Double-component polyurethane adhesive used in construction, and preparation method thereof

A two-component polyurethane technology for construction, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve the problem of low bond strength and low shear strength between rock wool and fiber cement boards. Low bond strength and other problems, to achieve the effect of increasing strength, improving bond strength, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

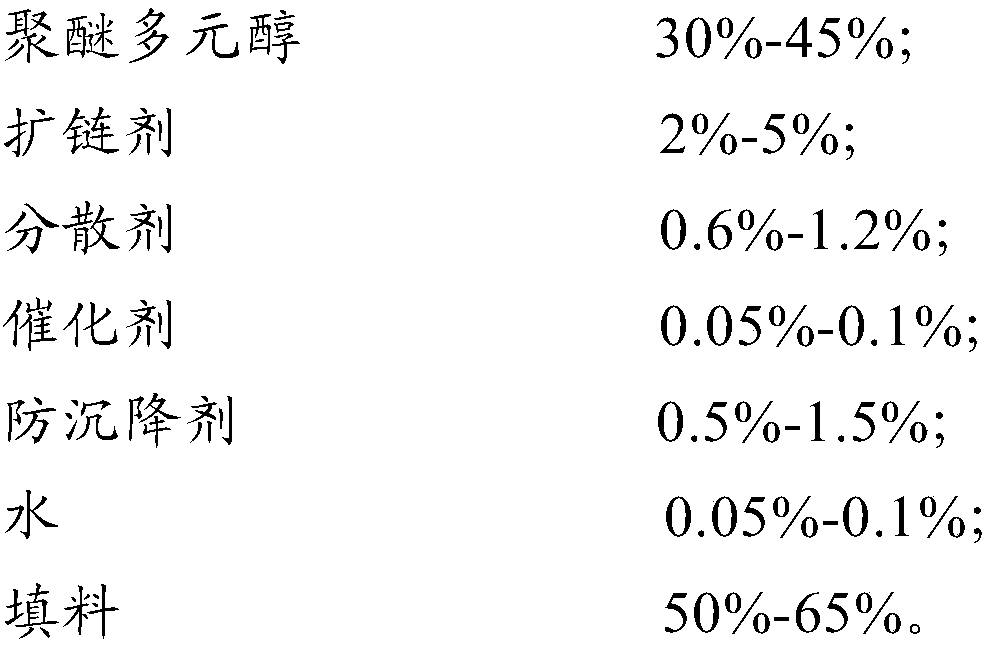

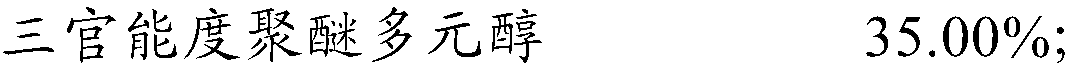

[0026] This embodiment provides a two-component polyurethane adhesive for construction, which is composed of component A and component B in a mass ratio of 5:1; component B is polymerized MDI, and component A includes the following components in mass percentage:

[0027]

[0028] Preparation:

[0029] (1) Add trifunctional polyether polyol, difunctional diethylene glycol, polyacid dispersant, dibutyltin dilaurate catalyst, modified urea solution and water into the reaction kettle in proportion, and stir for 5-10min to a uniform slurry to obtain a slurry;

[0030] (2) Add heavy calcium carbonate, talcum powder and nano-calcium carbonate to the slurry obtained in step (1), stir for 40-60min to a uniform paste, and obtain the A component;

[0031] (3) The components A and B are uniformly mixed in proportion to obtain the finished two-component polyurethane adhesive for construction.

Embodiment 2

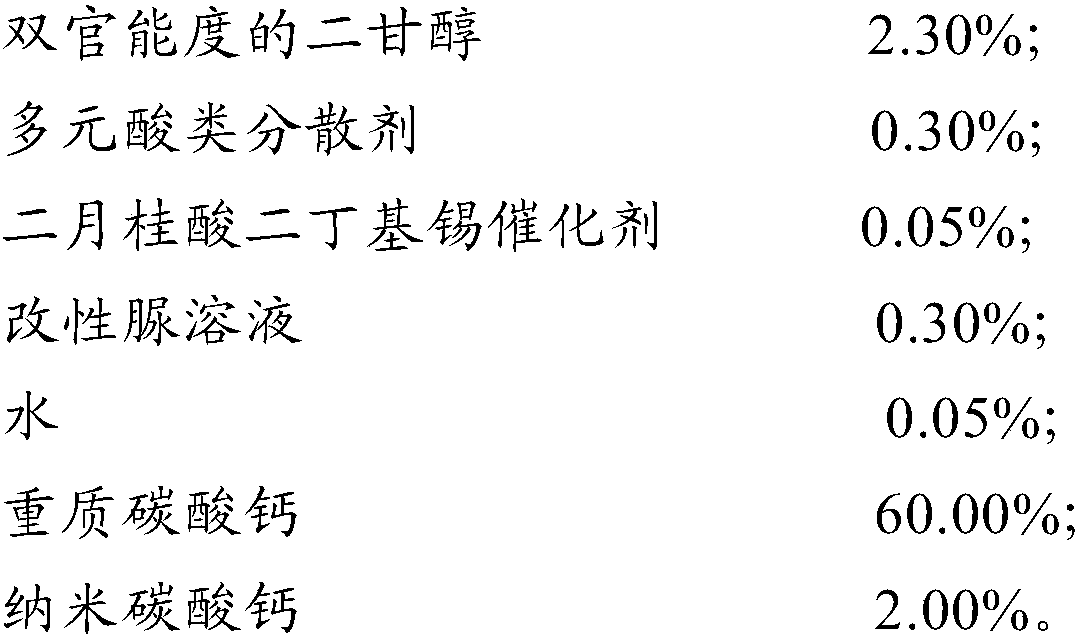

[0033] This embodiment provides a two-component polyurethane adhesive for construction, which is composed of component A and component B in a mass ratio of 5:1; component B is polymerized MDI, and component A includes the following components in mass percentage:

[0034]

[0035]

[0036] Preparation:

[0037] (1) Add trifunctional polyether polyol, difunctional diethylene glycol, polyacid dispersant, dibutyltin dilaurate catalyst, modified urea solution and water into the reaction kettle in proportion, and stir for 5-10min to a uniform slurry to obtain a slurry;

[0038] (2) Add heavy calcium carbonate and nano-calcium carbonate to the slurry obtained in step (1), stir for 40-60min to a uniform paste, and obtain the A component;

[0039] (3) The components A and B are uniformly mixed in proportion to obtain the finished two-component polyurethane adhesive for construction.

Embodiment 3

[0041] This embodiment provides a two-component polyurethane adhesive for construction, which is composed of component A and component B in a mass ratio of 5:1; component B is polymerized MDI, and component A includes the following components in mass percentage:

[0042]

[0043] Preparation:

[0044] (1) Add liquid components (difunctional polyether polyol, multifunctional small molecule alcohol chain extender, polyacid dispersant, catalyst, anti-settling agent, water) into the reaction kettle, and stir for 5-10min to a uniform slurry to obtain a slurry;

[0045] (2) Add mica powder and heavy calcium carbonate to the slurry obtained in step (1), and stir for 40-60min to a uniform paste;

[0046] (3) Mix the A component and the B component obtained above according to the mass ratio of 5:1 to obtain the finished two-component polyurethane adhesive for construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com