Electrospark deposition process for oxidation resistant coating of cooling hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

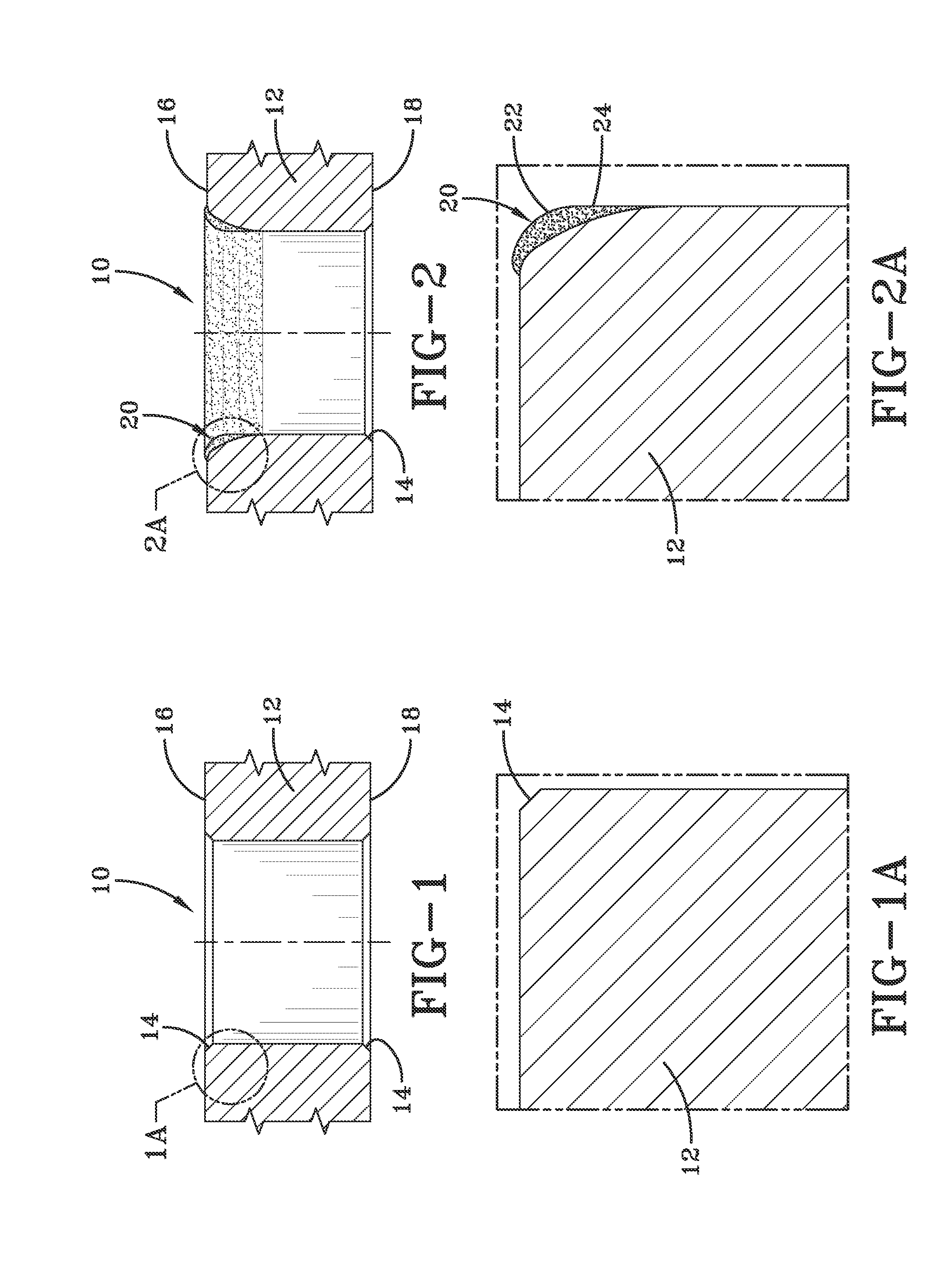

[0021]Referring to FIG. 1 a cross-sectional view of a prior art cooling hole is shown. A cooling hole 10 passes through a metal frame substrate 12. An edge 14 of the cooling hole 10 appears at each of the top surface 16 or the bottom surface 18 of metal frame substrate 12. Cooling hole 10 is formed in metal frame substrate 12 to provide air flow therethrough for cooling metal substrate 12 in harsh, high temperature environments, e.g., in a gas turbine engine transition piece (not shown). Edges 14 are subject to oxidation when exposed to harsh, high temperature environments such as are present in a gas turbine engine. The oxidized substrate material adjacent to cooling holes 10 results in cracks forming in metal substrate 12 around cooling holes 10. In particular, at the aft-facing side end of metal substrate 12 cracks are prone to form.

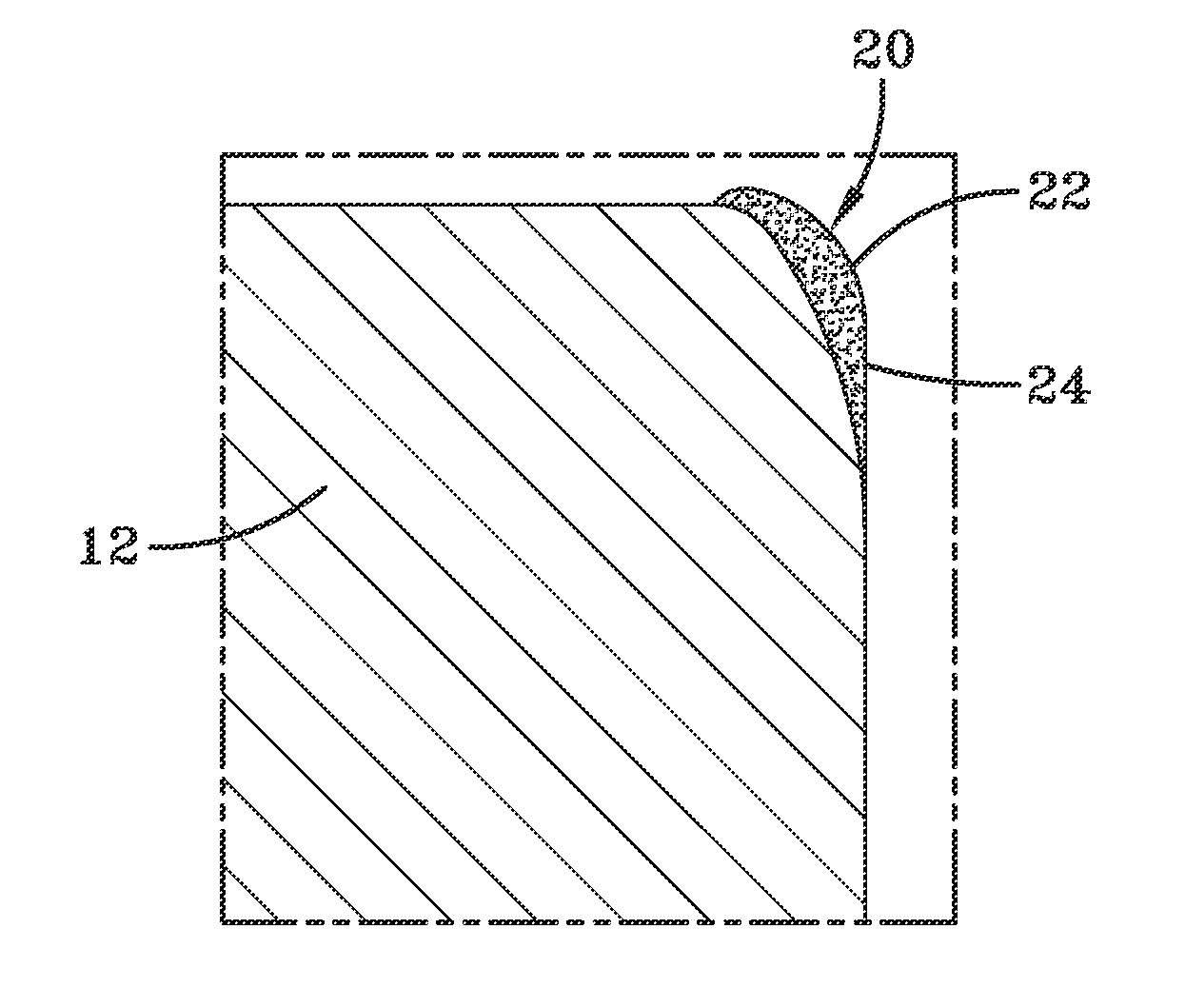

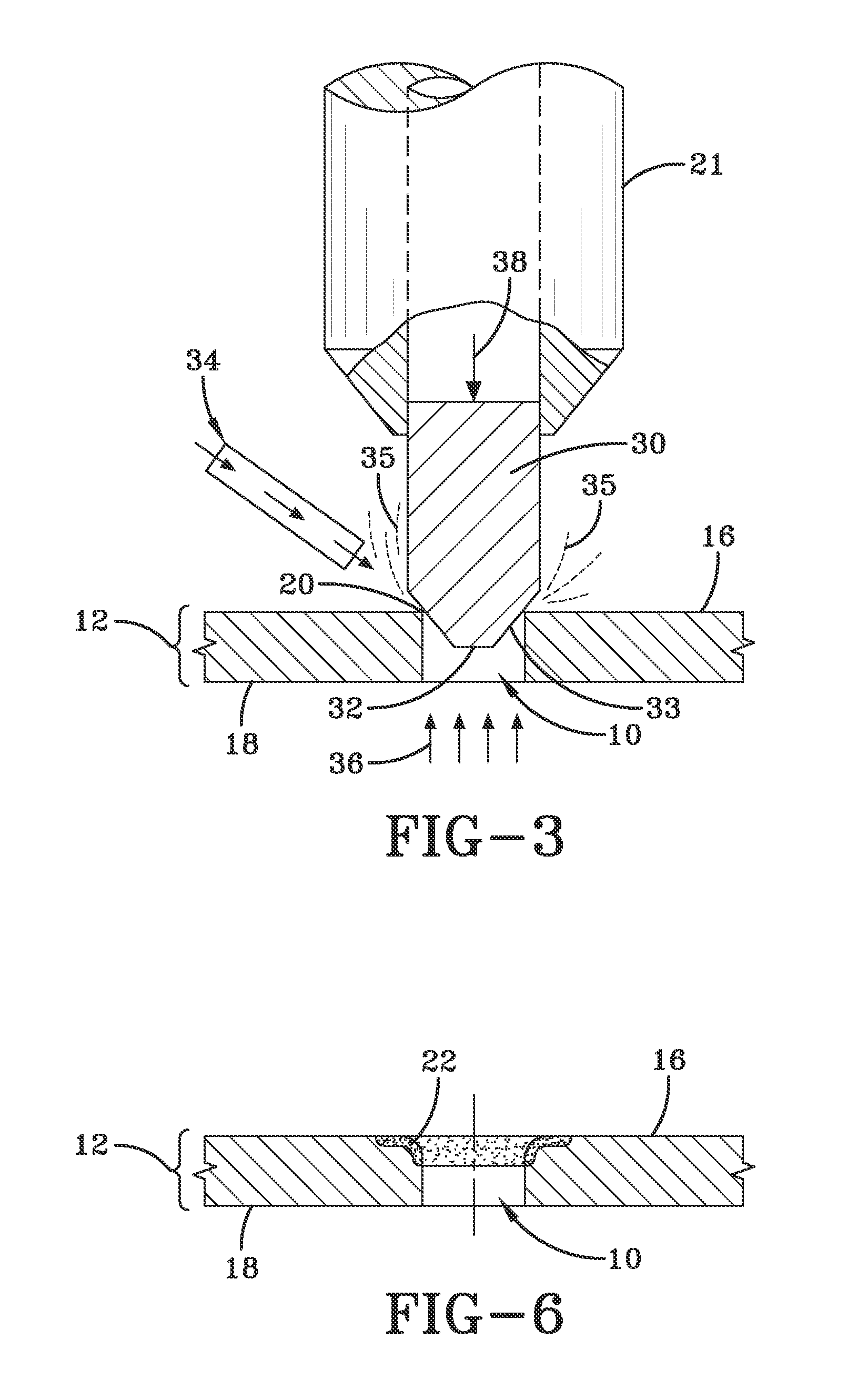

[0022]Referring next to FIGS. 2 and 2A, a cooling hole 10 is shown which has been treated by the ESD coating process described in greater detail belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com