High flame-retardant polyurethane composition and preparation method thereof

A technology of polyurethane and composition, applied in the field of high flame-retardant polyurethane composition and its preparation, can solve the problems of slowing down the reaction speed, appearing precipitation, affecting the use of foaming manufacturers, etc., and achieves high flame retardancy, good storage stability, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

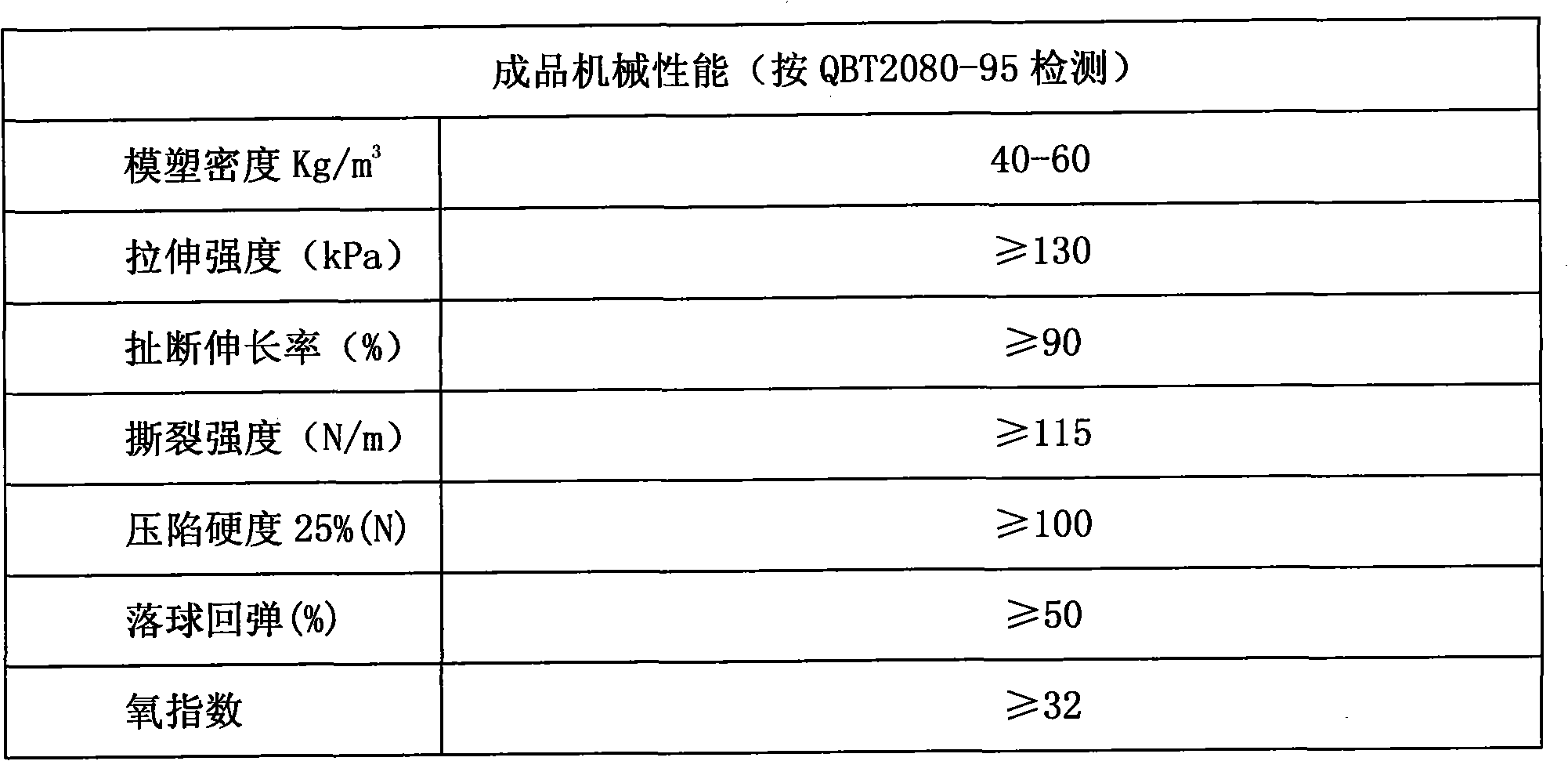

Examples

Embodiment 1

[0040] A component is:

[0041] 330N: 380

[0042] YB-3081: 520

[0043] TEOA: 5.0

[0044] B8715LF: 8.0

[0045] Deionized water: 30

[0046] HCFC-141B: 50

[0047] A-1: 1.0

[0048] A-33: 6.0

[0049] Component B is:

[0050] 330N: 70

[0051] TCPP: 100

[0052] PM-200: 330

[0053] T-80: 500

[0054] Preparation of component A materials: Put the weighed polyether polyol, flame retardant polyether polyol, crosslinking agent, foam stabilizer, water, physical blowing agent, and catalyst into the reaction kettle, and stir at room temperature for 3- After 4 hours, it can be loaded into barrels.

[0055] Preparation of component B materials: Put the weighed polyether polyol, flame retardant, polymerized MDI and toluene diisocyanate into the reaction kettle, react at 75-80°C for 2-3 hours, and then fill the barrel.

[0056] When using, mix A and B component materials according to the mass ratio of A:B=100:50, and then inject them into a mold with a mold temperature of...

Embodiment 2

[0058] A component is:

[0059] 330N: 480

[0060] POP-290E: 460

[0061] DEOA: 10

[0062] AK-7701: 6.0

[0063] Deionized water: 35

[0064] C-225: 9.0

[0065] Component B is:

[0066] 330N: 50

[0067] TCPP: 100

[0068] PM-200: 425

[0069] T-80: 425

[0070] Preparation of component A materials: Put the weighed polyether polyol, flame retardant polyether polyol, crosslinking agent, foam stabilizer, water, and catalyst into the reaction kettle, stir at room temperature for 3-4 hours, and then barreled.

[0071] Preparation of component B materials: Put the weighed polyether polyol, flame retardant, polymerized MDI and toluene diisocyanate into the reaction kettle, react at 75-80°C for 2-3 hours, and then fill the barrel.

[0072] When using, mix A and B component materials according to the mass ratio of A:B=100:60, and then inject them into a mold with a mold temperature of 45°C. After 7 minutes, open the mold and place it at room temperature for 24 hours. Can...

Embodiment 3

[0074] A component is:

[0075] 330N: 320

[0076] POP-290E: 540

[0077] TEOA: 7.0

[0078] DEOA: 13

[0079] L-3002: 9.0

[0080] Deionized water: 40

[0081] HCFC-141B: 60

[0082] A-1: 1.0

[0083] C-225 10

[0084] Component B is:

[0085] 330N: 50

[0086] TCPP: 100

[0087] PM-200: 350

[0088] T-80: 500

[0089] Preparation of component A materials: Put the weighed polyether polyol, flame retardant polyether polyol, crosslinking agent, foam stabilizer, and catalyst into the reaction kettle, stir at room temperature for 3-4 hours, and then fill the barrel .

[0090] Preparation of component B materials: Put the weighed polyether polyol, flame retardant, polymerized MDI and toluene diisocyanate into the reaction kettle, react at 75-80°C for 2-3 hours, and then fill the barrel.

[0091] When using, mix A and B component materials according to the mass ratio of A:B=100:60, and then inject them into a mold with a mold temperature of 60°C. After 7 minutes, open t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com