A rubber parts manufacturing automatic processing fixture

A technology for tooling fixtures and rubber parts, applied in the field of tooling fixtures, can solve the problems that the roughness is difficult to meet the standard, it is difficult to meet the processing requirements, and the inner surface of the rubber bushing is difficult to process, so as to achieve good surface roughness and high-quality equipment. Utilization, avoid workpiece bending deformation and the effect of processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

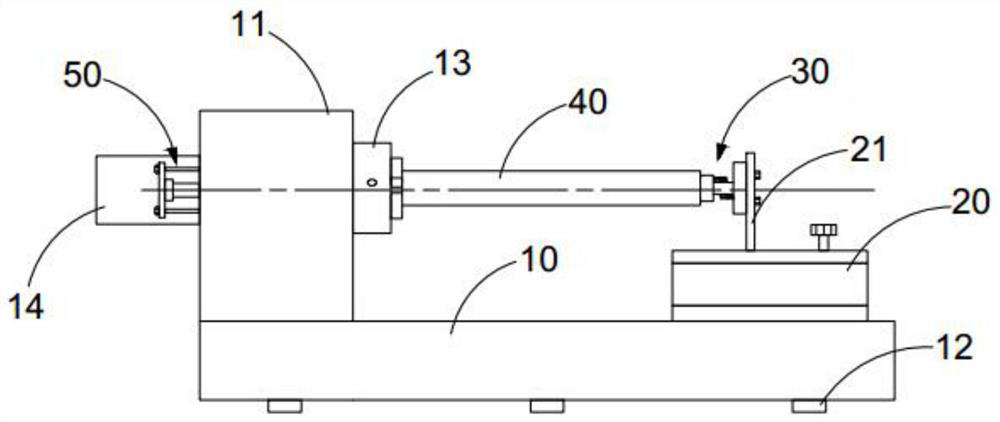

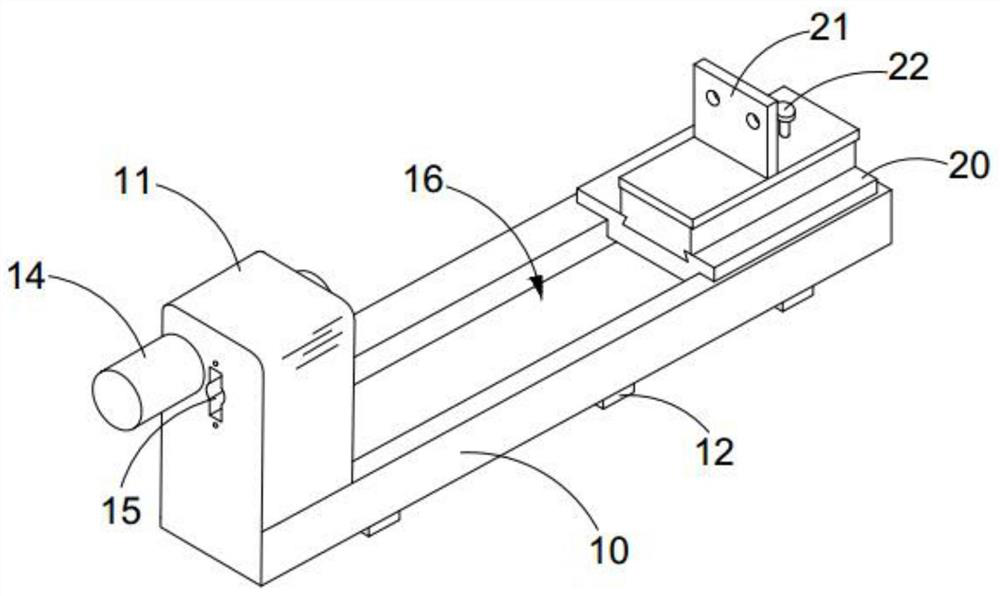

[0043] see Figure 1-8 As shown, a kind of automatic processing fixture for rubber parts manufacturing, including:

[0044] Bed 10, one side of bed 10 is provided with the bedside box 11 that three-jaw chuck 13 is installed, and the other side is provided with tailstock 20, and the first limit assembly 30 is installed on the tailstock 20, and the tailstock 20 top A supporting connecting plate 21 perpendicular to the horizontal plane is provided, and the supporting connecting plate 21 and the three-jaw chuck 13 face opposite to each other to assemble the first limit assembly 30,

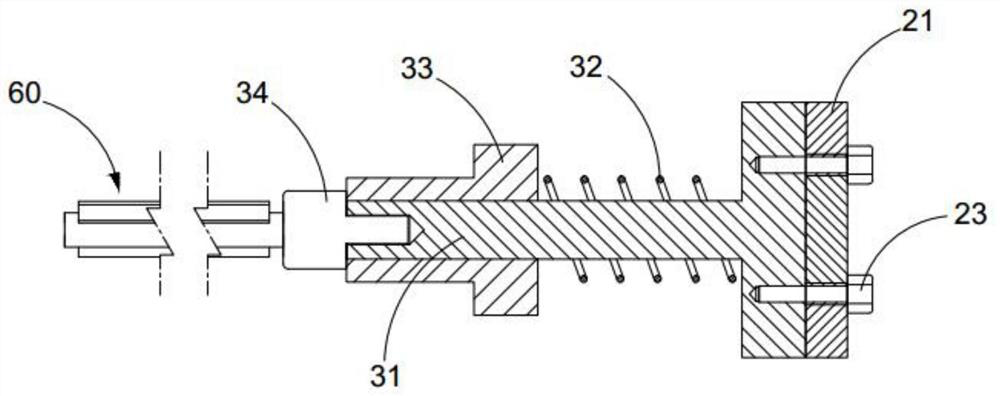

[0045] Wherein, the first limiting assembly 30 includes a limiting main part 31, the limiting main part 31 has a cylindrical structure, and the bottom of the cylindrical structure is provided with an assembly base plate that is mated with the supporting connecting plate 21; the limiting main part 31 The upper sleeve is connected with the limited auxiliary part 33, and the limited auxiliary part 33 is...

Embodiment 2

[0059] A method of using automatic processing fixtures for rubber parts manufacturing:

[0060] - put the third limit assembly 70 into the bedside box 11 to limit the clamping length of the rubber part 40 relative to the three-jaw chuck 13 and make the rubber part 40 coaxial with the three-jaw chuck 13;

[0061] - sliding the tailstock 20 to insert the grinding assembly 60 into the processing hole of the rubber piece 40, and limit the movement range of the rubber piece 40 in the axial direction through the first stopper assembly 30;

[0062] - Control and drive the main motor 14 to start, and the three-jaw chuck 13 drives the clamped rubber part 40 to rotate relative to the grinding assembly 60, and completes the machining of the inner surface of the round hole of the rubber part 40.

[0063] The fixture using method provided by the present invention can realize inner hole processing and fast deburring operation of rubber parts such as shaft sleeves, meet the requirements of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com