Two-component polyurethane composite adhesive and preparation method thereof

A two-component polyurethane and composite adhesive technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low impact strength, high strength, and decreased peel strength, and achieve good adhesion. The effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

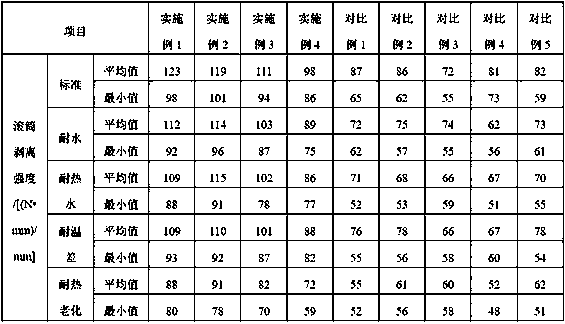

Examples

Embodiment 1

[0025] A two-component polyurethane composite adhesive, including A component and B component;

[0026] The A component includes: 18 parts by mass of modified castor oil polyol, 12 parts by mass of castor oil polyol, 8 parts by mass of branched polyether / polyester polyol, 0.8 parts by mass of nano-reinforcement material, and 56 parts by mass of filler , 1 part by mass of water remover, 1.5 parts by mass of calcium oxide, 5 parts by mass of activated alumina powder, and 0.8 parts by mass of auxiliary agent;

[0027] The B component is 25 parts by mass of polymerized MDI. The average molecular weight of the modified castor oil polyol is 900-1000, the average functionality is 2.78-3.25, and the hydroxyl value range is 200-240 mg KOH / g. The preparation method of the modified castor oil polyol is as follows: take 1000 parts by mass of castor oil, 50 parts by mass of polyol, and 1 part by mass of the first catalyst, mix them, stir in a nitrogen environment, and slowly heat up to 18...

Embodiment 2

[0032] A two-component polyurethane composite adhesive, including A component and B component;

[0033]The component A includes: 15 parts by mass of modified castor oil polyol, 10 parts by mass of castor oil polyol, 5 parts by mass of branched polyether / polyester polyol, 0.5 parts by mass of nano-reinforcement material, and 55 parts by mass of filler , 0.5 parts by mass of water remover, 1 part by mass of calcium oxide, 4 parts by mass of activated alumina powder, 0.5 parts by mass of auxiliary agent;

[0034] The B component is 20 parts by mass of polymerized MDI. The average molecular weight of the modified castor oil polyol is 900-1000, the average functionality is 2.78-3.25, and the hydroxyl value range is 200-240 mg KOH / g. The preparation method of the modified castor oil polyol is as follows: take 1000 parts by mass of castor oil, 30 parts by mass of polyol, and 1 part by mass of the first catalyst, mix them, stir in a nitrogen environment, and slowly heat up to 180~220...

Embodiment 3

[0038] A two-component polyurethane composite adhesive, including A component and B component;

[0039] The component A includes: 20 parts by mass of modified castor oil polyol, 15 parts by mass of castor oil polyol, 10 parts by mass of branched polyether / polyester polyol, 1 part by mass of nano-reinforcement material, and 60 parts by mass of filler , 2 parts by mass of water remover, 2 parts by mass of calcium oxide, 6 parts by mass of activated alumina powder, and 1 part by mass of auxiliary agent;

[0040] The B component is 30 parts by mass of polymerized MDI. The average molecular weight of the modified castor oil polyol is 900-1000, the average functionality is 2.78-3.25, and the hydroxyl value range is 200-240 mg KOH / g. The preparation method of the modified castor oil polyol is as follows: take 1000 parts by mass of castor oil, 80 parts by mass of polyol, and 1 part by mass of the first catalyst, mix them, stir in a nitrogen environment, and slowly heat up to 180~220°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com