Release compositions for lignocellulosic composites

A technology of lignocellulose and composites, applied in the field of polyisocyanate adhesives/adhesives, which can solve the problems of production rate reduction and cost effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

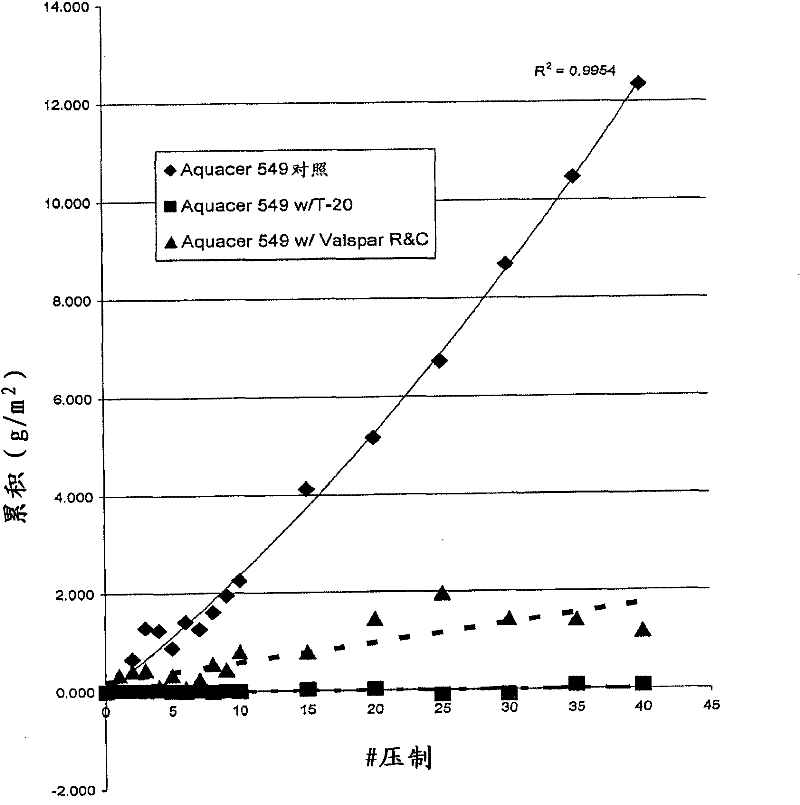

[0087] Experimental procedure: simulated mold-masking

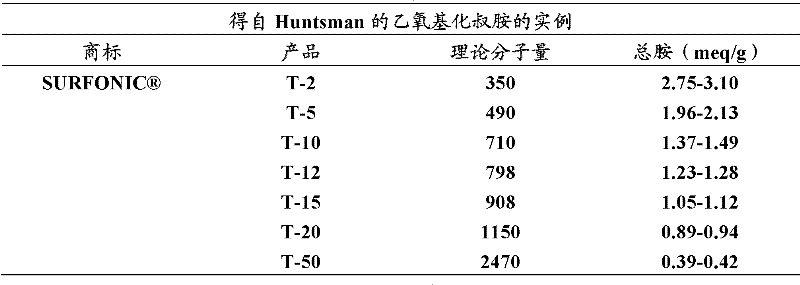

[0088] Tests were performed to evaluate the "anti-masking" properties of ethoxylated fatty amines. To do this, wood composite panels were pressed against metal shim stock to simulate mold masking. Wood composites were made from a substrate of Southern Ponderosa Pine (Pinus sp.) flakes measuring approximately 100 mm x 500 mm x 1 mm. Utilize 6wt% of The substrate was treated with M polymethylene diphenyl diisocyanate and 0.9% wood product accelerator 25010, both ex Huntsman. The adhesive treated substrate was formed into a 30 x 30 cm pad and placed on top of it were four thin nickel shim tray materials each measuring approximately 13 x 13 cm. The resulting wood composite mat was sprayed with 6.0 grams (at a concentration of 20% solids) of a paraffinic release wax from BYK USA 539 products. Thereafter, two sets of pads were sprayed with 6.0 grams (at a concentration of 20% solids) of anti-masking agent and one set of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com