Method for making a hydroentangled nonwoven fabric and the fabric made thereby

a non-woven fabric and hydroentangled technology, applied in the field of making a hydroentangled non-woven fabric and the fabric made thereby, can solve the problems of affecting the properties of the resulting non-woven material, adding to the time and cost of the process, and material stretching and ultimately tear, so as to improve the wet strength properties, improve the wet strength, and improve the effect of wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

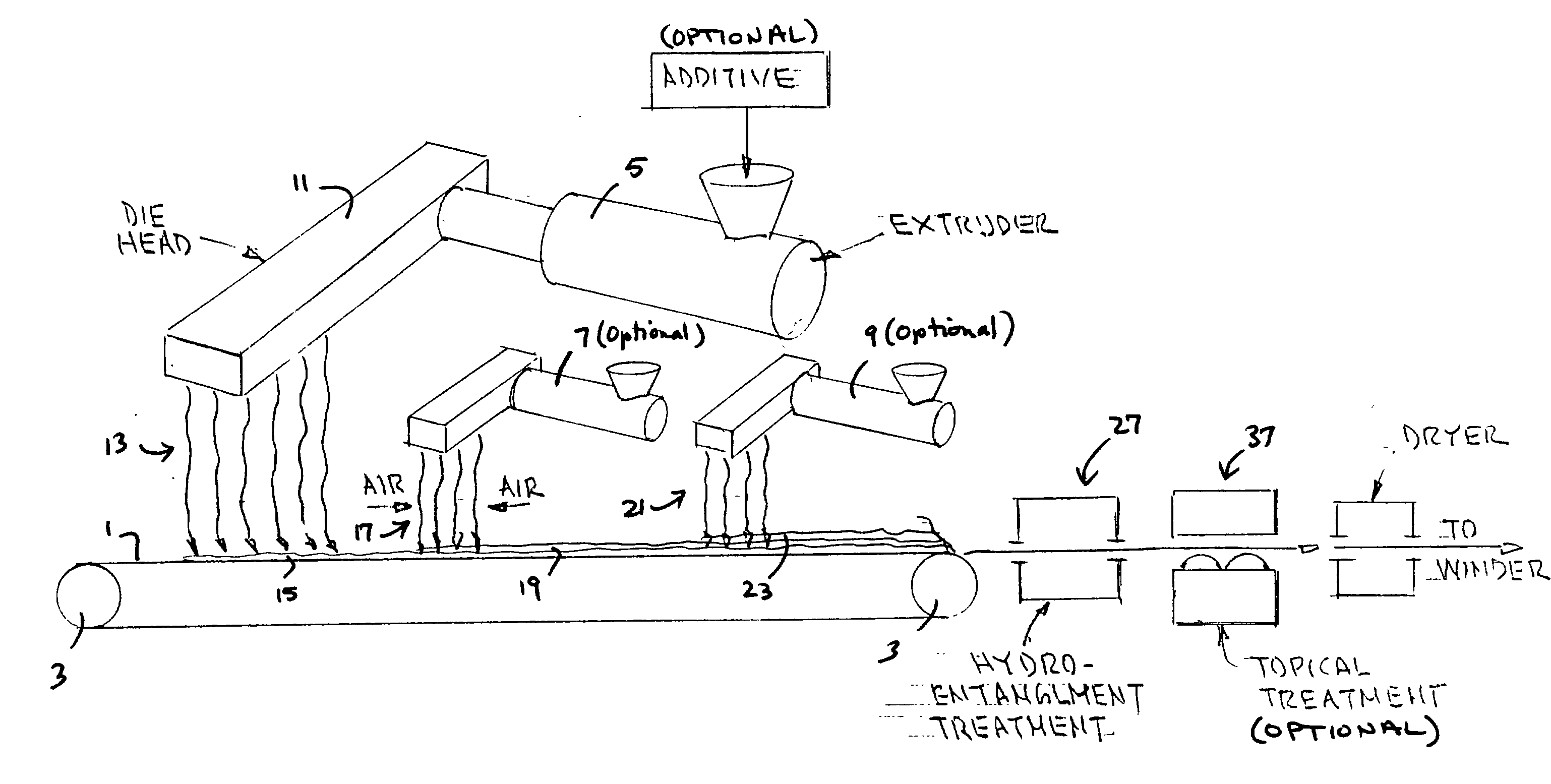

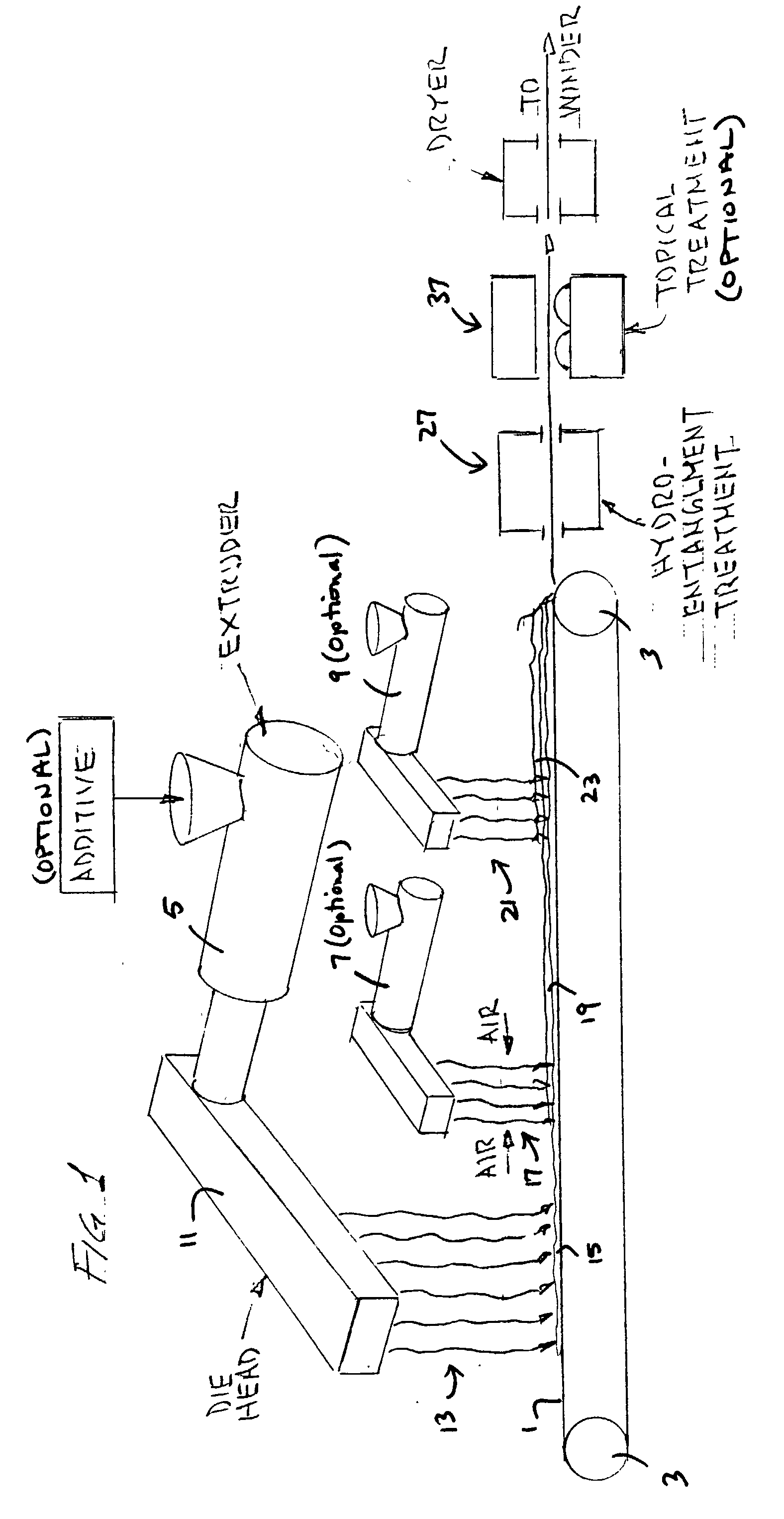

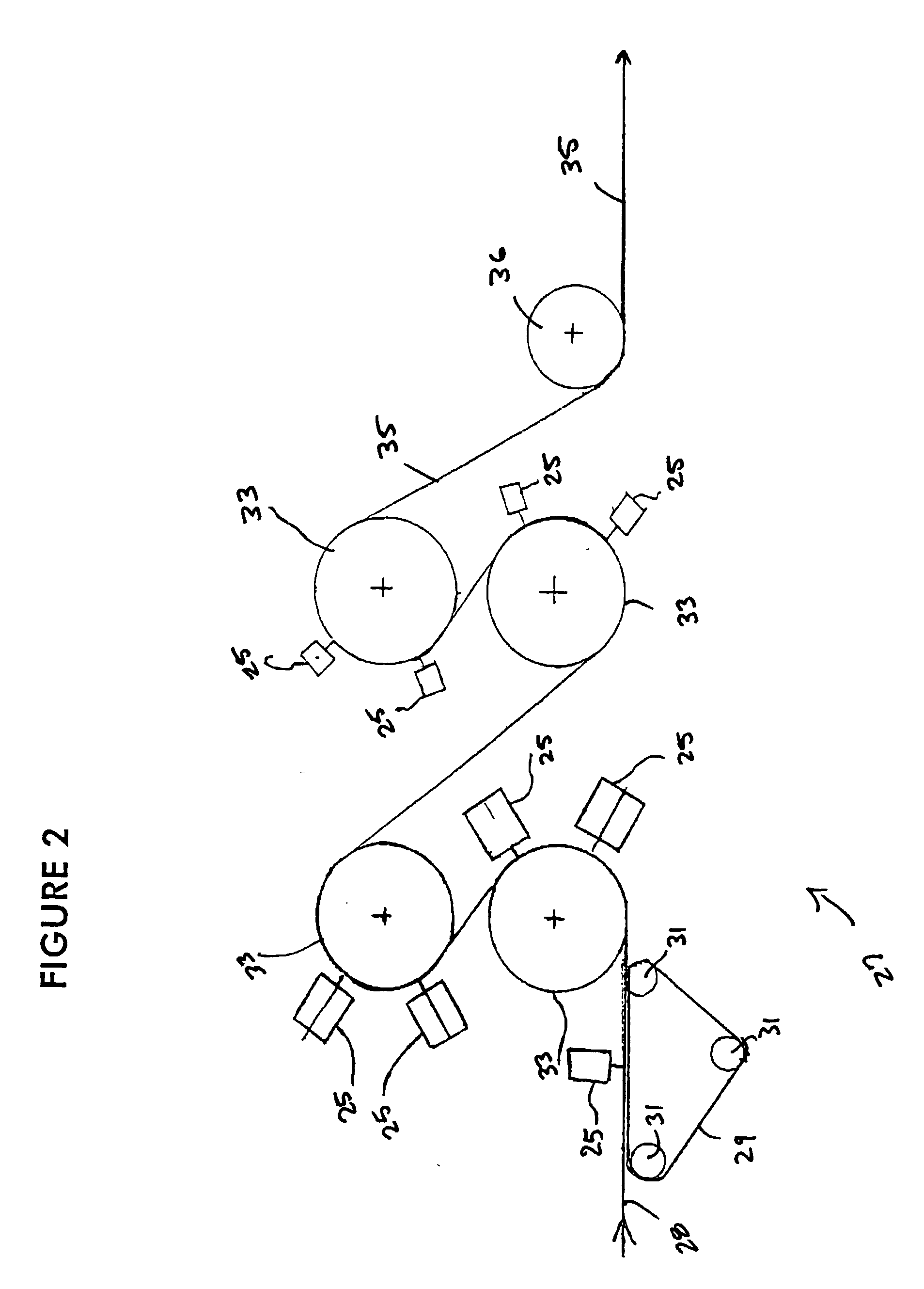

[0030] The hydroentangled nonwoven material provided by the process of the invention includes at least one layer of continuous filaments or fibers bonded by hydroentanglement in the absence of any prebonding of the filaments. The nonwoven material can be a single layer or multi-layer and include a combination of spunlaid and / or meltblown filament layer(s). The filaments forming the at least one layer are polymeric and continuous. The filaments can be made using conventional extrusion apparatus and techniques. The invention avoids the use of staple fibers. Preferably when a single layer, the nonwoven material is spunlaid. The hydroentangled nonwoven material of the invention has a superior tensile and elongation properties as compared to hydroentangled nonwoven materials made from staple fibers.

[0031] To provide a nonwoven material with high strength in the machine direction and cross-direction as well as having improved processability, both during manufacture and after manufacture, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com