Combined fiber reinforced water-blown polyurethane hard foam composite board, production method and production equipment thereof

A technology of polyurethane rigid foam and composite board, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc. Large external temperature difference and other problems, to achieve the effect of improving transverse strength and interlayer peeling strength, great social and economic benefits, and improving weather resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

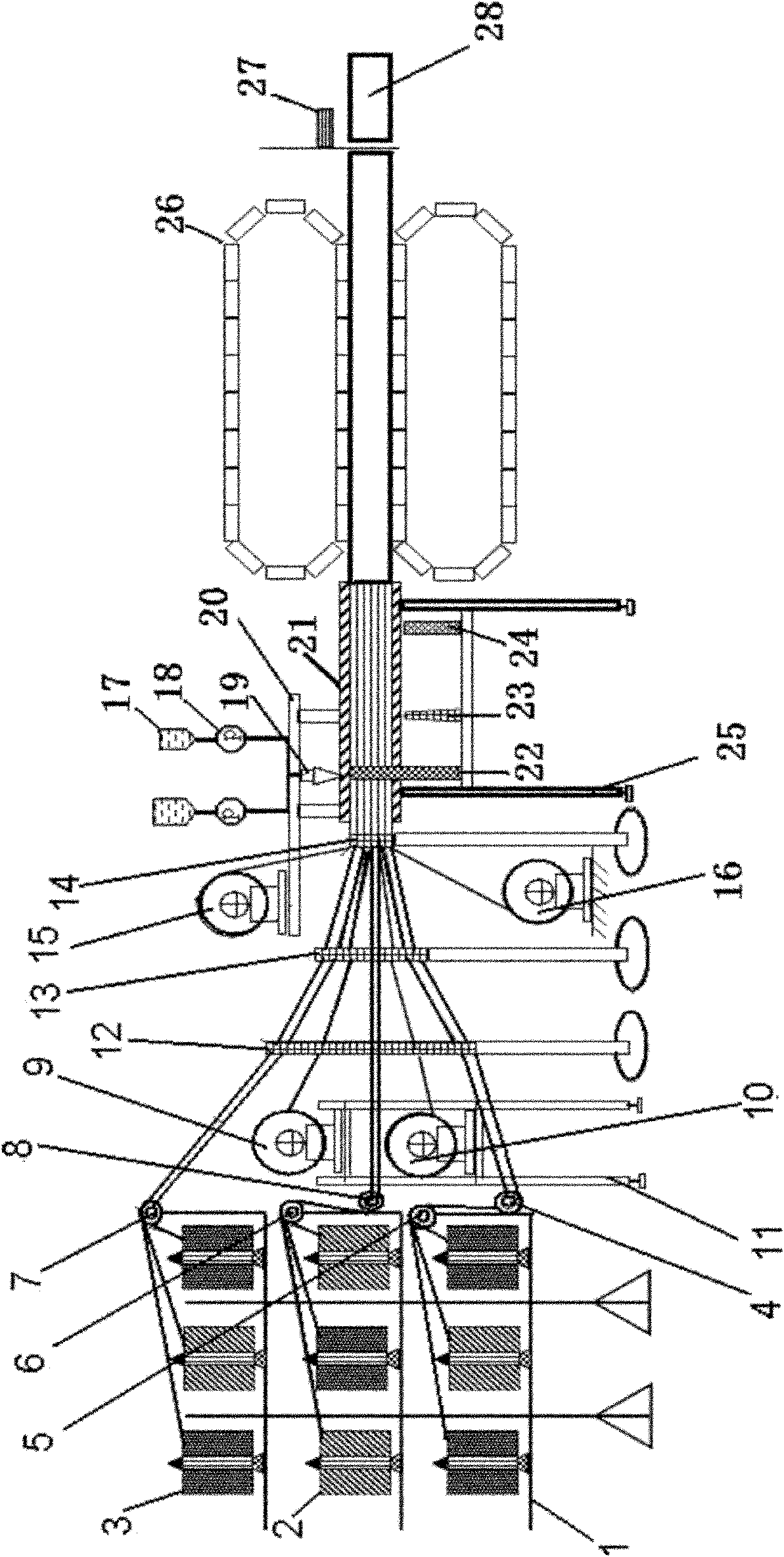

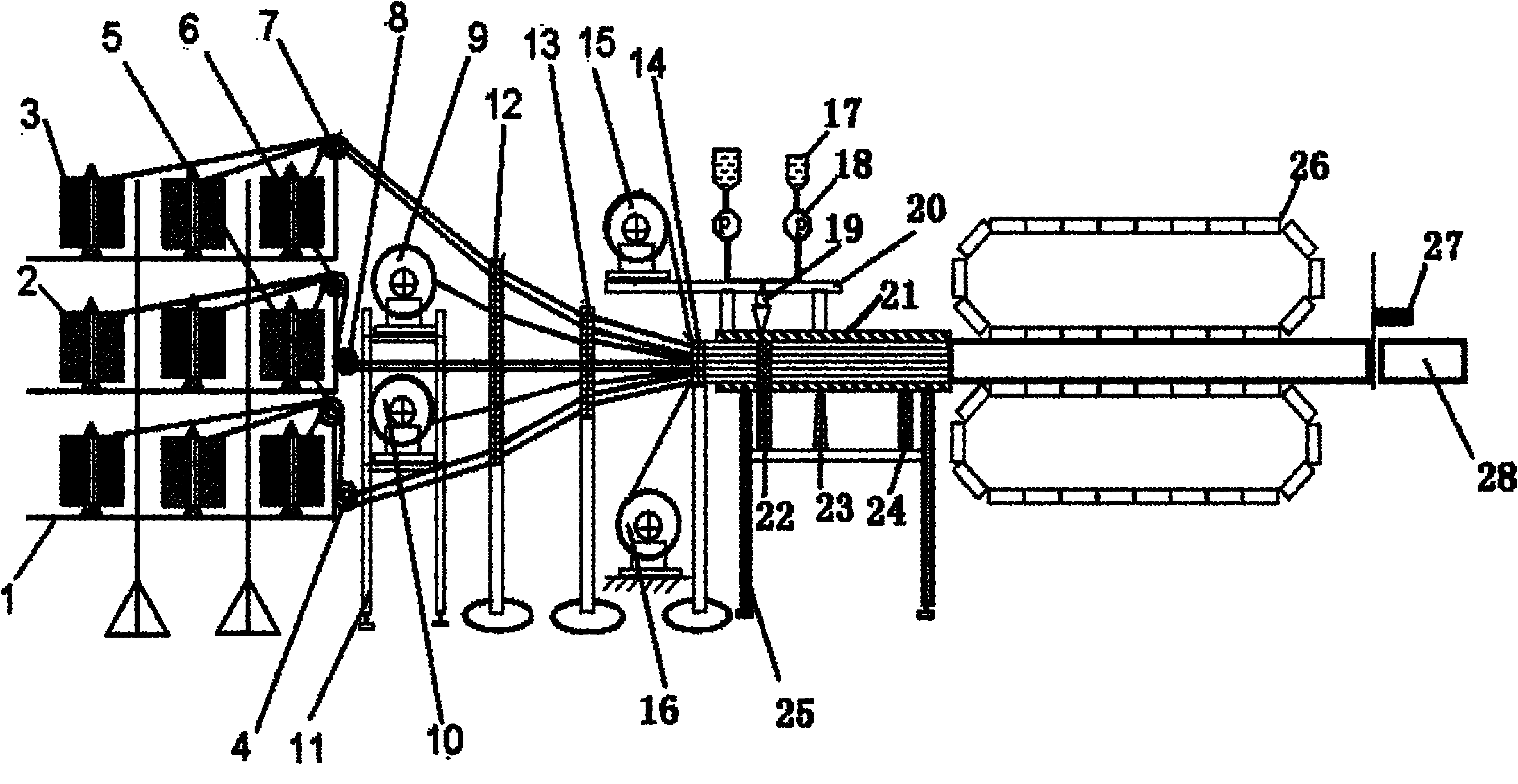

Method used

Image

Examples

Embodiment 1

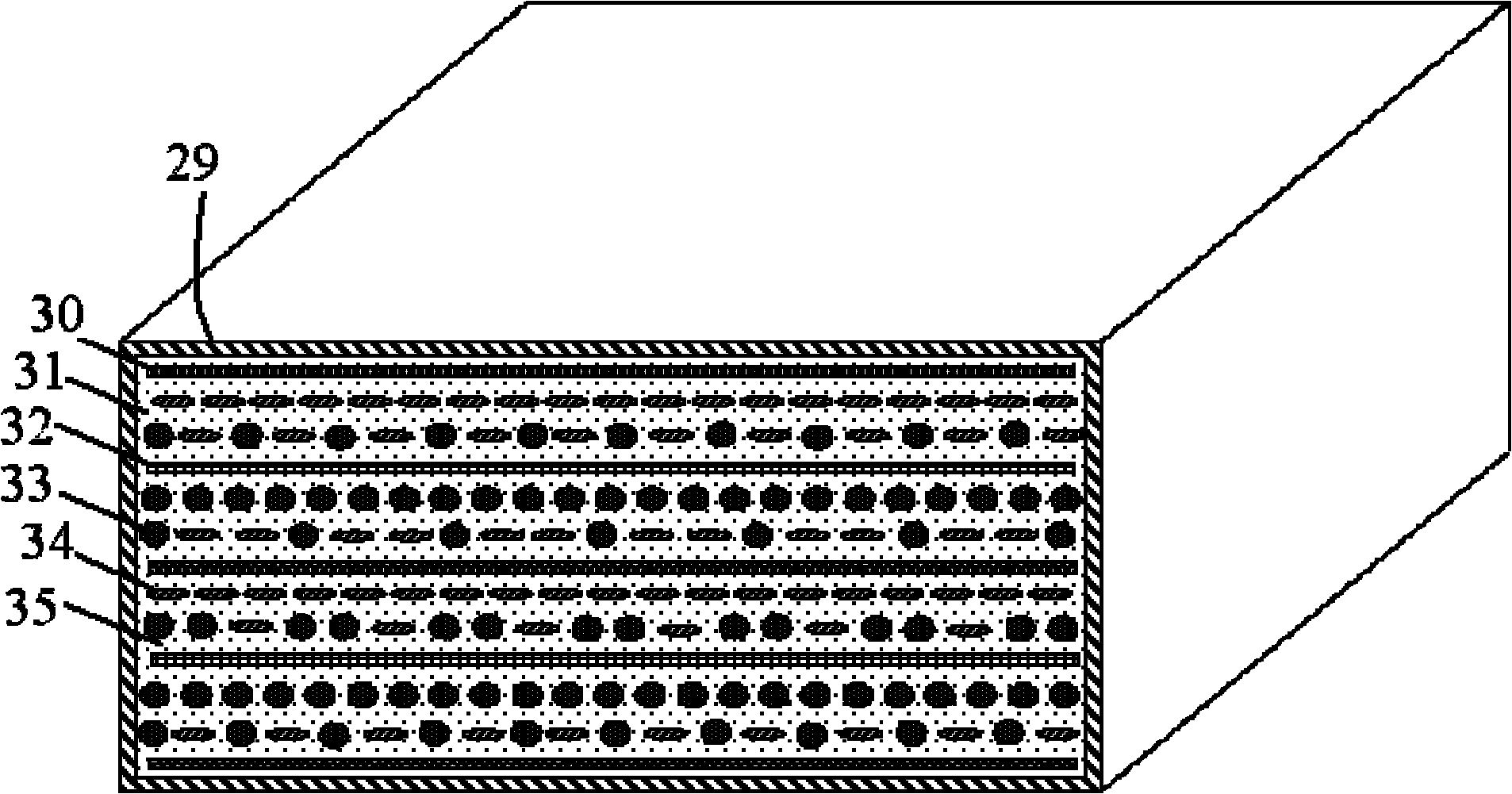

[0033] A composite fiber-reinforced water-foamed polyurethane rigid foam composite board, which uses a mixture of long glass fibers and chopped glass fibers as fiber reinforcements, and the fiber reinforcements are alternately and uniformly distributed in layers in the polyurethane foam raw material matrix;

[0034] Described polyurethane foam raw material composition comprises, by weight:

[0035] Polyether polyol 1, hydroxyl number 93-750mgKOH / g, molecular weight 150-1200, accounting for 80 parts;

[0036] Polyether polyol 2, hydroxyl number 28-93mgKOH / g, molecular weight 1200-4000, accounting for 5 parts;

[0037] Catalyst, triethylenediamine, accounts for 0.01 part;

[0038] Foam stabilizer, polydimethylsiloxane-polyoxyalkylene block copolymer, accounts for 1 part;

[0039] Distilled water, accounting for 0.2 parts;

[0040] Flame retardant, triphenyl phosphite, accounting for 5 parts;

[0041] Isocyanate, accounting for 100 parts;

[0042] The composition of the fibe...

Embodiment 2

[0049] A composite fiber-reinforced water-foamed polyurethane rigid foam composite plate, which uses long glass fibers as fiber reinforcements, and the fiber reinforcements are alternately and evenly distributed in layers in the polyurethane foam raw material matrix;

[0050] Described polyurethane foam raw material composition comprises, by weight:

[0051] Polyether polyol 1, hydroxyl number 93-750mgKOH / g, molecular weight 150-1200, accounting for 85 parts;

[0052] Polyether polyol 2, hydroxyl number 28-93mgKOH / g, molecular weight 1200-4000, accounting for 6 parts;

[0053] Catalyst, N, N'-dimethyl cyclohexylamine, accounts for 0.02 part;

[0054] Foam stabilizer is polydimethylsiloxane-polyoxyalkylene block copolymer, accounting for 3 parts;

[0055] Distilled water, accounting for 0.25 parts;

[0056] Flame retardant, three (beta-chloroethyl) phosphate, accounting for 10 parts;

[0057] Isocyanate, accounting for 110 parts;

[0058] The composition of the fiber reinf...

Embodiment 3

[0066] A composite fiber-reinforced water-foamed polyurethane rigid foam composite plate, which uses long glass fibers, carbon fibers and chopped glass fibers as fiber reinforcements, and the fiber reinforcements are alternately and evenly distributed in layers in the polyurethane foam raw material matrix;

[0067] Described polyurethane foam raw material composition comprises, by weight:

[0068] Polyether polyol 1, hydroxyl number 93-750mgKOH / g, molecular weight 150-1200, accounting for 90 parts;

[0069] Polyether polyol 2, hydroxyl number 28-93 mgKOH / g, molecular weight 1200-4000, accounting for 6.5 parts;

[0070] Catalyst, bis-(2-dimethylaminoethyl) ether, accounts for 0.04 part;

[0071] Foam stabilizer, sulfonated castor oil, accounts for 4 parts;

[0072] Distilled water, accounting for 0.3 parts;

[0073] Flame retardant, tri-(chloroisopropyl) phosphate (TCPP), accounts for 15 parts;

[0074] Isocyanates account for 120 parts;

[0075] The composition of the fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com