Direct inclination control rotor helicopter

A technology of rotor helicopter and tilt control, applied in the directions of rotorcraft, motor vehicles, aircraft, etc., can solve the problems of backwardness, model and quantity performance can not meet military and civil use, low capital investment, etc., to improve the service life, design and manufacture The effect of reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

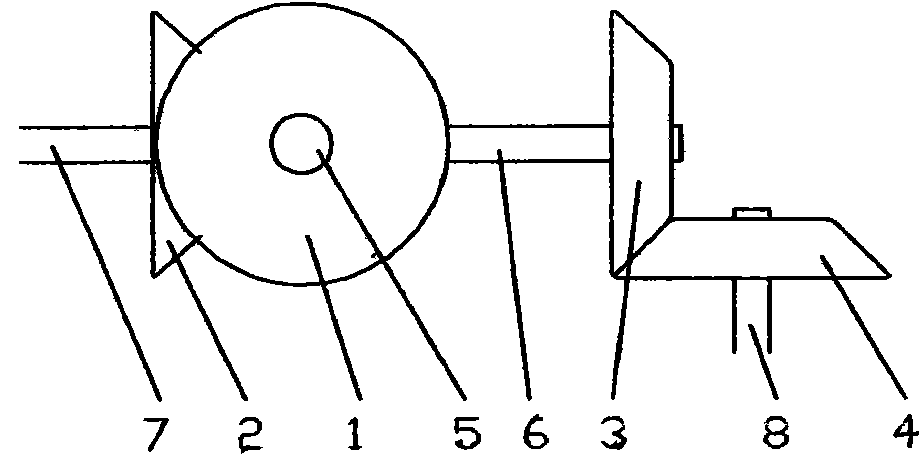

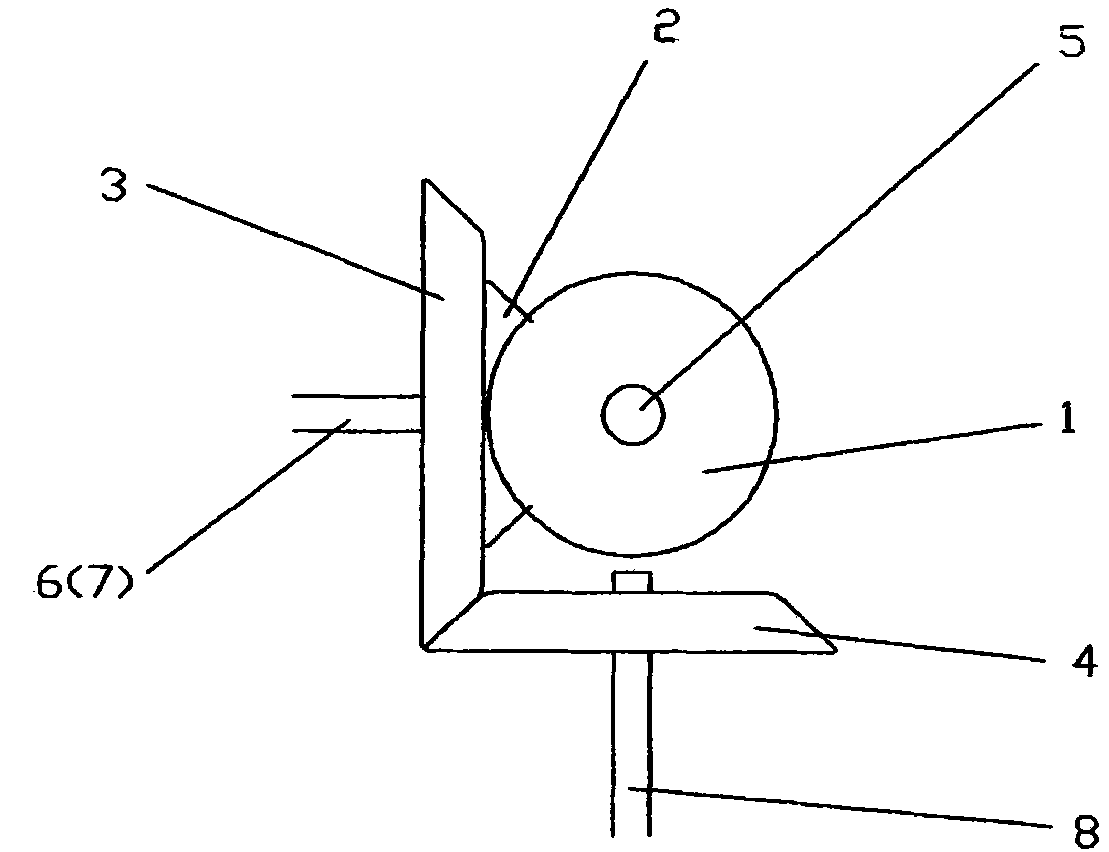

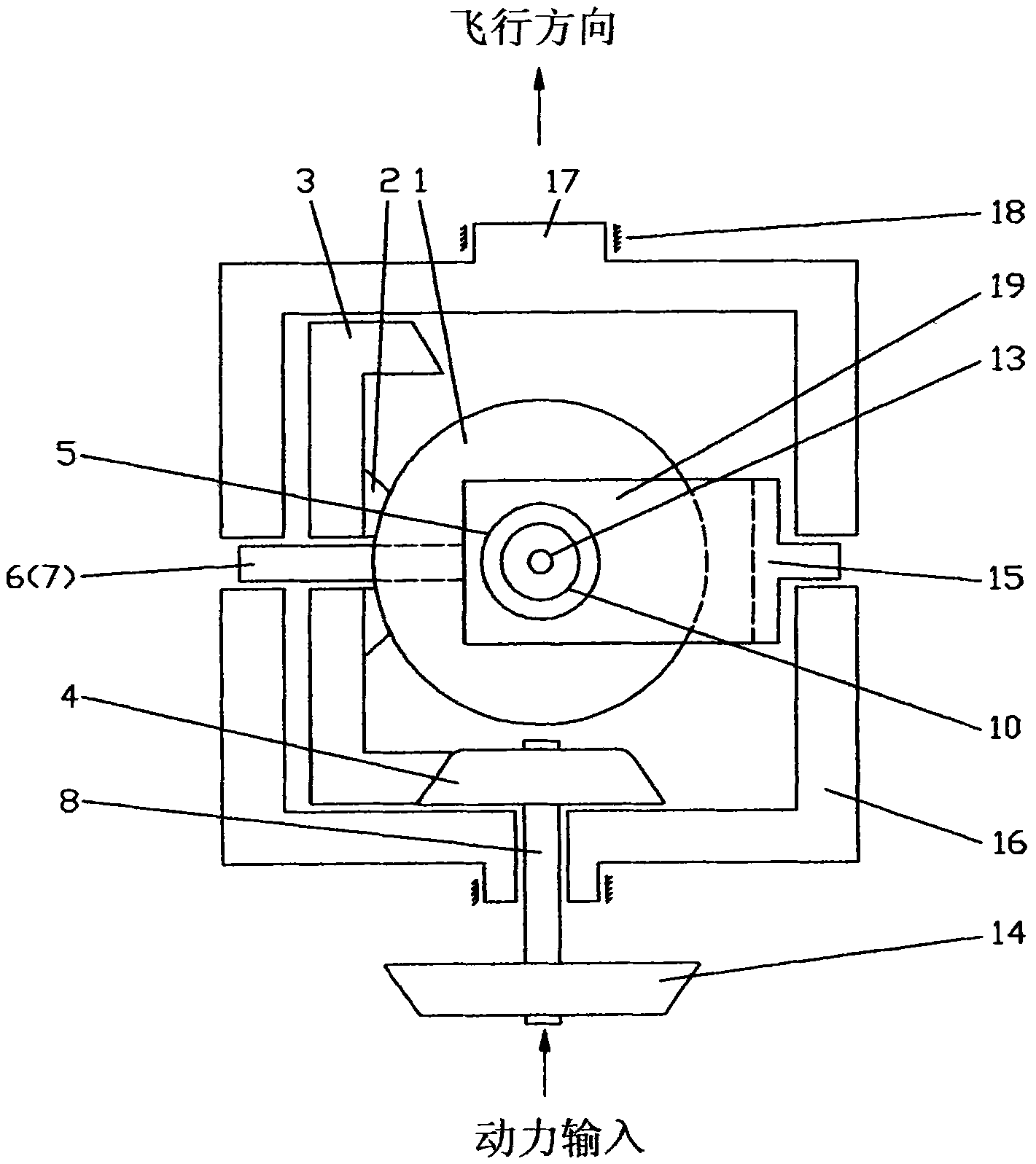

[0014] The invention is applicable to single-rotor helicopters, double (multi-rotor) helicopters, high-speed helicopters with thrust, unmanned aerial vehicles and other related aircraft and mechanical devices. Here we only take a single-person helicopter as an example to illustrate the relationship between the tilt manipulator and the structural arrangement of the whole machine system. Other forms will not be repeated.

[0015] The main shaft (17) on the frame (16) of the tilting manipulator is arranged on the fuselage bearing beam (18) of the helicopter, and the frame (16) can tilt around the main shaft (17). And the overall rotor can be tilted in any orientation with the total axis (17) as the vertical axis and the fork-shaped shaft (15) as the horizontal axis. Engine (21) transmits power to belt pulley (14) with belt (22) so that outer shaft (5) and inner shaft (10) drive rotor (11) and the resistance plate (12) of paddle root position to rotate. The driver on the buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com