Adhesive composition

A technology of adhesives and compositions, applied in the direction of adhesive types, adhesives, polyurea/polyurethane adhesives, etc., can solve the problems of short pot life, slow curing speed, and no curing speed of pot life. Achieve improved handling, excellent pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

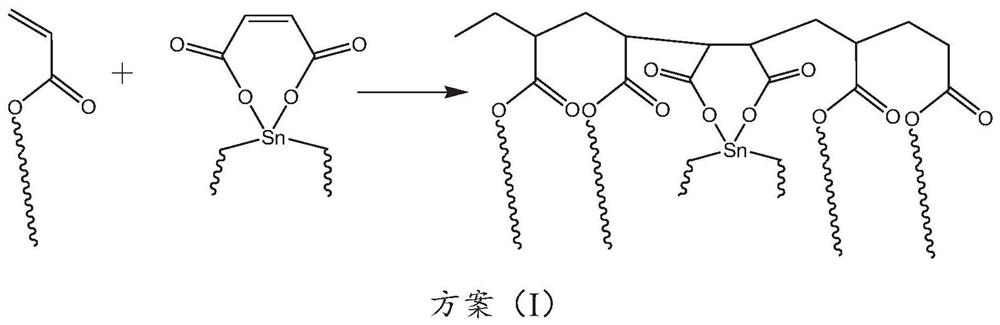

Method used

Image

Examples

Embodiment 1-4

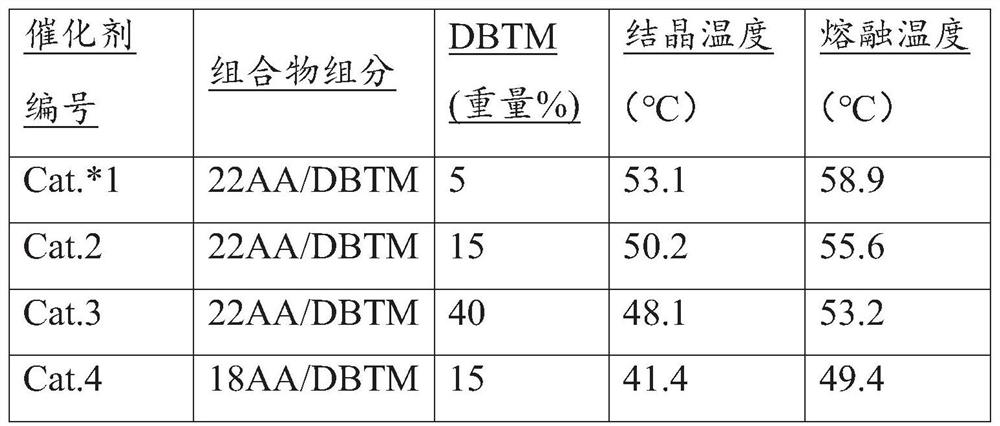

[0050] Examples 1-4 and Comparative Examples A and B

[0051] Application Performance Evaluation of 2K Solvent-free (SL) PU Adhesives with Copolymerization Crystallization Catalysts

[0052] Each of the four copolymerization crystallization catalysts described in Table II was added to a two-component (2k) solvent-free (SL) polyurethane (PU) adhesive composition to form the adhesive composition of the present invention; And evaluate the performance of the adhesive composition. The pot life and bond strength development properties of the adhesive compositions were evaluated. The performance results (pot life and bond strength development) of the inventive adhesive compositions (inventive examples 1-4) containing the co-polymerization crystallization catalysts Cat. 1-4 described in Table II were compared with the following, respectively: (1) a 2k SL PU adhesive composition in the absence of a copolymeric crystallization catalyst (Comparative Example A), and (2) a 2k SL PU a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com