Method for manufacturing bamboo wood whole-piece assembly and bamboo composite material

A manufacturing method and technology of composite materials, applied in chemical instruments and methods, manufacturing tools, flat products, etc., can solve problems such as poor dimensional stability, uneven density distribution, constraints, etc., to reduce the incidence of voids, ensure uniformity, The effect of improving the efficiency of blank assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Cutting: Select moso bamboo with a diameter of 80-90 mm, and cut the moso bamboo into a bamboo tube with a length of 1 m with a bamboo sawing machine.

[0027] (2) Sectioning: Use a bamboo cutting machine to divide the bamboo tube into 12 equal pieces of bamboo.

[0028] (3) Green removal: use a bamboo slicer to remove the green bamboo on the surface of the bamboo slices.

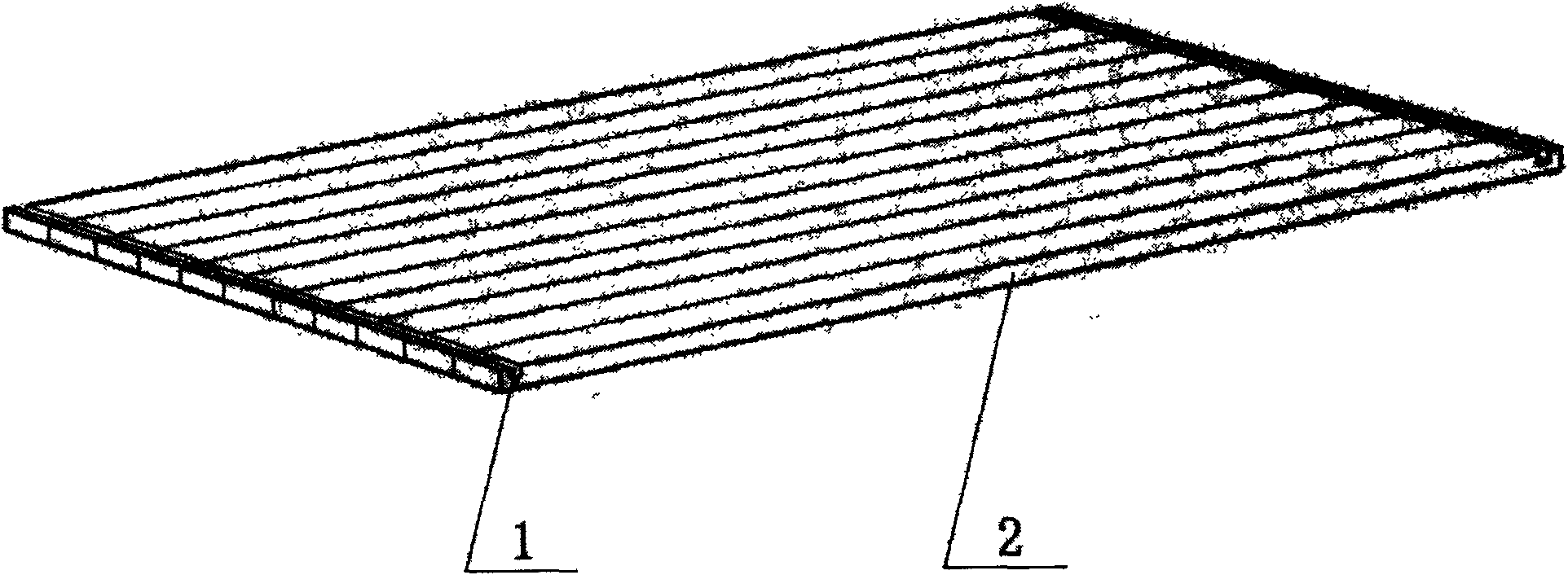

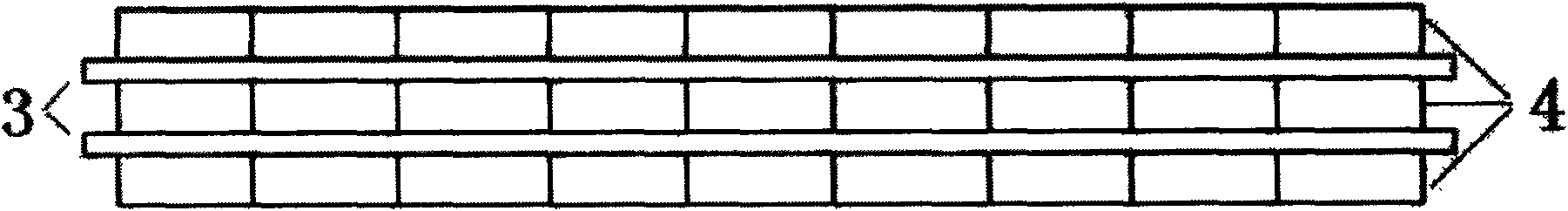

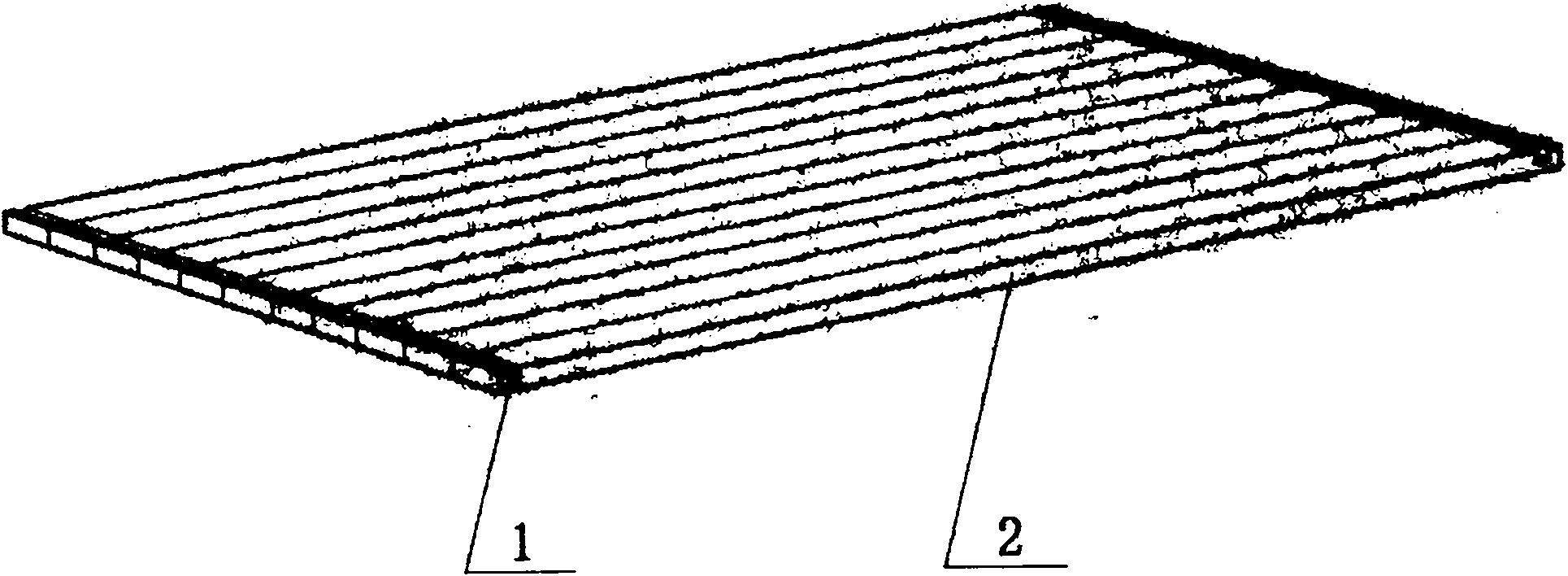

[0029] (4) Assembling, sawing grooves and pressing lines: arrange the bamboo slices 2 on the workbench, align the two ends of the bamboo slices 2 during the arrangement, and the total width of the bamboo slices after the arrangement is 500mm; compress the bamboo slices At both ends of the layer, adopt a cross saw to saw a saw groove 1 at the two ends of the bamboo slice 2 respectively, the width of the saw groove 1 is 2 mm, the depth of the saw groove 1 is 1 / 2 of the thickness of the bamboo slice 2, and the center of the saw groove 1 reaches The distance between the ends of the bamboo slices 2 i...

Embodiment 2

[0039] (1) Cutting: choose moso bamboo with a diameter of 110-120 mm, and cut the moso bamboo into a bamboo tube with a length of 2 m with a bamboo sawing machine.

[0040] (2) Sectioning: Use a bamboo cutting machine to divide the bamboo tube into 14 equal pieces of bamboo.

[0041] (3) Green removal: use a bamboo slicer to remove the green bamboo on the surface of the bamboo slices.

[0042] (4) Assembling, sawing groove 1 and crimping: the bamboo slices 2 are assembled on the workbench, and the two ends of the bamboo slices 2 are aligned during the arrangement. At both ends of the sheet layer, a saw groove 1 is respectively sawed at the two ends of the bamboo slice 2 by a scribe saw. The width of the saw groove 1 is 2mm, and the depth of the saw groove 1 is 2 / 3 of the thickness of the bamboo slice 2. The distance to the ends of the bamboo slices 2 is 150mm, and the hemp rope with a diameter of 3mm is pressed into the saw groove 1 to form a bamboo slice curtain.

[0043] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com