Device for replacing interface flange sealing ring of main transformer with oil

A technology for replacing interfaces and flange seals, which is applied in the direction of transformer/inductor cooling, transformer/inductor parts, electrical component structure associations, etc. Leakage, wasting the environment and other problems, to avoid unsafe fire hazards and environmental pollution, and reduce the waste of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

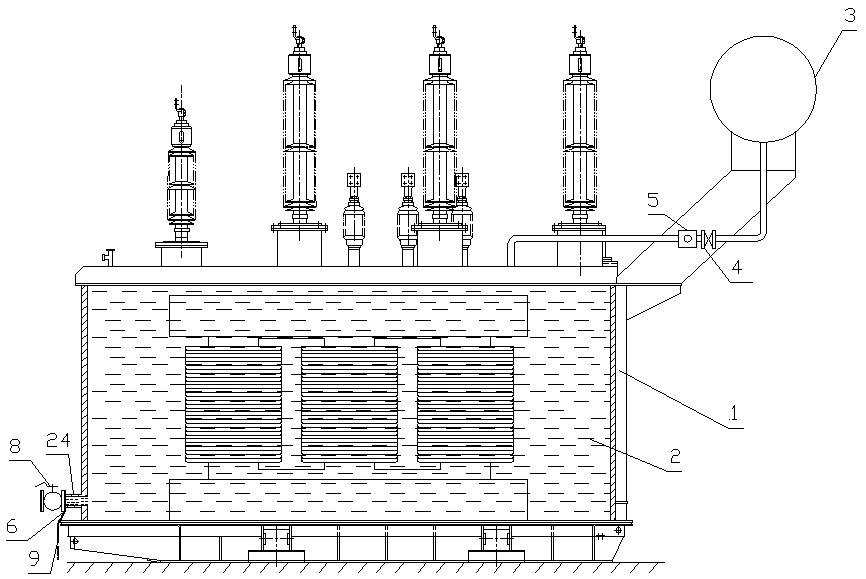

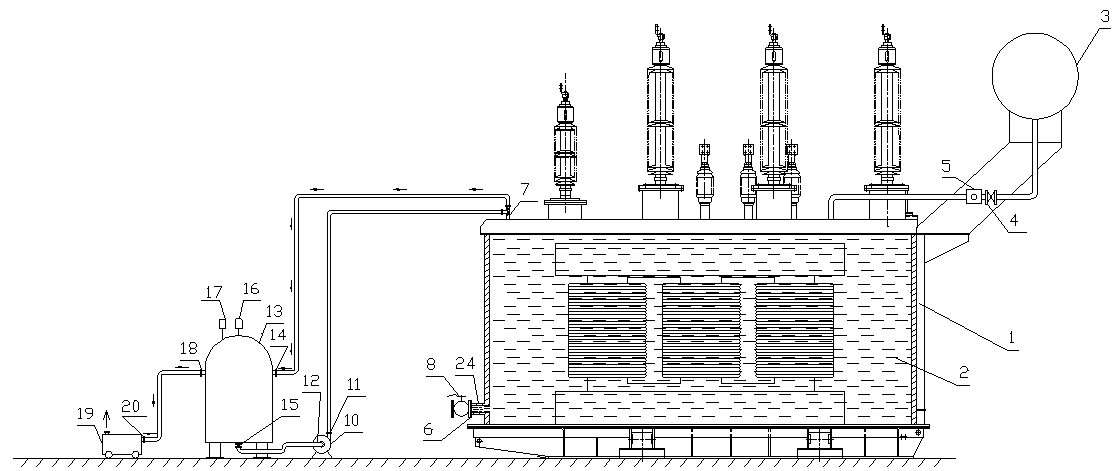

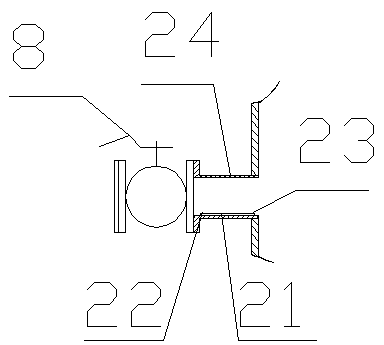

[0020] Please refer to figure 2 , the present invention provides a main transformer oil replacement interface flange sealing ring device, including the main transformer body, oil conservator, vacuum three-way valve, dynamic vacuum system, transformer oil arranged inside the main transformer body, the main transformer oil The main connecting pipe and oil drain valve installed at the lower part of the main body; the oil pillow is connected to the top of the main transformer body through a communication valve and a gas relay; the vacuum three-way valve is set on the top of the main transformer body and connected to the dynamic vacuum system.

[0021] In this embodiment, the oil conservator of the main transformer plays the role of balancing the thermal expansion and contraction of the oil level in the main transformer body. The vacuum three-way valve inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com