Latent catalyst

A latent catalyst, catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of inability to accelerate curing, complex reaction, and high activation temperature, Achieving excellent pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0035] The following examples are provided to further illustrate the invention, but should not be construed as limiting the scope of the claims. All parts and percentages are by weight unless otherwise indicated.

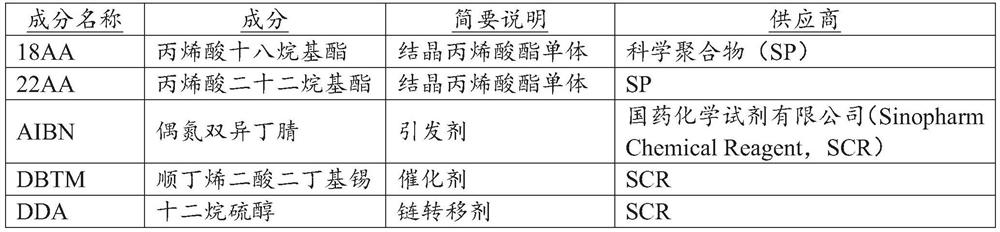

[0036] The various terms and names used in the invention examples (INV.Ex.) and comparative examples (Comp.Ex.) are explained in Table I below.

[0037] Table I-raw material

[0038]

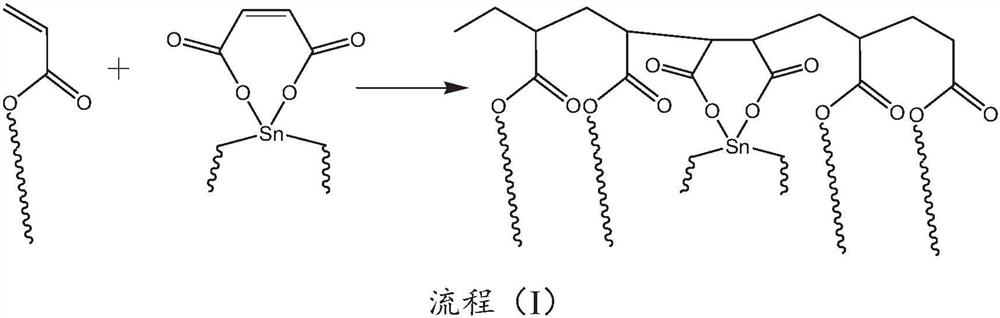

[0039] Synthesis of copolymerized crystallization catalyst

[0040] The copolymerized crystalline catalyst of the present invention is prepared in the toluene solution in the toluene solution: mixed with crystalline acrylate monomer, DBTM, initiator AIBN, chain extender, and toluene under slow stirring. Then, the temperature of the resulting mixture was raised to a temperature of 60 ° C to 80 ° C under continuous stirring; and the temperature of the mixture was maintained at 60 ° C to 80 ° C for 24 hours. Thereafter, the mixture was stopped and the mixture was stopped and cooled. The ...

example 1-4

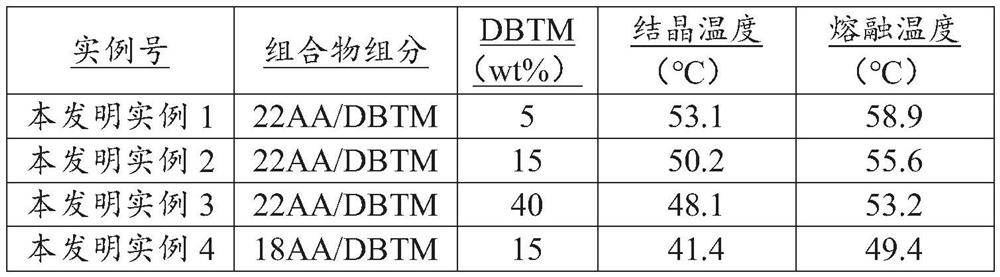

[0042] Four potential catalyst samples of the present invention (Examples 1-4) of the invention were prepared using the procedure of the above synthetic copolymerized crystalline catalyst. In each catalyst sample prepared, the DBTM concentration and the acrylate monomer type have changed; and each of the obtained copolymers exhibits crystallization temperature and melt temperature. Details of the above sample are listed in Table II.

[0043] Table II- copolymerization crystallization catalyst

[0044]

[0045] The use of the potential catalyst prepared in the art is apparent to those skilled in the art; and, for example, in one embodiment, the potenton can be used as an additive in a conventional polyurethane formulation, wherein the polyurethane formulation comprises isocyanate ( NCO) The prepolymer component, such as MF706A (available from Dow Chemical Company) and a hydroxyl (OH) component, such as C79 (available from Dow Chemical).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com