Anti-aging environment-friendly polyurethane foam combination material and preparation method thereof

A polyurethane foam, environment-friendly technology is applied in the field of aging-resistant and environment-friendly polyurethane foam composite materials and their preparation, which can solve the problems of inability to meet use requirements, aging of finished products, poor storage stability of composite materials, etc. Excellent, low VOC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

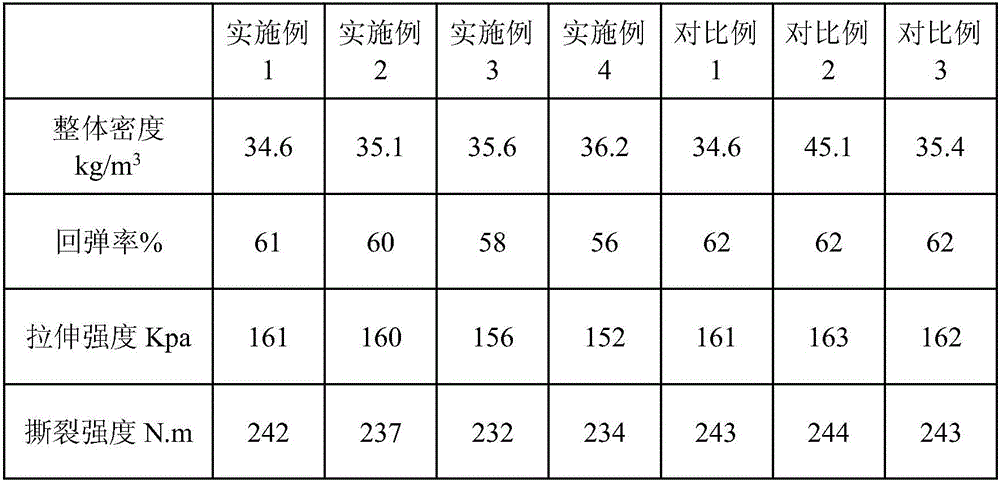

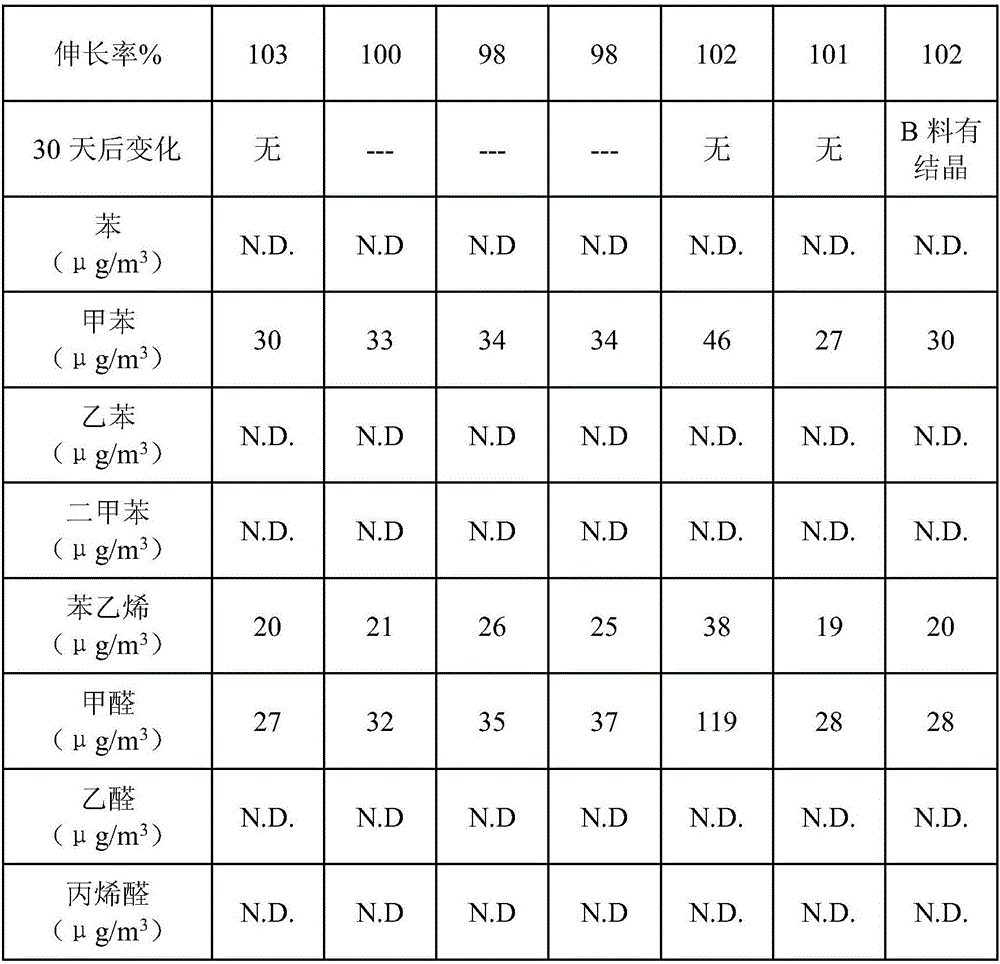

Examples

Embodiment 1

[0020] An aging-resistant and environmentally friendly polyurethane foam composite material, including material A and material B;

[0021] Proportioning in material A includes by mass fraction: polyether polyol: 42 parts, polymer polyol: 50 parts, foam stabilizer 2 parts, catalyst (bisdimethylaminoethyl ether): 1.5 parts, auxiliary agent ( Manganese dioxide, urea, and ethylenediamine are prepared in a mass ratio of 2:5:3): 1.5 parts, 2 parts of crosslinking agent (diethanolamine), foaming agent (1.4 parts of cyclopentane, n-pentyl a mixture of 1.4 parts of alkane and 1.2 parts of pure water): 14 parts;

[0022] The preparation of material B includes: 65 parts of toluene diisocyanate (TDI 80 / 20), 65 parts of modified diphenylmethane diisocyanate (MDI), and the mass ratio of liquefied MDI and polymerized MDI in modified diphenylmethane diisocyanate is 2:3 .

[0023] The above-mentioned material parts are all parts by mass.

[0024] A method for preparing an aging-resistant an...

Embodiment 2

[0027] An aging-resistant and environmentally friendly polyurethane foam composite material, including material A and material B;

[0028] Proportioning in material A includes by mass fraction: polyether polyol: 52 parts, polymer polyol: 70 parts, foam stabilizer 2.8 parts, catalyst (bisdimethylaminoethyl ether): 4 parts, auxiliary agent ( Manganese dioxide, urea, and ethylenediamine are prepared in a mass ratio of 2:5:3): 1.1 parts, 1.5 parts of crosslinking agent (diethanolamine), foaming agent (0.6 parts of cyclopentane, n-pentyl a mixture of 1.5 parts of alkanes and 0.9 parts of pure water): 13 parts;

[0029] The preparation of material B includes: 60 parts of toluene diisocyanate (TDI 80 / 20), 40 parts of modified diphenylmethane diisocyanate (MDI), and the mass ratio of liquefied MDI and polymerized MDI in modified diphenylmethane diisocyanate is 2:3 .

[0030] A preparation method and usage method of an aging-resistant environment-friendly polyurethane foam composite ...

Embodiment 3

[0032] An aging-resistant and environmentally friendly polyurethane foam composite material, including material A and material B;

[0033] The proportioning in material A includes by mass fraction: polyether polyol: 50 parts, polymer polyol: 82 parts, foam stabilizer 2.5 parts, catalyst (bisdimethylaminoethyl ether): 3 parts, auxiliary agent ( Manganese dioxide, urea, and ethylenediamine are formulated in a mass ratio of 2:5:3): 1.5 parts, 0.5 parts of crosslinking agent (diethanolamine), foaming agent (composed of 2 parts of cyclopentane, n-pentyl a mixture of 0.8 parts of alkane and 1.2 parts of pure water): 14 parts;

[0034] The preparation of material B includes: 55 parts of toluene diisocyanate (TDI 80 / 20), 25 parts of modified diphenylmethane diisocyanate (MDI), and the mass ratio of liquefied MDI and polymerized MDI in modified diphenylmethane diisocyanate is 2:3 .

[0035] A preparation method and usage method of an aging-resistant environment-friendly polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com