Environmental-friendly two-component polyurethane waterproof coating and preparation method thereof

A two-component polyurethane and waterproof coating technology, applied in the field of polyurethane, can solve the problems of high organic volatiles, non-environmental protection, and low solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

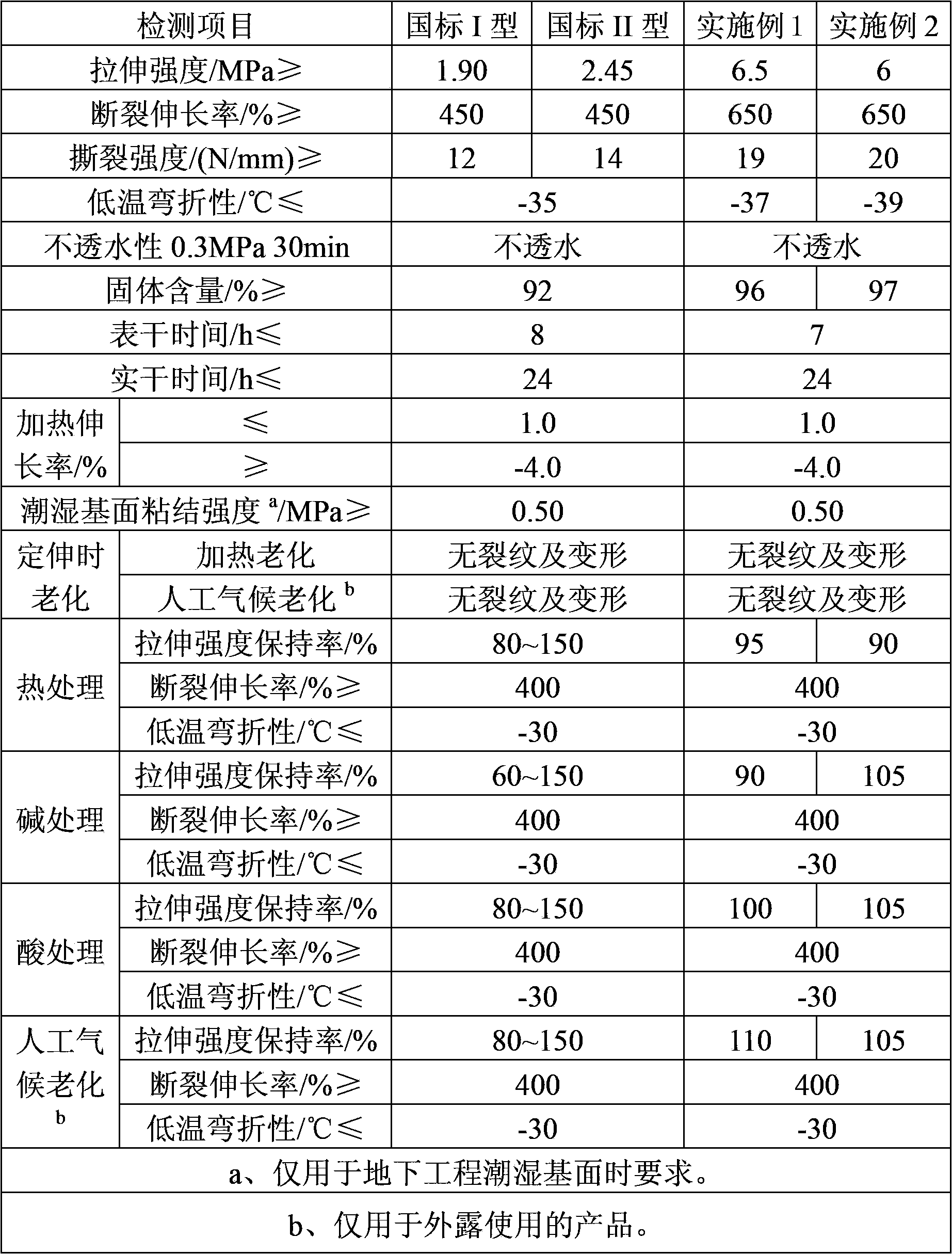

Examples

Embodiment 1

[0032] Prepare component A:

[0033] The raw materials of component A are 34% polyether polyol N220, 30% polyether polyol N330, 2% dipropylene glycol (relative molecular weight 134.7), 34% isocyanate 44V20L, and 10ppm polymerization inhibitor;

[0034] Add polyether polyol N220, polyether polyol N330 and dipropylene glycol to the reactor at room temperature, raise the temperature to 100°C under stirring, vacuumize and dehydrate and degas for 2 hours until the moisture content is less than 5 / 10,000, then cool down to 30°C Add diphenylmethane diisocyanate and polymerization inhibitor at ℃, react at 80℃ for 3 hours, cool down to 30℃, and pack into barrels;

[0035] Prepare B component:

[0036] The raw materials of component B are: 20% polyether polyol N220, 5% curing agent (dimethylthiotoluenediamine), 20% talc, 24.5% plasticizer (tributyl citrate) and 0.5% catalyst Triethylenediamine;

[0037] Put polyether polyol N220, plasticizer, filler and curing agent into the reaction ...

Embodiment 2

[0040] Prepare component A:

[0041] The raw materials of component A are 33% polyether polyol N220, 20% polyether polyol N330, 5% 1,4-butanediol (relative molecular weight 90.12), 42% isocyanate PM200 and 10ppm inhibitor (phosphoric acid);

[0042] Add polyether polyol N220, polyether polyol N330 and 1,4-butanediol to the reaction kettle at room temperature, raise the temperature to 80°C under stirring, vacuumize and dehydrate and degas for 3 hours, until the moisture content is less than 1 / 10,000 5. Cool down to 40°C, add MDI-50 and polymerization inhibitor, react at 85°C for 2.5 hours, cool down to 40°C, and load into barrels;

[0043] Prepare B component:

[0044] The raw materials of component B are: 15% polyether polyol N220, 7% curing agent (2,4-diamino-3,5-dimethylthiochlorobenzene), 40% calcium carbonate, 37% plasticizer (trioctyl acetyl citrate) and 1% catalyst triethylenediamine;

[0045] Put polyether polyol N220, plasticizer, filler and curing agent into the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com