Waste textile wall thermal insulation plate and preparation method thereof

A technology for waste textiles and thermal insulation boards, applied in the field of thermal insulation materials, can solve the problems of low recycling rate and difficult disposal of waste textiles, and achieve the effects of increased strength, low production cost, and good integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

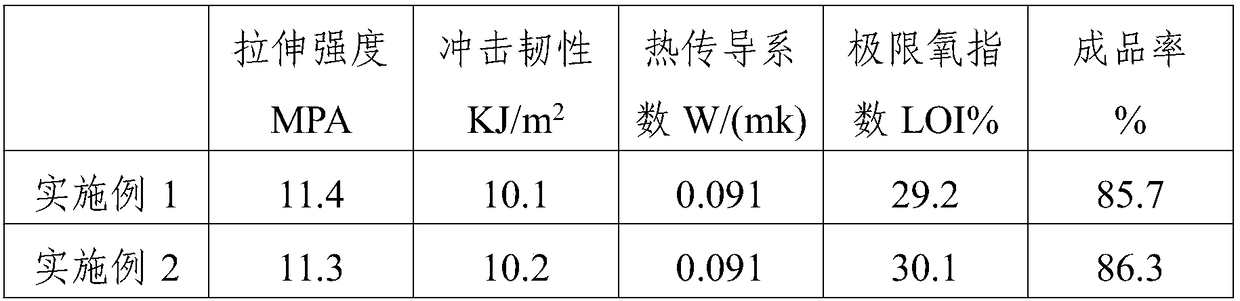

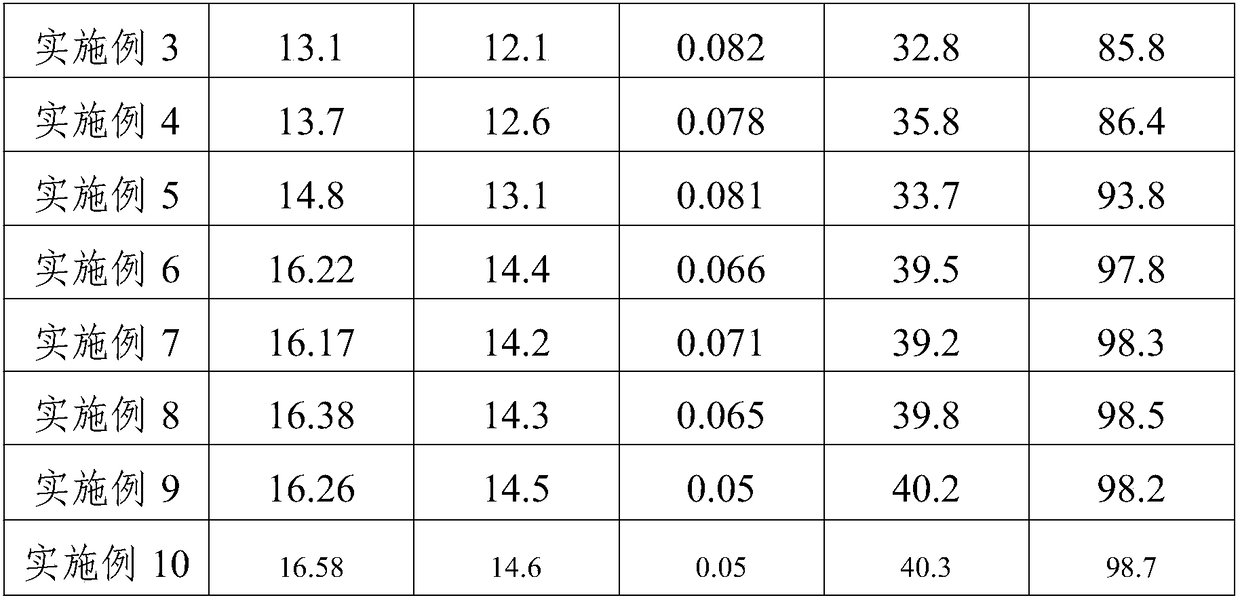

Examples

preparation example Construction

[0039] On the other hand, an embodiment of the present invention provides a method for preparing the above waste textile wall insulation board, comprising the following steps:

[0040] S1. Pretreatment of waste textiles: After the waste textiles are crushed, they are opened to obtain loose fibers, and the waste textiles are dried for later use; the titanate coupling agent is added to isopropanol, and then the waste textiles after opening and drying are added. Dried after soaking for 24 hours;

[0041] S2. Pretreatment of waste plastics: crushing waste plastics and extruding to granulate;

[0042] S3, mixing the waste textiles and waste plastics pretreated in steps S1 and S2 for kneading;

[0043] S4. Slowly add polyether polyol and polymerized MDI to the mixture obtained from the above kneading and kneading. The kneading temperature is 90-100°C, and the kneading time is 45-60 min. After the kneading is completed, add thermoplastic polyurethane and flame retardant in turn to c...

Embodiment 1

[0061] S1. Pretreatment of waste textiles: After the waste textiles are crushed, they are opened to obtain loose fibers, and the waste textiles are dried for later use; the titanate coupling agent is added to isopropanol, and then the waste textiles after opening and drying are added. After soaking for 24 hours, dry it for later use; wherein the ratio of the waste textiles after opening and drying to the titanate coupling agent is 5:1;

[0062] S2. Pretreatment of waste plastics: crushing waste plastics and extruding to granulate;

[0063] S3. Mix and knead the waste textiles and waste plastics pretreated in steps S1 and S2 at 100° C. for 180 minutes; the pretreated waste textiles and waste plastics are added in an amount of 30% and 10% respectively;

[0064] S4. Slowly add polyether polyol and polymerized MDI to the mixture obtained from the above kneading and kneading, the kneading temperature is 90°C, and the kneading time is 45 minutes; after the kneading is completed, add...

Embodiment 2

[0068] S1. Pretreatment of waste textiles: After the waste textiles are crushed, they are opened to obtain loose fibers, and the waste textiles are dried for later use; the titanate coupling agent is added to isopropanol, and then the waste textiles after opening and drying are added. After soaking for 24 hours, dry it for later use; wherein the ratio of the waste textiles after opening and drying to the titanate coupling agent is 5:1;

[0069] S2. Pretreatment of waste plastics: crushing waste plastics and extruding to granulate;

[0070] S3. Mix and knead the waste textiles and waste plastics pretreated in steps S1 and S2 at 160° C. for 300 minutes; the pretreated waste textiles and waste plastics are added in an amount of 30% and 10% respectively;

[0071] S4. Slowly add polyether polyol and polymerized MDI to the mixture obtained from the above kneading and kneading, the kneading temperature is 100°C, and the kneading time is 60 minutes; after the kneading is completed, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com