flexible polyurethane foam

A flexible polyurethane foam technology, applied in the field of flexible polyurethane foam, can solve problems such as unsuitable comfort and support performance, difficulty in processing and molding, and use of unfavorable raw materials and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

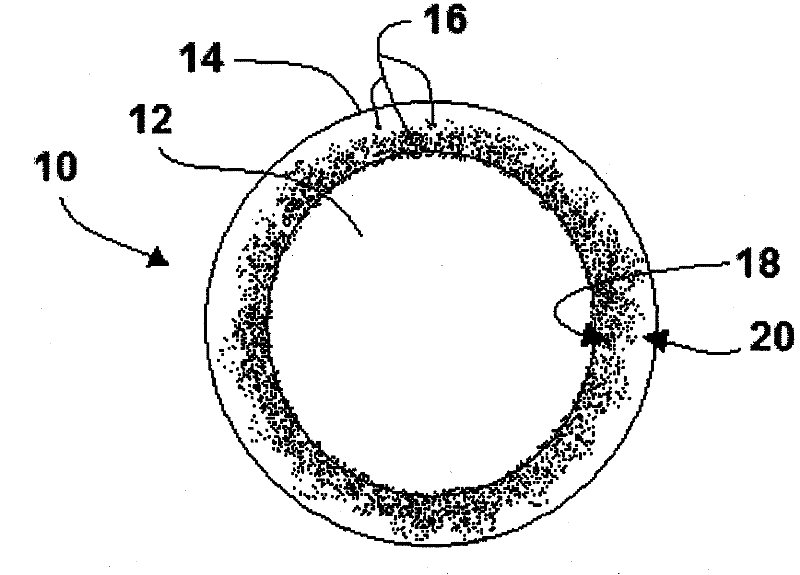

Image

Examples

Embodiment 1

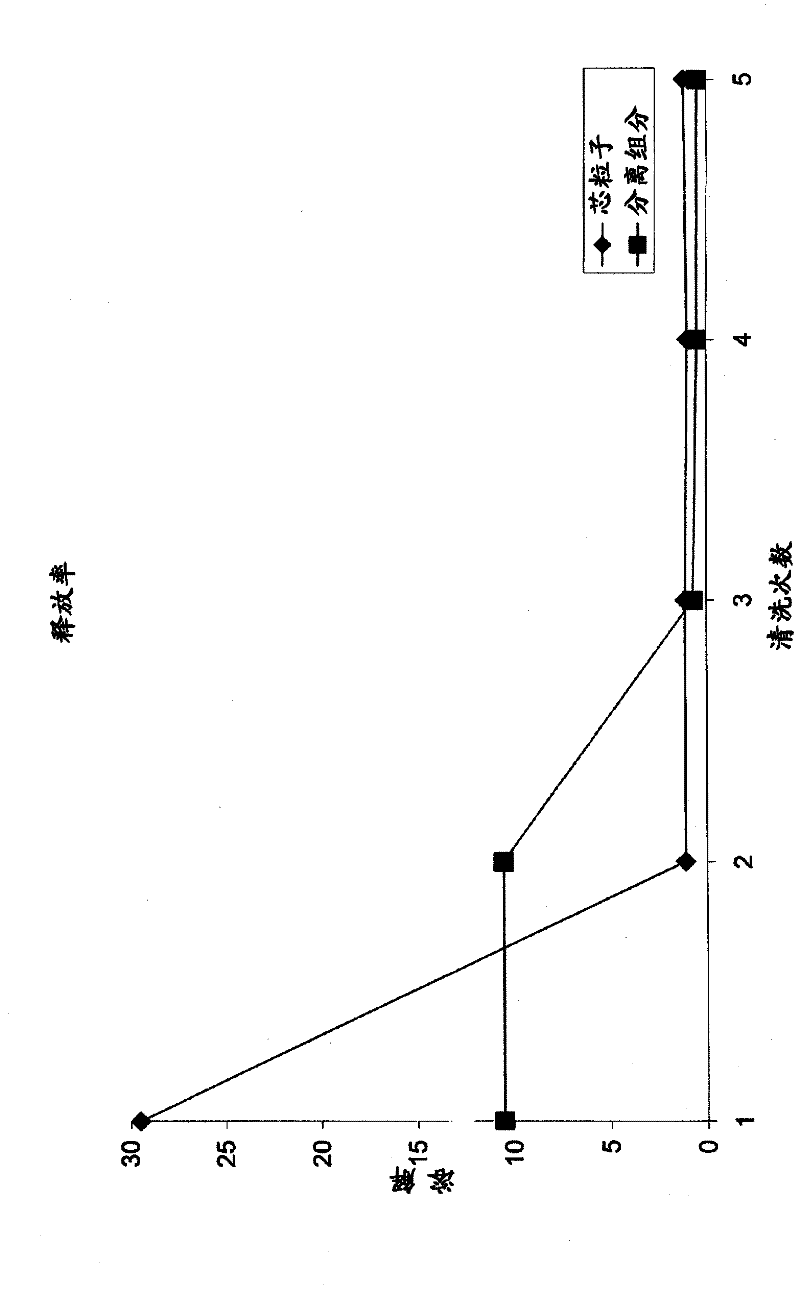

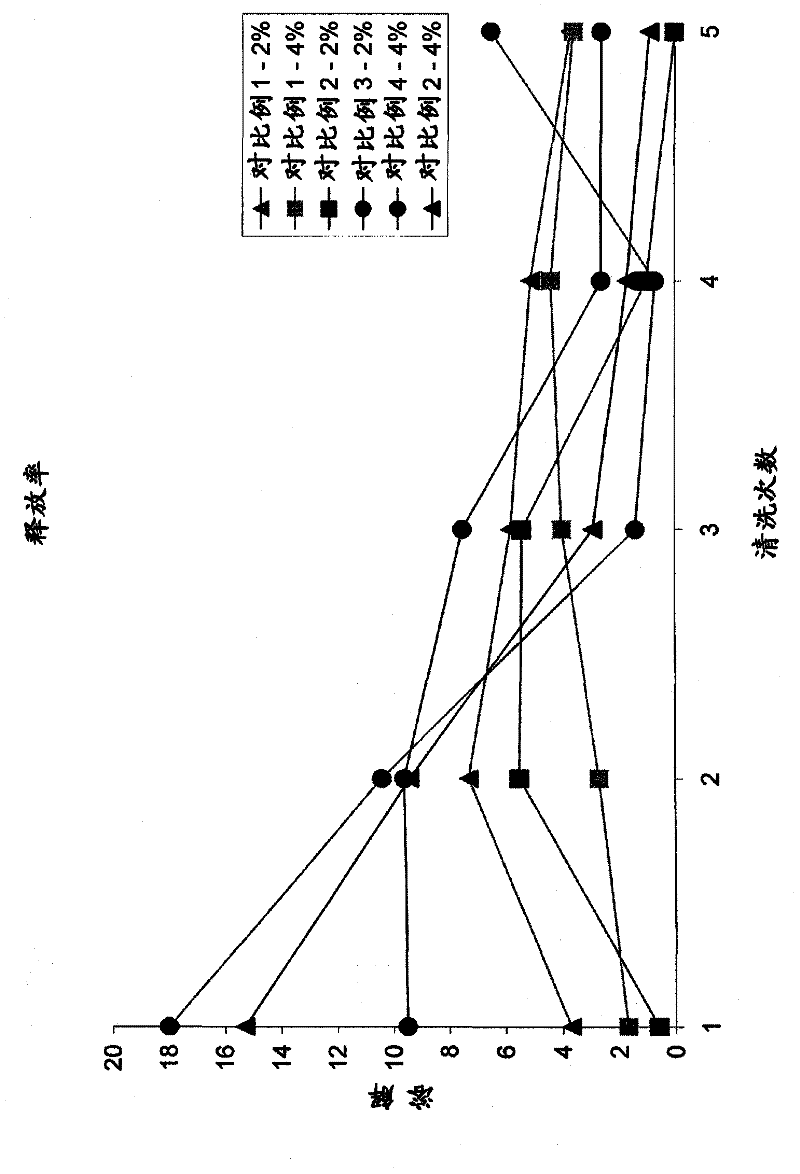

[0095] The flexible polyurethane foams of Example 1 and Example 2 comprised the same formulation with the obvious difference that the formulation of Example 2 contained a flame retardant additive whereas the formulation of Example 1 contained no flame retardant additive. Additionally, the flexible polyurethane foams of Example 1 and Example 2 had the same percent height loss when subjected to 80,000 cycles of slamming. However, unexpectedly, even without the flame retardant additive, the flexible polyurethane foam of Example 1 is flame retardant according to the flammability test of California Technical Bulletin 117, while the flexure of the flexible polyurethane foam of Example 1 The amount of fatigue is irrelevant. Furthermore, since the flexible polyurethane foam of Example 1 does not contain flame retardant additives, the flexible polyurethane foam is cost-effective to manufacture.

[0096] In contrast, the flexible polyurethane foam of Comparative Example 4 failed the ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com