Reaction-curable polyurethane resin composition and two-part reaction-curable polyurethane adhesive made by using the same

A polyurethane resin, curing technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve problems such as unachieved, achieve the effect of inhibiting foaming phenomenon and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

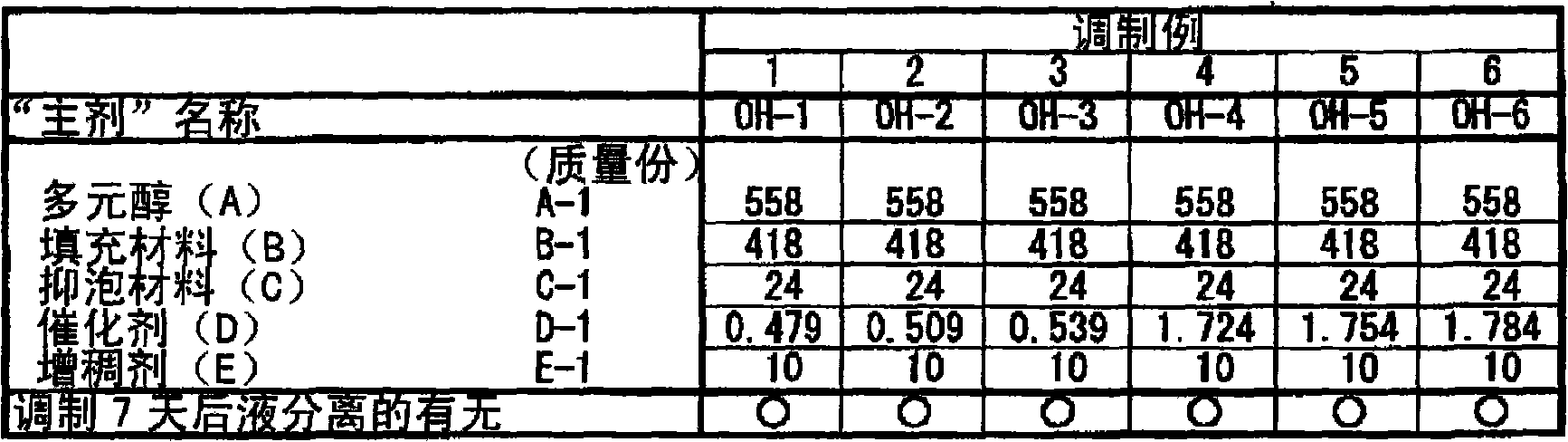

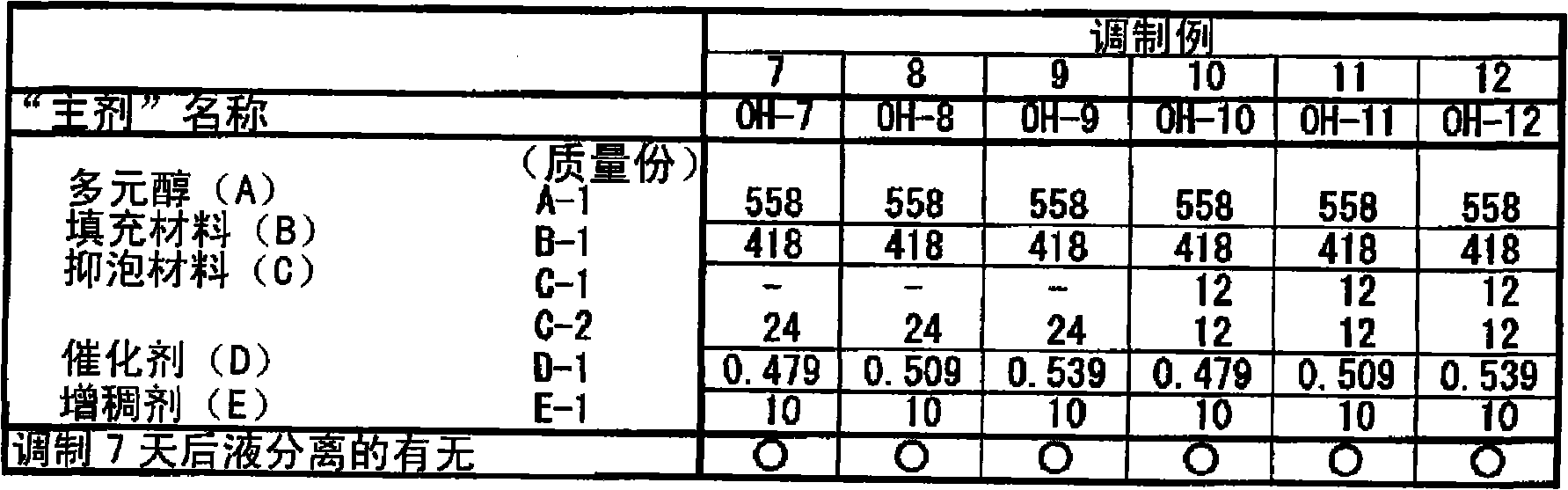

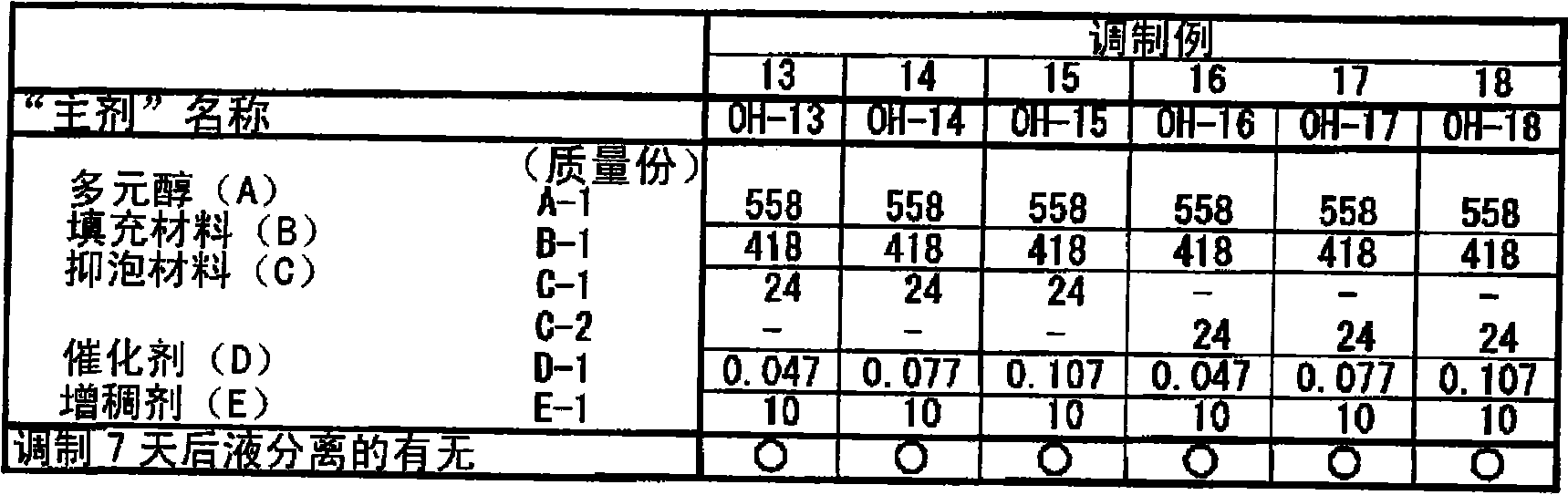

[0101] Examples 1-12, Comparative Examples 1-12

[0102] Prepare the above-mentioned "OH-1" ~ "OH-24" as the main ingredient, prepare the above "NCO-1" ~ "NCO-3" as the curing agent, and prepare the liquid The temperature was adjusted to 25°C. According to the combinations shown in the following Tables 5 to 8, and according to the main agent / curing agent=3 / 1 (mass ratio) and a total of 100g, they were packed into a stainless steel container, and a bench drill (Ryobi Sales Co.) was stirred and uniformly mixed for 10 seconds at a rotation speed of 300 rpm to obtain a mixture (composition of the present invention / composition for comparison).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com