Heat-retaining and sound-insulating metal decorating plate

A metal decoration, thermal insulation and sound insulation technology, applied in the field of building decoration materials, can solve the problems of indoor environmental pollution, poor impact resistance, easy to cause fire, etc., achieve the effect of firm combination, increase service life, and avoid easy fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

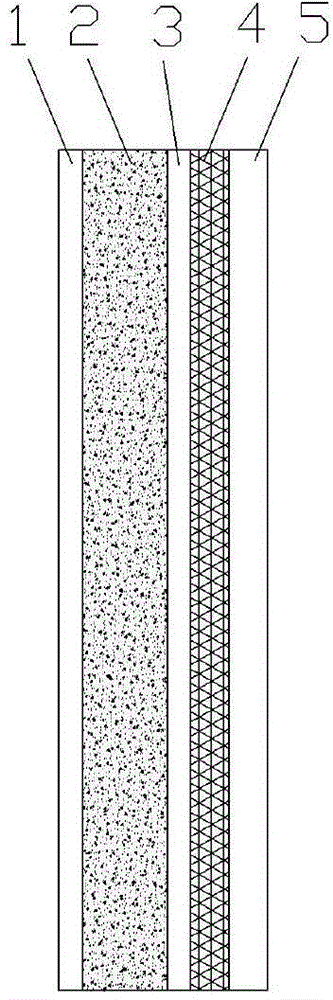

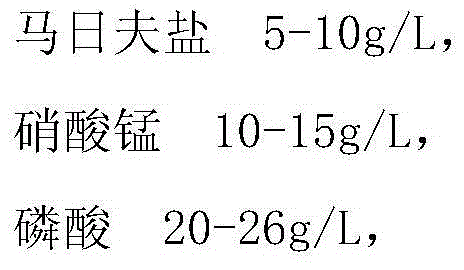

[0017] A heat-insulating and sound-insulating metal decorative plate, comprising a metal heat-insulating base plate and a sound-insulating decorative layer, and the sound-insulating decorative layer is arranged on the right side of the metal heat-insulating base plate. The thermal insulation foam layer 2 and the second steel plate 3, the first steel plate 1 and the second steel plate 3 are all phosphating, and the thermal insulation foam layer 2 is polyurethane rigid foam combined with polyether and polymeric MDI directly on the first steel plate 1 and the second steel plate 3 produced by the reaction. By arranging the heat insulating foam layer 2 between the first steel plate 1 and the second steel plate 3, the heat insulating foam layer 2 is not in direct contact with the fire source, avoiding the danger that the heat insulating material is easy to catch fire. In addition, the first steel plate 1 and the second steel plate 3 The surface of the steel plate 3 is treated with p...

Embodiment 2

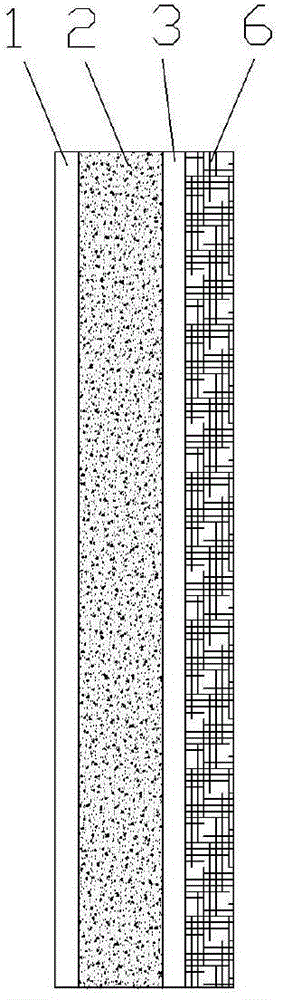

[0024] A heat-insulating and sound-insulating metal decorative plate, comprising a metal heat-insulating base plate and a sound-insulating decorative layer, and the sound-insulating decorative layer is arranged on the right side of the metal heat-insulating base plate. The thermal insulation foam layer 2 and the second steel plate 3, the first steel plate 1 and the second steel plate 3 are all phosphating, and the thermal insulation foam layer 2 is polyurethane rigid foam combined with polyether and polymeric MDI directly on the first steel plate 1 and the second steel plate 3 produced by the reaction. By arranging the heat insulating foam layer 2 between the first steel plate 1 and the second steel plate 3, the heat insulating foam layer 2 is not in direct contact with the fire source, avoiding the danger that the heat insulating material is easy to catch fire. In addition, the first steel plate 1 and the second steel plate 3 The surface of the steel plate 3 is treated with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com