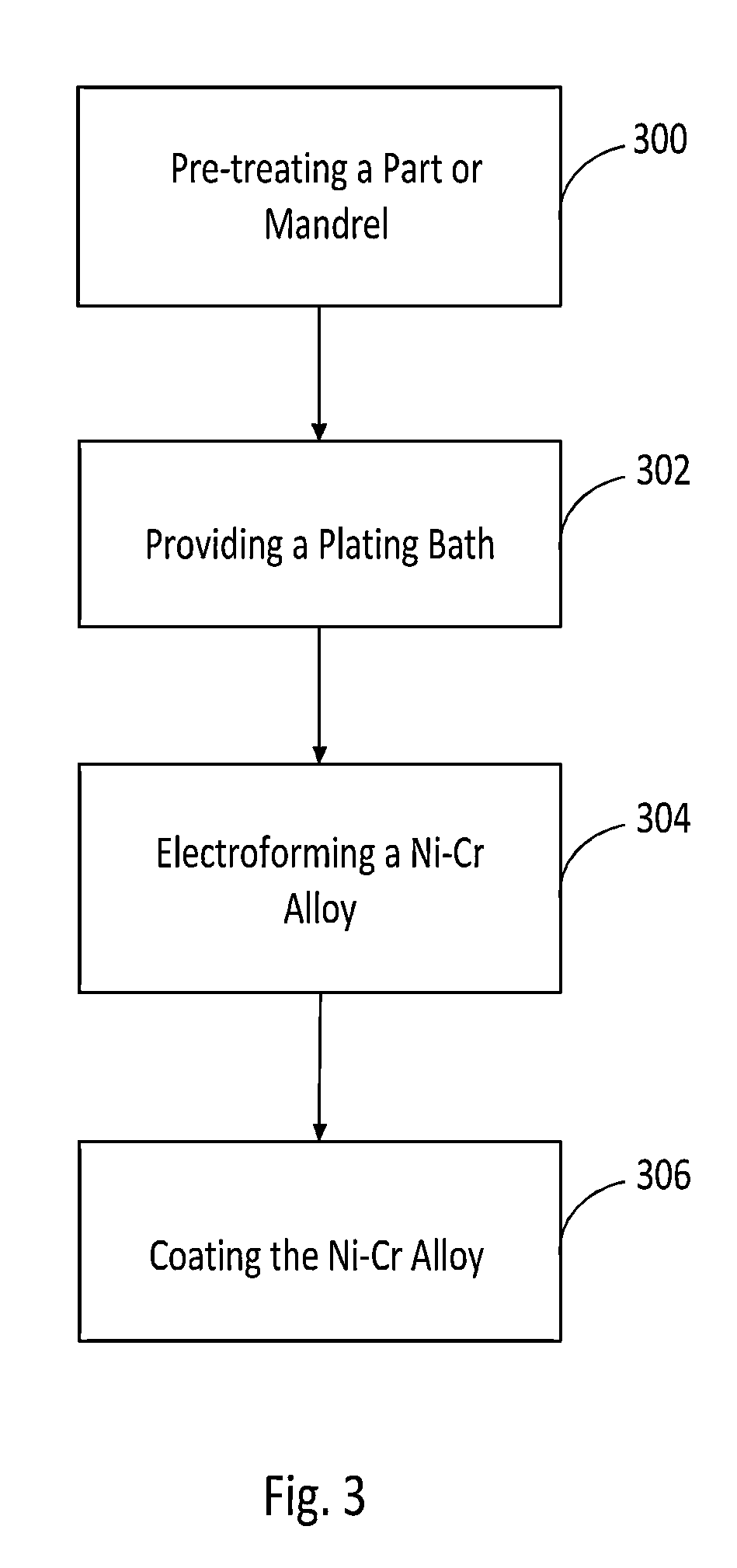

[0017]Electroforming is a metal forming process that forms self-supporting metal parts or components through electrodeposition. Electroforming a Ni—Cr alloy is a cost-effective and environmentally friendly method to make some high temperature-resistant turbine engine components with complex geometries and tighter tolerance.

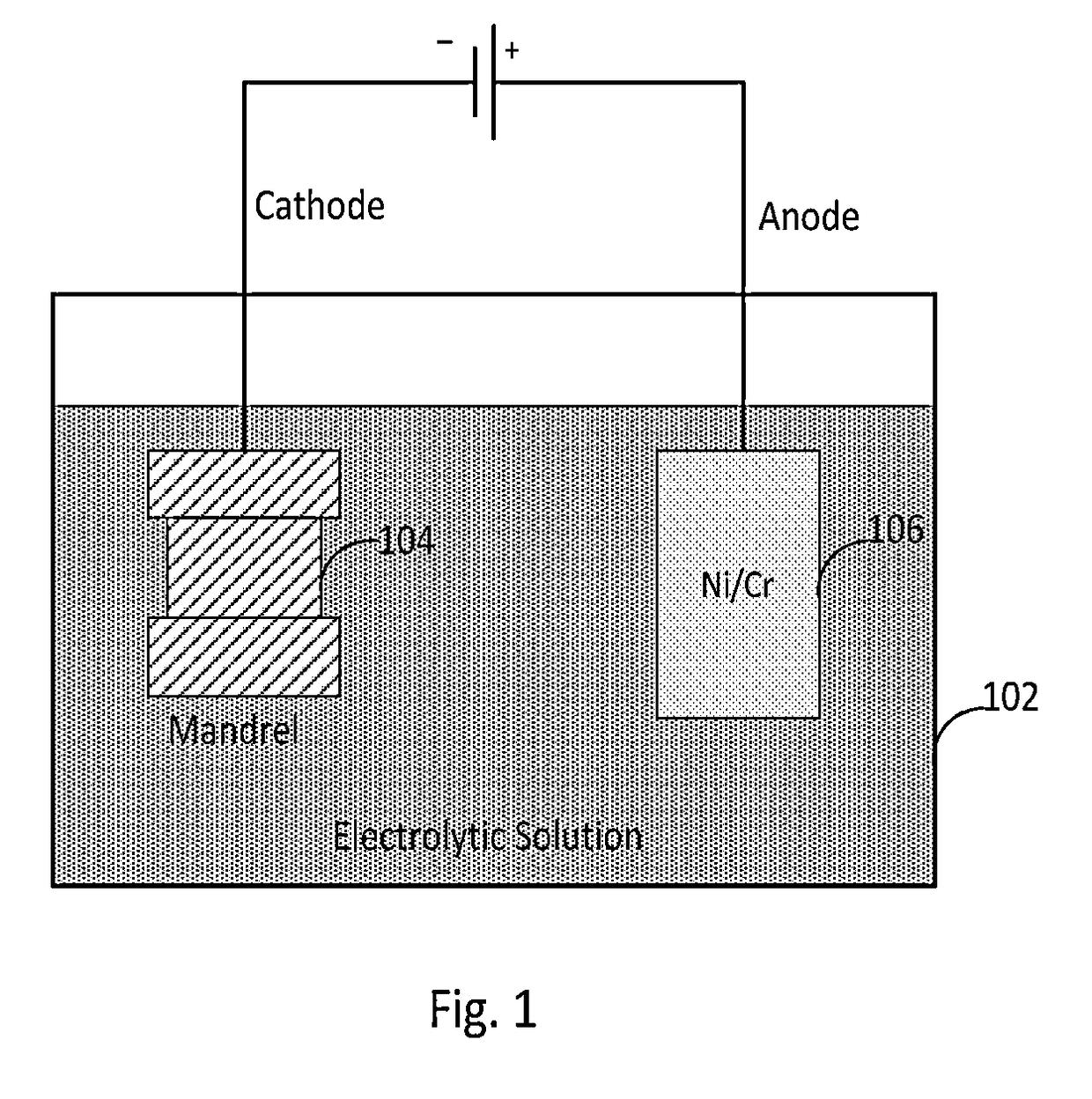

[0018]According to an aspect of the present disclosure, an electroformed nickel-chromium (Ni—Cr) alloy for use as a turbine component is disclosed. The Ni—Cr alloy comprises from 2 to 50 wt % chromium and the balance nickel, and can be made thicker than at least 10 μm to form self-supporting turbine components. The Figure illustrates a plating bath containing an electrolyte solution for electroforming a Ni—Cr alloy according to an aspect of the present invention.

[0019]FIG. 1 illustrates a plating bath filled with an electrolytic solution for electroforming a Ni—Cr alloy according to an embodiment of the present disclosure Referring now to FIG. 1, there is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar ratio | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com