Method for forming polyolefin microporous membrane and application thereof

A technology of polyolefin microporous film and polyolefin flow, which is applied in the field of polyolefin film manufacturing, and can solve problems such as difficulty in achieving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

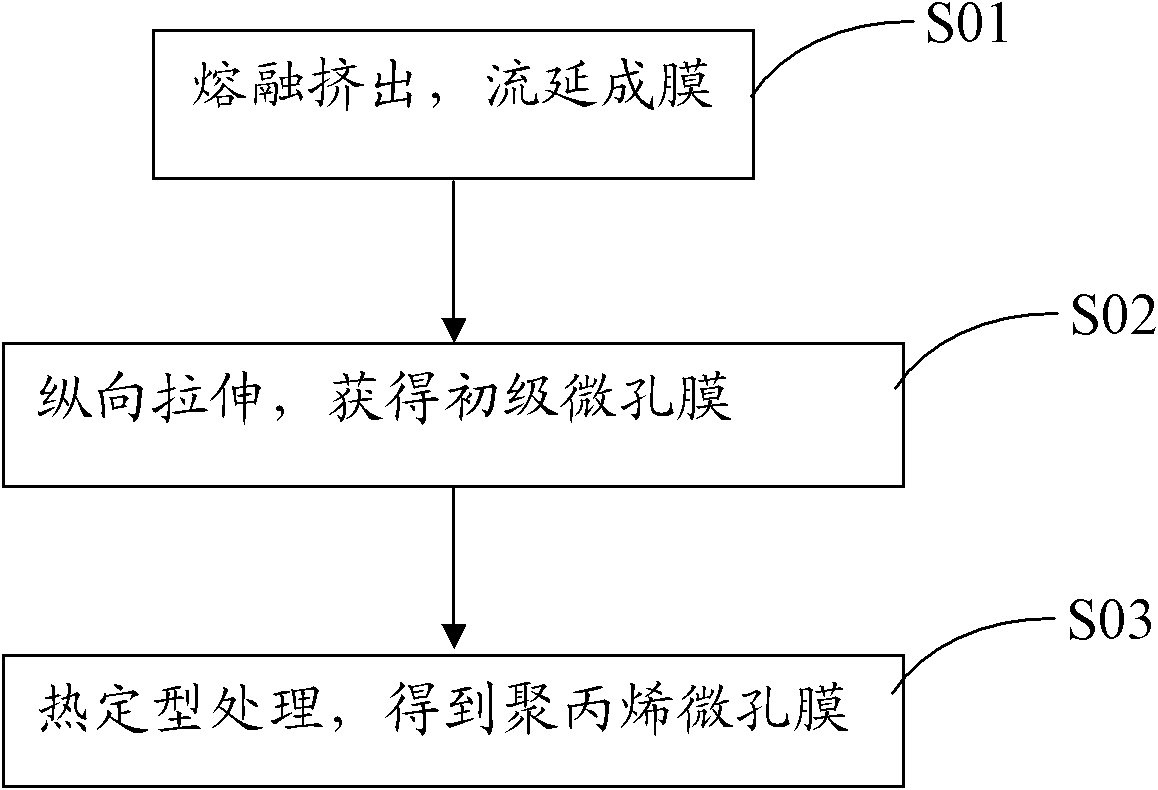

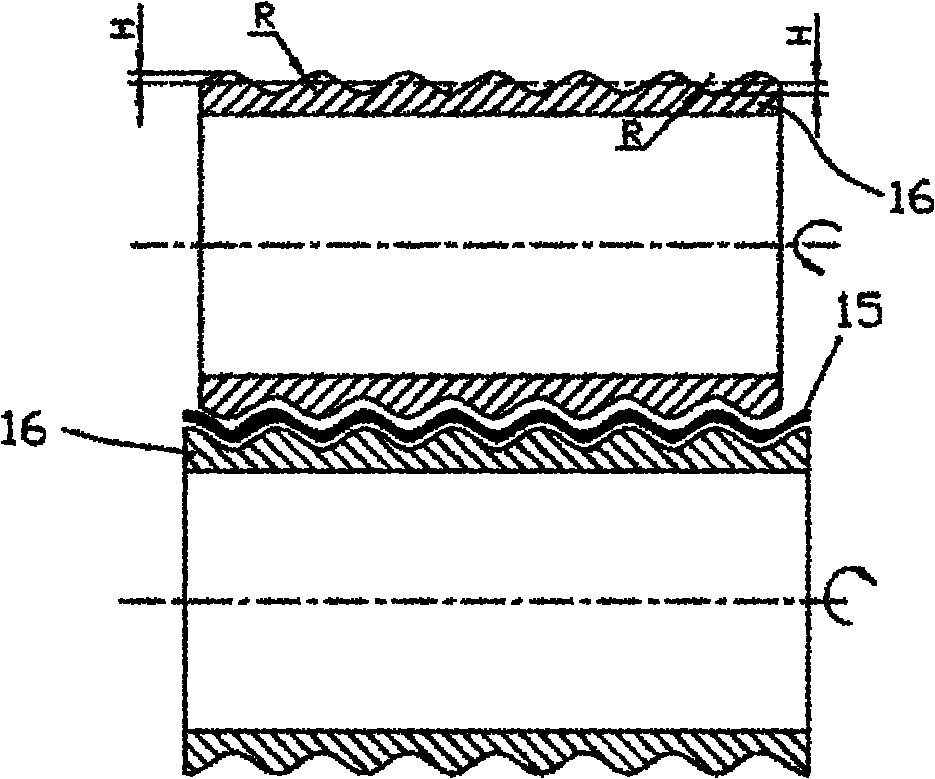

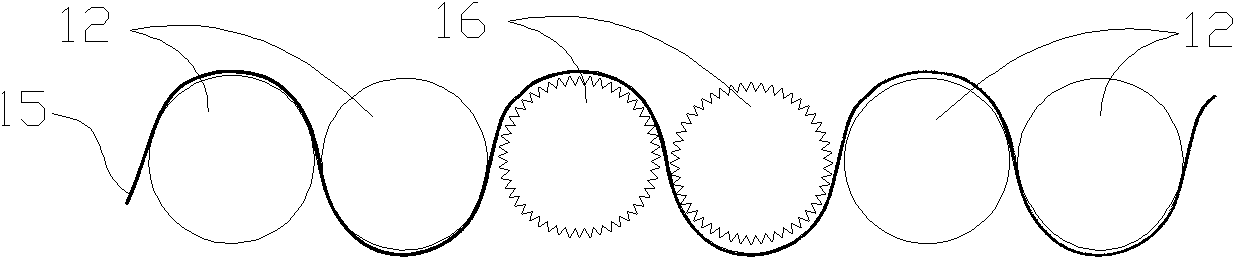

[0038] Homopolypropylene with a melt index of 3.0g / 10min was used, melted and extruded by a single-screw extruder, and cast into a thick film. The extrusion temperature was 220°C, the temperature of the casting roll was 60°C, and the thickness of the cast thick film was 30 μm. It was then heat-treated in an oven at 150°C for 10 hours. The cold drawing temperature is 20°C, the cold drawing ratio is 20%, the hot drawing temperature is 140°C, and the hot drawing ratio is 120%. The heat setting temperature is 140°C, and the heat setting time is 20s. The two corrugated rollers are located in the middle of the 6 sizing rollers, the corrugated rollers have H / R=0.35, and the transverse stretching ratio is 1.2 times to obtain the final PP microporous membrane.

Embodiment 2

[0040] Homopolypropylene with a melt index of 3.0g / 10min was used, melted and extruded by a single-screw extruder, and cast into a thick film. The extrusion temperature was 220°C, the temperature of the casting roll was 60°C, and the thickness of the cast thick film was 30 μm. Then heat treatment in an oven at 150°C for 10 hours. The cold drawing temperature is 25°C, the cold drawing ratio is 20%, the hot drawing temperature is 140°C, and the hot drawing ratio is 120%. The heat setting temperature is 140°C, and the heat setting time is 20s. The two corrugated rollers are located in the middle of the 6 sizing rollers, the corrugated rollers H / R=0.1, and the transverse stretching ratio is 1.1 times to obtain the final PP microporous membrane.

Embodiment 3

[0042] Homopolypropylene with a melt index of 3.0g / 10min was used, melted and extruded by a single-screw extruder, and cast into a thick film. The extrusion temperature was 220°C, the temperature of the casting roll was 60°C, and the thickness of the cast thick film was 30 μm. Then heat treatment in an oven at 150°C for 10 hours. The cold drawing temperature is 25°C, the cold drawing ratio is 20%, the hot drawing temperature is 140°C, and the hot drawing ratio is 120%. The heat setting temperature is 140°C, and the heat setting time is 20s. Two corrugated rollers are located in the middle of the 6 sizing rollers, the corrugated rollers have H / R=0.6, and the transverse stretching ratio is 1.3 times to obtain the final PP microporous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com