Preparation method of SU8 mold

A mold and fiber optic panel technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as shedding and deformed substrates, reduce internal stress, make the model or structure firm, improve process repetition rate and finish the product rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

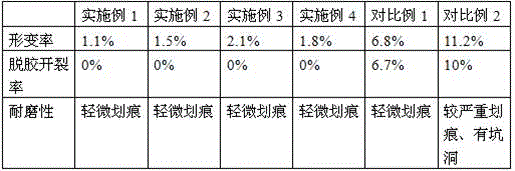

Examples

Embodiment 1

[0025] The goal of this example is to make a 20 μm thick SU8 mold.

[0026] (1) Uniform glue;

[0027] ① Add SU8 dropwise to the center of the fiber optic panel;

[0028] ② Put the fiber optic panel at an acceleration of 600rpm / min 2 Accelerate from standstill to 600rpm / min for 30s;

[0029] ③At an acceleration of 4000rpm / min 2 Accelerate to 1800rpm / min for 13s;

[0030] ④At an acceleration of 1500rpm / min 2 Accelerate to 2000rpm / min for 38s;

[0031] ⑤ With an acceleration of 1500rpm / min 2 Accelerate to 2200rpm / min for 30s;

[0032] ⑥ With a deceleration rate of 300rpm / min 2 Reduce the speed to 800rpm / min for 15s;

[0033] ⑦ Gradually reduce the speed and stop the glue rejection;

[0034] (2) Pre-baking: Place the fiber optic panel coated with SU8 film on a hot plate and pre-baked. The first stage is 60°C for 7 minutes, and the second stage is 90°C for 8 minutes;

[0035] (3) Exposure: Use 365nm ultraviolet light to expose the SU8 film covered with the mask, and the...

Embodiment 2

[0041] The goal of this example is to make a 35 μm thick SU8 mold.

[0042] (1) Uniform glue;

[0043] ① Add the photoresist dropwise to the center of the fiber optic panel;

[0044] ②Set the fiber optic panel at an acceleration of 560rpm / min 2 Accelerate from standstill to 600rpm / min for 26s;

[0045] ③At an acceleration of 4000rpm / min 2 Accelerate to 1800rpm / min for 15s;

[0046] ④At an acceleration of 2500rpm / min 2 Accelerate to 2000rpm / min for 39s;

[0047] ⑤ With an acceleration of 1000rpm / min 2 Accelerate to 2200rpm / min for 32s;

[0048] ⑥ With a deceleration rate of 300rpm / min 2 Reduce the speed to 800rpm / min for 15s;

[0049] ⑦ Gradually reduce the speed and stop the glue rejection;

[0050] (2) Pre-baking: place the fiber optic panel coated with SU8 film on a hot plate for pre-baking, the first stage is 60°C, 8min, the second stage is 90°C, 12min;

[0051] (3) Exposure: Expose the masked SU8 film with 365nm ultraviolet light, the exposure dose is 155mJ / cm2,...

Embodiment 3

[0057] The goal of this example is to make a 45 μm thick SU8 mold.

[0058] (1) Uniform glue;

[0059] ① Add the photoresist dropwise to the center of the fiber optic panel;

[0060] ② Put the fiber optic panel at an acceleration of 500rpm / min 2 Accelerate from standstill to 600rpm / min for 25s;

[0061] ③At an acceleration of 4000rpm / min 2 Accelerate to 1800 rpm / min for 14.5s;

[0062] ④At an acceleration of 1800 rpm / min 2 Accelerate to 2000 rpm / min for 35s;

[0063] ⑤At an acceleration of 3000 rpm / min 2 Accelerate to 2200 rpm / min for 40s;

[0064] ⑥ With a deceleration rate of 300 rpm / min 2 Reduce the speed to 800 rpm / min for 15s;

[0065] ⑦ Gradually reduce the speed and stop the glue rejection;

[0066] (2) Pre-baking: place the fiber optic panel coated with SU8 film on a hot plate for pre-baking, the first stage is 60°C, 7.8min, the second stage is 90°C, 15min;

[0067] (3) Exposure: Use 365nm ultraviolet light to expose the SU8 film covered with the mask, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com