Coarse TDI (toluene diisocynate) treating method

A treatment method, technology of toluene diisocyanate, applied in adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve problems such as environmental pollution, high cost of tar solid waste, and achieve significant economic benefits, save money, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] S1. Mix crude TDI with polymeric MDI at a mass ratio of 1.1:1 at 150-180°C to generate a modified isocyanate whose viscosity is between 4800-5200mPa·s (mPa·s). , the mass fraction of the isocyanate group contained in the modified isocyanate is 28-30%, that is, the NCO% of the modified isocyanate is 28-30%;

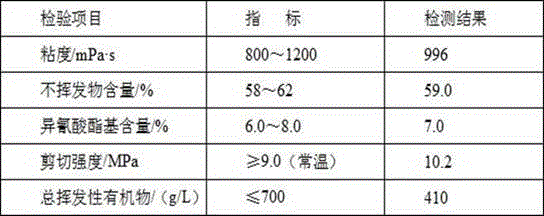

[0026] S2. Put 100g of polyether polyol (MN-3050D) into a clean three-necked bottle, stir, heat up to 105-110°C and reflux, dehydrate for 1 hour, cool down to 50°C, add 50g of butyl acetate, and control the temperature at 40-50°C , slowly add 120g of modified crude TDI under constant stirring, keep warm at 65°C for 1h, then raise the temperature to 80-90°C for prepolymerization reaction, react for 3h, add 60g of butyl acetate to dissolve the prepolymer; at 75°C Add 25g of 1,4-butanediol, raise the temperature to 85-90°C for chain extension reaction, react for 1h, cool down to below 40°C, filter, and discharge. The obtained filtrate is the prepared polyurethane adhe...

Embodiment 2

[0034] S1. Mix crude TDI with polymeric MDI at a mass ratio of 1.1:1 at 150-180°C to generate a modified isocyanate whose viscosity is between 4800-5200mPa·s (mPa·s), The mass fraction of isocyanate groups contained in the modified isocyanate is 28% to 30%;

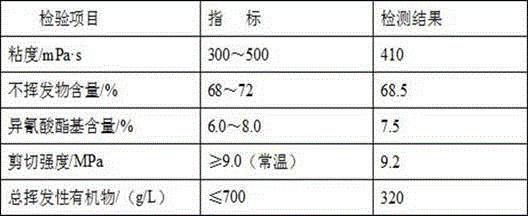

[0035] S2. Put 70g of polyether polyol DL-2000D and 30g of polyether polyol 330N into a clean three-necked bottle, stir, heat up to 105-110°C and reflux, dehydrate for 1h, cool down to 50°C, add 100g of dimethyl carbonate, control The temperature is 40-50°C, slowly add 100g of modified crude TDI under constant stirring, keep warm at 65°C for 1 hour, then raise the temperature to 80-90°C for polymerization reaction, react for 3 hours, cool down to below 40°C, filter, Discharge. The obtained filtrate is the prepared environment-friendly polyurethane adhesive.

[0036] Polymerized MDI used in the present embodiment is 44V20, produced by Bayer Company;

[0037] Crude TDI is produced by Cangzhou Dahua, which contains about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com