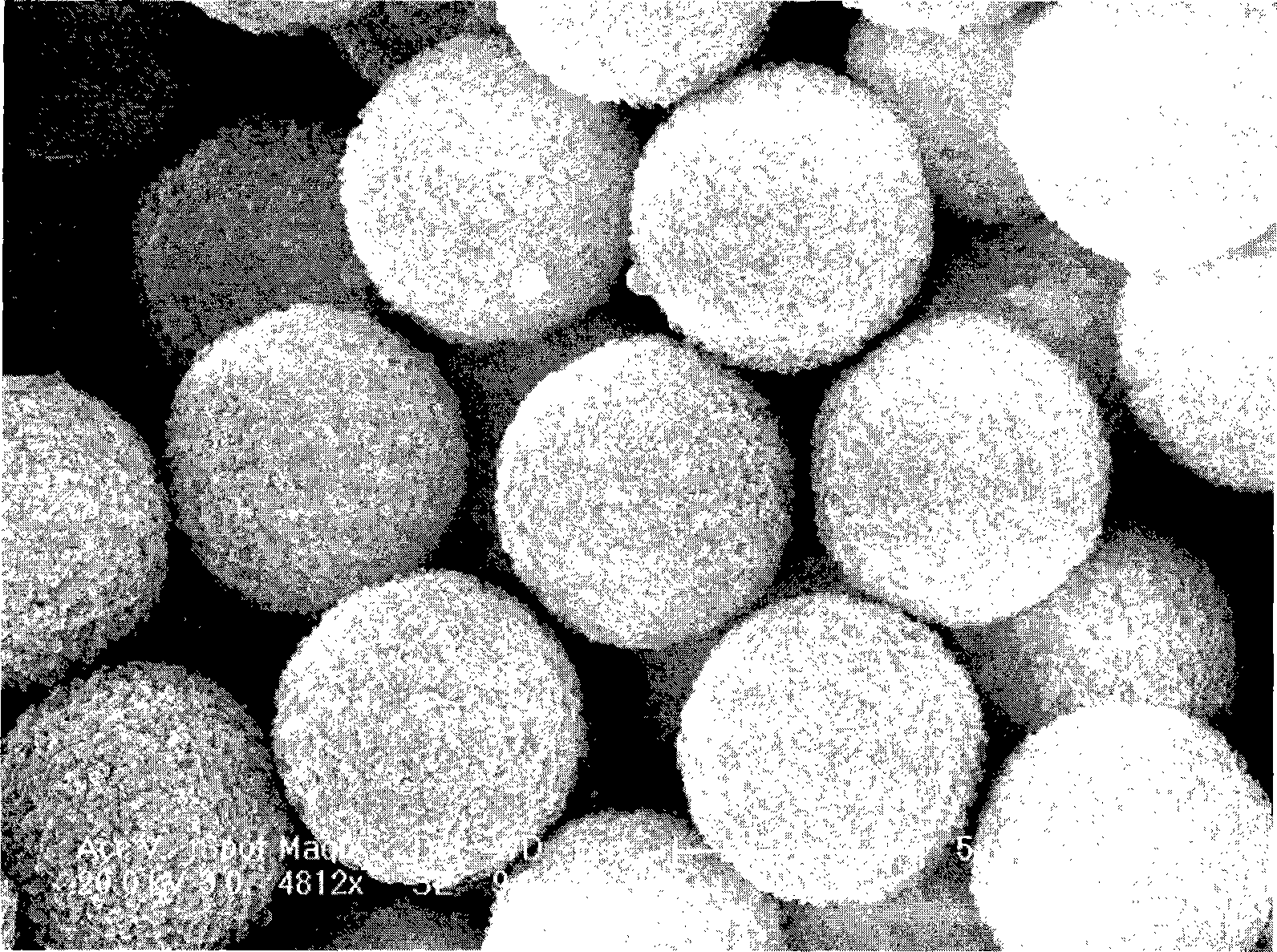

Preparation of monodisperse porous polymer microsphere

A porous polymer and monodisperse technology, which is applied in the field of preparation of monodisperse porous polymer microspheres, can solve the problem of limited second monomer content and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Preparation of monodisperse porous polymer PSD microspheres

[0020] (1) Configure an aqueous ethanol solution of 0.25wt% sodium dodecylsulfonate, the ethanol water is a solvent, and the ethanol:water mass ratio is 5:1 to obtain a dispersion;

[0021] (2) Take 25g of dispersion liquid, add 0.5g of polystyrene seed microspheres, and ultrasonically disperse for 5-20min to obtain seed emulsion;

[0022] (3) Take 25g of the dispersion, add 0.5g of 1-chlorododecane as a swelling aid, and disperse ultrasonically for 10 to 60 minutes to obtain a swelling aid emulsion;

[0023] (4) Mix the dispersed seed emulsion and swelling aid emulsion, place in a four-port reactor equipped with mechanical stirring, reflux condenser, nitrogen conduit, and thermometer, and swell at 30°C and 120rpm for 8 to 24 hours; The first step is swelling to obtain the activated seed emulsion;

[0024] (5) Take 40g of dispersion, add 4g of styrene, 2g of divinylbenzene, 0.06g of dibenzoyl ...

Embodiment 2

[0028] Embodiment 2: the preparation of monodisperse porous polymer PSDM microsphere

[0029] (1)-(4) are the same as Example 1

[0030] (5) Add 3.6g styrene, 1.8g divinylbenzene, 0.6g methyl methacrylate, 0.06g dibenzoyl peroxide, 2g toluene, 2g n-heptane to 40g dispersion liquid, and ultrasonically disperse for 30min to obtain Mixed monomer, initiator, porogen emulsion;

[0031] (6)-(8) are the same as Example 1, that is, obtain 4.1 μm monodisperse porous polymer PSDM microspheres.

Embodiment 3

[0032] Embodiment 3: the preparation of monodisperse porous polymer PSDA microsphere

[0033] (1)-(4) are the same as Example 1

[0034] (5) Take 40 g of the dispersion and add 5 g of styrene, 3 g of divinylbenzene, 2 g of acrylonitrile, 0.1 g of dibenzoyl peroxide, and 10 g of toluene. Ultrasonic dispersion for 30 minutes to obtain mixed monomer, initiator and porogen emulsion;

[0035] (6)-(8) are the same as Example 1, that is, obtain 3.7 μm monodisperse porous polymer PSDA microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com