Highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and preparation method thereof

A technology of nitrile rubber and wear-resistant nitrile, applied in the field of polymer materials, can solve the problems of inability to carry out large-scale promotion and application, low friction coefficient of nitrile rubber, limited impact resistance and wear resistance, etc. The effect of increasing wear resistance and increasing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

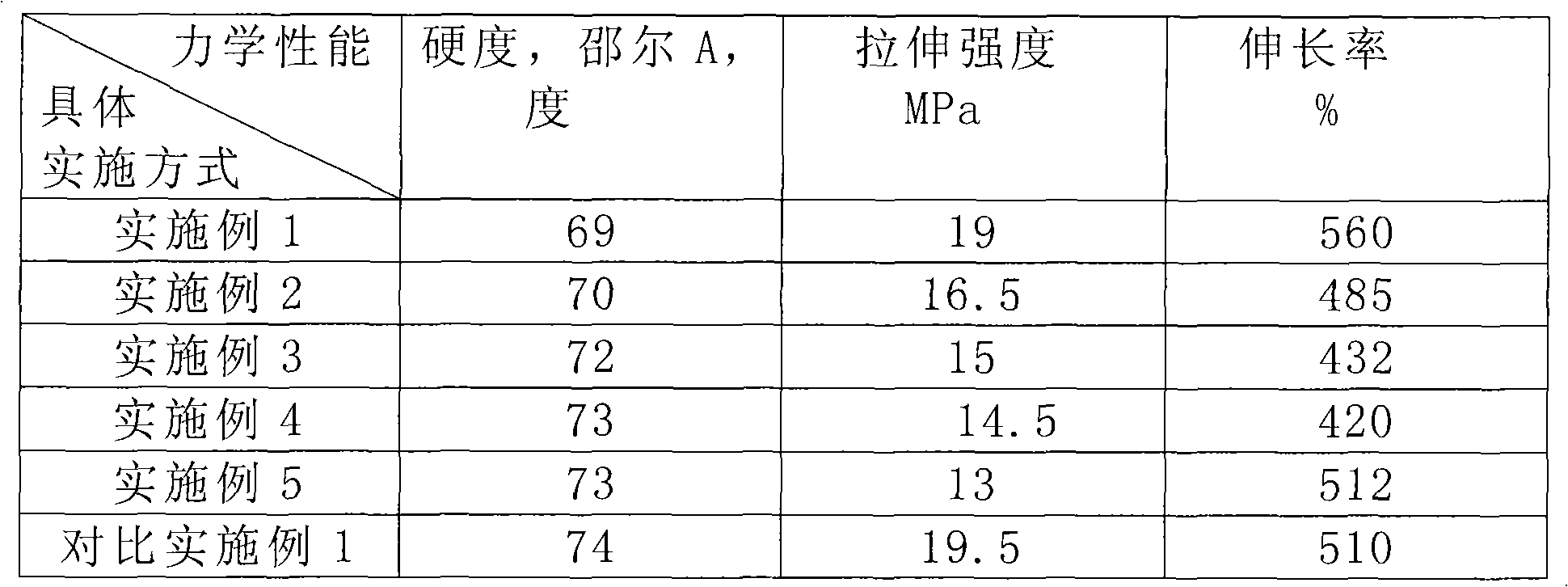

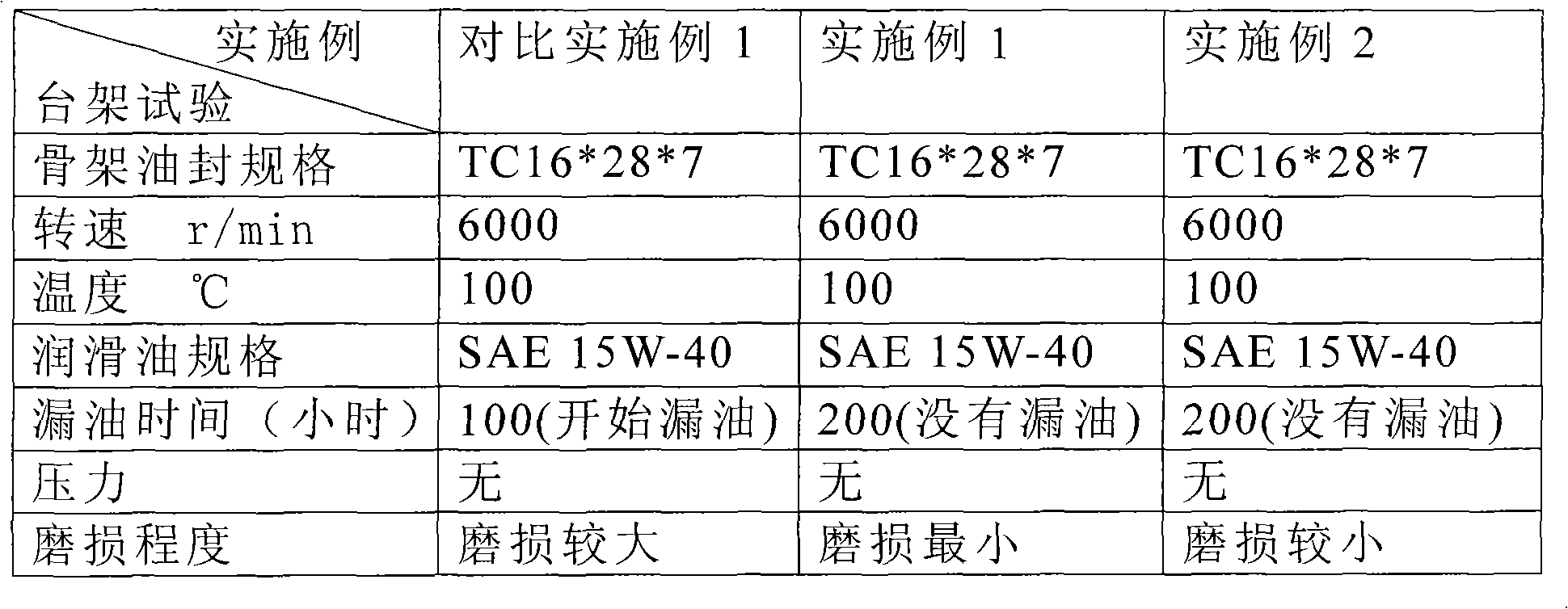

Examples

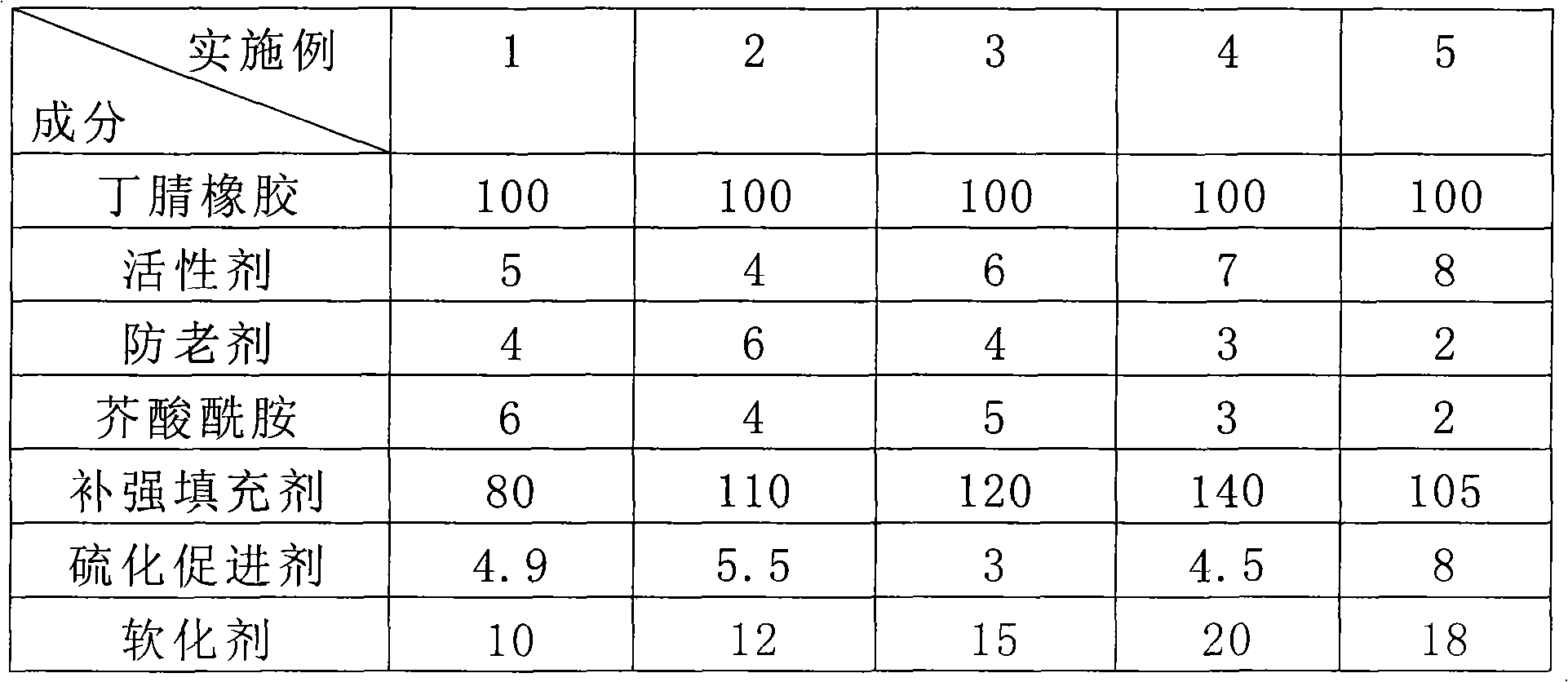

Embodiment 1

[0033]The active agent described in embodiment 1 is made up of zinc oxide: 4 parts and stearic acid: 1 part; Described anti-aging agent is made up of anti-aging agent RD: 2 parts and anti-aging agent MB: 2 parts; Described reinforcement The filler is made up of 40 parts of high wear-resistant carbon black and 40 parts of semi-reinforced carbon black; the vulcanization accelerator is composed of accelerator CBS: 2 parts, accelerator TMTD: 1.3 parts, accelerator TETD1.3 parts and sulfur: 0.3 parts; the softener is dinonyl phthalate.

Embodiment 2

[0034] The active agent described in embodiment 2 is made up of zinc oxide: 3 parts and stearic acid: 1 part; Described anti-aging agent is made up of anti-aging agent RD: 2 parts, anti-aging agent MB: 1 part and anti-aging agent D: 3 parts Composition; The described reinforcing filler is made up of 20 parts of high wear-resistant carbon black, 60 parts of fast extrusion carbon black and diatomite: 30 parts; The described vulcanization accelerator is made up of accelerator TETD: 2 parts, accelerator DM: 3 parts and 0.5 part of sulfur, the softener is dinonyl phthalate.

Embodiment 3

[0035] The active agent described in embodiment 3 is made up of zinc oxide: 5 parts and stearic acid: 1 part; Described anti-aging agent is made up of anti-aging agent BLE: 2 parts and anti-aging agent 4010NA: 2 parts; Described reinforcement The filler consists of calcium bicarbonate: 30 parts, diatomite: 30 parts and high wear-resistant carbon black 60 parts; the vulcanization accelerator consists of accelerator TMTD: 1 part and accelerator CBS: 1 part, sulfur 1 part Composition, described softening agent is dioctyl phthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com