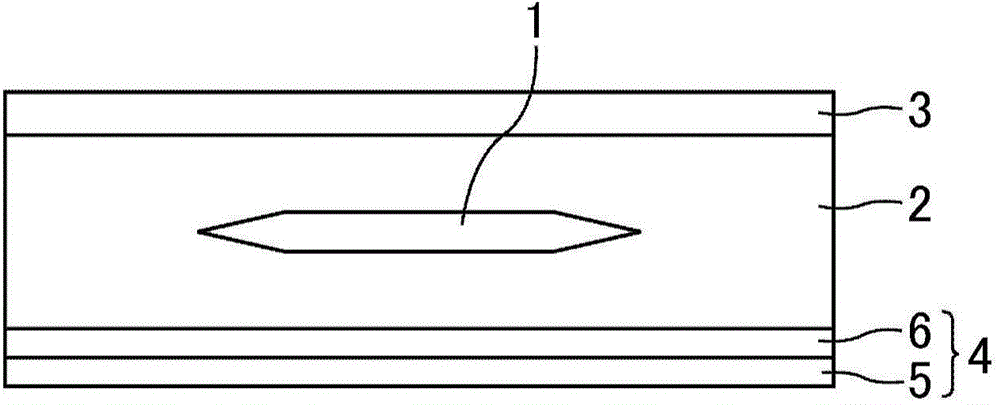

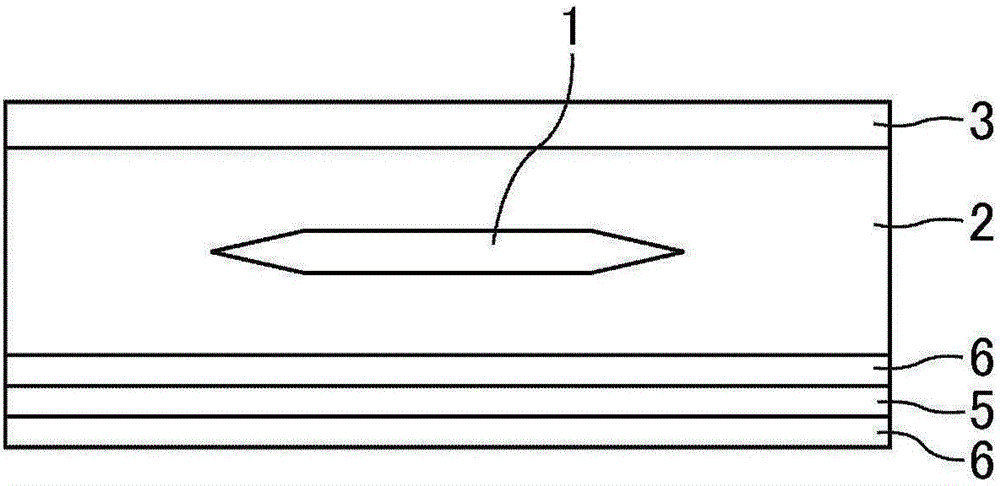

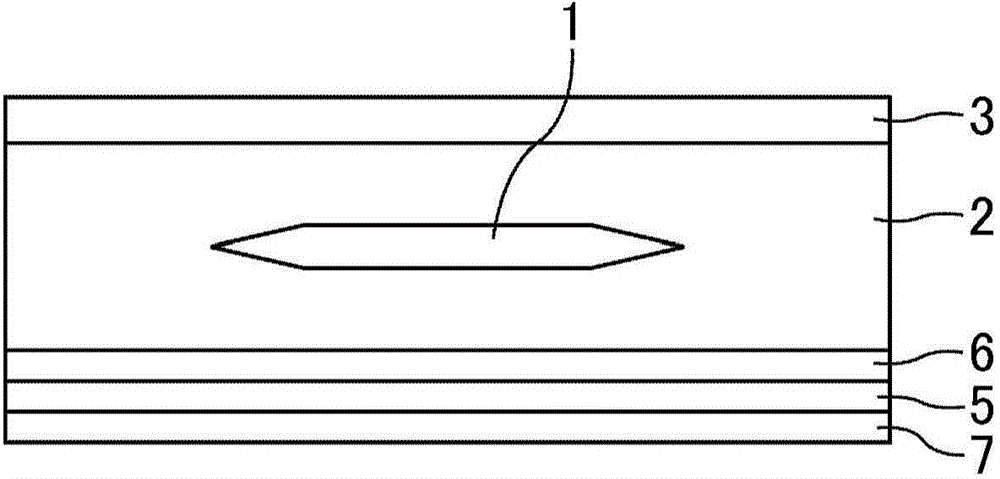

Coating material, coating film, solar-cell-module backsheet, and solar-cell module

A coating and film coating technology, which is applied to electrical components, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0154] Under stirring, 223.2 parts by mass of curable TFE-based copolymer (Zeffle GK570 manufactured by Daikin Industries, Ltd., 65% by mass of solid content, 60 mgKOH / g of hydroxyl value, solvent: butyl acetate), titanium dioxide (DuPont) as a white pigment, 250 parts by mass of Ti-Pure R960 manufactured by the company and 126.8 parts by mass of butyl acetate were premixed, and then 780 parts by mass of glass beads with a diameter of 1.2 mm were charged and dispersed at 1500 rpm for 1 hour using a pigment disperser. Thereafter, glass beads were sieved with #80 mesh, and 269.2 parts by mass of a curable TFE-based copolymer (Zeffle GK570) was added to the solution to prepare a white paint.

[0155] In 100 parts by mass of the white paint, 20.8 parts by mass of a curing agent (Duranate K6000, manufactured by Asahi Kasei Chemical Co., Ltd., active methylene compound-blocked isocyanate of HDI) (with respect to the curable functional group in the curable TFE-based copolymer) was mix...

Embodiment 1

[0157] About the paint 1 obtained in the preparation example 1, the pot life was measured by the method shown below. The results are shown in Table 1.

[0158] (Applicable period)

[0159] Performed according to JIS K5600-2-6. Put the curable paint prepared in each preparation example into a polypropylene container with a volume of 100 ml, seal it, store it at 25° C., measure the viscosity in due course, and set the time until the viscosity reaches twice the initial value as the pot life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com